For business professionals in Barbados, the high cost of electricity is a persistent challenge. With rates among the highest in the region—often exceeding $0.30 USD per kWh—these energy expenses squeeze profit margins and threaten stability.

This high cost stems from the island’s near-total reliance on imported fossil fuels, a vulnerability that ripples through every sector of its economy.

Yet, this significant challenge also presents a unique business opportunity. It raises a compelling question: instead of merely consuming solar energy, what if Barbados could produce its own solar modules? This article explores the feasibility of establishing a small-scale solar module production line on the island by analyzing the market drivers, operational requirements, and economic potential of such a venture.

Table of Contents

The Strategic Case for Local Production in Barbados

The idea of manufacturing in a market that has long relied on imports might seem ambitious, but a closer look at the island’s strategic landscape reveals a compelling logic. The drivers behind this logic are not merely theoretical; they are rooted in national policy and concrete economic realities.

Economic and Policy Drivers

-

High Electricity Costs: The sheer cost of energy is a primary motivator. Locally produced modules could reduce the overall cost of solar installations, accelerating adoption for both commercial and residential users looking to lower their energy bills.

-

Energy Independence: Barbados’s National Energy Policy (NEP 2019-2030) sets a bold target: 100% renewable energy generation and a carbon-neutral island-state by 2030. Achieving this goal will require a massive deployment of solar capacity, and a local assembly line directly supports this national vision by reducing dependence on volatile global supply chains and foreign exchange.

-

Government Support: The government’s commitment to the NEP creates a favorable environment for investment in renewables. While direct subsidies for manufacturing may vary, the policy itself signals market stability and long-term demand for solar products.

This is why firms like J.v.G. Technology, which help entrepreneurs enter the sector, find that markets with strong government mandates and clear economic pain points—like Barbados—present the most robust business cases.

manufacturing solar panels, with raw materials and a factory on the left, and a finished panel being processed on the right.”/>

manufacturing solar panels, with raw materials and a factory on the left, and a finished panel being processed on the right.”/>Defining ‘Small-Scale’ in a Barbadian Context

When considering manufacturing, matching the scale of an operation to its market size is crucial. A “small-scale” facility in this context typically refers to an annual production capacity of 20 to 50 megawatts (MW)—a world away from the gigawatt-scale factories common in Asia.

A 50 MW line, for instance, could produce approximately 125,000 modules per year (assuming an average module power of 400W). This scale is large enough to be commercially viable and contribute meaningfully to the nation’s energy goals, yet small enough to remain manageable from an investment and operational standpoint. For any prospective investor, understanding the full scope of what such a production line entails is the essential first step.

Key Operational Requirements

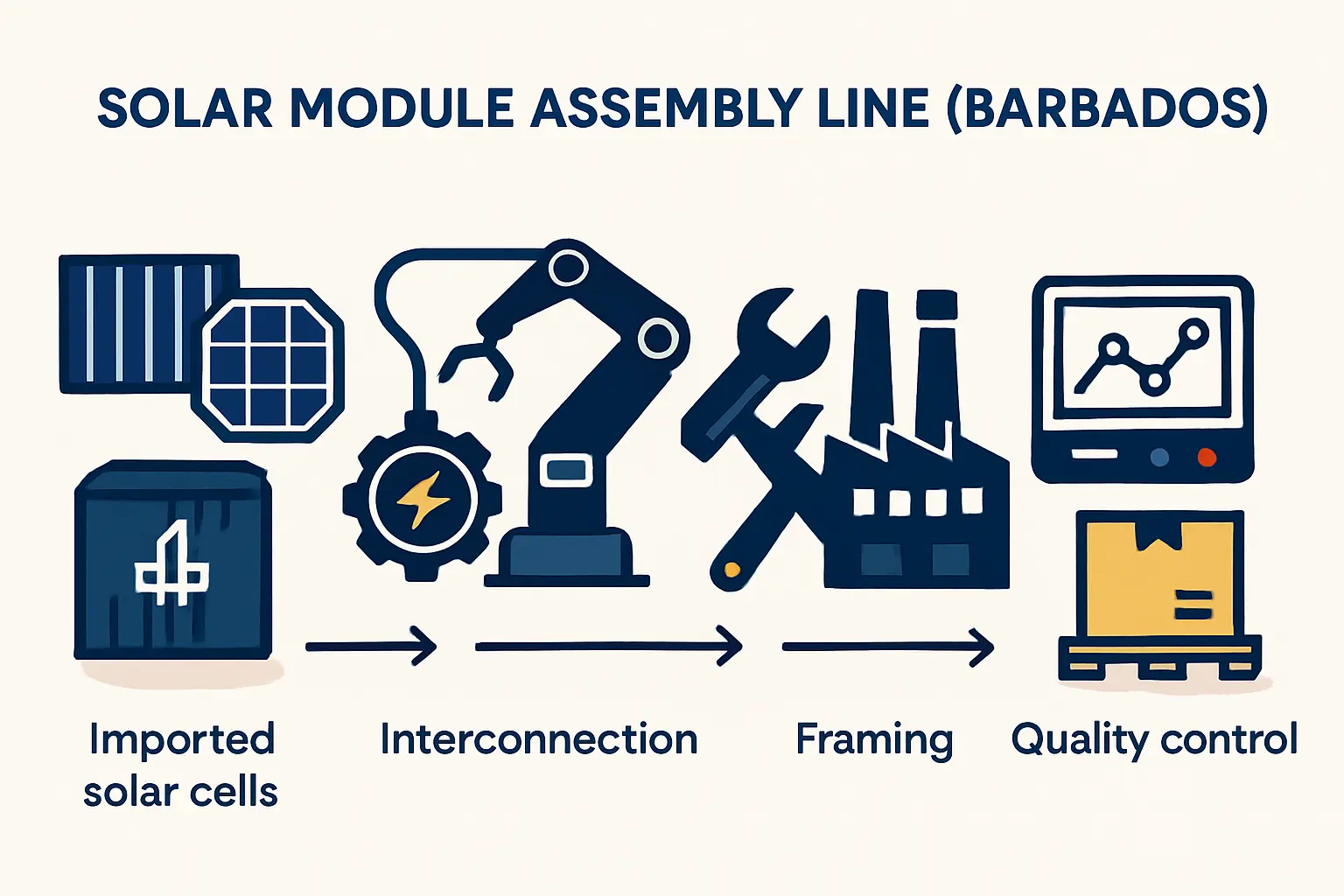

Starting a solar factory involves more than just purchasing machinery; an investor must consider the entire operational framework.

1. The Facility

A 20-50 MW line doesn’t require a massive industrial complex. A suitable factory building is typically 1,500 to 2,500 square meters. In Barbados, key considerations include a hurricane-resistant structure and a climate-controlled, low-dust interior to protect sensitive materials and equipment.

2. The Workforce

A semi-automated, small-scale line has the advantage of a modest labor requirement. Such a facility can be run effectively by a team of just 25 to 35 employees, including operators, technicians, quality control personnel, and administrative staff. Barbados’s well-regarded educational system and skilled workforce are significant assets here. While specific training on the machinery is necessary, the core technical aptitude is often already in place.

3. The Investment

The financial commitment is naturally a primary concern. While the investment for solar manufacturing at this scale is considerable, it is not prohibitive for a serious investor. The total capital expenditure for a turnkey 20-50 MW line—including machinery, installation, and training—falls within a specific range best detailed in a formal business plan. This makes it an ideal venture for established entrepreneurs looking to diversify into a high-growth industry.

Market Potential: Beyond Barbados’s Borders

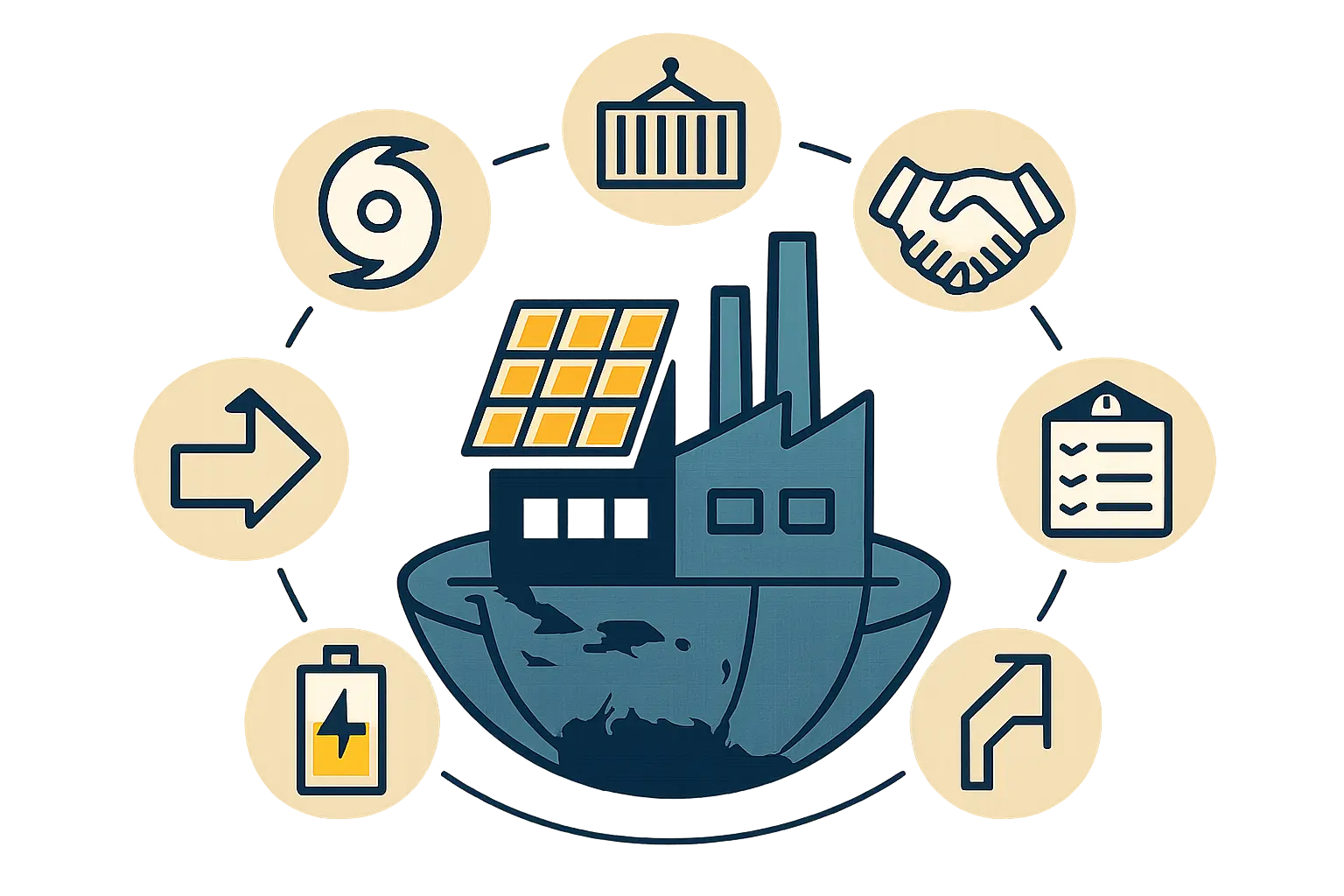

A common concern for investors is whether the local Barbadian market, with a population under 300,000, is large enough to sustain a factory on its own. While domestic demand driven by the 2030 energy goal is substantial, the true opportunity extends to the entire Caribbean Community (CARICOM).

The CARICOM Advantage

As a member of CARICOM, Barbados has preferential trade access to a market of millions across more than a dozen member states. Many of these nations share similar challenges: high electricity costs, dependence on imported fuel, and vulnerability to climate change.

A ‘Made in Barbados’ solar module could be a highly attractive product within this bloc, offering:

-

Reduced shipping times and costs compared to imports from Asia.

-

Products potentially better suited to regional conditions (e.g., high humidity, salt mist, hurricane risk).

-

The ability to serve smaller, intermittent orders that larger global manufacturers might ignore.

This export-oriented strategy transforms the business model from merely serving a local need to becoming a regional energy solution provider.

Conclusion: A Calculated Opportunity

While establishing a small-scale solar module factory in Barbados is a complex undertaking, it represents a calculated and strategic business opportunity. The convergence of high energy costs, strong government policy, and access to the wider CARICOM market creates a compelling case for local production.

For the right entrepreneur—one with a solid business background and the capital to invest—this is a chance to build a profitable enterprise that also addresses a critical national challenge. Such a venture would contribute to a more resilient and energy-independent future for Barbados and the wider Caribbean region.

The next logical step for any interested entrepreneur is to develop a detailed, data-driven business plan. This would involve obtaining specific quotes for a turnkey production line and conducting a formal market analysis for both domestic and regional sales projections.

Frequently Asked Questions (FAQ)

For business professionals new to this industry, several questions naturally arise.

Do I need a PhD in physics to run a solar factory?

That’s a common misconception. While technical understanding is important, an investor doesn’t need to be a photovoltaic scientist. The key is to have a strong business background and to work with experienced partners who provide turnkey solutions, including process engineering, machine commissioning, and staff training. When structured correctly with the right partners, a solar factory is an entirely manageable business venture.

How long does it take to become operational?

From signing a contract with a turnkey equipment provider to producing the first certified module, a realistic timeline is typically 9 to 12 months. This period includes factory preparation, machine manufacturing and shipping, installation, and the initial training phases.

Is it possible to compete with major international producers?

Competing with global giants on price-per-watt alone is not the objective. A small-scale factory competes on different terms:

-

Agility: Responding quickly to local and regional demand.

-

Logistics: Offering significantly faster delivery and lower shipping costs within CARICOM.

-

Customization: Producing modules specifically designed for tropical coastal environments.

-

National Pride: Supporting local economic development and energy independence.