Disclaimer: This case study represents a composite example derived from real-world

consulting work by J.v.G. Technology GmbH in solar module production and factory optimization. All data points are realistic but simplified for clarity and educational purposes.

In the competitive global solar market, profit margins are often shaped by factors beyond production efficiency. An entrepreneur might build a state-of-the-art facility, only to find its products uncompetitive in key markets like Europe or North America due to import tariffs.

This hidden cost can erode viability before the first container is even shipped. However, a strategic choice of manufacturing location can transform these tariffs from a barrier into a significant competitive advantage.

Vietnam, through its network of free trade agreements (FTAs), offers a powerful gateway for solar module manufacturers to access high-value international markets on preferential terms. This article explores how leveraging these agreements can be the cornerstone of a successful export-oriented solar business.

Understanding the Tariff Advantage: EVFTA and CPTPP

Free Trade Agreements are pacts between two or more countries to reduce or eliminate barriers to trade, such as tariffs and quotas. For a solar module manufacturer, this means products can enter a partner country’s market at a lower cost than those from a non-partner country, securing an immediate price advantage.

Vietnam has been proactive in forging these relationships, with two agreements standing out as particularly relevant for the solar industry.

The EU-Vietnam Free Trade Agreement (EVFTA)

Effective since August 2020, the EVFTA is a landmark agreement that progressively eliminates over 99% of all customs duties between the European Union and Vietnam. For solar module manufacturers, this is a game-changer.

Products manufactured in Vietnam that meet the agreement’s criteria can enter the 27-country EU bloc tariff-free. Given that the EU is one of the world’s largest and most mature solar markets, this access provides a substantial commercial edge over competitors from countries facing standard import duties.

The Comprehensive and Progressive Agreement for Trans-Pacific Partnership (CPTPP)

The CPTPP is a trade agreement among 11 countries around the Pacific Rim, including major markets like Canada, Mexico, Japan, and Australia. This agreement opens up a diverse range of export destinations for a Vietnam-based factory.

A manufacturer can strategically target growing solar markets within this bloc, benefiting from reduced or eliminated tariffs that competitors outside the CPTPP still face. This dual-agreement advantage positions Vietnam as a unique export hub, providing preferential access to both established European markets and dynamic economies across the Pacific.

The Critical Factor: Navigating Rules of Origin

Simply assembling solar modules in Vietnam is not enough to qualify for the benefits of these FTAs. The core of every trade agreement lies in its ‘Rules of Origin’ (RoO), the criteria used to determine a product’s national source. In essence, they are the product’s ‘passport’, proving it was genuinely ‘made in Vietnam’ and not just routed through it.

To gain this passport, a product must undergo a ‘substantial transformation’ within the country. This is typically measured by a ‘local value content’ (LVC) requirement, often mandating that a certain percentage—for example, 40%—of the product’s value must originate from Vietnam.

This prevents producers in non-FTA countries from simply shipping nearly-finished goods to Vietnam for final, minor assembly to circumvent tariffs. For an entrepreneur planning a new factory, understanding this from day one is crucial. It means the entire business model, from supply chain design to the choice of solar module production machines, must be engineered to create the required level of local value.

Building a Compliant and Competitive Factory

Achieving the necessary local value content requires a strategic approach to factory design and operations. A successful solar panel manufacturing business plan must address how the facility will meet these RoO requirements.

This often involves several key considerations:

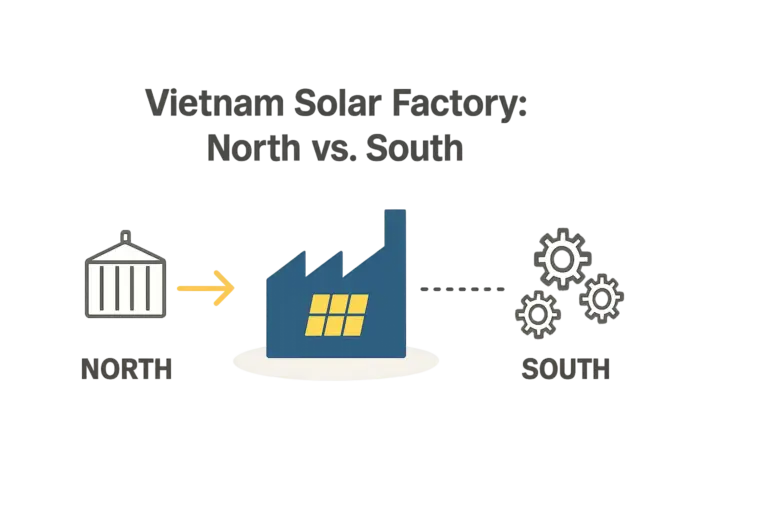

- Process Integration: A simple final assembly line may not be sufficient. The manufacturing process must include significant transformative steps within Vietnam. This could involve cell stringing, lamination, and framing, rather than just connecting pre-assembled components.

- Local Sourcing: Incorporating locally sourced materials, such as aluminum frames, junction boxes, or glass, directly contributes to the local value content percentage. A thorough analysis of Vietnam’s domestic supply chain is a crucial part of the planning phase.

- Operational Costs: Labor, utilities, and factory overhead incurred in Vietnam also count towards the local value requirement.

Setting up a turnkey solar module factory with an experienced partner ensures these complex requirements are integrated into the facility’s design from the outset. Experience from turnkey projects shows that mapping the supply chain and production processes to meet RoO standards is as fundamental as the initial financial modeling.

Beyond Tariffs: Additional Advantages of Manufacturing in Vietnam

While the FTA network is a primary draw, Vietnam offers several other key advantages for industrial investors:

- Strategic Location: Situated in the heart of Southeast Asia, Vietnam offers excellent logistical connections to global shipping routes.

- Stable Environment: The country is known for its political stability and a government actively encouraging investment in high-tech manufacturing.

- Labor Force: Vietnam has a young, technically-inclined, and increasingly skilled workforce, providing a solid foundation for operations.

- Developing Infrastructure: Continuous investment in ports, highways, and industrial parks supports the growth of export-oriented manufacturing.

These factors combine to create a robust ecosystem for entrepreneurs looking to build a globally competitive manufacturing operation.

Frequently Asked Questions (FAQ)

What is the typical tariff for solar modules entering the EU without an FTA?

Standard tariffs for solar modules from countries without a preferential trade agreement with the EU can vary but have historically been significant enough to impact market competitiveness. The EVFTA effectively reduces this rate to zero for qualifying products from Vietnam.

How complex is it to prove ‘Rules of Origin’ compliance?

It requires meticulous documentation and transparent accounting. A company must be able to prove the origin of its components and the value added at each stage of production within Vietnam. Setting up proper tracking systems from the beginning is essential.

Does Vietnam have a reliable supply of raw materials for solar manufacturing?

Vietnam’s industrial ecosystem is growing. While core components like solar cells may still need to be imported, the local supply chain for materials like aluminum frames, glass, and plastics is developing. A key part of the initial business plan is identifying and establishing relationships with reliable local and regional suppliers.

What is the typical timeline for starting a solar module production line in Vietnam?

With proper planning and an experienced implementation partner, a 20-50 MW solar module production line can be operational in under a year, from initial planning to the first certified module.

Conclusion: From Local Production to Global Opportunity

Choosing a manufacturing location is one of the most consequential decisions an entrepreneur will make. In the solar industry, this choice extends far beyond labor costs and logistics; it directly impacts market access and price competitiveness.

Vietnam, with its strategic trade agreements like the EVFTA and CPTPP, offers more than just a production base. It provides a platform for tariff-free entry into some of the world’s most valuable solar markets. However, unlocking this potential requires a deep understanding of the Rules of Origin and a deliberate plan to build a compliant and efficient factory. By planning for these requirements from the start, a new solar enterprise can build a durable competitive advantage for years to come.

Download the Vietnam Solar Export Strategy Case Study (PDF)

Author: This case study was prepared by the

turnkey solar module production specialists at J.V.G. Technology GmbH

It is based on real data and consulting experience from J.v.G. projects

worldwide, including installations ranging from 20 MW to 500 MW capacity.