Entrepreneurs looking to enter the solar manufacturing sector often view the United States as a primary target market. They read about tax credits and bonuses for projects using ‘Made in America’ components and recognize a significant opportunity, but the rules can seem complex.

What exactly does ‘domestic content’ mean, and how can a new manufacturer ensure its products qualify? This lack of clarity can be a major barrier to entry.

The US Inflation Reduction Act (IRA) has created powerful incentives for renewable energy projects. For manufacturers supplying this market, understanding these incentives isn’t just a technicality—it’s a critical business strategy. This guide breaks down the US Treasury’s guidance on the domestic content bonus, explaining the requirements in clear, business-focused terms.

What is the Domestic Content Bonus?

The Domestic Content Bonus is an additional 10% Investment Tax Credit (ITC) available to US-based solar project developers. This bonus is granted on top of the base tax credit if the project meets specific criteria for using American-made steel, iron, and manufactured products.

Manufacturers don’t receive this tax credit directly; the incentive goes to the project developer or owner in the United States. However, its existence creates a strong market preference for components that help them qualify. A solar module or tracker system that meets the domestic content requirements becomes significantly more valuable to a US customer, giving its manufacturer a powerful competitive advantage.

The Two Core Requirements for Compliance

To qualify for the 10% bonus, a solar project must satisfy two distinct conditions from the US Treasury: the Steel or Iron Requirement and the Manufactured Products Requirement. Both must be met independently.

Requirement 1: The Steel or Iron Standard

This requirement is straightforward: all steel or iron used in a project’s structural components must be 100% manufactured in the United States. This includes all manufacturing processes, from the initial melting and pouring to the final coating of the steel or iron items.

It applies to components that function primarily as structural supports. For a typical ground-mount solar installation, this would include items such as:

- Piles, ground screws, or other foundation posts

- The steel or iron racking structures that hold the modules

- The torque tubes and fasteners used in a solar tracker system

The standard doesn’t apply to components where steel or iron is a secondary part of larger equipment, such as the nuts and bolts inside a solar inverter. They fall under the Manufactured Products Requirement instead.

Requirement 2: The Manufactured Products Standard

This is the more complex requirement and the one most relevant to manufacturers of high-value equipment like solar modules, inverters, and trackers. The rule states that all manufactured products in the project must be produced in the United States.

A product is considered ‘produced in the United States’ if two conditions are met:

- All manufacturing processes for the product take place in the United States.

- All of the product’s components are of US origin.

The guidance, however, provides a crucial alternative for compliance known as the ‘Adjusted Percentage Rule.’ This rule acknowledges the global nature of supply chains. Under this rule, a manufactured product is still considered of US origin if its American-made components and manufacturing costs meet a minimum percentage threshold.

For projects that begin construction before 2025, this minimum threshold is 40%. This percentage is scheduled to increase in subsequent years, rising to 55% for projects starting in 2027 and beyond.

A Practical Breakdown: Calculating the Domestic Cost Percentage

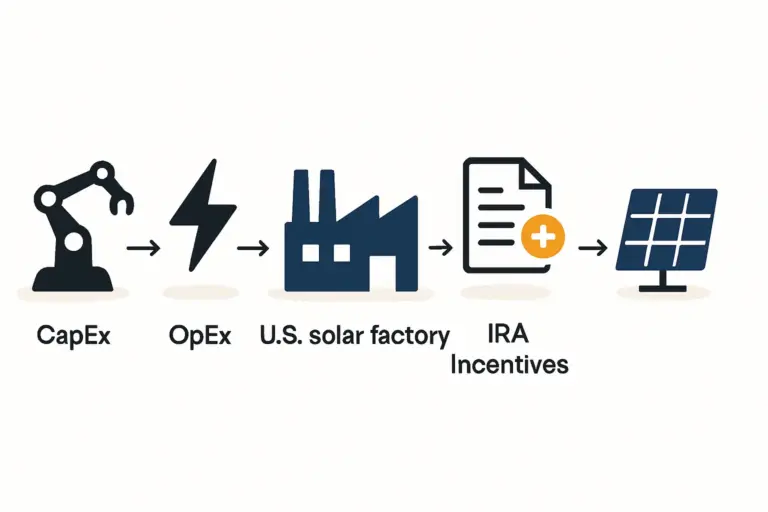

For a manufacturer, mastering this cost calculation is essential, as it determines whether your product can be marketed as ‘domestic content compliant’ to US customers. The formula is based on the direct costs of manufacturing a product.

The formula: (Cost of US-Sourced Components + US Direct Labor & Overhead) / (Total Component Costs + Total Direct Labor & Overhead)

Let’s consider a simplified example for a solar module produced in a US factory aiming to meet the 40% threshold.

US-Sourced Costs:

- Solar Cells (from a US supplier): $50

- Front Glass (from a US supplier): $10

- Direct Factory Labor (US workers): $8

- Factory Overhead (US facility): $7

- Total US Costs: $75

Non-US Sourced Costs:

- Backsheet (imported): $5

- Aluminum Frame (imported): $15

- Junction Box (imported): $5

- Total Non-US Component Costs: $25

Calculation:

- Total US Costs: $75

- Total Manufacturing Costs: $75 (US Costs) + $25 (Non-US Costs) = $100

- Domestic Content Percentage: $75 / $100 = 75%

In this scenario, the module comfortably exceeds the 40% requirement and would qualify as a US-manufactured product. To optimize these costs, it’s essential to first understand the complete solar panel manufacturing process.

Which Components Count? The Official Safe Harbor List

For clarity, the US Treasury has published a ‘safe harbor’ list identifying key manufactured products and their components for solar projects. If a manufacturer produces an item on this list, it is officially considered a ‘Manufactured Product’ for the purposes of the domestic content calculation.

For a utility-scale project using solar trackers, the list includes:

- Photovoltaic Modules: The individual solar panel components like cells, wafers, glass, encapsulant, and frames are considered.

- Inverters: This includes central inverters, string inverters, and their internal components.

- Battery Packs: For projects with energy storage, the battery pack assembly is a manufactured product.

- Solar Trackers: Specifically called out are torque tubes, structural fasteners, and drive systems.

The list gives manufacturers a clear roadmap, helping them identify which parts of their supply chain need to be evaluated for US sourcing.

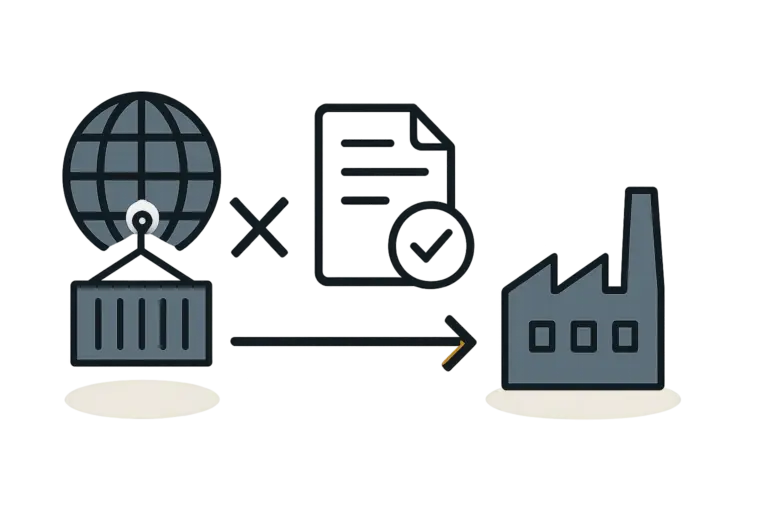

Common Challenges for International Manufacturers

Entrepreneurs planning to supply the US market often face three primary challenges with these requirements.

-

Supply Chain Verification: Establishing a reliable and cost-effective supply chain for US-made components (like solar cells, wafers, or specialty glass) can be difficult. This requires rigorous due diligence to ensure suppliers genuinely meet the ‘manufactured in the US’ criteria.

-

Cost Management: US-sourced components and labor can carry a price premium. Manufacturers must carefully model their costs to ensure their final product remains competitive, even with the advantage the 10% bonus provides to their customers.

-

Documentation and Certification: The burden of proof lies with the project developer, but they will demand extensive documentation from their suppliers. Manufacturers must maintain meticulous records of their sourcing and production costs to provide the necessary certifications.

Frequently Asked Questions (FAQ)

Q1: Does my factory have to be in the United States to supply domestic content products?

While theoretically possible to meet the 40% threshold using US components in a foreign factory, it is practically very difficult. The guidance heavily favors final assembly and manufacturing processes occurring within the US. For this reason, most companies aiming for compliance establish production facilities in the United States.

Q2: Who is officially responsible for certifying domestic content compliance?

The US project owner or taxpayer is responsible for claiming the tax credit and attesting to the Treasury that the requirements have been met. To do this, they will require formal certifications and detailed documentation from all their equipment suppliers, including solar module, inverter, and racking manufacturers.

Q3: What happens if a project fails to meet the domestic content threshold?

If a project does not meet the requirements, it simply does not qualify for the additional 10% bonus credit. This doesn’t invalidate the project’s eligibility for the base 30% Investment Tax Credit. The project can still proceed, but with a lower financial return for its investors.

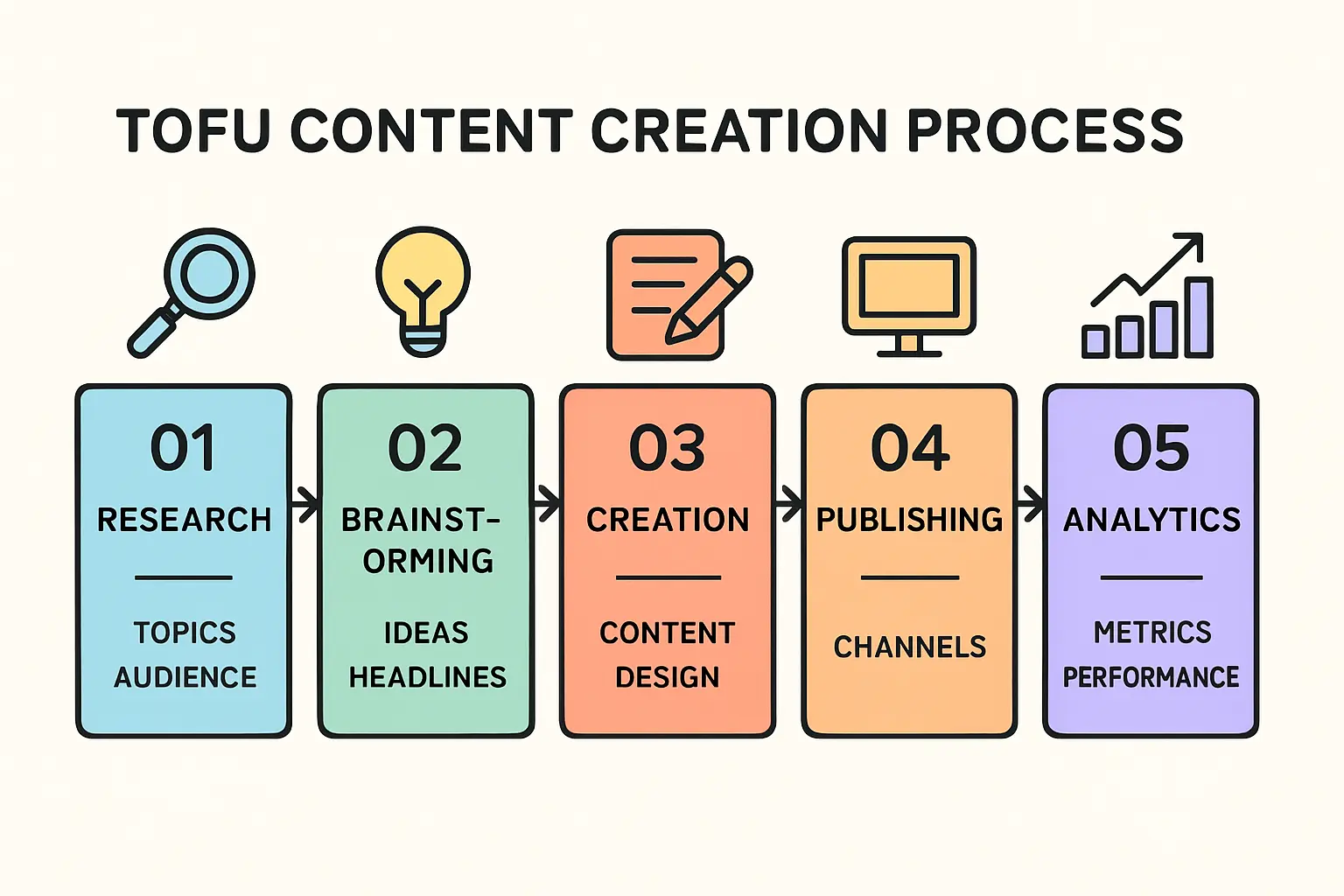

Q4: How does a structured business plan help address these complexities?

A comprehensive business plan forces an entrepreneur to address these issues head-on during the planning phase. It includes detailed supply chain analysis, cost modeling, and a documentation strategy—all of which are foundational for success in the US market.

Planning Your Entry into the US Solar Market

The domestic content bonus is more than a regulatory detail; it is a significant market force shaping the solar energy supply chain in the United States. For a new manufacturer, it presents both a challenge and an immense opportunity.

Success requires a strategic approach grounded in a deep understanding of the rules. By carefully planning production, validating the supply chain, and managing costs, a manufacturer can make its products highly attractive to US project developers. Navigating these requirements and building a successful enterprise starts with a thorough solar panel manufacturing business plan.