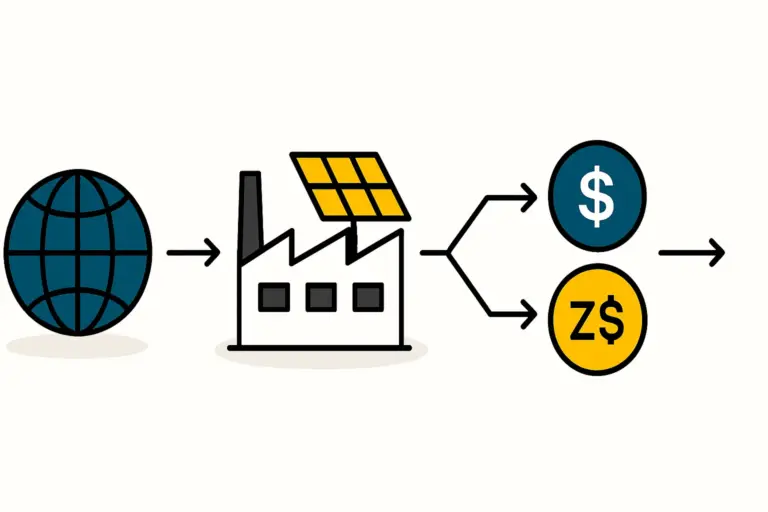

Supplying Solar Modules to Zimbabwe’s Mining and Agricultural Sectors

For many entrepreneurs exploring the solar industry, the most visible market is residential—panels on individual homes. In an economy like Zimbabwe’s, however, a far more significant and commercially stable opportunity lies within the country’s industrial backbone: the mining and agricultural sectors.

These foundational industries are also acutely vulnerable to the single greatest threat to their productivity and profitability: an unreliable and costly power supply. This analysis outlines the demand for solar energy within these two key sectors, making a data-driven case for establishing a local solar module manufacturing facility to serve these industrial off-takers directly.

The Core Challenge: Power Deficits and Operational Costs

Zimbabwe’s national grid faces a persistent power deficit, often amounting to several hundred megawatts. This shortfall results in frequent load shedding and unpredictable power outages, forcing industrial consumers to rely on expensive and carbon-intensive diesel generators.

For any industrial operator, this creates two critical problems:

-

Operational Disruption: Unplanned downtime leads to significant production losses, missed deadlines, and increased operational risk.

-

High Energy Costs: Diesel power can be three to four times more expensive than grid electricity, directly eroding profit margins. Energy often represents one of the largest operational expenditures for mines and large-scale commercial farms.

Solar photovoltaic (PV) systems offer a direct solution to both challenges. They provide a reliable, cost-predictable source of daytime power, reducing dependence on both the unstable grid and volatile diesel prices.

Quantifying the Opportunity in Zimbabwe’s Mining Sector

The mining industry is the engine of Zimbabwe’s economy, contributing significantly to GDP and foreign currency earnings. It is also enormously energy-intensive. Key minerals extracted, such as platinum, gold, and chrome, require continuous power for processing plants, ventilation, and dewatering pumps.

A Look at the Numbers

Energy as an Operating Cost: For many mining operations, electricity accounts for up to 25% of total operational expenditure (OPEX). A reduction in this cost has a direct and substantial impact on profitability.

Estimated Power Demand: The Chamber of Mines of Zimbabwe has estimated the sector’s total power requirement to be in the hundreds of megawatts. With current supply deficits, a significant portion of this demand is either unmet or met with costly diesel generation.

Scalable Solar Projects: A medium-sized mining operation might require a solar plant ranging from 5 MW to 20 MW to offset its daytime energy consumption. The demand from a single large-scale mine could be equivalent to thousands of residential installations.

The Business Case for Mines

For a mine operator, the value proposition of solar is not primarily environmental; it is economic. A locally supplied solar system offers:

- Cost Savings: Lowering the blended cost of energy by reducing diesel consumption.

- Operational Certainty: Ensuring a stable power supply during daylight hours, which is critical for continuous processing operations.

- Long-Term Price Stability: Locking in energy costs for 20-25 years, insulating the business from fuel price fluctuations and electricity tariff hikes.

Supplying this sector requires robust, high-efficiency modules that can perform reliably in demanding industrial environments. Understanding the solar panel manufacturing process is crucial for tailoring products to meet these specific industrial requirements.

Assessing Demand in the Agricultural Sector

Zimbabwe’s agricultural sector, particularly tobacco, horticulture, and grain farming, is another cornerstone of the economy with significant, untapped demand for solar energy. The primary energy requirement is for water pumping and irrigation.

Key Demand Drivers

- Irrigation Needs: Modern commercial farming relies on extensive irrigation systems. Pumping water from boreholes or reservoirs is an energy-intensive process traditionally powered by grid electricity or diesel engines. A single irrigation pump system for a commercial farm can require 30-100 kW of power.

- Agro-Processing: Post-harvest activities such as curing, sorting, packing, and cold storage all require a consistent power supply. Power outages can lead to spoilage and significant financial loss.

- Expansion Potential: Zimbabwe has vast tracts of arable land that remain underutilised due to a lack of power for irrigation. Access to affordable solar energy could unlock this potential, driving further demand for PV modules.

A local manufacturer can serve this market by producing modules optimised for water pumping applications and assembling complete solar-powered irrigation solutions. This presents an opportunity to move beyond simply selling a component to providing a comprehensive solution.

The Business Case for Local Solar Module Manufacturing

While importing solar modules is an option, establishing a local manufacturing facility in Zimbabwe offers distinct strategic advantages when targeting industrial clients.

-

Reduced Logistical Costs and Lead Times: Importing finished modules involves significant shipping costs, import duties, and potential delays. Local production provides faster delivery and a more resilient supply chain.

-

Customisation and Local Support: A local factory can produce modules tailored to specific environmental conditions (e.g., high temperatures, dust) and offer immediate technical support and warranty fulfillment—a crucial factor for industrial buyers.

-

Contribution to Local Content Policies: Governments often favor suppliers who invest locally, create jobs, and contribute to industrialisation. This provides a competitive advantage in securing large private and public sector contracts.

-

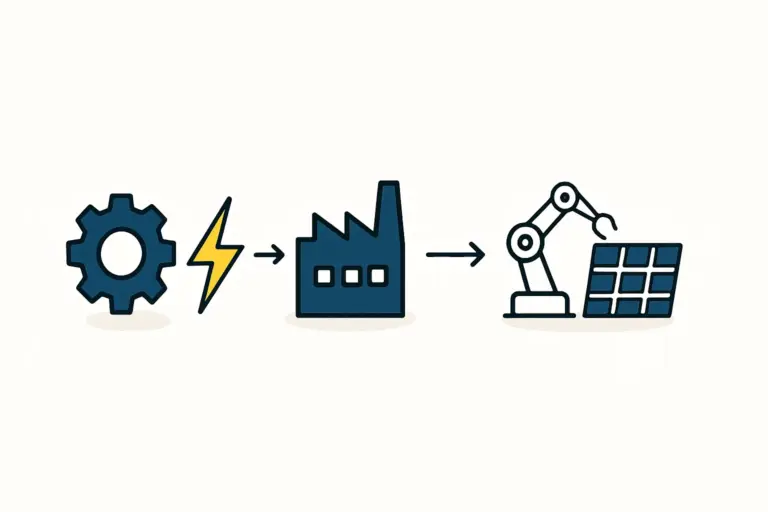

Phased Market Entry: An entrepreneur does not need to build a gigawatt-scale factory from day one. The complete guide on how to start a solar panel business explains how a semi-automated line of 20-50 MW annual capacity is a logical and profitable entry point, perfectly sized to serve the initial demand from these industrial sectors.

This venture requires a clear understanding of the initial investment. The solar panel manufacturing plant cost is a critical factor that must be carefully evaluated in a detailed feasibility study. Based on experience from J.v.G. Technology GmbH turnkey projects, a well-planned facility can achieve profitability by focusing on these high-value commercial and industrial clients, who prioritize reliability and long-term value over the lowest possible upfront cost.

Frequently Asked Questions (FAQ)

Why would a mining company buy from a local factory instead of importing from a major global brand?

Industrial clients prioritise reliability, long-term support, and operational continuity. A local manufacturer can offer faster delivery, on-the-ground technical support, and quicker warranty claims processing. These factors often outweigh a marginal price difference from a large international supplier with no local presence.

What size solar module factory is suitable for targeting this market?

A 20 MW to 50 MW per year semi-automated production line is an excellent starting point. This capacity is large enough to supply several significant industrial projects annually without requiring the massive capital investment of a fully automated gigafactory.

Are there government incentives for setting up a manufacturing plant in Zimbabwe?

Zimbabwe offers various investment incentives, often including tax breaks, duty exemptions on capital equipment, and special economic zone status for new manufacturing projects. A thorough investigation with the Zimbabwe Investment and Development Agency (ZIDA) is a necessary step in the planning phase.

How does the demand from mining and agriculture compare to the residential market?

While the residential market involves more customers, the industrial market is characterised by much larger project sizes. A single mining project can represent a demand of 10-20 MW, equivalent to the demand from 2,000 to 4,000 typical homes. This allows a manufacturer to achieve scale with fewer, larger sales.

Next Steps in Your Analysis

The mining and agricultural sectors in Zimbabwe present a clear and quantifiable demand for a reliable local supply of solar modules. This opportunity stems from solving a fundamental economic challenge—the high cost and poor reliability of energy.

For entrepreneurs and business professionals, the next step is to translate this market analysis into a detailed business plan. This includes a comprehensive financial model, a review of sourcing for raw materials, and a logistical plan for establishing and operating the facility.

This specialised market requires a focused strategy, but for the right investor, it offers a direct path to building a profitable and impactful business that powers the engines of the national economy.