Uruguay has earned a global reputation for its commitment to renewable energy, with over 98% of its electricity generated from clean sources. For an entrepreneur considering the solar manufacturing sector, this national focus creates a compelling opportunity.

Translating this favorable environment into a functioning factory, however, involves a series of practical, on-the-ground steps. The first critical task is securing a suitable plot of industrial land with reliable access to essential utilities. This guide breaks down the process of acquiring industrial land, navigating zoning laws, and establishing utility connections for a solar module manufacturing plant in Uruguay, offering key insights for investors.

Understanding Uruguay’s Industrial Landscape

Before searching for a specific site, it’s crucial to understand the country’s strategic industrial corridors and the government frameworks designed to support investment. Most industrial activity is concentrated in locations offering logistical and workforce advantages.

Key industrial zones are primarily located in:

- Montevideo and its metropolitan area: The nation’s capital and primary economic hub.

- Canelones: A department adjacent to Montevideo with extensive industrial parks and land.

- Colonia: A key location due to its strategic ports, providing excellent access for importing raw materials and exporting finished modules.

The Uruguayan government actively encourages foreign investment through its promotion agency, Uruguay XXI. A central piece of this framework is the Investment Promotion Law (No. 16,906), which offers significant tax incentives for projects declared to be of national interest. A solar manufacturing facility, contributing to a strategic national industry, would be a strong candidate for these benefits.

The Land Acquisition Process: Key Considerations

Selecting the right location involves more than just price and size. The process requires a careful evaluation of zoning regulations, environmental requirements, and the legal frameworks governing different types of industrial land. Understanding the solar factory building requirements from the outset is foundational to any successful project.

Zoning and Environmental Permitting

Once a potential region is identified, the next step is to verify that the specific land is zoned for industrial use. This information is managed at the municipal level, where each department has its own land-use plans.

Simultaneously, any industrial project requires an environmental license from the National Directorate of Environment (DINAMA). This involves submitting an environmental impact assessment and demonstrating that the facility’s operations will adhere to national standards. Based on J.v.G. Technology GmbH’s global experience with turnkey projects, beginning this process early is highly recommended, as it can significantly impact the overall project timeline.

Free Trade Zones (FTZs) vs. Standard Industrial Land

Uruguay offers a distinct choice between locating a factory on standard industrial land or within a designated Free Trade Zone. This decision carries significant implications for taxation and operations.

-

Standard Industrial Land: Allows for greater flexibility in location and operations. The business operates under the standard Uruguayan tax regime but can benefit from the Investment Promotion Law.

-

Free Trade Zones (FTZs): These are designated areas, such as Zonamerica or the Parque de las Ciencias, offering comprehensive tax exemptions. Companies within an FTZ are exempt from all national taxes, including corporate income tax and VAT. In exchange, they must adhere to specific regulations, such as exporting a high percentage of their production.

For an entrepreneur focused on serving international markets, an FTZ offers a compelling financial advantage. For a business aiming to supply the domestic or regional Mercosur market, the benefits may be less pronounced.

Securing Essential Utility Connections

A solar module factory is a sophisticated industrial facility that depends on an uninterrupted supply of high-quality utilities. The solar panel manufacturing process requires stable power for sensitive machinery and clean water for various production stages. Fortunately, Uruguay’s state-owned utility providers have a strong reputation for reliability.

Electricity Supply: Partnering with UTE

The national power company, UTE (Administración Nacional de Usinas y Trasmisiones Eléctricas), is responsible for all electricity transmission and distribution. Establishing a connection for an industrial-scale facility involves several steps:

-

Initial Application: Submitting a formal request that details the projected power demand (in kVA), load characteristics, and factory location.

-

Feasibility Study: UTE conducts a technical study to determine the nearest connection point and assess whether grid upgrades, such as a dedicated substation, are required.

-

Connection Agreement: A formal contract is signed, outlining the technical specifications, costs, and timeline for the connection.

Uruguay’s grid is notably stable, with an average interruption duration index (SAIDI) of just 4.5 hours per year. This high reliability is a significant advantage for operating sensitive manufacturing equipment.

Water and Wastewater Management: Working with OSE

The state-owned water utility, OSE (Obras Sanitarias del Estado), manages water supply and sanitation services. The process mirrors that for electricity: an application must be submitted detailing the required water volume and wastewater discharge characteristics. OSE then assesses the local network’s capacity and defines the connection requirements. A water treatment plan for industrial effluent may be necessary to comply with DINAMA’s environmental regulations.

Data and Telecommunications: Leveraging ANTEL’s Network

High-speed data connectivity is essential for modern manufacturing. ANTEL, the state-owned telecommunications company, has invested heavily in a nationwide fiber-optic network that provides reliable, high-bandwidth internet access, even in many industrial areas outside major cities.

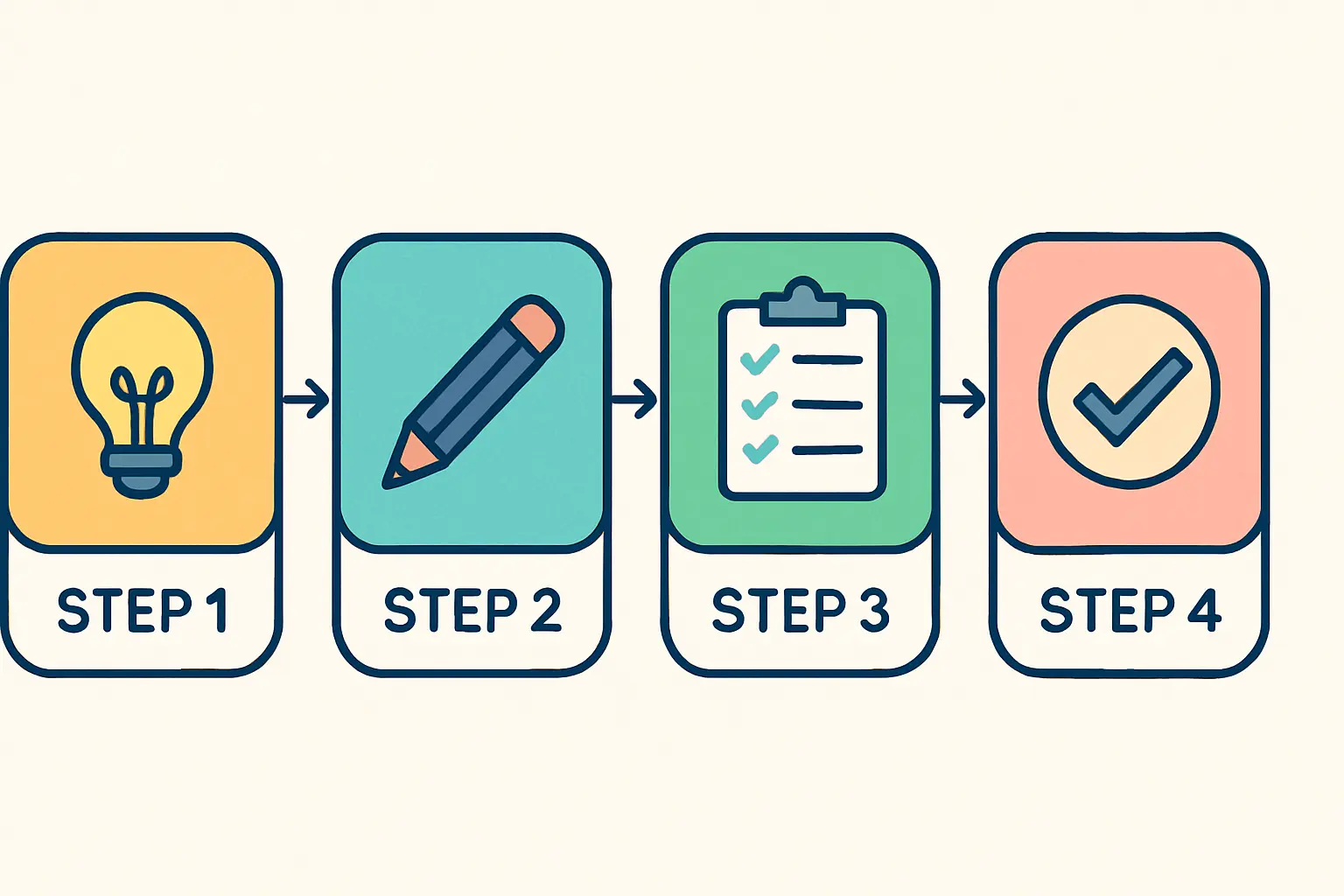

A Typical Project Timeline and Sequence

Understanding the sequence of these activities is crucial for effective project planning. While every project is unique, a typical timeline involves several overlapping phases. As the processes for land acquisition, permitting, and utility contracting are interdependent, a proactive, structured approach is essential for avoiding delays. This type of planning is a core component of learning how to start a solar module factory efficiently.

Frequently Asked Questions (FAQ)

What are the primary benefits of Uruguay’s Free Trade Zones?

The primary benefit is a comprehensive exemption from all national taxes, including corporate income tax, VAT, wealth taxes, and import duties on machinery and raw materials—a significant advantage for export-oriented manufacturing.

How long does the environmental permitting process with DINAMA typically take?

The timeline can vary depending on the project’s complexity, but a standard industrial facility can expect the process to take 6 to 18 months. It’s a critical long-lead item to factor into the project schedule from the very beginning.

Is it necessary to hire a local consultant to navigate this process?

While not legally mandatory, it is highly recommended. A local legal or engineering consultancy with experience in industrial projects can navigate municipal regulations, manage dealings with utility companies, and expedite permitting processes far more effectively than an outside team.

What level of power consumption should a 50 MW solar factory anticipate?

A semi-automated 50 MW solar module factory typically requires a consistent power supply of approximately 300 to 500 kVA. This figure can vary based on the specific technology and level of automation in the production line.

Your Next Steps for a Successful Project

Securing land and utilities is a foundational milestone in establishing a solar manufacturing plant in Uruguay. The process requires diligent research, strategic decisions about location and legal structure, and careful coordination with multiple state agencies. By understanding Uruguay’s well-defined procedures and leveraging its pro-investment framework, entrepreneurs can lay the groundwork for a successful and impactful manufacturing venture.