Thinking about manufacturing solar panels in Andorra? It’s an exciting prospect in a unique location—one full of opportunities, but also presenting its own specific challenges.

Whether you’re an investor, a budding entrepreneur, or a curious policymaker, you’ve come to the right place. We’ll walk you through the essential technology decisions you’ll face, focusing on Andorra’s distinct alpine climate and determining the right manufacturing scale for your venture.

We’ll dig into why certain solar cell technologies, like HJT or advanced Mono-PERC, excel in high-altitude environments. We’ll also tackle a key question: should you opt for a manual, semi-automated, or fully-automated production line?

We’ll break down these options, looking at how market demand, investment readiness, and long-term vision influence this crucial choice. Ultimately, success in solar manufacturing in Andorra hinges on a smart, well-thought-out strategy that balances cutting-edge technology with the practical realities of operating in the region.

Table of Contents

Why Solar Module Manufacturing in Andorra Makes Sense

Tucked away in the Pyrenees, Andorra is making serious moves in renewable energy, with solar photovoltaics (PV) playing a starring role. There’s a palpable ambition to boost energy independence and champion sustainable development, creating fertile ground for local solar module manufacturing. This isn’t just wishful thinking; it aligns well with the insights from the ‘Solar Manufacturing Opportunities in Andorra’ report.

However, turning this potential into a thriving manufacturing sector requires careful consideration of the technologies and production scales that best fit Andorra’s unique landscape. Making the right choices from day one is vital for smooth operations, economic viability, and long-term sustainability.

Manufacturing Solar Panels in Andorra: Your Tech Roadmap for Alpine Climate and Production Scale” class=”wp-image-34019″ srcset=”https://www.pvknowhow.com/wp-content/uploads/2025/06/Technological-Considerations-for-Solar-Module-Manufacturing-in-Andorra_-Adapting-to-Scale-and-Climate-1-1024×683.webp 1024w, https://www.pvknowhow.com/wp-content/uploads/2025/06/Technological-Considerations-for-Solar-Module-Manufacturing-in-Andorra_-Adapting-to-Scale-and-Climate-1-500×333.webp 500w, https://www.pvknowhow.com/wp-content/uploads/2025/06/Technological-Considerations-for-Solar-Module-Manufacturing-in-Andorra_-Adapting-to-Scale-and-Climate-1-768×512.webp 768w, https://www.pvknowhow.com/wp-content/uploads/2025/06/Technological-Considerations-for-Solar-Module-Manufacturing-in-Andorra_-Adapting-to-Scale-and-Climate-1-600×400.webp 600w, https://www.pvknowhow.com/wp-content/uploads/2025/06/Technological-Considerations-for-Solar-Module-Manufacturing-in-Andorra_-Adapting-to-Scale-and-Climate-1.webp 1536w” sizes=”auto, (max-width: 1024px) 100vw, 1024px” />

Manufacturing Solar Panels in Andorra: Your Tech Roadmap for Alpine Climate and Production Scale” class=”wp-image-34019″ srcset=”https://www.pvknowhow.com/wp-content/uploads/2025/06/Technological-Considerations-for-Solar-Module-Manufacturing-in-Andorra_-Adapting-to-Scale-and-Climate-1-1024×683.webp 1024w, https://www.pvknowhow.com/wp-content/uploads/2025/06/Technological-Considerations-for-Solar-Module-Manufacturing-in-Andorra_-Adapting-to-Scale-and-Climate-1-500×333.webp 500w, https://www.pvknowhow.com/wp-content/uploads/2025/06/Technological-Considerations-for-Solar-Module-Manufacturing-in-Andorra_-Adapting-to-Scale-and-Climate-1-768×512.webp 768w, https://www.pvknowhow.com/wp-content/uploads/2025/06/Technological-Considerations-for-Solar-Module-Manufacturing-in-Andorra_-Adapting-to-Scale-and-Climate-1-600×400.webp 600w, https://www.pvknowhow.com/wp-content/uploads/2025/06/Technological-Considerations-for-Solar-Module-Manufacturing-in-Andorra_-Adapting-to-Scale-and-Climate-1.webp 1536w” sizes=”auto, (max-width: 1024px) 100vw, 1024px” />Getting to Grips with Andorra’s Operational Environment

Before diving into specific technologies, it’s crucial to understand the local environmental and climatic factors. These will shape not only the manufacturing process but also how the modules perform in Andorra’s sunshine and snow. What exactly will your future modules be up against?

A. Sunshine & Energy Potential: What Andorra Offers

Andorra is blessed with considerable solar resources. On average, the country sees an annual solar energy production potential of around 1,753 kWh per kWp installed. Naturally, this ebbs and flows with the seasons, peaking in summer (about 6.76 kWh/kWp/day) and dipping in winter (around 2.42 kWh/kWp/day) (ProfileSolar Andorra, PVknowhow.com). With over 11,000 buildings identified as having a collective PV potential of 266 GWh/year, local solar generation could cover up to 48% of Andorra’s electricity demand (ARI.ad Solar Potential). This inherent potential signals a strong domestic market for locally manufactured modules.

B. Alpine Climate 101: Key Considerations for Solar Modules in Andorra

Andorra’s alpine climate is a double-edged sword for solar PV systems, offering distinct advantages while also posing hurdles that require careful planning:

- Cooler Temperatures, Higher Efficiency: Solar panels generally perform better in colder temperatures, so Andorra’s high-altitude environment can boost module output. However, materials must be tough enough to handle the thermal stress from significant temperature swings between day and night.

- Heavy Snow Load: Heavy snowfall is a major factor. Modules must be robust enough to bear considerable snow weight without damage. Strategies like increasing tilt angles for better shedding or using bifacial modules can also reduce snow-related losses and harness reflected light (the albedo effect) from snow cover (Alpine PV Stressors, EWZ High Alpine PV).

- Windy Conditions: Mountainous regions are often windy. Manufacturing must account for this by using strong frames and ensuring modules are compatible with robust mounting systems to guarantee long-term stability and performance.

- Intense UV Radiation: Higher altitudes mean stronger UV radiation, which can accelerate the degradation of certain module materials. Choosing highly UV-resistant encapsulants and backsheets is essential.

- The Albedo Advantage: Snow-covered surfaces are brilliant at reflecting sunlight. Bifacial solar modules are fantastic in these conditions, as they can capture this reflected light from their rear side, boosting overall energy yield, especially in winter (Posigen All Weather Solar).

Choosing the Right Solar Cell Technologies for Andorra

Picking the right solar cell technology is fundamental to maximizing performance and ensuring modules can withstand Andorra’s alpine conditions over the long run.

A. A Quick Look at Today’s Leading Solar Cell Technologies

Several technologies currently lead the global market:

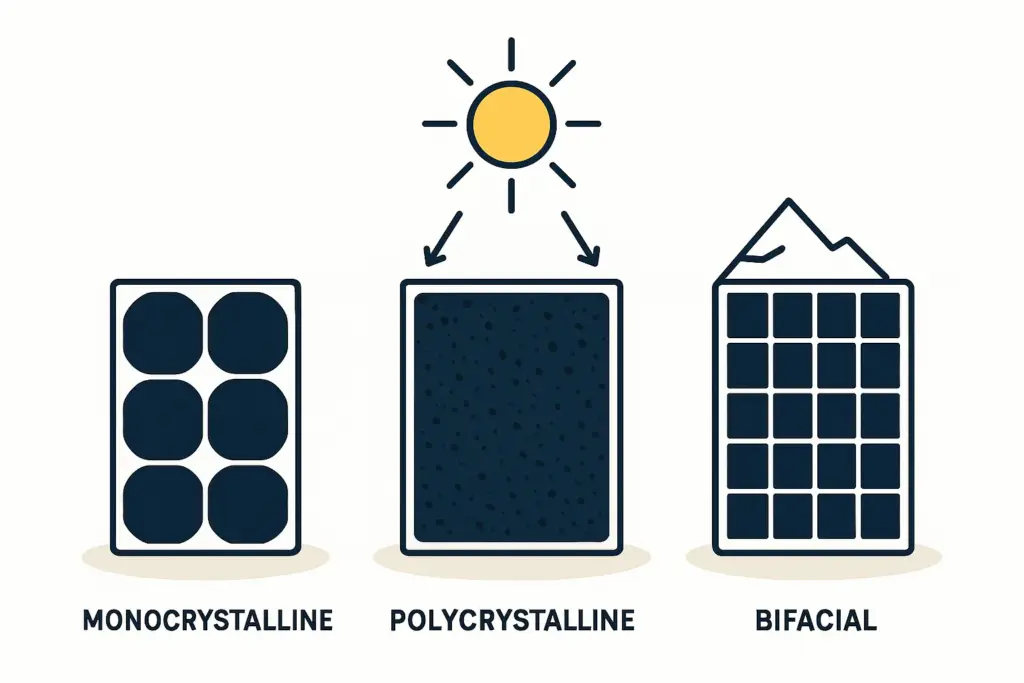

- Monocrystalline Silicon (Mono-Si): Known for higher efficiency and better performance in low-light conditions compared to polycrystalline cells. They also tend to have a good temperature coefficient.

- Polycrystalline Silicon (Poly-Si): Traditionally more cost-effective to produce but with lower efficiency and a poorer temperature coefficient than mono-Si panels.

- Thin-Film (a-Si, CdTe, CIGS): While some types offer benefits like flexibility and better high-temperature performance, crystalline silicon technologies dominate the market in terms of share, efficiency, and bankability for most standard projects.

- The Advanced Crystalline Silicon Crew (PERC, HJT, TOPCon, Bifacial): This is where it gets interesting.

- PERC (Passivated Emitter and Rear Cell): This enhancement to traditional mono-Si cells achieves higher efficiency and has become a market workhorse.

- HJT (Heterojunction Technology): By combining crystalline silicon with amorphous silicon thin-film layers, HJT achieves excellent temperature coefficients and very high efficiency.

- TOPCon (Tunnel Oxide Passivated Contact): Another advanced cell technology giving PERC and HJT a serious run for their money in the high-efficiency stakes.

- Bifacial Modules: These modules can capture sunlight from both the front and rear sides, a potential game-changer in environments with high albedo like snowy Andorran landscapes.

B. Tech Deep Dive: What Works Best in Alpine Conditions?

For Andorra’s unique environment, certain technological features offer significant advantages:

- Temperature Coefficient Matters: This metric indicates how much a panel’s power output drops as its temperature climbs. Technologies like HJT and some advanced Mono-PERC modules boast superior (lower) temperature coefficients. They lose less efficiency as temperatures fluctuate—a key advantage even in cool climates, as direct sunlight still warms the modules considerably.

- Performance When the Sun is Shy (Low Irradiance): Winter months and cloudy days mean less intense sunlight. Technologies that excel in these low-light conditions, such as most monocrystalline types (including PERC and HJT), are preferable for consistent year-round generation.

- Durability and Resistance are Key: Modules for Andorra need robust frames to handle snow and wind. High-quality encapsulation (like POE for better PID resistance and UV stability) and durable backsheets are vital for longevity when facing moisture, UV radiation, and large temperature swings.

- Bifacial Technology – A Snowy Superpower: Given Andorra’s snowy winters, bifacial modules are incredibly compelling. They can capture reflected light from snow-covered ground, potentially boosting energy yield by 5-20% or more, depending on installation and ground conditions. This can significantly improve winter production figures.

C. Emerging Tech and Andorra’s Solar Future

While established crystalline silicon technologies are the current workhorses, it’s smart to monitor emerging technologies like perovskites or tandem cells, which could find niche applications in Andorra down the line. For initial manufacturing efforts, however, focusing on proven, robust, and high-efficiency crystalline silicon variants—particularly those suited for alpine conditions like HJT and bifacial PERC—is the recommended path. It’s also telling that major bodies like the US Department of Energy continue to fund R&D for crystalline silicon, signaling its ongoing importance and future potential (DOE Solar Funding).

Choosing Your Manufacturing Scale: How Big Should You Go?

Once you’ve considered the technology, the next step is determining the scale of your operation. Deciding between a manual, semi-automated, or fully-automated setup is a major crossroads with significant implications for your investment, output capacity, and flexibility. What factors are weighing most heavily on your mind? I’d love to hear your thoughts in the comments below!

A. The Hands-On Route: Manual Solar Module Assembly

- What it involves: Most steps, from cell tabbing and stringing to lamination prep and framing, are done manually.

- The upsides: The upsides are primarily the lowest initial capital expenditure (CapEx), great flexibility for custom modules, and the opportunity to train and build local skills.

- The downsides: Throughput is lower, typically ranging from less than 1 MW to 5 MW annually. You’ll also face higher labor costs per unit, potential variations in quality control, and the work is physically demanding.

- Is it right for Andorra? This approach is a good fit for pilot projects, R&D initiatives, highly customized architectural solar, or to serve a small, emerging local demand before scaling up.

B. The Balanced Approach: Semi-Automated Solar Module Manufacturing

- What it involves: This approach combines automated machinery for critical or labor-intensive steps (like cell stringing, lay-up, and lamination) with manual labor for other tasks (such as junction box application, framing, and final inspection).

- The upsides: It strikes an excellent balance between CapEx and improved throughput (typically 10 MW to 50 MW annually). You also get better quality consistency than with fully manual lines. It’s a great stepping stone toward future automation.

- The downsides: Downsides include a moderate CapEx, the need for skilled technicians to operate and maintain the machines, and a significant manual workforce.

- Is it right for Andorra? This is likely the most pragmatic starting point for Andorra if the goal is to serve consistent local demand and tap into niche export markets. It offers a fantastic balance of investment, output, and adaptability.

C. All-In Automation: Fully-Automated Solar Module Manufacturing

- What it involves: Nearly the entire production line is automated, from wafer handling to final module testing and packaging, with minimal human intervention.

- The upsides: The main advantages are the highest throughput (from 100 MW to GW annually), the most consistent quality, and the lowest per-unit labor cost at high volumes.

- The downsides: The CapEx is very high, requiring large and stable demand to be economically viable. It offers less flexibility for product variations and requires highly skilled engineering and maintenance staff. Global solar module manufacturing capacity is soaring, mainly driven by these large-scale facilities, and is expected to hit 1.8 TW by 2025 (PV Tech Global Capacity, PVKnowHow Global Capacity).

- Is it right for Andorra? This scale is unlikely to be viable for Andorra alone unless it’s part of a much larger regional export strategy or if significant, long-term off-take agreements are already secured. The domestic Andorran market, while growing, would not typically support such a massive scale from the start.

D. Key Factors Guiding Your Scale Choice in Andorra:

- Your Target Market: A realistic assessment of local demand is crucial, from residential and commercial installations to potential utility-scale projects like the 69 MW plant currently under construction (PVKnowHow News). This should be weighed against any export potential. Market research points to growth in Andorra’s solar panel market, which is encouraging (6Wresearch Andorra Market).

- Investment Capital Available: The initial CapEx varies hugely between these scales. Small-scale operations might get off the ground for $20,000-$50,000, while larger, automated lines will require substantially more investment (ZenBusiness Solar Startup Cost).

- Skilled Labor: Assess the local workforce, their technical skills, and the training needed for each scale, while also considering labor costs.

- Supply Chain Health: Consider the logistics of sourcing all your raw materials (cells, glass, encapsulants, frames, etc.).

- Government Backing: Look for policies or incentives that encourage local manufacturing, as these can significantly impact your venture’s financial viability.

Crunching the Numbers: Techno-Economic Considerations

Profitability in solar module manufacturing typically hovers around 5-10%. This is often influenced by high material and labor costs, but strong demand in the solar sector helps offset these (GoSpringSolar Profitability).

- Breaking Down Manufacturing Costs: The main cost drivers are solar cells, glass, aluminum frames, encapsulants, backsheets, and junction boxes. You also have labor, energy for your plant, and equipment depreciation to account for.

- How Technology and Scale Impact Costs: Opting for advanced tech like HJT might mean higher upfront cell costs but can lead to higher module prices due to superior performance and longevity. Automation, on the other hand, reduces per-unit labor costs but increases capital investment and maintenance expenses.

- Staying Competitive: For an Andorran setup, competing on cost against global mass manufacturers will be difficult. The competitive edge lies in focusing on exceptional quality, specialized alpine-ready modules, excellent local service, and leveraging the “Made in Andorra” brand. A semi-automated line producing high-performance modules tailored for alpine conditions could find a strong and sustainable niche.

Ready to take the next step? Learn the fundamentals with our free e-course or see how our services can help. For a detailed roadmap, our Premium Business Plan E-Course offers personalized guidance to get your venture off the ground. Let’s build your solar success story together.

The Practicalities: Regulatory, Infrastructure, and Workforce in Andorra

Setting up a successful manufacturing facility requires navigating several practical aspects beyond technology and economics:

- Permits, Licenses, and Red Tape: You’ll need to understand and comply with all Andorran regulations for industrial operations, environmental standards, and building codes.

- Logistics – Getting Things In and Out: Efficiently sourcing raw materials (many of which will likely be imported) and shipping finished goods requires solid logistical planning, especially given Andorra’s landlocked position.

- Building Your Team: Access to a skilled technical workforce is vital. This might involve setting up training programs to develop skills in solar manufacturing processes, quality control, and equipment maintenance.

Conclusion: A Strategic Path to Solar Module Manufacturing in Andorra

Is launching a solar module manufacturing venture in Andorra promising? Absolutely, provided you take a strategic approach. Focus on these key takeaways:

- Smart Technology Choices: Prioritize robust, high-efficiency solar cell technologies (like HJT or bifacial Mono-PERC) that offer superior performance and durability in Andorra’s alpine climate, especially for handling temperature swings and snow load.

- The Right Manufacturing Scale: A semi-automated manufacturing line likely offers the best initial balance for Andorra. It’s robust enough to cater to local demand with good potential for specialized exports, all while managing investment risk. You might also consider a phased approach, starting with a pilot line to test the waters.

- Know Your Niche: Focus on developing modules truly optimized for alpine conditions. This can be your unique selling point, allowing you to create a higher-value product that customers specifically seek out.

Aligning your technology selection and manufacturing scale with Andorra’s environmental conditions, market size, investment capacity, and strategic energy goals is the cornerstone of success. By doing this, Andorra can build a resilient and sustainable local solar manufacturing capability, contributing powerfully to its renewable energy targets and fostering skilled employment.

If you’re considering this venture or have more questions, we at PVknowhow.com have spent over two decades helping entrepreneurs set up solar module factories worldwide.

We thrive on turning ambition into operational reality. Let’s have a friendly chat about your Andorran solar dream – we’d be glad to help you explore the possibilities and take the next steps.

References

All references

- PVknowhow.com: Andorra Solar Report

- ProfileSolar: Solar PV Analysis Andorra la Vella

- Andorra Research + Innovation (ARI.ad): Solar Potential of Andorra

- EWZ: High Alpine Photovoltaic Systems

- Alpine PV Wiki: Alpine PV Stressors

- Posigen: How Solar Panels Work in All Weather Conditions

- PV Tech: Global Solar Module Manufacturing Capacity to Reach 1.8TW in 2025

- PVknowhow.com News: Solar Module Capacity Global Manufacturing 2025

- Energy.gov: FY25 Solar Module and Solar Hardware (SMASH) Incubator

- 6Wresearch: Andorra Solar Panel Market Industry Report

- PVknowhow.com News: Construction Begins on 69 MW Photovoltaic Plant

- ZenBusiness: How to Start a Solar Panel Business

- GoSpringSolarNow: How Profitable is Solar Business?