For any manufacturing business, the sudden silence of machinery is a costly problem. When a production line halts from an unexpected power outage, the consequences extend far beyond a moment of darkness. It means missed deadlines, wasted materials, and a direct hit to the bottom line.

In Ukraine today, these interruptions are not rare occurrences but a persistent operational risk that demands a strategic response. The scale of the challenge is significant. According to Ukrenergo, the national power grid operator, targeted attacks have damaged or destroyed a substantial portion of Ukraine’s thermal and hydroelectric generation capacity.

This has created a structural electricity deficit that can reach up to 5 gigawatts during peak consumption hours. For a factory owner, this translates into an environment of scheduled blackouts and unpredictable grid instability, making reliable production nearly impossible. This guide explains the strategic value of on-site power generation and outlines the key components for achieving energy independence for your facility.

The New Reality of Ukraine’s Energy Landscape

The systematic damage to centralized power infrastructure has fundamentally altered the operational landscape for all industries. The state’s response, as outlined by government officials, is a strategic pivot towards a decentralized energy system—one less vulnerable to large-scale attacks. This approach encourages businesses and municipalities to develop their own independent power sources.

This shift is not merely a temporary fix; it represents a long-term strategy for national resilience. For business leaders, this context transforms energy from a simple utility expense into a critical element of business continuity planning. Relying solely on a grid that faces a potential 20-30% generation shortfall is no longer a viable strategy for any enterprise that depends on consistent power.

The proactive solution is to establish a ‘captive’ power plant: an on-site generation and storage system dedicated to your facility’s needs.

An Introduction to Captive Power Plants for Industrial Use

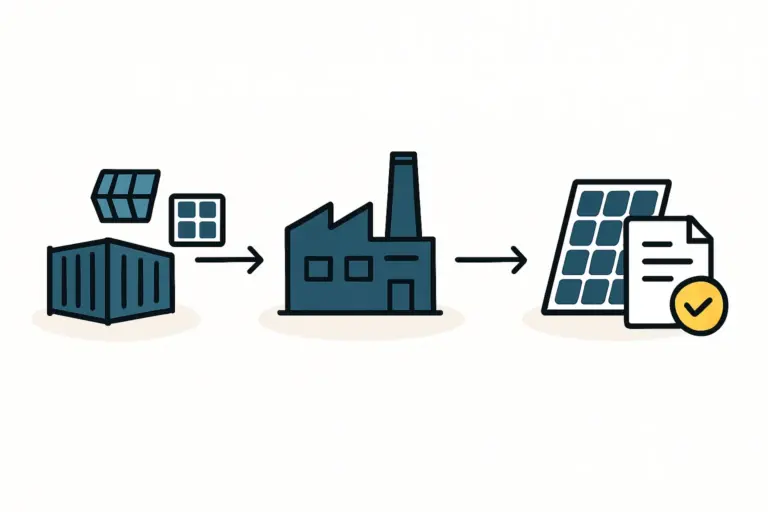

A captive power plant is an electricity generation facility that an industrial or commercial business builds and manages for its own consumption. It acts as a primary or backup power source, insulating the business from the volatility of the public grid. For most modern industrial applications, this system consists of two core components working in harmony.

1. Solar Photovoltaic (PV) Array

The solar PV array is the power generation engine of the system. Solar panels, installed on factory rooftops or adjacent land, convert sunlight directly into electricity. This clean, silent process generates power during daylight hours, which can directly run machinery, lighting, and other operational loads. Given Ukraine’s favorable solar irradiation levels, a well-designed PV system can meet a significant portion of a factory’s daytime energy demand.

2. Battery Energy Storage System (BESS)

If the PV array is the engine, the BESS is the fuel tank and control system. This system of industrial-grade batteries stores excess energy generated by the solar panels during the day. This stored energy can then be deployed at night, on cloudy days, or, most critically, during a grid blackout. A BESS ensures a seamless, uninterrupted flow of electricity to your critical loads, effectively creating a private, stable microgrid for your operations. It acts as a buffer, absorbing the shocks of grid instability and keeping your production lines running smoothly.

The Strategic Business Case for Energy Independence

While the initial motivation for exploring on-site power often stems from mitigating blackouts, the business case extends much further. Investing in a captive power plant is a strategic decision that delivers compounding returns.

Mitigating Production Downtime

The most immediate return is the near-elimination of production losses caused by power failures. For processes that require continuous operation—such as in food processing, chemical production, or precision manufacturing—even a brief interruption can ruin entire batches of product. A captive power system ensures your most critical machinery remains operational, protecting revenue and preserving materials.

Achieving Predictable Operational Costs

Electricity tariffs can be volatile, subject to market fluctuations and regulatory changes. On-site solar generation locks in a significant portion of your energy costs for the 25+ year lifespan of the system. This cost predictability simplifies financial forecasting and budgeting, providing a competitive edge in a turbulent economic environment.

Enhancing Operational Resilience

A facility with its own power source is inherently more resilient. It can continue to operate when competitors are forced to shut down, allowing you to capture market share and build a reputation for reliability—especially when fulfilling export orders with strict deadlines.

Key Considerations for Planning Your On-Site Power Solution

Developing an effective captive power plant requires careful planning tailored to your facility’s specific needs. This involves a systematic evaluation of several key factors.

Assessing Your Energy Demand

The first step is to understand your factory’s electricity consumption profile. This involves analyzing hourly and daily usage data to identify peak loads and critical circuits. This ‘load profile’ analysis determines the right size for the solar array and battery storage system to ensure your operational needs are met.

Integrating Solar PV and Battery Storage

The PV array and the BESS must be sized to work together efficiently. An oversized solar array without sufficient battery capacity will result in wasted energy, while an undersized array may not adequately charge the batteries or power the facility. The goal is to create a balanced system that maximizes self-consumption of the solar energy you generate.

Space and Structural Requirements

Solar panels can be installed on rooftops or on the ground. A structural assessment of your factory’s roof is necessary to ensure it can support the weight of the panels and racking. If roof space is insufficient, a ground-mounted system on an adjacent plot of land is an excellent alternative.

Financial Planning

A captive power plant is a significant capital investment. A detailed financial model should be developed to project the return on investment (ROI), factoring in the cost of avoided downtime, energy savings, and available government incentives or grants. Understanding the investment requirements for solar projects is a critical step in securing financing and ensuring the project’s long-term viability.

A Broader Perspective on Energy Sector Involvement

As Ukraine undergoes a fundamental restructuring of its energy system, new opportunities are emerging. For some entrepreneurs, the logic extends beyond simply consuming self-generated power.

The national push for decentralized generation is creating a substantial domestic market for solar components. Visionary business leaders may see an opportunity not just in securing their own energy but also in starting a solar manufacturing business to supply the growing local demand. This involves a deeper understanding of solar panel manufacturing machinery and production processes, representing a powerful step towards vertical integration and contributing directly to national energy security.

Frequently Asked Questions (FAQ)

How much space is needed for an industrial solar installation?

A general estimate is that 1 megawatt (MW) of solar panels requires approximately 1 hectare (10,000 square meters) for a ground-mounted system or a similar amount of unobstructed rooftop area. The exact space depends on panel efficiency and layout.

What is the typical lifespan of such a system?

Modern solar panels typically have a performance warranty of 25 years and can continue producing power for 30 years or more. Battery energy storage systems generally have a lifespan of 10-15 years, depending on the technology and usage patterns.

Can the system operate completely off-grid?

Yes, a properly sized solar and battery storage system can be designed to operate independently of the grid. However, most industrial systems are grid-tied, allowing them to draw power from the grid when needed and potentially export excess power back to it, depending on local regulations.

What are the main maintenance requirements?

Solar PV systems require minimal maintenance, primarily consisting of periodic cleaning of the panels and inspection of electrical components. Battery systems also require regular monitoring and inspection as specified by the manufacturer to ensure optimal performance and safety.

The Path Towards Energy Resilience

In the face of profound challenges to Ukraine’s energy infrastructure, passive reliance on the grid is no longer a sustainable business strategy. On-site power generation using solar PV and battery storage has evolved from a ‘green’ initiative into a core component of industrial risk management and business continuity.

By investing in energy independence, factory owners can protect their operations from instability, gain control over a critical input cost, and build a more resilient and competitive enterprise. For those looking to understand how similar projects have been implemented, reviewing industrial solar power case studies can provide valuable, real-world insights into the planning and execution process. The journey to energy security begins with the strategic decision to take control of your power supply.