An entrepreneur planning to establish a solar module factory in Belgium starts sourcing the necessary equipment. The high-precision stringer comes from a specialist in Germany, the laminator from a reputable Chinese manufacturer, and the cell tester from South Korea. Each machine arrives with its own documentation and a CE mark. On the surface, the project appears ready.

However, this process uncovers a critical and often underestimated challenge. Under European Union law, combining these individual machines into a functional, interconnected system creates a new entity: an ‘assembly of machinery.’ The responsibility for ensuring this entire integrated line complies with stringent EU safety directives falls squarely on the factory owner. This guide breaks down the key safety requirements and the process for CE certification for solar production lines in Belgium and across the EU—a crucial topic to address early in your Solar Factory Business Plan.

Table of Contents

What is CE Marking? More Than Just a Sticker

The CE marking is a mandatory conformity mark for many products sold within the European Economic Area (EEA). It is not a quality certification or a mark of origin issued by an independent body. Instead, it represents a manufacturer’s self-declaration that their product meets all applicable EU health, safety, and environmental protection requirements.

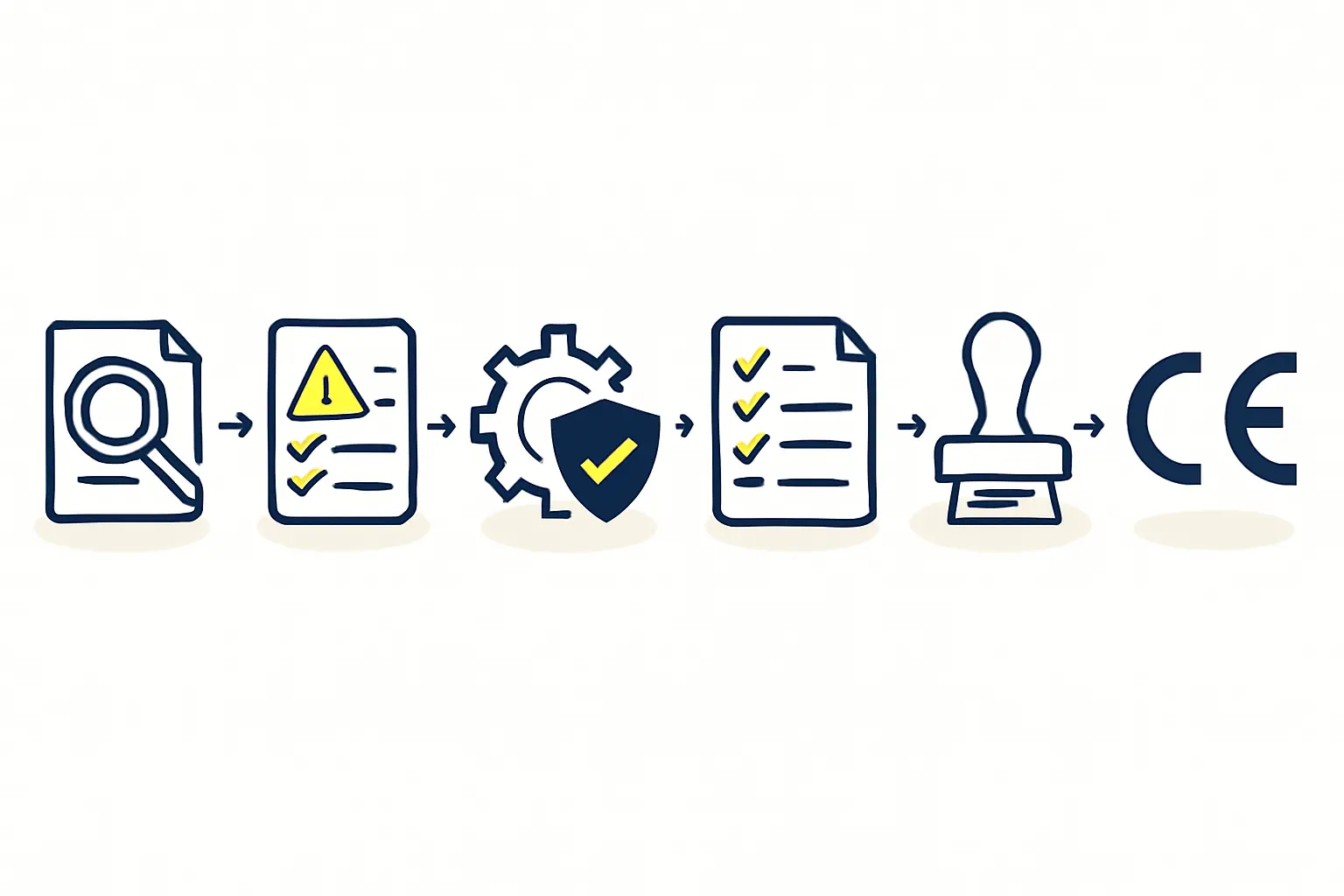

For a machine destined for the EU market, the original equipment manufacturer (OEM) is responsible for:

- Identifying all relevant EU directives (e.g., Machinery Directive, Low Voltage Directive).

- Conducting a thorough risk assessment.

- Compiling a comprehensive technical file as proof of conformity.

- Issuing an EU Declaration of Conformity (DoC).

- Affixing the CE mark to the machine.

This process certifies a machine’s safety as a standalone unit. For a factory owner, however, the real challenge begins when these individual, CE-marked units are integrated into a single production line.

The Core Legal Framework: Key EU Directives

Several EU directives govern the safety of industrial equipment. For a solar module production line, the following are especially relevant.

The Machinery Directive (2006/42/EC)

This is the cornerstone of machine safety in the EU. It applies not only to individual machines but also to interchangeable equipment, safety components, and, most importantly, assemblies of machinery. The directive mandates that machines be designed and constructed to be operated, adjusted, and maintained without posing a risk to people.

Low Voltage and EMC Directives

Low Voltage Directive (2014/35/EU): This applies to all electrical equipment operating with a voltage between 50 and 1,000 V for alternating current or 75 and 1,500 V for direct current. Nearly every machine in a solar production line falls within this scope, requiring robust protection against electrical hazards.

Electromagnetic Compatibility (EMC) Directive (2014/30/EU): Because a factory floor is an electromagnetically active environment, this directive is vital. It ensures that equipment neither generates nor is affected by electromagnetic disturbance, preventing interference that could disrupt the sensitive electronics controlling the solar module manufacturing process.

The ‘Assembly of Machinery’: A Critical Concept for Factory Owners

This is arguably the most critical concept for an entrepreneur to understand. When individual, CE-marked machines (like a stringer, layup station, and laminator) are linked by a common control system to function as an integrated whole, they form an ‘assembly of machinery.’

In the eyes of EU law, the entity that creates this assembly—typically the factory owner or a system integrator—becomes the manufacturer of this new, larger machine. This brings with it the full legal responsibility to CE mark the entire line.

This means the factory owner must:

- Conduct a new, overarching risk assessment for the entire line, focusing on hazards that arise from the interaction between machines.

- Ensure the safety and control systems are properly integrated. For example, an emergency stop button must halt all interconnected machinery that could pose a danger.

- Create a single, consolidated technical file for the entire assembly.

- Issue a single EU Declaration of Conformity for the completed production line.

Based on experience from J.v.G. turnkey projects, many entrepreneurs are surprised by this obligation. They often assume that the CE marks on individual machines are sufficient. This misunderstanding can lead to significant delays and costs when local safety authorities, like the FPS Economy in Belgium, conduct inspections.

Harmonized Standards: Your Path to Presumed Conformity

While EU directives state what safety objectives must be achieved, they do not specify how. That is where harmonized standards come in. These are detailed technical specifications developed by European standards bodies (CEN, CENELEC).

Although not legally mandatory, following these standards provides a ‘presumption of conformity’ with the directives, making it the most reliable and straightforward path to compliance. Two key standards for a PV production line are:

- EN ISO 12100: This standard provides the framework for conducting a risk assessment, a fundamental requirement for identifying and mitigating potential hazards.

- EN 60204-1: This standard details the safety requirements for the electrical equipment of machines, covering everything from operator controls to wiring and protection against electric shock.

An engineer uses these standards to systematically analyze the production line, identify risks at the interfaces between machines, and implement appropriate safety measures, such as light curtains, physical guarding, and integrated emergency stop circuits.

The Role of a Turnkey Partner in Ensuring Compliance

Creating a compliant ‘assembly of machinery’ from globally sourced equipment is a complex undertaking that poses a significant risk for investors without a deep background in EU safety engineering. This is where a turnkey solutions provider adds substantial value.

When an entrepreneur engages a partner for a Turnkey Solar Production Line, the responsibility for the overall integration and final CE marking of the entire assembly shifts to that partner. The provider then acts as the ‘manufacturer’ of the integrated line, managing the entire conformity assessment process.

This comprehensive service includes:

- Sourcing compliant machinery or bringing sourced equipment into compliance.

- Designing the integrated safety system.

- Performing the overall risk assessment.

- Compiling the complete technical file and issuing the final Declaration of Conformity.

This approach de-risks the project for the investor, ensuring the finished factory meets all legal requirements for operation within the EU from day one.

Frequently Asked Questions (FAQ)

Q: Who is ultimately responsible for the CE mark of the entire line?

A: The entity that assembles the individual machines into an integrated system and puts it into service. In most cases, this is the factory owner, unless this responsibility is contractually assigned to a turnkey provider.

Q: Is a CE mark from a non-EU manufacturer valid in the EU?

A: Yes, provided the manufacturer has correctly followed the entire EU conformity assessment procedure. However, the importer (the factory owner) has a legal duty to verify that the manufacturer has completed these steps. Simply seeing a CE logo is not enough; you must obtain and review the Declaration of Conformity and parts of the technical file.

Q: What is a ‘Declaration of Conformity’ (DoC)?

A: The DoC is a one-page legal document signed by the manufacturer, formally declaring that the product complies with all relevant EU directives. It must list the directives and harmonized standards that were applied. A valid DoC is required for every CE-marked machine.

Q: Do I need a Notified Body?

A: A Notified Body is an independent, third-party organization designated by an EU country to assess the conformity of certain high-risk products before they are placed on the market. Most machines in a standard solar production line are not on the ‘high-risk’ list (Annex IV of the Machinery Directive), so a Notified Body is typically not required. The manufacturer’s self-declaration is sufficient.

Q: How long does the certification process for an assembly of machinery take?

A: The process can take several weeks to months, depending on the line’s complexity and the completeness of the documentation from individual machine suppliers. This timeline must be factored into the overall project schedule.

Conclusion: Planning for Compliance from Day One

Navigating the EU’s safety and certification landscape is a non-negotiable part of establishing a solar module factory in a member state like Belgium. The key takeaway is that building a production line is not just about procuring machines; it is about creating a single, integrated, and legally compliant system.

Understanding the concept of the ‘assembly of machinery’ and its associated responsibilities is fundamental for any investor. Addressing these requirements early in the planning phase, whether independently or with an experienced turnkey partner, is essential for avoiding costly regulatory hurdles and ensuring a smooth, safe, and successful start of operations.