When an entrepreneur enters the solar manufacturing sector, the initial focus is often on technology and products. Yet, one of the most critical decisions for long-term success is made before any equipment is purchased: choosing the right location. In a market like Benin, with its significant growth potential, selecting the right site is not just a logistical exercise—it’s a strategic decision that shapes everything from operational costs and timelines to market access.

This article offers a framework for evaluating potential locations for a solar panel factory in Benin. It examines the key criteria for investors and weighs the advantages of dedicated industrial zones against those of developing a standalone site. The goal is to break down this complex decision into a structured process, enabling investors to lay a solid foundation for their manufacturing enterprise.

Table of Contents

Foundational Criteria for Site Selection

Before comparing specific locations, investors must understand the three pillars that support a successful manufacturing operation. A weakness in any of these areas can create significant operational friction and unforeseen costs.

-

Logistics and Market Access: At its core, a solar factory is a conversion business—it imports raw materials and exports finished goods. Proximity to an efficient international seaport is therefore non-negotiable for receiving bulk materials like solar glass, cells, and aluminum frames. Equally important is the road network connecting the factory to the port and to regional markets.

-

Infrastructure Reliability: Consistent, high-quality infrastructure is the lifeblood of a modern factory. This includes a stable supply of electricity to run sensitive machinery like laminators and cell stringers, access to sufficient water for cleaning and cooling processes, and high-speed telecommunications for business operations.

-

Business and Regulatory Environment: A supportive environment that facilitates rather than hinders business is crucial. This includes streamlined processes for business registration, customs clearance, and obtaining permits. Access to a trainable workforce and a stable, predictable fiscal policy are also key factors in a project’s financial viability.

The Port of Cotonou: Benin’s Logistical Gateway

Any discussion about industrial location in Benin must begin with the Port of Cotonou. As the country’s primary economic artery, its efficiency directly impacts the feasibility of any import-export business.

The Port of Cotonou serves not only Benin but also acts as a critical transit hub for landlocked neighbors—including Niger, Burkina Faso, and Mali—and for trade with Nigeria. For a solar module manufacturer, this presents a dual advantage:

- Efficient Inbound Logistics: Raw solar module components can be imported in containers and transported efficiently from the port to the factory.

- Expanded Market Reach: Finished solar panels can be exported to a vast regional market through the same logistical corridors, amplifying the opportunity beyond Benin’s borders.

Recent government reforms and investments have focused on improving the port’s performance and enhancing the road networks connecting it to the country’s interior, making it an increasingly reliable and strategic asset for industrial investors.

A Deep Dive into Benin’s Premier Industrial Zone: GDIZ

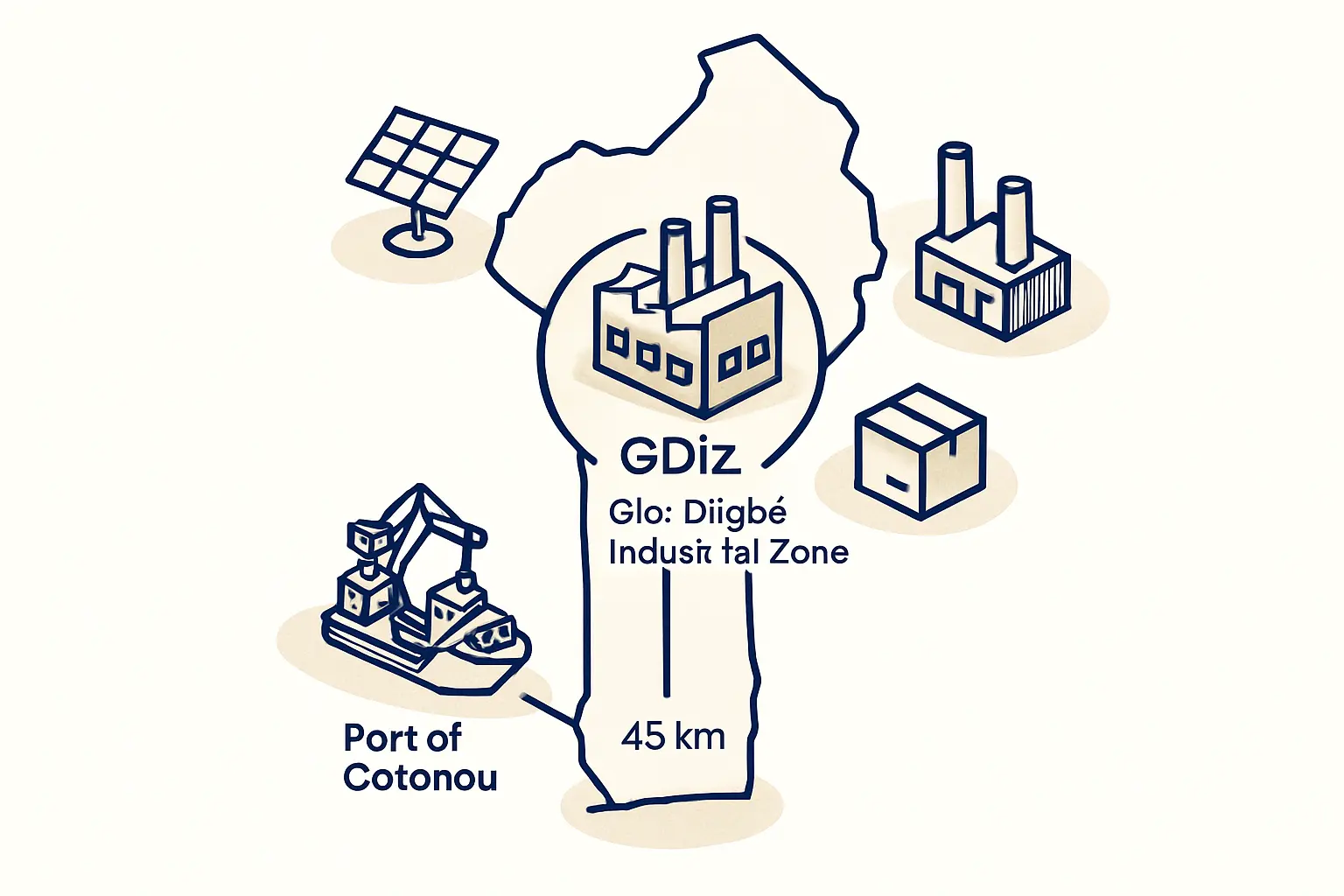

To address the infrastructure and regulatory hurdles that investors often face in emerging markets, Benin has invested heavily in creating specialized industrial zones. The most prominent of these is the Glo-Djigbé Industrial Zone (GDIZ), located about 45 kilometers from Cotonou.

GDIZ is designed as a self-contained ecosystem for manufacturing, offering solutions to many of the foundational criteria previously mentioned. Experience from turnkey solar production line projects consistently shows that locating within such a zone can significantly de-risk an investment.

The ‘One-Stop-Shop’ Advantage

One of the greatest challenges for a new investor is navigating the administrative landscape. GDIZ addresses this through its integrated “one-stop-shop” service center. This facility brings together all the necessary government agencies—including customs, tax authorities, and business registration services—under one roof.

For an entrepreneur, this translates into tangible benefits:

- Reduced Bureaucracy: Less time spent moving between different government offices.

- Faster Setup: A streamlined process for company incorporation, permits, and licenses.

- Clearer Processes: A single point of contact for administrative requirements.

This approach aligns with the core principle of a well-structured solar factory business plan: minimizing uncertainty and accelerating the timeline to production.

Critical Infrastructure within the Zone

Perhaps the most compelling argument for locating within GDIZ is the quality of its pre-installed infrastructure.

-

Stable Power Supply: The zone is equipped with its own dedicated thermal power plant. This solves the number one operational concern for most manufacturers in the region: grid instability. A reliable power source is essential for the sensitive, high-throughput machinery used in a solar factory.

-

Integrated Utilities: The zone provides reliable access to water, wastewater treatment, and a network of paved internal roads. This eliminates the need for an investor to fund and build this critical infrastructure from scratch.

Significant Financial Incentives

To attract investment, GDIZ offers a highly favorable fiscal regime for companies operating within its borders. According to APIEx (Benin’s Investment and Export Promotion Agency), any GDIZ company benefits from a special tax status that includes:

- A complete exemption from corporate income tax for up to 10 years, depending on the sector and investment amount.

- A 0% Value Added Tax (VAT) on equipment and raw materials imported for production within the zone.

These incentives have a direct and substantial impact on a project’s investment requirements and long-term profitability, improving the return on investment and shortening the payback period.

Comparing a Zone Location vs. a Standalone Site

An investor can also choose to acquire land and develop a factory outside a designated zone. However, it is crucial to weigh the perceived freedom against the practical responsibilities.

| Factor | Inside an Industrial Zone (e.g., GDIZ) | Standalone Site |

|---|---|---|

| Infrastructure | Turnkey access to stable power, water, and roads. | Investor is responsible for securing connections, which may involve high costs and long delays. |

| Administration | Streamlined “one-stop-shop” for permits and customs. | Requires navigating multiple government agencies independently. |

| Timeline | Faster setup due to pre-approved status and existing infrastructure. | Potential for significant delays due to permitting and utility connection processes. |

| Initial Cost | Lease or purchase costs may be higher, but many capital expenditures are avoided. | Land may be cheaper, but total project cost can escalate due to infrastructure development. |

| Financials | Access to significant tax holidays and exemptions. | Standard national tax regime applies. |

For most international investors, especially those without deep experience in the region, the managed environment of an industrial zone offers a more predictable and secure path to establishing a successful solar factory.

Frequently Asked Questions (FAQ)

-

How long does it take to set up a factory in a zone like GDIZ?

While the zone’s one-stop-shop accelerates administrative processes, the overall project timeline depends on factory construction and equipment installation. With a structured approach and an experienced turnkey partner, a 25–50 MW production line can be operational in under 12 months from the start of construction. -

Is the workforce in Benin skilled enough for solar manufacturing?

Benin has a young, growing, and trainable population. A standard part of establishing a new solar factory involves a comprehensive training program for operators and technicians, typically conducted by the equipment suppliers. J.v.G. Technology GmbH, for instance, incorporates on-site staff training as a core component of its turnkey solutions. -

What are the main logistical challenges even with a good location?

Even within GDIZ, which has an on-site customs office, managing the import of specialized machinery and materials requires meticulous documentation and coordination. Working with an experienced freight forwarder who understands local procedures is essential to avoid delays at the Port of Cotonou. -

Can a factory in Benin export to neighboring countries?

Absolutely. This is one of the key strategic advantages. Benin’s membership in the Economic Community of West African States (ECOWAS) and its logistical position as a gateway to Nigeria, Niger, and Burkina Faso make it an ideal hub for serving the wider regional market.

Conclusion and Next Steps

Choosing where to build a solar factory in Benin is a foundational decision that will influence the project’s entire lifecycle. While a low-cost standalone plot of land may seem tempting, the practical, de-risked advantages offered by a managed industrial zone like GDIZ are compelling.

The combination of reliable infrastructure, streamlined administration, and significant financial incentives creates an environment where investors can focus on their core business: manufacturing high-quality solar modules.

Once a location has been shortlisted, the next logical phase involves detailed facility design, financial modeling, and selecting the right production equipment. A clear understanding of the chosen site’s benefits provides the solid foundation needed to move forward with these critical next steps.