Disclaimer: This case study represents a composite example derived from real-world

consulting work by J.v.G. Technology GmbH in solar module production and factory optimization. All data points are realistic but simplified for clarity and educational purposes.

Even with a state-of-the-art production facility, a highly skilled workforce, and a robust business plan, one factor can bring an entire operation to a standstill: logistics. The ability to consistently source high-quality raw materials and efficiently export finished products isn’t just an operational detail. It’s the central nervous system of a modern solar module manufacturing business.

Vietnam has rapidly emerged as a global manufacturing powerhouse, particularly in the renewable energy sector. Its strategic location, favorable trade agreements, and skilled labor force make it an attractive base for entrepreneurs entering the solar industry. Success, however, hinges on mastering the complex flow of goods across its borders. This article outlines the critical inbound and outbound logistics that define the viability of a solar factory in Vietnam.

The Two Sides of a Solar Factory’s Logistics Puzzle

The logistics of a solar manufacturing operation consist of two distinct but interconnected streams:

- Inbound Logistics: The process of sourcing, importing, and receiving all the necessary raw materials and components required for production.

- Outbound Logistics: The process of packaging, documenting, and exporting the finished solar modules to international markets.

A failure in the inbound stream starves the factory of essential materials, halting production. Meanwhile, a failure in the outbound stream creates costly inventory backlogs and damages customer relationships. Mastering both is essential for profitability and long-term growth.

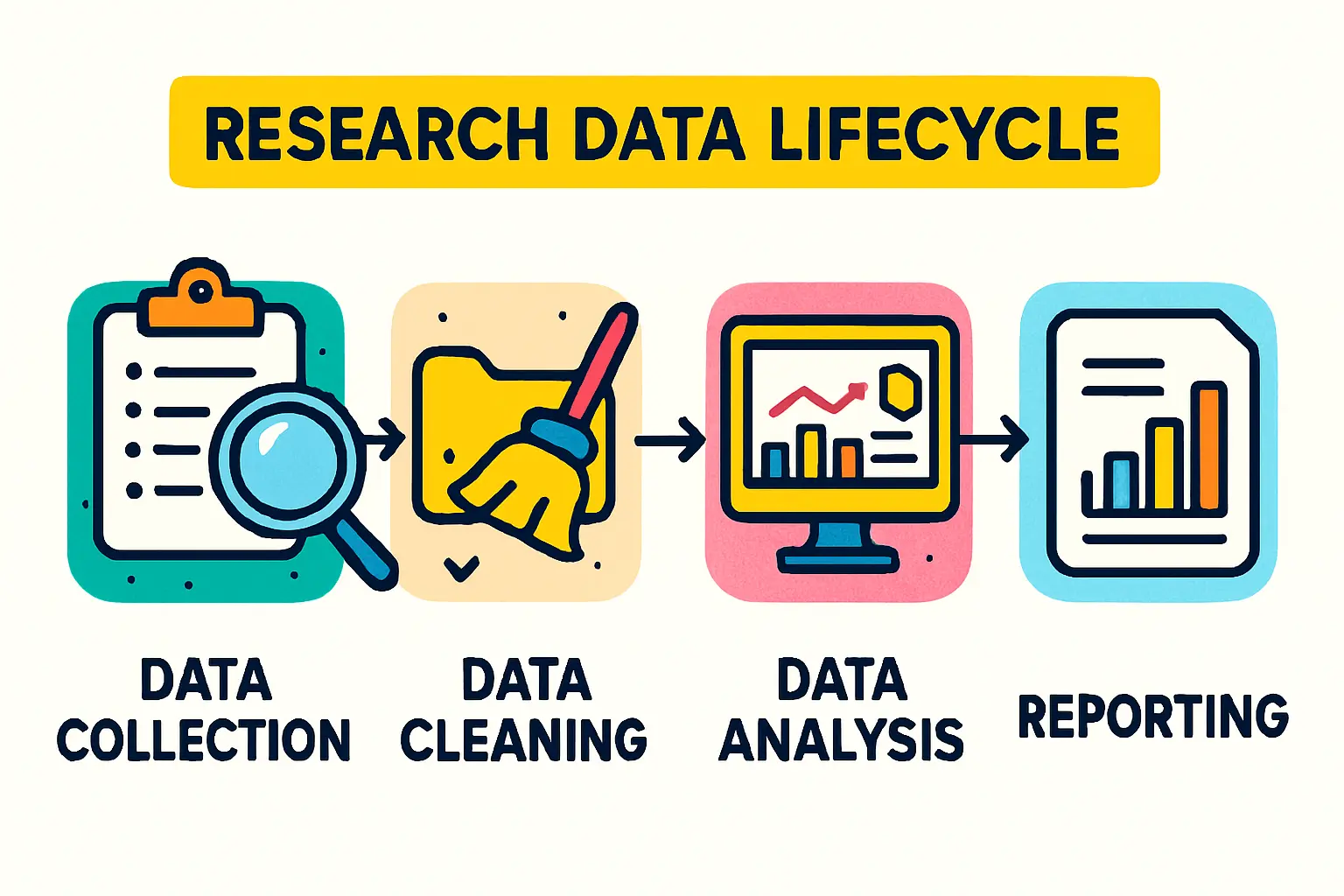

Inbound Logistics: Sourcing Your Raw Materials

The quality and cost of a finished solar module are determined long before it reaches the assembly line; they’re rooted in the quality and cost of its constituent parts. A well-managed inbound supply chain is the foundation of a competitive product.

The Critical Bill of Materials (BOM)

A typical solar module is an assembly of several key components. For a new enterprise, sourcing these items reliably is the first major logistical challenge. The primary components on a bill of materials (BOM) include:

- Solar Cells: The most critical and costly component. The majority of high-efficiency monocrystalline cells are currently sourced from manufacturers in China and Southeast Asia.

- Glass: Specially tempered, low-iron, anti-reflective coated glass for the front side.

- Backsheet or Rear Glass: A protective polymer backsheet for glass-foil modules, or a second pane of glass for glass-glass modules.

- Encapsulant (EVA/POE): Polymer sheets that laminate the cells between the glass and backsheet, protecting them from moisture and impact.

- Aluminum Frames: Provide structural rigidity and a means for mounting.

- Junction Boxes: Contain the bypass diodes and output cables.

Based on experience gained from European PV manufacturers’ turnkey projects, new factory owners often find that establishing reliable supply lines for A-grade cells and specialized solar glass is among their most demanding initial tasks.

Navigating Vietnamese Import Channels

Since most core components are imported, understanding Vietnam’s port and customs infrastructure is fundamental.

- Key Import Hubs: For factories in northern Vietnam, the Port of Hai Phong is the primary gateway for inbound materials. For those in the south, terminals around Ho Chi Minh City (e.g., Cat Lai) are the logistical centers.

- Customs and Tariffs: Each component has a specific HS (Harmonized System) code that determines its import duty. While Vietnam has policies to encourage manufacturing, it is crucial to work with an experienced local customs broker to ensure compliance and avoid costly delays. All documentation, including the commercial invoice, packing list, and bill of lading, must be flawless.

Entrepreneurs often overlook the time and working capital required to manage this inbound flow. Lead times for materials like solar cells can be several weeks, demanding careful financial and production planning.

Outbound Logistics: Exporting Your Finished Solar Modules

Once modules are assembled, tested, and certified, the second half of the logistics journey begins: delivering them to global customers.

From Production Line to Global Markets

The outbound process starts the moment a module passes its final quality inspection.

- Packaging: Modules are carefully stacked on custom-built pallets, typically holding 30–37 modules each, to prevent damage during transit.

- Container Loading: These pallets are strategically loaded into standard 40-foot shipping containers. A typical 40-foot High Cube (HC) container can accommodate approximately 800–950 modules, depending on their size and frame thickness.

- Freight Forwarding: A freight forwarder books space on a container vessel, manages transport from the factory to the port, and handles all export documentation.

Key Export Hubs and Strategic Advantages

The same ports that serve as import hubs—Hai Phong and Ho Chi Minh City—are the primary arteries for exports.

- Documentation for Export: Key documents include the Certificate of Origin (which can be vital for customers claiming preferential tariff rates), the Bill of Lading (the contract between the shipper and the carrier), and the commercial invoice. Accuracy is paramount.

- Localization Awareness: Vietnam’s participation in major free trade agreements, such as the EU-Vietnam Free Trade Agreement (EVFTA) and the Comprehensive and Progressive Agreement for Trans-Pacific Partnership (CPTPP), offers a significant competitive advantage. This means modules manufactured in Vietnam can enter key markets like the EU, Canada, or Japan with lower or zero import tariffs compared to products from other nations—a powerful selling point.

The entire journey, from a container leaving the factory gate to its arrival at a port in Europe or North America, typically takes 25 to 45 days. This transit time must be factored into sales agreements and cash flow projections.

Common Challenges and Strategic Considerations

A successful logistics strategy is proactive, anticipating potential disruptions.

- Supply Chain Volatility: Global shipping costs and component availability can fluctuate dramatically. A sound strategy involves building relationships with multiple suppliers and logistics partners to avoid over-reliance on a single source.

- Quality Control: Responsibility for quality doesn’t end at the factory door. Verifying that incoming materials meet specifications is just as important as testing the final product. A single bad batch of EVA encapsulant, for example, can lead to the delamination and failure of thousands of modules in the field.

- Working Capital Management: Long shipping times for both inbound materials and outbound products tie up significant capital in inventory. Managing the cash conversion cycle requires effective financial planning.

A comprehensive business plan for a solar module manufacturing plant must dedicate a detailed section to its supply chain and logistics strategy, as these elements directly impact cost, quality, and delivery timelines.

Frequently Asked Questions (FAQ)

Why is Vietnam a popular location for solar manufacturing?

Vietnam offers a combination of competitive labor costs, government incentives for high-tech industries, a strategic location in Asia, and major trade advantages through its free trade agreements. This makes it an effective hub for exporting to global markets.

Where do most raw materials for solar panels come from?

The global supply chain for solar components is heavily concentrated in East and Southeast Asia. China is the dominant producer of silicon wafers and solar cells, the foundational materials for module manufacturing. Other components like glass, frames, and junction boxes are also widely produced in the region.

What is the average shipping time from Vietnam to Europe or North America?

Sea freight from Vietnam typically takes 25–35 days to major ports in Europe and 20–30 days to the West Coast of North America. These timelines can be affected by port congestion, weather, and specific shipping routes.

How does a new factory owner establish these supply chains?

Establishing robust supply chains is a multi-step process: identifying and vetting potential suppliers, auditing their facilities, negotiating contracts, and selecting experienced logistics partners. This is often done with the guidance of a technical consultant or as part of a turnkey production line setup, where established relationships and processes can be leveraged. Necessary factory certifications also play a role in qualifying for certain supply chains.

Conclusion: Your Supply Chain Is Your Lifeline

For an entrepreneur looking to enter the solar manufacturing industry in Vietnam, the physical factory is only one part of the equation. The invisible network of suppliers, shipping lanes, and customs procedures that forms the supply chain is what truly brings the business to life.

While the complexities can seem daunting, they are manageable with diligent planning, the right local partners, and a clear understanding of the end-to-end process. By treating logistics as a core strategic function rather than a back-office task, a new manufacturing enterprise can build a resilient and competitive operation poised for success in the global solar market.

Download the Vietnam Solar Supply Chain Case Study (PDF)

Author: This case study was prepared by the

turnkey solar module production specialists at J.V.G. Technology GmbH

It is based on real data and consulting experience from J.v.G. projects

worldwide, including installations ranging from 20 MW to 500 MW capacity.