In early 2023, Hanwha Qcells announced a landmark investment of over $2.5 billion to expand its solar manufacturing operations in Georgia. While headlines focused on the project’s impressive scale, the strategic choice of location points to a deeper reality.

While federal policies create the opportunity, state-level incentives often determine where capital is actually deployed. For any entrepreneur or business professional considering entry into this sector, understanding this dynamic is crucial.

The U.S. Inflation Reduction Act (IRA) has firmly positioned the nation as a premier destination for solar manufacturing, but its federal tax credits are just the starting point. The most competitive projects are built on a sophisticated strategy that layers federal, state, and local benefits. This article provides a comparative analysis of key state-level incentive programs, offering a framework for strategic site selection for your new solar manufacturing venture.

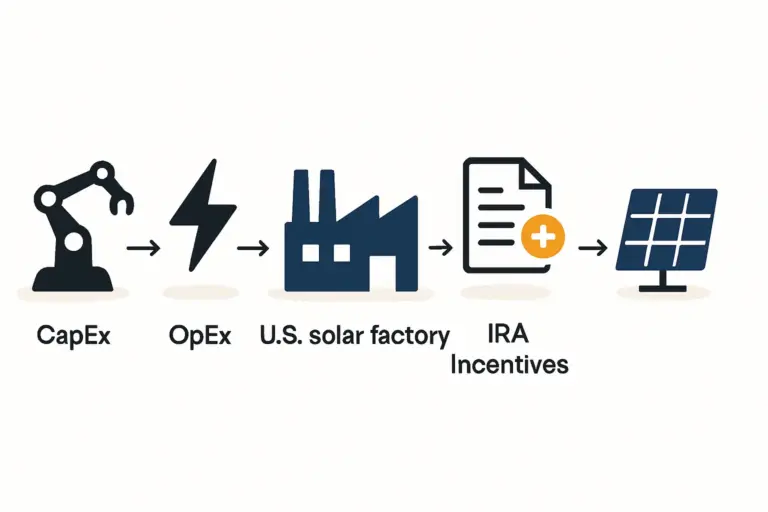

The Federal Foundation: How the IRA Changed the Game

Before examining state-specific programs, it’s essential to understand the federal landscape that’s fueling the current investment boom. The IRA introduced two powerful mechanisms that directly benefit solar manufacturers:

-

Advanced Manufacturing Production Credit (45X MPTC): This production-based credit provides manufacturers with a direct payment for each U.S.-made solar component produced, from polysilicon to cells and modules. It directly rewards domestic output.

-

Investment Tax Credit (ITC) Adders: The traditional ITC for clean energy projects now includes bonus credits for projects using domestically produced components. This incentivizes developers to purchase U.S.-made modules, creating built-in demand for new domestic factories.

These federal programs provide a powerful financial tailwind, but they are available nationwide. The critical differentiator in project viability and profitability is often the unique incentives offered by individual states.

Key Factors in Site Selection for a Solar Factory

A successful site selection process must balance financial incentives with operational realities. Before comparing states, it’s important to weigh the core criteria that influence a manufacturing plant’s long-term success. A well-structured business plan for solar panel manufacturing must rigorously evaluate each of these elements.

Workforce Availability and Skill Level

Access to a trained and reliable workforce is paramount, including not only assembly line workers but also skilled technicians, engineers, and management personnel. States with strong vocational training programs and university partnerships often hold a significant advantage.

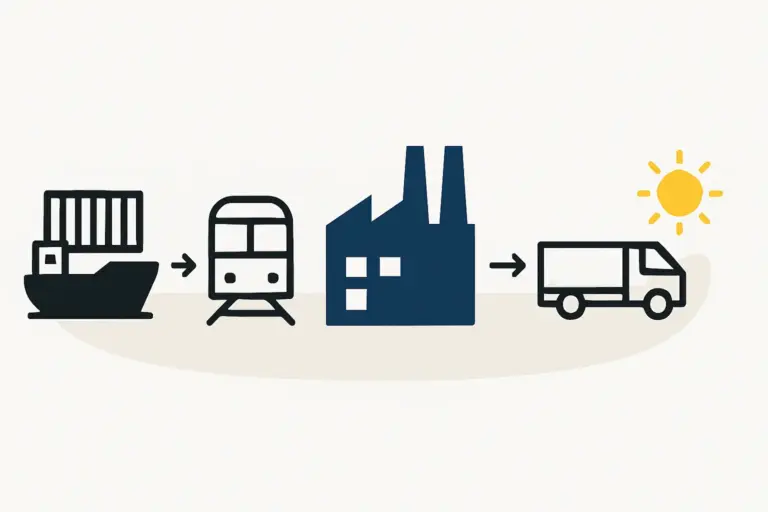

Logistics and Supply Chain Access

The cost and efficiency of moving raw materials in and finished products out are critical. Proximity to major ports, interstate highways, and rail networks can substantially impact operational expenses and delivery timelines.

Energy Costs and Grid Infrastructure

A solar factory is an energy-intensive operation, so the cost and reliability of electricity are major factors in the overall operating budget. The capacity of the local grid to support a new industrial facility without requiring costly upgrades is another crucial consideration.

A Comparative Look at Leading States for Solar Manufacturing

While many states are competing for investment, Georgia, Ohio, and Arizona have emerged as early leaders, each offering a distinct value proposition for potential investors.

Georgia: The Logistics and Speed Powerhouse

Georgia has successfully attracted significant investment by combining a business-friendly environment with world-class logistics.

-

Workforce Development: Its flagship ‘Quick Start’ program is a state-funded initiative that provides customized workforce training for new and expanding businesses at no cost. This significantly reduces the time and expense of onboarding a new labor force.

-

Logistical Superiority: The Port of Savannah is one of the busiest and most efficient container terminals in North America, offering excellent access for importing raw materials and exporting finished modules.

-

Business Climate: A relatively low rate of unionization and a streamlined regulatory environment are often cited as key advantages for large-scale industrial projects.

Ohio: The ‘Silicon Heartland’ Advantage

Positioning itself as the ‘Silicon Heartland,’ Ohio leverages its deep industrial roots and proximity to major markets to attract high-tech manufacturing.

-

Industrial Ecosystem: The state has a strong heritage in automotive and general manufacturing, providing a deep pool of engineering talent and an established network of industrial suppliers.

-

Research and Development: Proximity to leading research institutions and a focus on advanced manufacturing make it an attractive location for companies developing next-generation photovoltaic technologies.

-

Market Access: Its central location provides efficient access to major population centers in the Midwest and Northeast, reducing domestic transportation costs.

Arizona: The Established Solar Ecosystem

As a state with high solar irradiation and a long history in the solar industry, Arizona offers a mature ecosystem for new manufacturers.

-

Skilled Talent Pool: Decades of solar development have created a deep and experienced workforce, from installers to R&D professionals. This established talent base is difficult to replicate.

-

Proximity to Key Markets: Its location offers strategic access to the large California market as well as cross-border trade opportunities with Mexico.

-

University Partnerships: Strong collaborations with universities like Arizona State University provide a steady pipeline of engineering talent and opportunities for joint research.

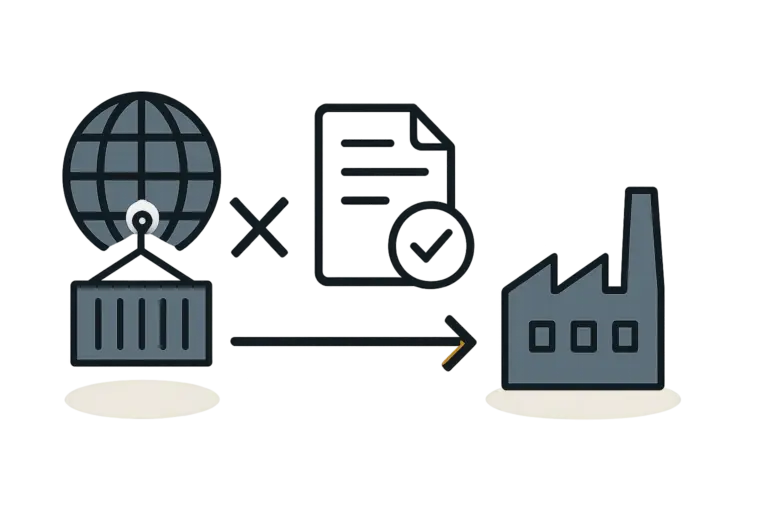

Navigating the Complexities: Common Challenges for New Entrants

While the opportunities are significant, entrepreneurs entering the U.S. market will need to navigate potential challenges that can impact project timelines and budgets.

The Skilled Labor Gap

Despite state-led training programs, the competition for experienced technicians and engineers is intense. The rapid influx of new factories is creating a labor shortage that can lead to increased wage pressures and recruitment difficulties.

Supply Chain Dependencies

Onshoring module assembly does not eliminate reliance on a global supply chain. Key materials and sub-components, from specialized glass to junction boxes, are often sourced from Asia. New manufacturers will therefore need to develop robust and resilient supply chain strategies.

The Reality of Grid Interconnection

Connecting a new, large industrial facility to the local electricity grid can be a lengthy and expensive process. Securing permits and negotiating the terms of interconnection can take months, if not longer, and may involve significant capital outlay for infrastructure upgrades. These factors must be included when calculating the total solar panel manufacturing plant cost.

Building a Multi-Layered Incentive Strategy

The most successful investment strategies are those that ‘stack’ incentives from multiple levels of government. Federal credits provide the foundation, state programs add a critical second layer, and local incentives can provide the final push that makes a project exceptionally profitable.

Local incentives, offered by counties or municipalities, often include:

-

Property Tax Abatements: Reducing or eliminating property taxes for a set period (e.g., 10-15 years) can save millions of dollars over the life of the project.

-

Site Development Grants: Financial assistance for land acquisition, infrastructure development, and utility connections.

-

Streamlined Permitting: A commitment from local authorities to expedite the permitting process, reducing delays and administrative costs.

Experience from J.v.G. turnkey projects shows that negotiating these local packages is a critical phase of site selection, one that requires careful planning and a clear understanding of the economic value the project brings to the community.

Frequently Asked Questions (FAQ)

What is the typical timeline for securing state incentives?

The process can range from 6 to 18 months. It typically involves extensive negotiation and requires a detailed business plan, financial projections, and commitments regarding job creation and capital investment.

Do I need a local partner to apply for these programs?

While not always mandatory, having local legal and consulting partners is highly advisable. They understand the local political landscape and have established relationships that can facilitate the negotiation process.

How do incentives affect the choice between a small-scale and large-scale factory?

Most significant state-level incentive packages are tied to benchmarks for job creation and capital investment. Larger projects (e.g., a fully automated turnkey solar panel production line) with higher investment and employment figures typically qualify for more substantial and comprehensive support.

Are these incentives available to foreign-owned companies?

Yes, in nearly all cases. U.S. economic development programs are designed to attract investment and create jobs, regardless of the company’s country of origin. The primary criteria are the quality of the project and its economic impact on the state and local community.

What is the first step in exploring site selection?

The foundational step is to develop a clear understanding of your operational needs and business goals. This forms the basis of a comprehensive guide on how to start a solar panel manufacturing business, allowing you to evaluate how different locations and their incentive packages align with your specific requirements.

Conclusion: Your Next Steps in Strategic Site Selection

Choosing a location for a solar manufacturing facility is one of the most critical decisions an investor will make. While the lure of generous incentives is strong, a holistic analysis that balances financial benefits with operational fundamentals like workforce, logistics, and infrastructure is essential.

The current landscape, shaped by the IRA, offers an unprecedented opportunity for new entrants. By understanding the interplay between federal policy, state strategies, and local economic conditions, you can identify a location that not only maximizes profitability but also positions your venture for long-term, sustainable growth in the burgeoning American solar industry.