An entrepreneur planning a solar module factory in a temperate climate like Germany would likely focus on securing land, equipment, and skilled labor. However, transplanting that same factory blueprint to a tropical coastal location like Barbados presents an entirely new set of challenges.

The very air — warm, humid, and laden with salt — becomes a primary adversary to production quality and operational longevity. Ignoring these environmental factors is a common yet costly oversight for new entrants in the solar industry. It can lead to premature equipment failure, high defect rates, and a facility that deteriorates years ahead of schedule.

This guide outlines the critical adaptations a solar manufacturing facility needs to not only survive but thrive in a tropical coastal environment.

Table of Contents

The Invisible Threats: Humidity and Salt Mist

The success of any solar module factory hinges on its ability to produce high-quality, reliable panels consistently. In a tropical climate, this consistency is directly threatened by two main environmental factors: high relative humidity (RH) and airborne salinity (salt mist).

How Humidity Compromises Module Quality

Several stages of the solar panel manufacturing process are highly sensitive to moisture. The lamination process, where the solar cell “sandwich” is bonded together, is particularly vulnerable.

Research from the International Electrotechnical Commission (IEC) highlights this risk. The rigorous “damp-heat test” (IEC 61215) exposes modules to 85°C and 85% relative humidity for 1,000 hours to test their durability. If raw materials like EVA encapsulant absorb moisture in a high-humidity factory before lamination, this failure point is essentially built directly into the panel. This can lead to delamination, bubbling, and reduced performance and lifespan once the module is in the field.

A controlled factory environment is non-negotiable. Decades of engineering experience have established best practices for a stable indoor climate:

- Temperature: 21-23°C (70-73°F)

- Relative Humidity: Below 40%

Achieving these conditions in a location like Barbados, where ambient RH can exceed 80%, requires a specialized approach to the building’s design and its Heating, Ventilation, and Air Conditioning (HVAC) system.

The Corrosive Effect of Salt Mist

For facilities near the coast, salt carried by sea breezes poses a significant threat. According to the ISO 9223 standard on environmental corrosivity, coastal areas often fall into the C4 (High) or C5 (Very High) categories.

This saline environment aggressively attacks:

- The Building Structure: Untreated steel beams, metal cladding, and fasteners can rust rapidly, compromising the building’s structural integrity.

- Manufacturing Equipment: Precision machinery, including robotic arms, conveyor systems, and electrical cabinets, is susceptible to corrosion. This can cause frequent breakdowns, shorten equipment lifespan, and significantly increase maintenance costs.

A project manager overseeing a J.v.G. turnkey project in a coastal region noted, “We saw standard galvanized steel components show signs of rust within 18 months. The client’s initial savings on building materials were quickly erased by the cost of repairs and operational downtime.”

Designing a Resilient Factory: Key Adaptations

A successful tropical solar factory must be engineered from the ground up to counteract its environment. This involves strategic choices in building design, material selection, and technology. A thorough review of infrastructure requirements is a foundational step in the planning phase.

1. The Building as a Protective Shell

The factory building is the first line of defense. Standard industrial construction is insufficient.

- Structural Materials: All structural steel should be hot-dip galvanized or coated with marine-grade paint systems. Using stainless steel for critical components, especially for externally exposed parts, is a wise investment.

- HVAC and Dehumidification: The HVAC system is not merely for comfort; it is a critical piece of production equipment. It must be engineered for industrial-scale dehumidification and may represent a larger portion of the initial investment compared to a factory in a dry climate. Positive air pressure helps prevent humid, unfiltered air from entering when doors are opened.

- Airlocks and Zoning: Creating airlocks at loading bays and personnel entrances helps maintain the controlled internal atmosphere. The production floor should be isolated from warehousing and office areas to ensure the most sensitive processes have the tightest climate control.

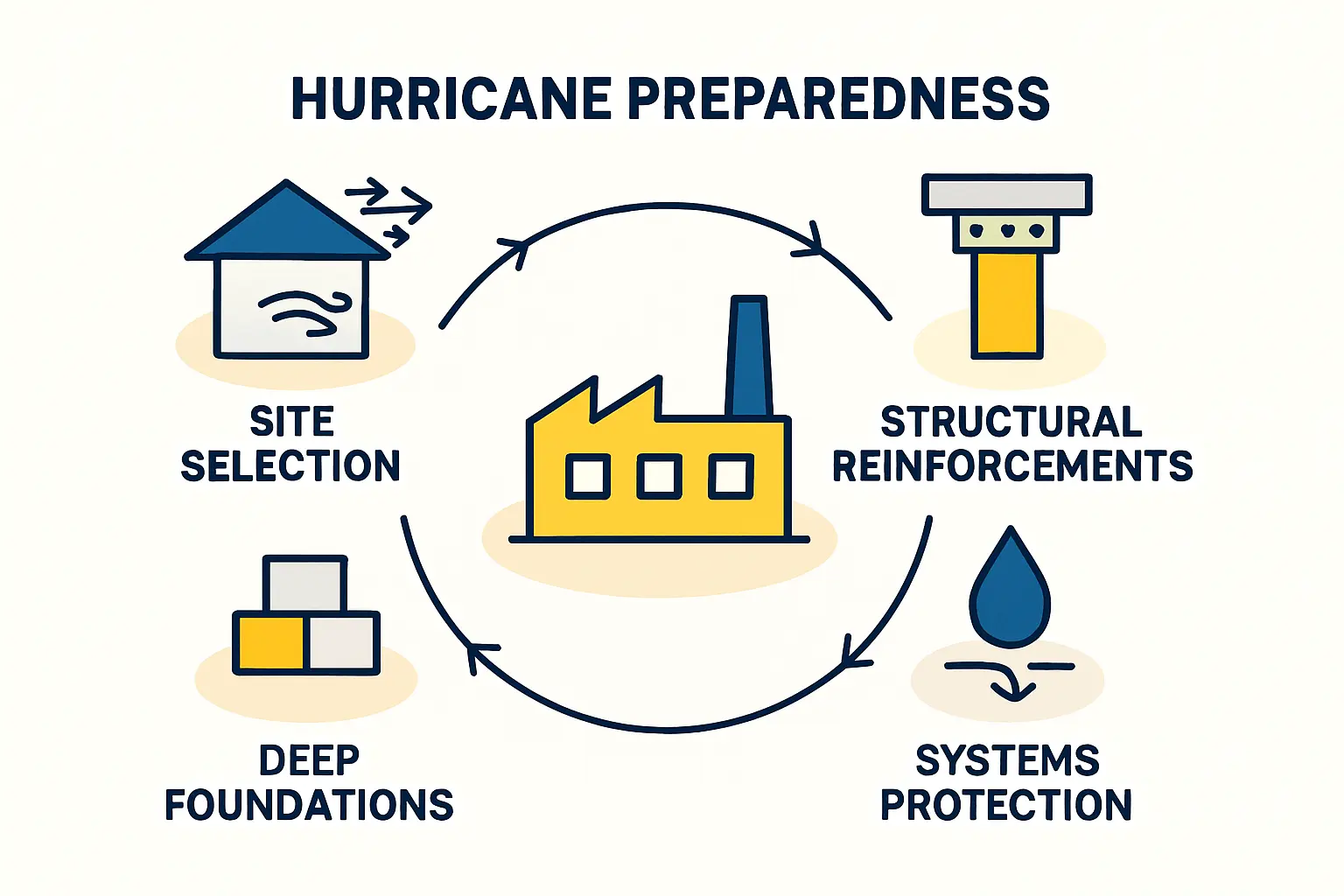

2. Hurricane and Extreme Weather Preparedness

For regions like the Caribbean, hurricane preparedness is a critical design constraint.

- Structural Reinforcement: The building must be designed and constructed to meet or exceed local building codes for high-wind events, such as those based on ASCE 7 standards. This includes reinforced foundations, walls, and roof structures.

- Component Security: External equipment, such as HVAC units and transformers, must be securely anchored. Window and door systems should be impact-rated.

- Operational Continuity Plan: A documented plan for shutting down production, securing materials and equipment, and restarting operations post-storm is essential for minimizing financial losses.

3. Equipment and Technology Specification

Machinery selection must also account for the ambient environment.

- Corrosion-Resistant Machinery: When procuring a turnkey manufacturing line, specifying corrosion-resistant features is vital. This may include stainless steel frames, sealed electronic enclosures with high IP (Ingress Protection) ratings, and protective coatings on sensitive parts. While this can increase the initial equipment cost by 5-15%, it prevents far greater expenses from maintenance and premature replacement.

- Climate-Controlled Storage: Raw materials, especially polymer-based encapsulants (EVA) and backsheets, must be stored in a climate-controlled environment to prevent moisture absorption. This dedicated storage area should maintain the same strict humidity levels as the main production floor.

The Business Case for Climate Adaptation

These adaptations are not optional expenses but critical investments designed to protect the entire business. A factory properly engineered for its environment will benefit from:

- Higher Product Quality: Fewer defects related to moisture and contamination.

- Improved Yield: Consistent production output without interruptions from environmental variables.

- Longer Equipment Lifespan: Reduced maintenance costs and delayed capital expenditure on replacement machinery.

- Brand Reputation: Producing reliable modules that meet international certification standards builds trust in the market.

Understanding these nuanced requirements is paramount for any entrepreneur entering this industry. Platforms like pvknowhow.com provide structured educational resources to help prospective owners navigate these complex technical and financial planning stages.

Frequently Asked Questions (FAQ)

What is the ideal humidity level for a solar factory?

Industry best practice is to maintain a relative humidity level below 40% in all production and sensitive material storage areas to prevent moisture contamination, particularly during the lamination process.

How much extra does a climate-proofed factory cost?

The additional upfront investment for a fully climate-adapted building and machinery in a tropical coastal location can range from 10% to 20% of the total capital expenditure. However, this investment typically prevents much larger operational losses and repair costs over the life of the facility.

Can standard European machines be used in a tropical climate?

While standard machines can function, their lifespan will be significantly reduced without adaptation. It is far more cost-effective to specify machines with enhanced corrosion protection and sealed electronics from the outset than to constantly repair or prematurely replace standard equipment.

What is the biggest hidden risk of ignoring these factors?

The biggest hidden risk is a high, hard-to-diagnose rate of module failure after a few years in the field. This can lead to massive warranty claims and irreparable damage to the company’s reputation, far outweighing any initial savings.

How does this affect the project timeline?

Incorporating these designs adds complexity to planning and requires specialized engineering and material sourcing, which must be factored into the project timeline. A well-planned project, even with these considerations, can still have a line operational in under 18 months.

Next Steps: From Awareness to Action

For any investor considering a solar factory in a location like Barbados, recognizing the unique challenges of a tropical coastal environment is the first critical step. The next phase is to translate this awareness into a detailed technical specification and a robust business plan that accurately budgets for these necessary adaptations.

Building a resilient, high-quality manufacturing operation begins with a design philosophy that respects and masters its local environment.