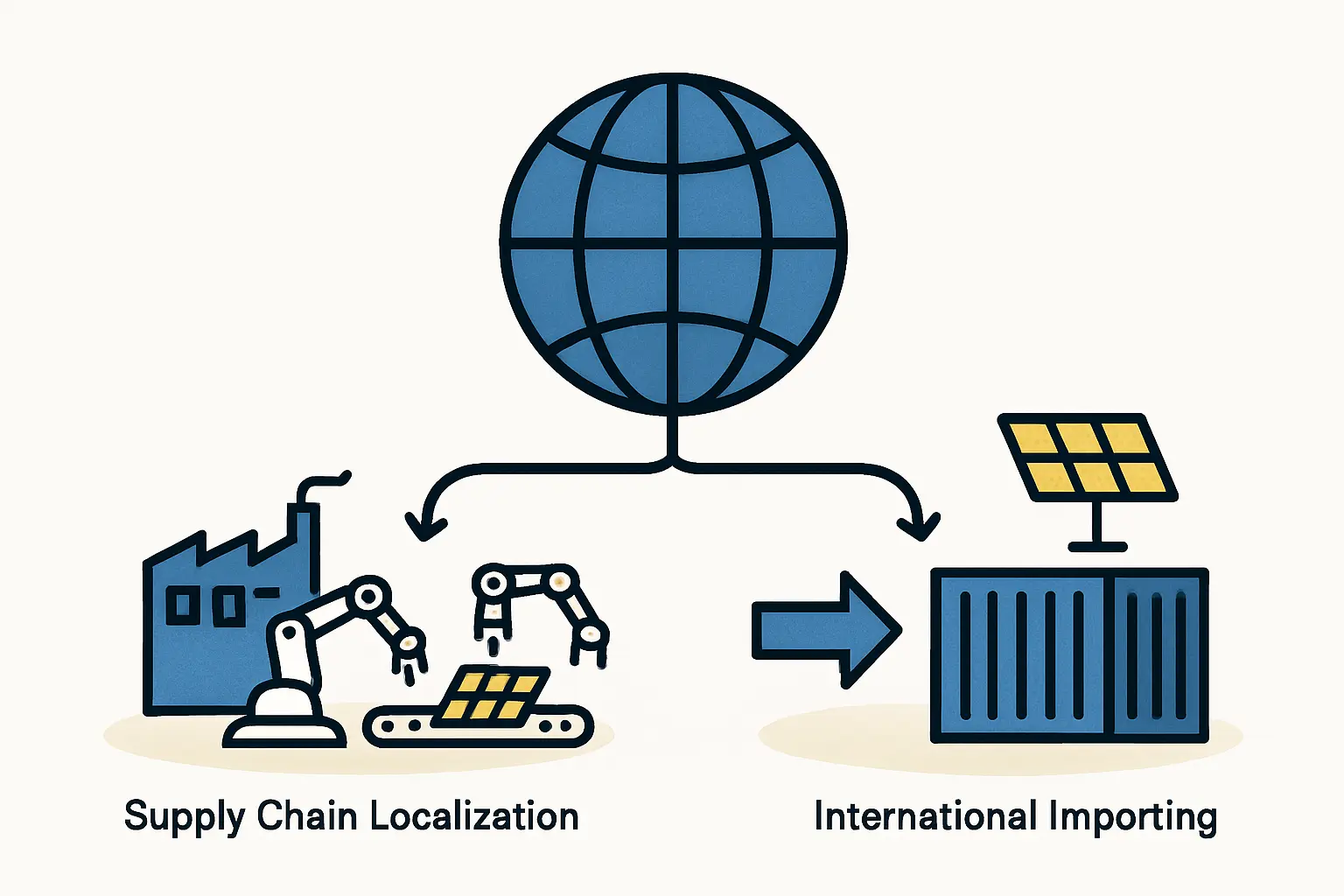

For an entrepreneur planning a solar module factory in Bangladesh, one critical decision must be made before the first machine is ordered: where to source raw materials. This decision—whether to import components or source them locally—has a profound impact on cost, quality, and the business’s long-term viability.

Relying entirely on imports may seem faster at first, but it exposes the operation to currency fluctuations, shipping delays at ports like Chittagong, and the challenge of controlling quality from thousands of miles away.

Developing a local supply chain presents its own set of hurdles, but it offers a path toward greater control, cost stability, and a stronger contribution to the national economy. This analysis examines the trade-offs between these two strategies, providing a framework for making an informed decision tailored to the unique opportunities in the Bangladeshi market.

Table of Contents

The Current Landscape: Bangladesh’s Reliance on Imports

Bangladesh has shown a strong commitment to expanding its renewable energy capacity. National policies like the 8th Five Year Plan and the Mujib Climate Prosperity Plan set ambitious targets for solar power generation. However, the domestic solar industry, while growing, remains focused on assembling modules from components imported almost entirely from China.

This heavy reliance on a single import channel creates several business risks:

-

Currency Volatility: Payments for materials are made in foreign currencies (USD or RMB), exposing businesses to the fluctuating exchange rate of the Bangladeshi Taka. This can unpredictably inflate production costs.

-

Logistical Hurdles: International shipping involves long lead times, potential customs delays, and congestion at major ports. These factors can disrupt production schedules and tie up working capital.

-

Quality Assurance: Verifying material quality before shipment is difficult and expensive. Discovering defects upon arrival can lead to significant financial losses and production downtime.

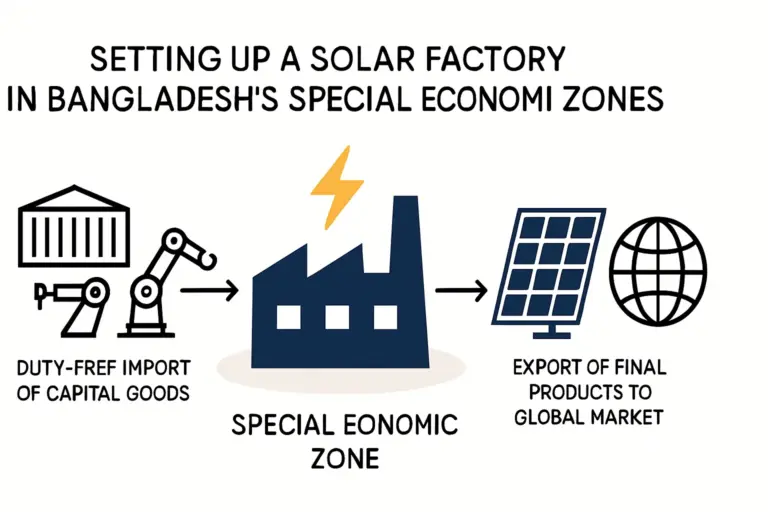

While the government offers incentives like duty-free import of capital machinery, the raw materials themselves are often subject to tariffs, adding another layer of cost to an import-dependent model. For a new venture to succeed, it must weigh these challenges against the potential for localization. A comprehensive supply chain assessment is a critical first step in navigating this complexity.

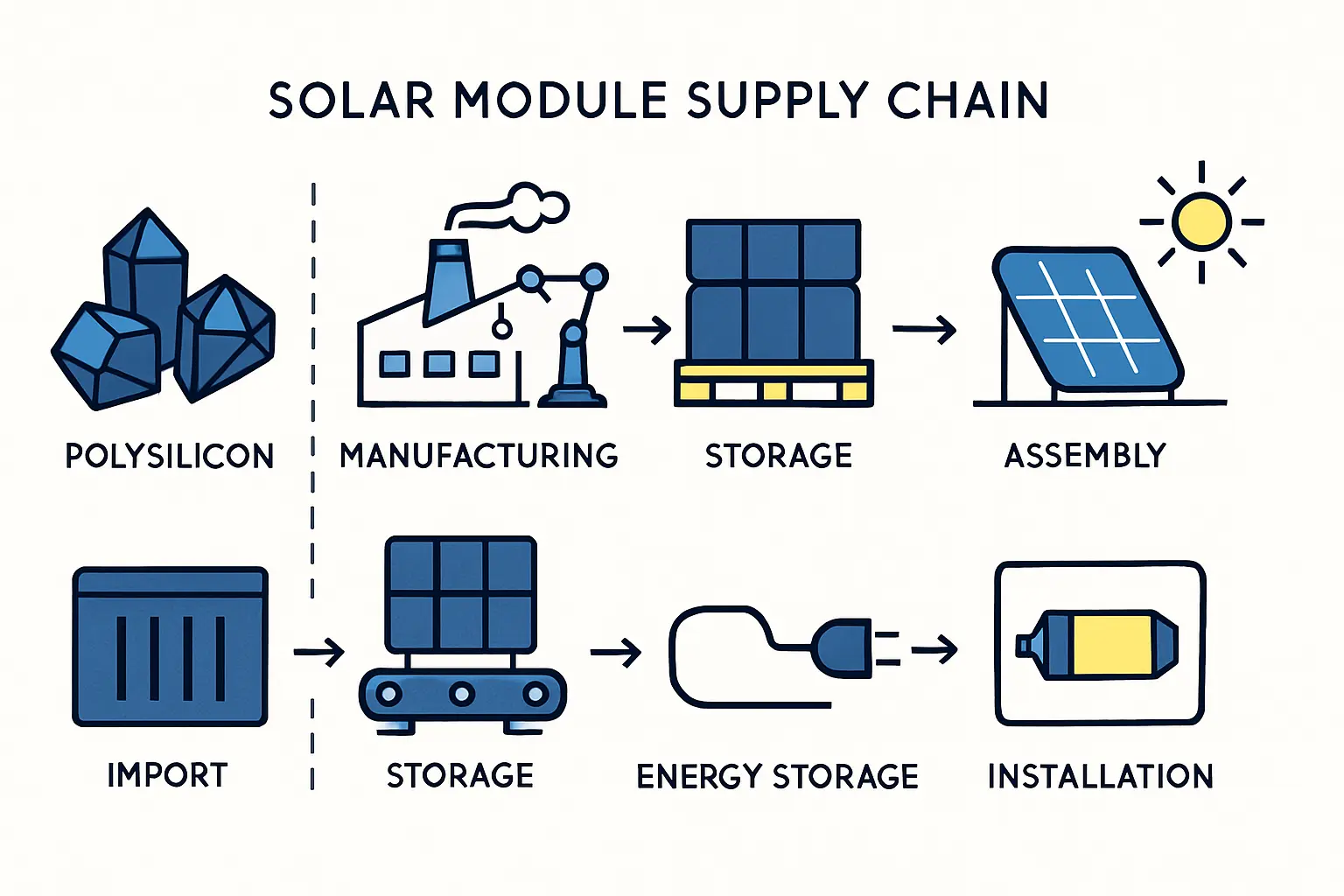

Deconstructing the Solar Module: A Bill of Materials Analysis

To understand the potential for localization, we must first break down a solar panel into its core components. The feasibility of sourcing each part locally varies significantly based on the required technology, capital investment, and existing industrial base in Bangladesh.

An analysis of the primary raw materials for solar panels reveals a clear hierarchy of opportunities for effective Bangladesh sourcing.

Solar Cells: The Imported Core

Solar cells are the most technologically complex and capital-intensive components of a module. Currently, nearly 100% of solar cells are imported, mainly from China. Establishing local cell manufacturing requires an extremely high initial investment and a deep pool of specialized expertise, making it an unrealistic starting point for most new entrants in Bangladesh. For the foreseeable future, cells will remain an imported necessity.

Solar Glass: A Clear Opportunity for Localization

A solar module’s front requires highly specialized, low-iron, tempered glass for maximum light transmission and durability. While Bangladesh has an established glass industry, producing solar-grade glass requires specific upgrades to its production lines. This gap represents a significant opportunity. Partnering with or encouraging an existing local manufacturer to adapt its process could create a reliable, cost-effective domestic source, reducing import dependency on this bulky and fragile material.

Aluminum Frames: Leveraging Existing Strengths

Bangladesh already has a robust aluminum extrusion industry. Since the aluminum frames for solar modules use relatively standard profiles, they are a prime candidate for immediate localization. Sourcing frames locally can drastically reduce shipping costs and lead times while supporting another domestic industry.

Encapsulants (EVA) and Backsheets: A Future Possibility

Materials like Ethylene Vinyl Acetate (EVA) encapsulant and polymer backsheets are critical for protecting solar cells. Their production is rooted in the chemical industry, and while they are currently imported, local manufacturing is technically feasible. This could become a medium-to-long-term opportunity as the domestic solar ecosystem matures and attracts investment in related chemical industries.

Junction Boxes and Cables: The Assembly vs. Manufacturing Question

Junction boxes can be sourced in two ways: imported as complete units or assembled locally from imported parts like diodes, connectors, and housings. Local assembly is an achievable first step that requires minimal investment and creates local jobs. Full component-level manufacturing is more complex but could become viable as market demand grows.

The Strategic Business Case for Localization

Beyond a component-level analysis, building a local supply chain is a strategic decision with far-reaching benefits. J.v.G. Technology GmbH’s experience with turnkey projects across emerging markets shows that ventures integrating local sourcing often build more resilient and profitable operations.

The advantages extend beyond simple cost savings:

-

Operational Agility: A local supply chain shortens lead times from months to weeks or even days. This allows a manufacturer to be more responsive to market demand and operate with a leaner inventory.

-

Risk Mitigation: Localization provides a natural hedge against global shipping disruptions and foreign currency risk, leading to more predictable production costs and a more stable financial model.

-

Enhanced Quality Control: Having suppliers nearby enables easier collaboration, faster feedback loops, and on-site quality inspections, ensuring materials meet exact specifications before entering the production line.

-

Brand Building: A “Made in Bangladesh” solar module with significant local content can be a powerful marketing tool, resonating with national pride and government initiatives.

A Phased Approach to Localization

The decision to localize is not an all-or-nothing choice. The most successful strategies involve a phased, hybrid approach. A new solar module factory can begin by localizing the “low-hanging fruit” while continuing to import the most complex components.

A practical roadmap could look like this:

-

Phase 1 (Year 1): Start by sourcing aluminum frames and arranging for the local assembly of junction boxes. Import all other critical materials, including cells, glass, and backsheets.

-

Phase 2 (Years 2-3): Work with a local glass manufacturer to develop a solar-grade glass supply chain. This is the next major step in reducing import volume and cost.

-

Phase 3 (Year 4+): As the market matures, explore the feasibility of local production for EVA and backsheets, potentially through a joint venture or partnership.

This methodical approach allows a business to expand its local sourcing capabilities in step with its operational experience and market presence. The initial design of a turnkey solar module manufacturing line should be flexible enough to accommodate this evolving strategy.

Frequently Asked Questions (FAQ)

What are the main risks of relying solely on imports for a factory in Bangladesh?

The primary risks include unpredictable cost increases from currency fluctuations, production delays caused by international shipping and port congestion, the difficulty of ensuring consistent material quality from overseas, and having significant capital tied up in inventory during long transit times.

Is it realistic to produce solar cells in Bangladesh today?

For most new entrants, manufacturing solar cells locally is generally unrealistic. It requires extremely high capital investment—often hundreds of millions of dollars—and advanced technological expertise. It is more practical to first focus on module assembly and localizing other components.

Which component is the easiest to source locally first?

Aluminum frames are typically the most straightforward component to localize. Bangladesh has an existing aluminum extrusion industry that can readily produce the required profiles, offering immediate cost and logistical savings.

How do import duties affect the cost of setting up a factory?

While the Bangladeshi government often allows duty-free import of capital machinery to establish a factory, the raw materials for production may still be subject to import duties and taxes. These costs must be factored into the final module’s price-per-watt, as they can make a locally produced panel less competitive if not managed through strategic sourcing.

What kind of government support is available for local manufacturing?

Support often includes tax holidays for new ventures, duty-free import of capital equipment, and preferential treatment in government tenders for locally manufactured goods. Entrepreneurs should consult with investment authorities like BIDA (Bangladesh Investment Development Authority) for the most current information.

Ultimately, establishing a successful solar manufacturing plant in Bangladesh requires a nuanced supply chain strategy. Instead of a simple binary choice, entrepreneurs should view it as a strategic process of phased localization. By starting with achievable components and building capabilities over time, a new venture can build a resilient and competitive enterprise that is both nationally significant and well-positioned for long-term growth.