Venezuela’s Energy Paradox: A Critical Market for Ruggedized Solar Modules

It’s a paradox: a nation with one of the world’s largest oil reserves finds its own energy-intensive industries, like oil extraction and mining, struggling with unreliable power. For years, Venezuela’s centralized electrical grid has been plagued by significant challenges, leaving remote industrial operations vulnerable to frequent and costly outages. This reality creates a compelling, high-value market for a specific product: locally manufactured, ruggedized solar modules designed to withstand demanding industrial environments.

This article explores the business case for establishing a solar module factory in or near Venezuela to serve this niche. We’ll outline the unique technical requirements for modules in the oil and mining sectors and explain why local production offers a clear strategic advantage over importation.

The Venezuelan Energy Paradox: A Challenge for Key Industries

Venezuela’s economic backbone—its oil and mining sectors—is concentrated in geographically isolated regions. Far from urban centers, these operations are often at the mercy of an unstable national power grid. When the grid fails, multi-million dollar operations are forced to rely on diesel generators. But this solution is fraught with its own challenges, including high fuel costs, complex logistics, and constant maintenance.

For an oil drilling site or a remote mining concession, a power outage isn’t a minor inconvenience; it’s a direct threat to productivity and profitability. Consistent, reliable energy is essential for powering everything from extraction equipment and processing machinery to communication systems and personnel housing. This critical need for energy independence is the primary driver for off-grid solar power.

Why Standard Solar Modules Are Not Sufficient

An entrepreneur might assume that any standard solar module could meet this demand. Industrial environments like oil fields and mines, however, present conditions far harsher than a typical residential rooftop or commercial solar farm.

Common challenges in these locations include:

- High Humidity and Salinity: Coastal and jungle environments accelerate corrosion.

- Dust and Particulates: Mining and drilling operations generate significant airborne debris that can abrade module surfaces and infiltrate seals.

- High Temperatures: Intense solar irradiation and heat from machinery can degrade module components over time.

- Risk of Physical Impact: The presence of heavy machinery, tools, and operational activities increases the likelihood of accidental impacts.

Standard solar modules, designed for more benign conditions, can fail prematurely in such settings. These failures lead to system downtime and erode the operator’s confidence in solar technology. The solution lies in modules specifically engineered for durability—often referred to as ‘ruggedized’ modules. A common approach is using glass-glass solar modules, which offer superior protection and longevity.

Defining the ‘Ruggedized’ Module for Industrial Use

A ruggedized solar module isn’t a fundamentally new technology but an evolution of standard design, with specific components enhanced for durability. These key features are integrated during the manufacturing process to ensure long-term performance in harsh conditions.

Key Specifications for Industrial-Grade Modules:

- Thicker Glass: Using 3.2 mm or even 4.0 mm tempered glass on the front—instead of the standard 2.0-2.5 mm—provides significantly higher resistance to impact from falling tools, debris, or extreme weather like hail.

- Robust Framing: A stronger, thicker aluminum frame (e.g., 40 mm profile) enhances the module’s structural integrity, preventing torsion and bending during transport and installation on industrial racks.

- Enhanced Sealing and Encapsulation: Using high-quality encapsulants and edge sealants is critical for preventing moisture and dust ingress, which can cause delamination and corrosion of solar cells over time.

- Durable Junction Boxes: IP68-rated junction boxes provide the highest level of protection against dust and water, ensuring electrical connections remain secure and corrosion-free throughout the module’s lifespan.

By focusing on these features, a manufacturer can produce a premium product that commands a higher price and delivers the reliability industrial clients demand.

The Strategic Advantage of Local Manufacturing

While importing ruggedized modules is possible, establishing a local or regional manufacturing facility offers powerful competitive advantages.

-

Reduced Logistical Costs and Complexity: Solar modules are bulky and relatively heavy. Shipping them internationally, especially to remote inland locations, incurs significant freight, insurance, and customs costs. Local production drastically reduces these expenses.

-

Customization and Agility: An industrial client may have specific requirements for module size, voltage, or mounting points. A local factory can quickly adapt production to meet these custom needs, offering a level of service distant international suppliers cannot match.

-

Faster Delivery and Replacement: When a project requires additional modules or a replacement for a damaged unit, a local manufacturer can respond in days rather than weeks or months. This speed is a critical selling point for industries where downtime is extremely costly.

-

Economic and Political Goodwill: Building a factory creates local jobs and contributes to the region’s industrial base. This approach is often viewed favorably by governments and large corporate clients, potentially leading to preferential treatment in contracts.

Based on experience from J.v.G. turnkey projects, identifying and serving a high-demand local niche is a proven strategy for new manufacturers to establish a profitable and defensible market position. A small-to-medium scale factory, perhaps in the 20-50 MW annual capacity range, would be ideally sized to serve Venezuela’s industrial sector without being over-leveraged.

Assembling the Right Production Line

Setting up a production line for ruggedized modules doesn’t require starting from scratch. Instead, it involves making strategic choices when selecting core manufacturing equipment.

For instance, the laminator must be capable of handling thicker glass and glass-glass configurations, while the automatic framing machine needs to be specified for more robust 40 mm frames. These are adjustments to a standard production line, not a complete reinvention. With proper planning and expert guidance, a new entrepreneur can configure a factory specifically for this high-margin product category.

Frequently Asked Questions (FAQ)

-

What is the primary difference between a standard and a ruggedized solar module?

The main difference lies in the robustness of the components. A ruggedized module typically features thicker glass, a stronger aluminum frame, and superior sealing (IP68-rated junction box) to better withstand the physical impacts, high humidity, dust, and extreme temperatures found in industrial settings. -

Why can’t these industries simply rely on diesel generators?

While diesel generators are a common backup, they come with significant drawbacks: high and volatile fuel costs, logistical challenges in transporting fuel to remote sites, constant maintenance requirements, and environmental impacts from noise and emissions. Solar power, in contrast, offers a silent, low-maintenance solution with a stable and predictable energy cost after the initial investment. -

Is Venezuela the only market for such specialized modules?

Absolutely not. The principles discussed here apply globally. Any industry operating in a remote, off-grid, or harsh environment is a potential customer for ruggedized modules. This includes mining operations in Africa, agricultural facilities in the Middle East, telecommunication towers in remote mountains, and offshore oil and gas platforms. -

What kind of investment is needed to start a factory for these modules?

The investment depends on the desired production capacity, level of automation, and location. A well-planned, semi-automated line with an annual capacity of 20-50 MW can be an effective entry point for serving a niche market like this. A detailed business plan is essential to determine the precise capital requirements.

Next Steps in Your Exploration

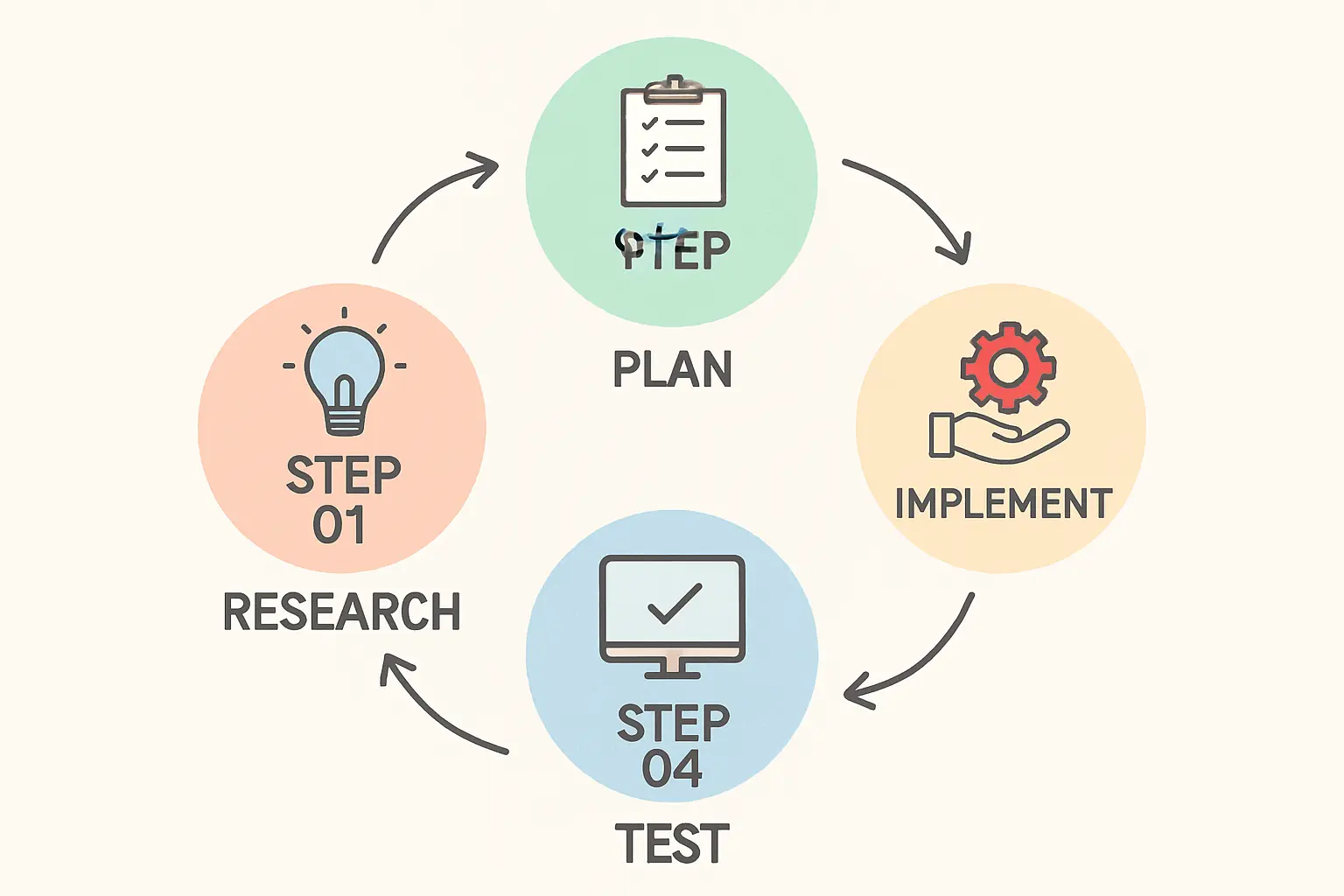

Understanding a specific market need—like the demand for durable solar modules in Venezuela’s industrial sector—is the first step toward building a successful manufacturing enterprise. The next stage is translating this opportunity into a concrete business plan that covers factory layout, equipment selection, supply chain logistics, and financial modeling.

For entrepreneurs ready to take that next step, our expert-led courses on pvknowhow.com provide the structured framework and guidance needed to build a successful solar manufacturing business.