For any entrepreneur entering the solar manufacturing sector, choosing a location is a critical strategic decision. While established hubs in Asia offer scale, emerging locations can present unique competitive advantages.

Ukraine, despite its current challenges, represents a compelling and often overlooked opportunity for businesses targeting the European Union market. The advantage isn’t just proximity; it’s a strategic combination of trade agreements and logistical frameworks that can significantly reduce costs and complexity.

This article breaks down the supply chain dynamics for a solar module factory in Ukraine. We explain how to structure the import of raw materials and the export of finished goods to leverage Ukraine’s preferential trade status with the EU, turning a potential logistical hurdle into a distinct business advantage.

Understanding Ukraine’s Trade Advantage with the EU

The foundation of Ukraine’s strategic position is its strong, formalized trade relationship with the European Union. Two key instruments govern this relationship, creating a highly favorable environment for manufacturers.

The DCFTA and Autonomous Trade Measures (ATMs)

The Deep and Comprehensive Free Trade Area (DCFTA), part of the broader EU-Ukraine Association Agreement, grants tariff-free, quota-free access to the EU market for the vast majority of Ukrainian goods. In 2022, the EU further reinforced this commitment by introducing Autonomous Trade Measures (ATMs), temporarily suspending all remaining tariffs and trade defense measures.

For a solar module manufacturer, this translates into an immediate price advantage. A module produced in Ukraine can enter any EU member state without import duties, giving it a clear financial edge over products from countries that lack such agreements.

The Critical Role of ‘Rules of Origin’

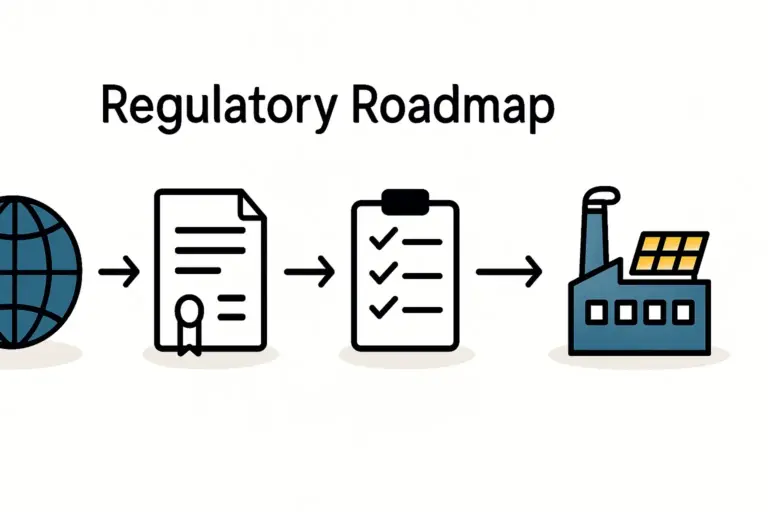

While tariff-free access is the primary benefit, it is not automatic. To qualify, a product must be proven to have ‘originated’ in Ukraine. This is determined by a set of criteria known as ‘Rules of Origin,’ which prevent goods from simply being trans-shipped through a country to take advantage of its free trade agreement.

For solar modules, this typically means the product must undergo ‘sufficient transformation’ within the country. Simply assembling a few imported components may not be enough; the manufacturing process must add a certain percentage of value to the final product within Ukraine. This makes the strategic sourcing of raw materials critical. An entrepreneur must design their supply chain not just for cost and availability, but also to ensure the final product meets these crucial origin requirements.

The PEM Convention: A Strategic Multiplier for Sourcing

This is a powerful, yet often misunderstood, strategic advantage. It might seem that meeting Ukrainian origin rules requires maximizing the use of Ukrainian raw materials. However, the ‘pan-Euro-Mediterranean (PEM) convention on preferential rules of origin’ changes this logic entirely.

The PEM convention allows for ‘cumulation of origin.’ In simple terms, materials originating from any other PEM member country (which includes the entire EU and EFTA states) can be treated as if they originated in Ukraine when used in production.

This has significant implications for a solar module factory’s supply chain:

-

Simplified Sourcing: A manufacturer can source high-value components like solar cells, specialized glass, and encapsulants from established suppliers in Germany, Poland, or Italy.

-

Easier Compliance: By using these EU-origin materials, the finished solar module more easily meets the ‘sufficient transformation’ threshold required for tariff-free export back to the EU.

-

Enhanced Quality: Access to top-tier European component suppliers can also contribute to a higher-quality and more easily certifiable final product.

This framework allows a business to combine the operational cost advantages of a Ukrainian location with the quality and logistical simplicity of a European supply chain.

Navigating Practical Logistics: From Sourcing to Export

The ongoing conflict has understandably shifted logistics away from sea routes to land-based transport via road and rail. While this presents challenges like potential border delays, dedicated initiatives and careful planning can ensure a resilient and efficient flow of goods.

Importing Raw Materials

The most effective strategy involves sourcing key components from EU countries with strong transport links to Ukraine, like Poland or Germany. Establishing relationships with logistics partners experienced in cross-border freight is essential. Leveraging the PEM convention this way is a cornerstone of a successful setup. Proper documentation confirming the EU origin of these materials is vital for the subsequent export process. Further details on sourcing are available in this guide on sourcing raw materials for solar module production.

Exporting Finished Modules

The primary document required for tariff-free export to the EU is the EUR.1 Movement Certificate. Issued by Ukrainian customs authorities, this document formally certifies that the goods comply with the Rules of Origin under the DCFTA. A well-documented supply chain, particularly one that utilizes cumulation of origin with EU materials, makes the application process for the EUR.1 certificate significantly more straightforward.

The Importance of Certification

Beyond tariffs, products must also meet the EU’s rigorous technical and safety standards—a non-negotiable requirement for market access. Finished solar modules must have CE marking, which signifies conformity with health, safety, and environmental protection standards. They also typically need to be certified according to International Electrotechnical Commission (IEC) standards, such as IEC 61215 and IEC 61730. Planning for this certification process from the outset is a critical step, a topic explored in detail in a comprehensive guide to solar module certifications.

Building a Resilient Supply Chain: A Practical Example

Based on experience from J.v.G. turnkey projects, a common and effective model has emerged. An investor planning a 20-50 MW facility in Western Ukraine, for instance, might structure their supply chain as follows:

-

Solar Cells: Sourced from a leading manufacturer in Germany.

-

Solar Glass & Backsheets: Sourced from specialized suppliers in Poland.

-

Aluminum Frames: Extruded and anodized locally in Ukraine to add domestic value.

-

Assembly & Lamination: Performed at the Ukrainian facility.

This hybrid approach allows the finished product to easily qualify for a EUR.1 certificate. It also minimizes transport distances for the most critical components and builds a robust, resilient operation that is less dependent on any single source.

Frequently Asked Questions (FAQ)

What is the single most important document for tariff-free export to the EU?

The EUR.1 Movement Certificate is the key document. It proves to EU customs that your product originates in Ukraine and is therefore eligible for tariff exemption under the DCFTA.

Do I need to source all my materials from the EU or Ukraine?

No. However, strategically sourcing high-value components from PEM member countries like those in the EU makes it significantly easier to meet the ‘Rules of Origin’ requirements through cumulation.

How are land-based logistics managed in the current climate?

Logistics require careful planning with experienced freight forwarders. The EU’s ‘Solidarity Lanes’ initiative has also helped streamline cross-border traffic, and many new logistics hubs have been developed near the border to facilitate smoother processing.

Can a solar module factory in Ukraine be cost-competitive?

Yes. The combination of lower operational and labor costs, coupled with complete tariff exemption for exports to the vast EU market, creates a compelling business case.

Your Next Steps in Planning

The logistical and regulatory landscape in Ukraine offers a distinct strategic advantage for those targeting the EU solar market. The key lies in understanding and leveraging the established trade frameworks—specifically the DCFTA and the PEM convention’s rules on cumulation of origin.

A successful venture is not built on opportunity alone, but on meticulous planning. The next logical step for any serious entrepreneur is to develop a comprehensive business plan that models material costs, logistics, production throughput, and certification timelines. This foundational work transforms a strategic concept into an actionable investment project.