An entrepreneur in Zambia’s Copperbelt or its fertile agricultural heartlands quickly encounters a fundamental paradox: abundant economic potential constrained by a lack of reliable energy.

Diesel generators are a common sight, but their high operational costs and maintenance needs erode the profitability of farms and small-scale mines. While solar power presents an obvious solution, a critical insight is often overlooked: the standard panels designed for residential rooftops are not built to withstand the unique demands of these environments.

This article explores the technical considerations for designing and manufacturing solar modules tailored to Zambia’s most vital off-grid sectors. It provides a framework for entrepreneurs to move beyond supplying generic products and develop market-specific energy solutions, building lasting value and a strong competitive advantage.

Understanding Zambia’s Energy Landscape: A Tale of Two Sectors

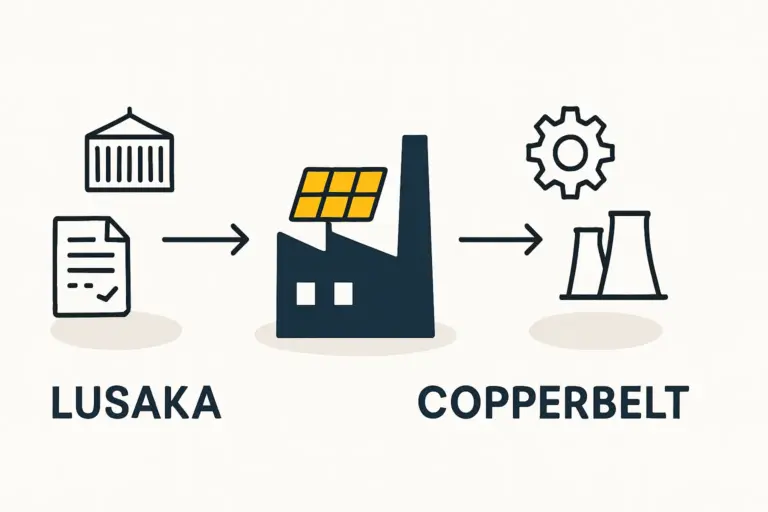

Zambia’s national electrification rate stands at approximately 44%, with rural access falling as low as 14%. This significant energy gap, coupled with an unreliable national grid, creates a substantial and growing market for decentralized, off-grid power solutions. Two sectors, in particular, represent the largest opportunity for localized solar manufacturing:

-

Agriculture: Employing roughly 70% of the nation’s workforce, the agricultural sector’s productivity is directly linked to energy access. Irrigation, cold storage, and crop processing are energy-intensive activities severely hampered by a lack of dependable power.

-

Mining: A cornerstone of the national economy, the mining industry—from small-scale operations to the support services for larger mines—requires consistent power for lighting, ventilation, and processing equipment, often in remote, off-grid locations.

For a new solar module manufacturer, understanding the distinct operational challenges of these two sectors is the first step in developing a successful product strategy.

Tailoring Solar Modules for Zambian Agriculture

The energy needs of a commercial farm are both cyclical and mission-critical. A power failure for an irrigation system during a dry spell, for instance, can be catastrophic. The solar modules powering these operations must be designed for uncompromising reliability.

Powering Productivity: From Irrigation to Cold Storage

The primary agricultural applications for solar power in Zambia include water pumping for irrigation, refrigeration for preserving produce, and running mills or dryers for post-harvest processing. These applications demand modules that can perform consistently under high temperatures and withstand the environmental rigors of a working farm.

Key Technical Specifications for Agricultural Modules

-

High-Temperature Performance: Zambia enjoys high solar irradiation but also experiences intense ambient temperatures. A module’s temperature coefficient is a critical parameter; a lower coefficient means the panel loses less power as it heats up, ensuring a better energy yield during the hottest parts of the day.

-

Moisture and Humidity Resistance: The country’s distinct rainy season brings high humidity, requiring modules built with high-quality encapsulation (EVA) and backsheets. These materials prevent moisture ingress, which can lead to delamination or internal corrosion over the module’s 25-year lifespan.

-

Mechanical Durability: Modules on a farm risk accidental impacts from machinery or damage from extreme weather like hail. A robust frame and thicker front glass can significantly improve their long-term resilience.

Designing for Durability: Solar Modules in the Mining Environment

If agricultural environments are demanding, mining sites are uniquely harsh. Here, the combination of dust, vibration, and physical impact risk creates an operational challenge where only the most robustly designed modules will perform and survive.

The Challenge of Dust, Vibration, and Impact

The most immediate issue on any mining site is dust. Soiling—the accumulation of fine particulate matter on a module’s surface—can drastically reduce its energy output. Constant vibrations from heavy equipment and blasting place stress on module components, while the risk of impact from debris is ever-present.

Essential Design Features for Mining Modules

-

Robust Construction: A stronger, thicker aluminum frame and 3.2mm tempered front glass (versus the 2.8mm standard) provide superior resistance to mechanical stress and impact.

-

PID Resistance: Potential Induced Degradation (PID) is a performance-degrading effect exacerbated by high temperatures and humidity. Selecting PID-resistant cells and high-quality materials is essential for modules deployed in Zambia’s climate.

-

Ease of Maintenance: While regular cleaning is unavoidable to combat soiling, certain anti-reflective or hydrophilic coatings on the glass can make cleaning easier and help maintain higher energy yields between maintenance cycles.

The Business Case for Application-Specific Module Design

Importing the lowest-cost standard module may seem like a sound strategy, but it is a false economy. These modules are likely to underperform and have a shorter operational life in the demanding conditions of Zambian agriculture and mining, leading to system failures and reputational damage for the supplier.

A manufacturer that invests in application-specific design creates a powerful market differentiator. By producing a more reliable and durable product, they offer a lower Levelized Cost of Energy (LCOE) to the end-user. This focus on long-term value is a cornerstone of any successful solar module manufacturing business plan. A well-designed module is not just a component; it is a commitment to the customer’s operational success.

Navigating Certifications and Local Requirements

Building a superior product is only half the battle; ensuring it meets internationally recognized standards is essential for market access and building trust. The core IEC (International Electrotechnical Commission) standards are the baseline for any quality solar module:

-

IEC 61215: Defines design qualification and type approval for performance.

-

IEC 61730: Outlines the requirements for module safety.

Beyond these, entrepreneurs should consider specialized tests, such as those for salt mist or ammonia resistance, to further validate a module’s durability in specific agricultural or chemical-rich mining environments. A comprehensive understanding of the key certifications for solar modules is non-negotiable for building an export-ready brand.

Aligning a manufacturing enterprise with national industrial policy can also create significant advantages. Experience from J.v.G. turnkey projects, for example, shows that demonstrating a commitment to local value creation often aligns with government objectives to reduce import dependency and foster domestic industry.

Frequently Asked Questions (FAQ)

Q1: Can I just use standard residential modules for these applications?

While possible, it’s not advisable. Standard modules may underperform in high heat and are not built to withstand the mechanical stresses of agricultural or mining sites. This can lead to premature failure, higher long-term costs, and dissatisfied customers.

Q2: How much more does it cost to produce a more robust module?

The incremental cost for a stronger frame or thicker glass is often marginal, especially when weighed against the significant gains in lifespan, reliability, and market reputation.

Q3: Do I need a massive factory to produce these specialized modules?

No. A flexible, small-to-medium scale turnkey solar production line with an annual capacity of 20–50 MW can be efficiently configured to produce various module types, allowing a manufacturer to adapt to specific market demands without a prohibitive initial investment.

Q4: What is the first step to determining the right module design for my target market?

A thorough market analysis combined with a technical feasibility study is the critical first step. This process involves understanding the precise needs of your target customers and designing a product that solves their specific challenges.

Conclusion: From Generic Product to Market-Specific Solution

Success in Zambia’s burgeoning off-grid solar market will not be defined by who sells the cheapest panel, but by who provides the most reliable, long-term energy solution. This requires a strategic shift in thinking: from importing a generic product to manufacturing a tailored solution designed for the realities of the local environment.

By focusing on the unique demands of the agricultural and mining sectors, entrepreneurs can build a resilient business and a trusted brand. Understanding these technical nuances is foundational to developing a solar manufacturing enterprise that is built to last.