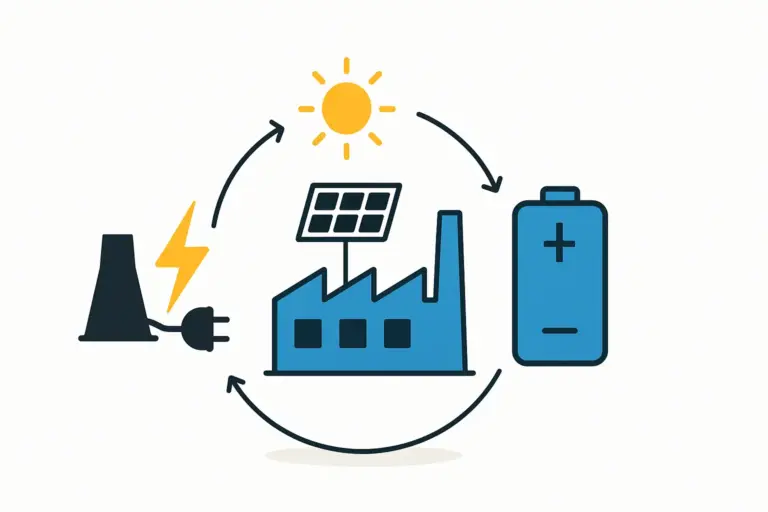

An entrepreneur planning a solar module assembly plant in Venezuela must make a critical decision at the outset: where to source the raw materials. This choice—whether to procure components locally or import them from established international markets—is more than a logistical detail. It’s a strategic decision that fundamentally shapes the business model, influencing everything from production costs and supply chain resilience to the final market price of the solar panels.

This analysis examines the cost-benefit considerations of both approaches, providing a framework for entrepreneurs to navigate the unique economic and industrial landscape of Venezuela.

The Strategic Importance of Material Sourcing

The choice to source locally or import involves a delicate balance of risks and rewards. While importing from established global suppliers often guarantees access to high-quality, certified components that meet international standards, this path comes with significant external risks. Local sourcing, on the other hand, can offer cost savings and supply chain stability but introduces challenges related to quality assurance and supplier capacity.

A successful solar manufacturing venture depends on a reliable and cost-effective supply of the essential components of a solar panel. Understanding the nuances of sourcing these materials within the Venezuelan context is a crucial first step.

Analyzing the Case for Importing Key Components

For many specialized photovoltaic components, importing remains the most practical option. High-technology items like solar cells, ethylene vinyl acetate (EVA) encapsulant, and specialized backsheets require significant capital investment and advanced chemical engineering capabilities that are not yet widely available in Venezuela.

Advantages of Importing:

- Quality and Certification: International suppliers provide components certified by bodies like TÜV and UL, which is essential for market acceptance and bankability.

- Technological Access: Importing ensures access to the latest, most efficient solar cell technologies (e.g., PERC, TOPCon), which is critical for producing competitive modules.

Challenges of Importing in Venezuela:

Despite these advantages, importing goods into Venezuela comes with substantial hurdles.

- Currency Fluctuation: The volatility between the Venezuelan Bolívar (VES) and the US Dollar (USD) introduces significant financial risk. A procurement budget set at the beginning of a quarter can become insufficient by the time payment is due.

- Customs and Tariffs: Navigating customs procedures can be complex and time-consuming. High import tariffs and taxes can substantially increase the ‘landed cost’ of materials, eroding potential profit margins.

- Logistical Delays: Port congestion and inland transportation challenges can lead to unpredictable delays, disrupting production schedules and increasing working capital requirements. Experience from past J.v.G. projects shows that even a seemingly simple shipment can face weeks of unforeseen delays at the port of entry.

Exploring Venezuela’s Local Sourcing Potential

While importing high-tech components is often necessary, Venezuela has a domestic industrial base that presents opportunities for sourcing other essential materials. A careful evaluation can unlock significant cost and logistical advantages.

Aluminum Frames: A Prime Opportunity

The aluminum frame is one of the most promising candidates for local sourcing. Venezuela has substantial bauxite reserves and a history of aluminum production. Although the national industry may be operating below full capacity, the capability to produce high-quality extruded aluminum profiles still exists.

Key Considerations:

- Supplier Qualification: Partnering with a local extruder who can meet the precise dimensional tolerances and quality standards for anodization is essential.

- Cost Savings: Sourcing bulky frames locally can dramatically reduce shipping costs and import duties, directly improving the cost structure of the final module.

Solar Glass: Potential with a Caveat

Sourcing solar-grade glass locally is theoretically possible but requires extreme diligence. Solar panels need low-iron, tempered glass to maximize light transmission and durability.

- The Quality Challenge: Standard architectural or window glass is unsuitable due to its high iron content, which blocks sunlight and reduces the panel’s efficiency. Any potential local supplier must be able to produce PV-grade glass consistently. A failure in glass quality can lead to widespread module failure in the field.

Junction Boxes, Backsheets, and EVA

These components are less likely to be sourced locally in the near term, as they involve complex polymer chemistry and precision electronics manufacturing. For a new venture, relying on established international suppliers for these critical items is the most prudent way to ensure product reliability and performance.

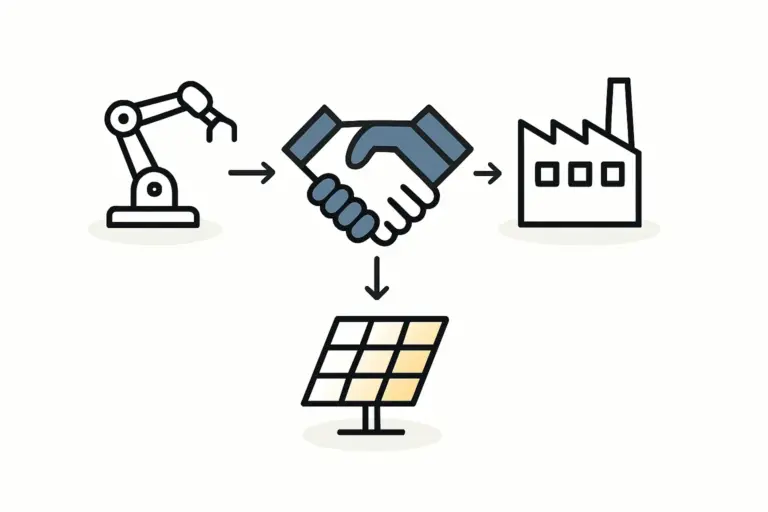

The Hybrid Model: A Practical Strategy for Venezuela

A hybrid sourcing model is therefore the most realistic and resilient strategy for a new solar module assembly plant in Venezuela. This approach strategically balances the benefits of local procurement with the quality assurance of imports.

A recommended hybrid sourcing plan would look like this:

- Primarily Imported:

- Solar Cells

- EVA Encapsulant

- Backsheet

- Junction Box

- Ribbon (Tabbing & Bus Wire)

- Strong Local Sourcing Potential:

- Aluminum Frames

- Packaging Materials (Cardboard, Pallets)

- Local Sourcing with Diligent Qualification:

- Solar Glass

This balanced approach allows a manufacturer to leverage local industry for bulky, less technologically sensitive items while relying on the global market for core, high-tech components. This not only optimizes cost but also aligns with national industrial development goals, such as the ‘Hecho en Venezuela’ (Made in Venezuela) policy, which may offer certain advantages.

Frequently Asked Questions (FAQ)

What is the most difficult component to source locally in a new market?

Solar cells are almost always the most difficult component to source locally. Cell manufacturing is extremely capital-intensive, requiring facilities that cost hundreds of millions of dollars and a highly specialized technical workforce. For this reason, nearly all new module assembly plants begin by importing cells from established global producers.

Can I use standard window glass for solar panels to save costs?

No. Using standard glass is a critical error. Its higher iron content significantly reduces the amount of light reaching the solar cells, lowering the panel’s power output and efficiency. Furthermore, it often lacks the strength and tempering required to withstand environmental stresses like hail and high winds for 25 years.

How does currency fluctuation truly affect my import strategy?

Currency volatility introduces uncertainty into your Bill of Materials (BOM) cost. If you must pay suppliers in USD but your revenue is in VES, a devaluation of the local currency can erase your profit margin between the time you place an order and the time you pay for it. This risk must be managed through financial hedging strategies or by structuring sales contracts in a stable currency.

Does ‘local sourcing’ automatically mean lower quality?

Not necessarily, but it does demand a more robust quality control process from the manufacturer. While international suppliers often have globally recognized certifications, local suppliers may not. The responsibility then falls to the module manufacturer to conduct rigorous audits, material testing, and ongoing quality checks to ensure all locally sourced components meet the required specifications. Establishing these in-house quality assurance protocols is a key part of the initial investment for a solar production line.

Next Steps for Aspiring Manufacturers

A resilient and cost-effective supply chain is the foundation of any successful solar manufacturing business. The optimal strategy for a venture in Venezuela is a carefully planned hybrid model that leverages local strengths while mitigating risks through strategic importation.

This requires in-depth feasibility studies, thorough supplier vetting, and a clear understanding of the total landed cost of all components. For entrepreneurs seeking a structured path through this complex planning phase, turnkey solar manufacturing solutions provide comprehensive guidance, from initial business plan development to factory commissioning.