The conversation around global supply chain resilience has shifted. For years, the United Kingdom has been a major market for solar energy deployment but not for manufacturing. Recent industrial strategy shifts, coupled with a growing demand for locally sourced green technology, are now creating a compelling opportunity for investors to establish solar module production facilities within the UK.

This presents a complex but potentially rewarding landscape for entrepreneurs looking to enter the sector. The challenge, however, is not merely financial. Unlike regions with established solar manufacturing ecosystems, selecting the right location in the UK requires a nuanced understanding of regional strengths, logistical networks, and local government incentives. A decision based on land cost alone can lead to unforeseen operational hurdles. This guide provides a comparative framework for evaluating potential UK hubs, helping business professionals make a more informed and strategic site selection.

Why Consider the UK for Solar Manufacturing?

Before examining specific locations, it is important to understand the strategic rationale for choosing the UK. The country’s legally binding net-zero targets create stable and growing domestic demand for solar modules. Furthermore, its proximity to the large European market offers significant export potential without the logistical complexities of transcontinental shipping.

It is important, however, to acknowledge the primary business challenge: operational costs, particularly labor, are higher than in established Asian manufacturing centers. This reality makes strategic site selection all the more critical. The right location can mitigate these costs through targeted incentives, access to a highly skilled and efficient workforce, and superior logistics, thereby building a strong business case for a UK-based solar factory.

A Framework for Site Selection: Key Evaluation Criteria

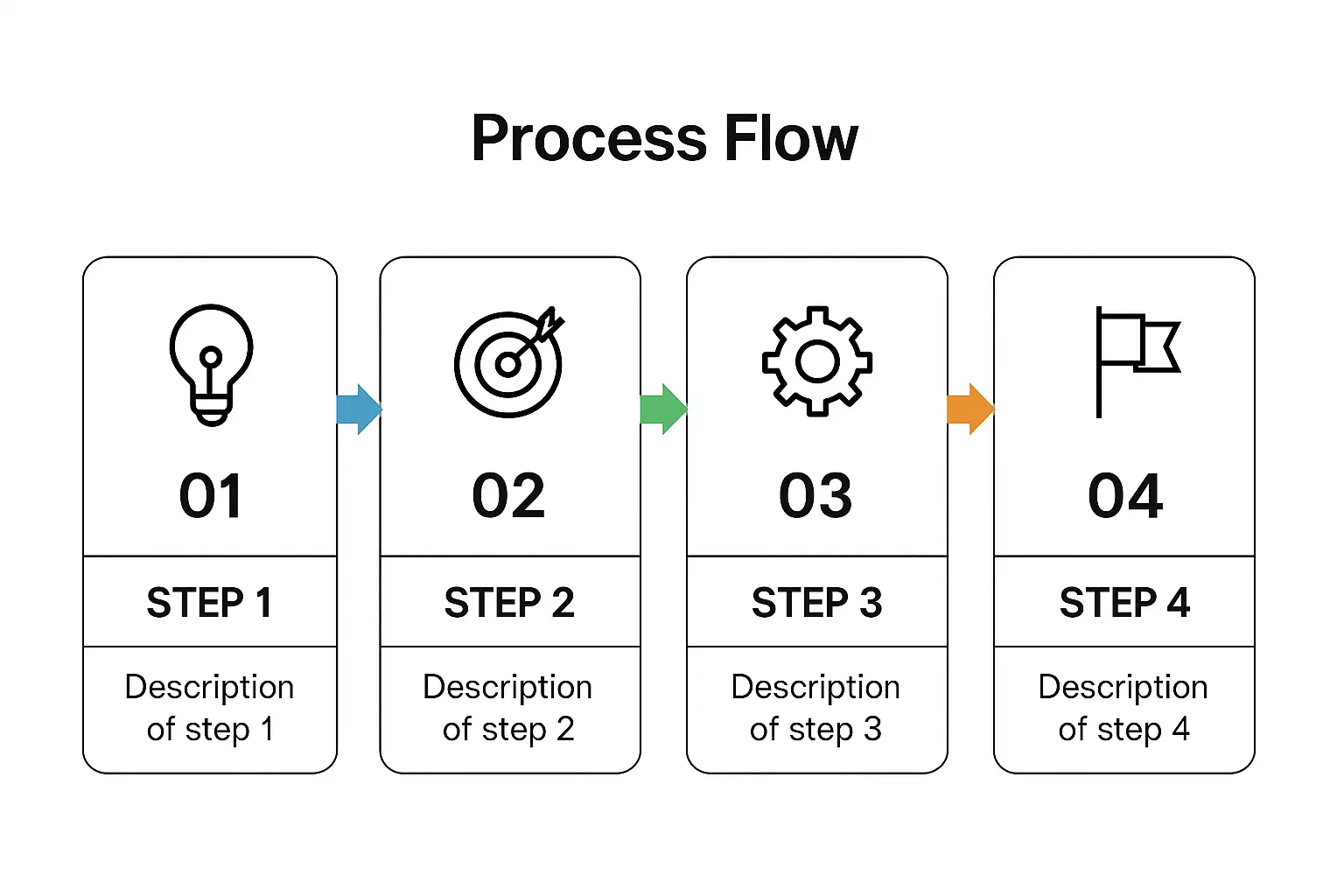

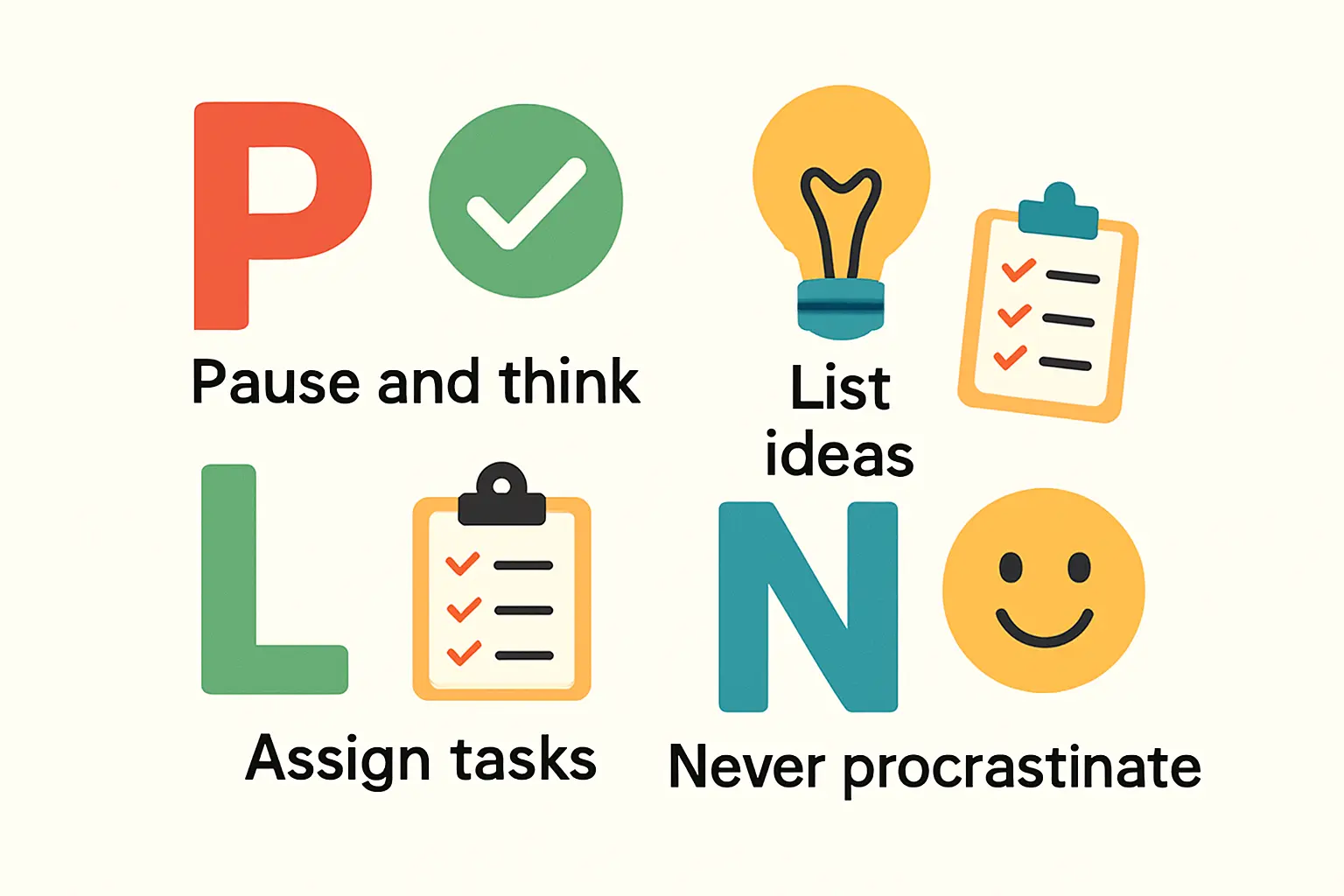

A systematic approach is essential for evaluating potential locations. Experience from numerous international factory planning projects shows that a successful site selection process focuses on four core pillars.

1. Infrastructure and Logistics

A solar module factory is fundamentally a logistics operation, importing raw materials and exporting finished goods. Proximity to deep-water ports is therefore a critical factor for managing the import of components such as solar cells, tempered glass, and aluminum frames. Equally important is access to robust national road and rail networks for the efficient distribution of finished modules to project sites across the UK and Europe. Any site evaluation must consider the entire journey of materials, from port to factory to customer.

2. Availability of Skilled Labor

Modern solar manufacturing is a highly automated process, but it still requires a technically proficient workforce. Key roles include process engineers, quality assurance technicians, and maintenance specialists who can manage and service sophisticated machinery. A location near universities with strong engineering programs or regions with a heritage in advanced manufacturing (such as automotive or aerospace) provides a valuable talent pool.

3. Government Incentives and Local Support

The UK government and devolved administrations offer various programs to attract investment in green technology. Two key initiatives are Investment Zones and Freeports. These designated areas provide tangible financial benefits, such as lower taxes, simplified customs procedures, and streamlined planning processes. Engaging with Regional Development Agencies (RDAs) early in the process can unlock access to grants, site selection assistance, and introductions to local supply chains. These incentives can significantly improve a project’s initial capital expenditure and long-term profitability.

4. Supply Chain and Industrial Ecosystem

No factory operates in isolation. Proximity to an established industrial ecosystem offers numerous advantages, including access to suppliers of industrial gases, packaging materials, and specialized maintenance services. Being located within a manufacturing cluster can foster innovation and collaboration while also providing a resilient local supply chain for non-specialized components.

Comparative Analysis of Potential UK Manufacturing Hubs

Using this framework, we can analyze several promising UK regions, each with a distinct profile.

North East England (Teesside, Sunderland)

Strengths: This region builds on its deep industrial heritage in the chemical and automotive sectors. The Teesside Freeport is one of the UK’s largest and most ambitious, offering significant tax and customs benefits. It has excellent port infrastructure at the Port of Tyne and Teesport, ideal for importing materials. A strong manufacturing workforce already exists and can be retrained for PV-specific processes.

Considerations: Although the workforce is skilled in manufacturing, it will require specific training to adapt to the nuances of the solar panel manufacturing process.

The Midlands (Coventry, Birmingham)

Strengths: Often called the UK’s manufacturing heartland, the Midlands offers unparalleled logistical advantages thanks to its central location. Its ‘golden triangle’ of logistics provides access to 90% of the UK population within a four-hour drive. The region is home to world-class research institutions like the Warwick Manufacturing Group and boasts a high concentration of engineering talent from the automotive and aerospace industries.

Considerations: As a high-demand area, competition for prime industrial land and skilled labor can be intense, potentially driving up costs.

South Wales (Cardiff, Swansea)

Strengths: South Wales has a notable history in electronics and advanced materials manufacturing. The region benefits from strong, proactive support from the Welsh Government, which is keen to attract green technology investment. It offers access to deep-water ports and has strong academic links with universities in Cardiff and Swansea, known for their research in renewable energy technologies.

Considerations: Logistical routes to mainland Europe are slightly longer compared to locations on England’s east coast.

Scotland (Central Belt, Dundee)

Strengths: Scotland’s ‘Silicon Glen’ corridor has a long-standing reputation in electronics and semiconductor manufacturing, creating a pool of highly qualified technical staff. Government bodies like Scottish Enterprise are well-structured to support incoming investors. The region is a leader in renewable energy generation, fostering a strong local culture of innovation.

Considerations: Scotland operates under a different legal and regulatory system than England and Wales, a factor requiring careful consideration during planning. Its northern location may also add marginal costs to logistics when serving the south of England.

The Business Case: Tying Location to Financial Viability

The choice of location is not an academic exercise; it directly impacts financial outcomes. For a typical 50 MW starter factory, locating within a Freeport could reduce customs duties on imported equipment and raw materials, directly lowering the initial capital investment. Tax incentives can accelerate the path to profitability by years.

Experience from J.v.G. Technology turnkey projects consistently shows that early and thorough due diligence on potential sites is one of the most critical factors for long-term success. A location that appears cheaper on paper may bring hidden costs in transportation or labor recruitment. In contrast, a site with higher initial land costs but superior infrastructure and incentives often provides a better return on investment. The process of planning, building, and commissioning such a facility is complex, but a well-designed turnkey solar factory solution can streamline this journey considerably.

Frequently Asked Questions (FAQ)

What is the typical size of a starter solar factory in the UK?

A common entry-level size is between 20 MW and 50 MW of annual production capacity. This typically requires a building of approximately 3,000 to 5,000 square meters to house the production line, warehousing, and office space.

How do UK labor costs affect the business model?

While hourly labor costs are higher than in Asia, this is often offset by higher productivity, lower turnover, and the benefits of automation. A modern, automated production line reduces the number of direct labor roles required, shifting the focus to higher-skilled technical and maintenance staff. The business model should prioritize efficiency and quality over low labor costs.

Are all necessary raw materials available within the UK?

Currently, key components like solar cells and specialized solar glass are primarily imported. However, the UK has a robust supply chain for other essential materials like aluminum (for frames), packaging, and industrial gases. A key part of site selection is mapping the proximity to these secondary suppliers.

How long does it take to set up a solar factory in the UK?

With a well-defined plan and the right partners, a 20-50 MW solar module line can become operational in under 12 months, from the final investment decision to the first certified module coming off the line. This timeline depends heavily on factors like building availability and machinery lead times.

Conclusion and Next Steps

Selecting a location for a solar factory in the United Kingdom is a strategic decision that extends far beyond a simple real estate transaction. It requires a detailed analysis of logistical networks, labor markets, government support structures, and the surrounding industrial ecosystem. While the UK presents challenges in its cost structure, its stable market, strong government support for green industries, and skilled workforce offer a unique and compelling opportunity for the discerning investor.

The right region will not only support the efficient production of solar modules but will also become a long-term partner in the factory’s success. A thorough evaluation, guided by a clear framework, is the first and most critical step in building a resilient and profitable solar manufacturing business in the UK.