Establishing a manufacturing facility in a country amidst an active conflict might seem counterintuitive. For entrepreneurs and investors with a long-term perspective, however, the current situation in Ukraine presents a unique strategic opportunity.

The systematic targeting of the nation’s centralized energy infrastructure has created an urgent and sustained demand for decentralized power solutions. Local solar module production is no longer just a commercial opportunity; it is a critical component of national energy security and resilience.

This analysis outlines the key factors for siting a solar module factory in Western Ukraine, focusing on a risk-mitigation framework that addresses security, logistics, and operational stability. For anyone considering this venture, the first step is a clear-eyed assessment of the on-the-ground realities and strategic advantages.

The Strategic Case for Local Solar Production

The core driver behind local manufacturing is the shift from a vulnerable, centralized power grid to a distributed network of energy sources. Businesses, hospitals, municipal services, and residential communities are all seeking energy independence to ensure their operational continuity.

The result is a robust domestic market for solar modules, largely insulated from global market fluctuations. A local factory can serve this demand more quickly and reliably than importers, while also contributing to the local economy through job creation and investment.

The long-term vision is to rebuild Ukraine with a modern, resilient, and sustainable energy backbone, powered by locally produced components.

Geographical Advantages of Western Ukraine

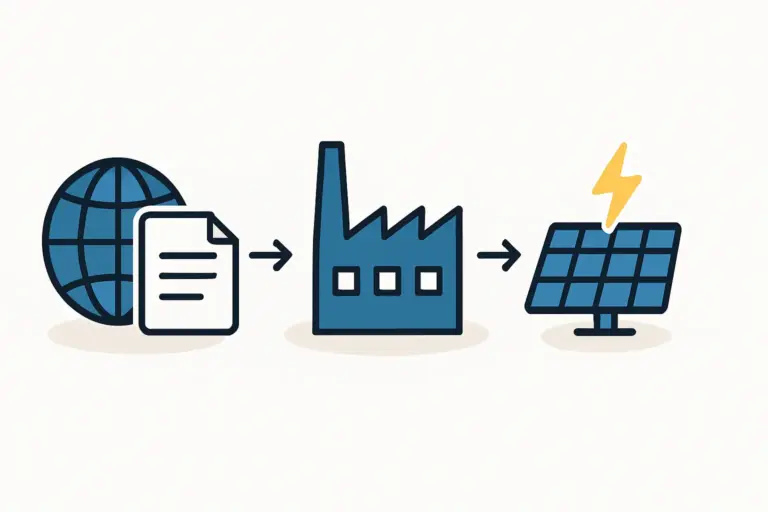

While no region is entirely without risk, Western Ukraine offers a comparatively stable operational environment. Oblasts such as Lviv, Ivano-Frankivsk, and Zakarpattia have experienced significantly less direct conflict and offer key logistical advantages.

The key strategic benefit is their direct proximity to the European Union. Shared borders with Poland, Slovakia, Hungary, and Romania provide multiple, redundant corridors for inbound supply chains and potential future exports. This proximity is fundamental to de-risking the entire operation.

Furthermore, this region has a history of industrial activity and a highly educated, motivated workforce. Skilled technicians, engineers, and managers—a critical factor for success—are readily available in cities like Lviv.

Mitigating Supply Chain Risks: A Logistical Framework

The reliability of the supply chain poses the most significant operational risk for any manufacturing plant in the region. A successful strategy bypasses Ukrainian seaports, leveraging secure European logistics hubs instead.

Inbound Logistics Strategy

-

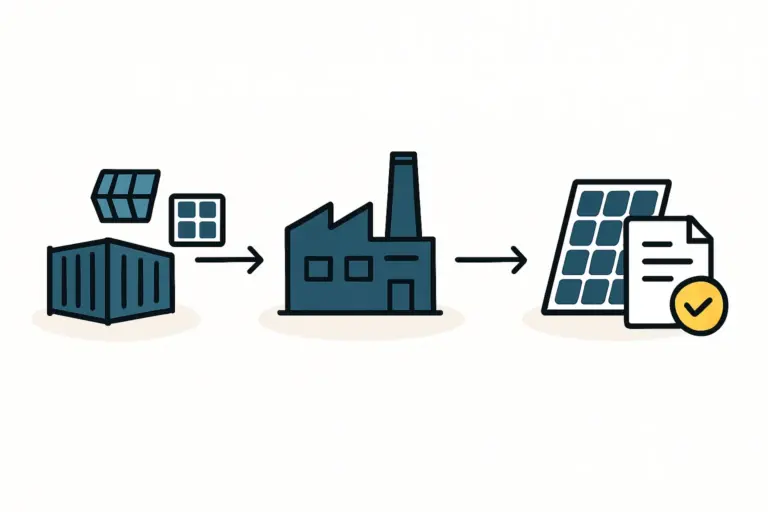

Sea Freight to EU Ports: Key raw materials like solar cells, glass, and encapsulants, typically sourced from Asia, should be directed to major northern European ports like Gdansk (Poland) or southern hubs like Constanta (Romania).

-

Overland Transport: From these ports, materials are transported overland by truck or rail into Western Ukraine. The well-developed road and rail networks between these countries and Ukraine ensure reliable transit.

-

Inventory Management: A robust inventory strategy is essential. Maintaining a larger-than-usual buffer stock of critical components—for instance, 6-8 weeks of production needs—at the factory can mitigate potential short-term border delays or transport disruptions.

This model creates a resilient supply chain, independent of Ukrainian maritime routes and protected by the logistical infrastructure of neighboring EU countries.

Facility and Infrastructure Considerations

Site selection is another critical risk mitigation step. Establishing the facility within a modern, well-managed industrial park is often the most secure and efficient approach.

These parks typically offer superior infrastructure, including:

Reliable grid connections and utility access.

High-quality, pre-existing buildings suitable for conversion or purpose-built facilities.

Integrated physical security services and controlled access points.

Operational Security Protocols

Beyond standard industrial safety, a facility in Ukraine demands enhanced security measures. A comprehensive plan should include:

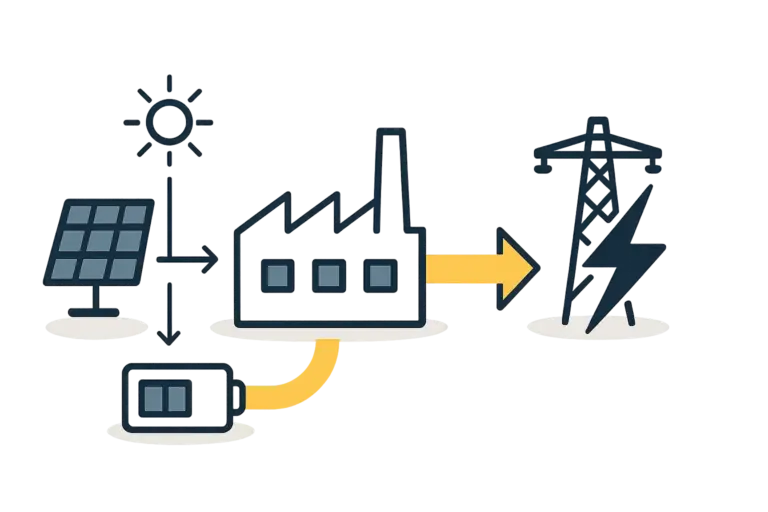

Backup Power: A robust on-site power generation system is non-negotiable. This should consist of a diesel generator and a battery storage system, ideally charged by the factory’s own solar module output.

Contingency Planning: Clear protocols for operational pauses during air raid alerts are necessary to ensure employee safety without excessively disrupting production.

Physical Security: Hardened infrastructure and professional on-site security personnel are essential for asset protection.

Financial and Operational Planning

A venture in this context requires meticulous financial planning that reflects its unique risk profile. The overall plant cost will need to incorporate budget lines for heightened insurance premiums, enhanced security infrastructure, and larger working capital reserves for inventory.

Based on experience from J.v.G. Technology GmbH turnkey projects in other emerging markets, a phased approach is recommended. Starting with a semi-automated production line of 20-50 MW annual capacity allows for a faster setup, a lower initial capital outlay, and a quicker path to generating revenue. This approach establishes a market presence and allows the operation to scale as the market and security situation evolve.

Frequently Asked Questions (FAQ)

Is it truly feasible to secure investment for a project in Ukraine today?

While perceived risk is high, the strategic importance of energy independence is attracting interest from development finance institutions, impact investors, and strategic partners. A well-structured business plan that clearly outlines a risk mitigation strategy is essential for securing financing. The investment case rests on the long-term, non-negotiable domestic demand for energy security.

How is production machinery transported to the facility?

Machinery, whether sourced from Europe or Asia, follows the same secure logistics channels as raw materials. It is shipped to a secure EU port and then transported overland via truck to the factory site in Western Ukraine under controlled and insured conditions.

What level of government support can be expected?

The Ukrainian government has designated energy independence as a national priority. Investors may find streamlined processes for permitting and land acquisition. While specific financial incentives can vary, the project aligns directly with national strategic goals, which can facilitate strong cooperation with local and national authorities.

What is a realistic timeline for establishing such a factory?

For a 20-50 MW facility, a realistic timeline from final investment decision to the start of production is approximately 12 to 18 months. This includes machinery procurement, shipping, installation, commissioning, and staff training. Thorough planning is key to meeting this schedule.