An entrepreneur’s new solar module assembly line near Gaborone is ready. The facility is complete, the staff is trained, and the first panels are already rolling off the production line. However, a critical step remains before a single unit can be sold: securing certification from the Botswana Bureau of Standards (BOBS).

This isn’t merely a quality seal; it’s the legal key to market access. Overlooking its complexities can lead to significant delays and unforeseen costs.

For any professional in this industry, understanding the regulatory landscape is as crucial as mastering the production process. A successful solar venture depends on meeting both technical requirements and official approvals. Explore the complete guide on how to start a solar panel factory to understand how certification fits into the broader project plan.

Table of Contents

What is BOBS Certification and Why is it Essential?

The Botswana Bureau of Standards (BOBS) is the national body responsible for setting and maintaining quality standards for goods and services sold within the country. In the solar industry, its role is to ensure that all photovoltaic (PV) modules—whether imported or locally manufactured—are safe, reliable, and perform as advertised.

The Botswana Energy Regulatory Authority (BERA) enforces this mandate, making BOBS certification a non-negotiable legal requirement. Attempting to sell non-certified panels can result in penalties and damage to a company’s reputation before it even has a chance to establish itself.

Viewing this as just a regulatory hurdle, however, is a missed opportunity. BOBS certification offers three distinct business advantages:

- Market Credibility: It signals to customers, financiers, and government bodies that your products meet established quality benchmarks.

- Competitive Edge: It levels the playing field, protecting serious local manufacturers from competition with low-quality, unverified imported products.

- Risk Mitigation: It ensures your products are safe, reducing the risk of liability from property damage or personal injury.

The Core Standards: Understanding BOS IEC 61215 and BOS IEC 61730

The foundation of BOBS certification for crystalline silicon solar panels rests on two key standards adopted directly from the globally recognized International Electrotechnical Commission (IEC). This alignment with international norms is excellent news for manufacturers with future export ambitions.

BOS IEC 61215: Design Qualification and Type Approval (Performance)

Think of this standard as the ultimate endurance test for your solar panel’s design, answering the key question: “Will this panel perform reliably for many years under harsh environmental conditions?” To verify this, panels undergo a series of accelerated stress tests that simulate decades of wear and tear in a controlled laboratory setting.

Key tests include:

- Thermal Cycling: The panel is subjected to extreme temperature swings to test the resilience of its solder joints and materials.

- Humidity-Freeze: This simulates conditions where moisture could enter and freeze inside the panel, testing the integrity of the lamination and edge seals.

- UV Exposure: Intense ultraviolet light exposure is used to check for material degradation and discoloration that could impact performance.

- Performance at STC: The panel’s power output is measured under Standard Test Conditions (STC) to verify it matches its specification sheet.

Passing this standard demonstrates that the module’s design is robust and its power output is dependable over the long term.

BOS IEC 61730: PV Module Safety Qualification

While BOS IEC 61215 focuses on performance, this standard is entirely about safety, addressing the critical question: “Is this panel safe for installers to handle and for end-users to have on their property?” It covers the prevention of electrical shock, fire hazards, and personal injury throughout the panel’s lifetime.

Safety tests include:

- Insulation Tests: These ensure no electrical current can leak to the module’s external surfaces, such as the frame.

- Wet Leakage Current Test: Simulating rain confirms the panel remains electrically safe even when wet.

- Mechanical Load Tests: Pressure is applied to the front and back of the panel to ensure it can withstand wind and snow loads without breaking in a hazardous way.

Meeting this standard is fundamental to building a trustworthy brand and protecting your business from liability.

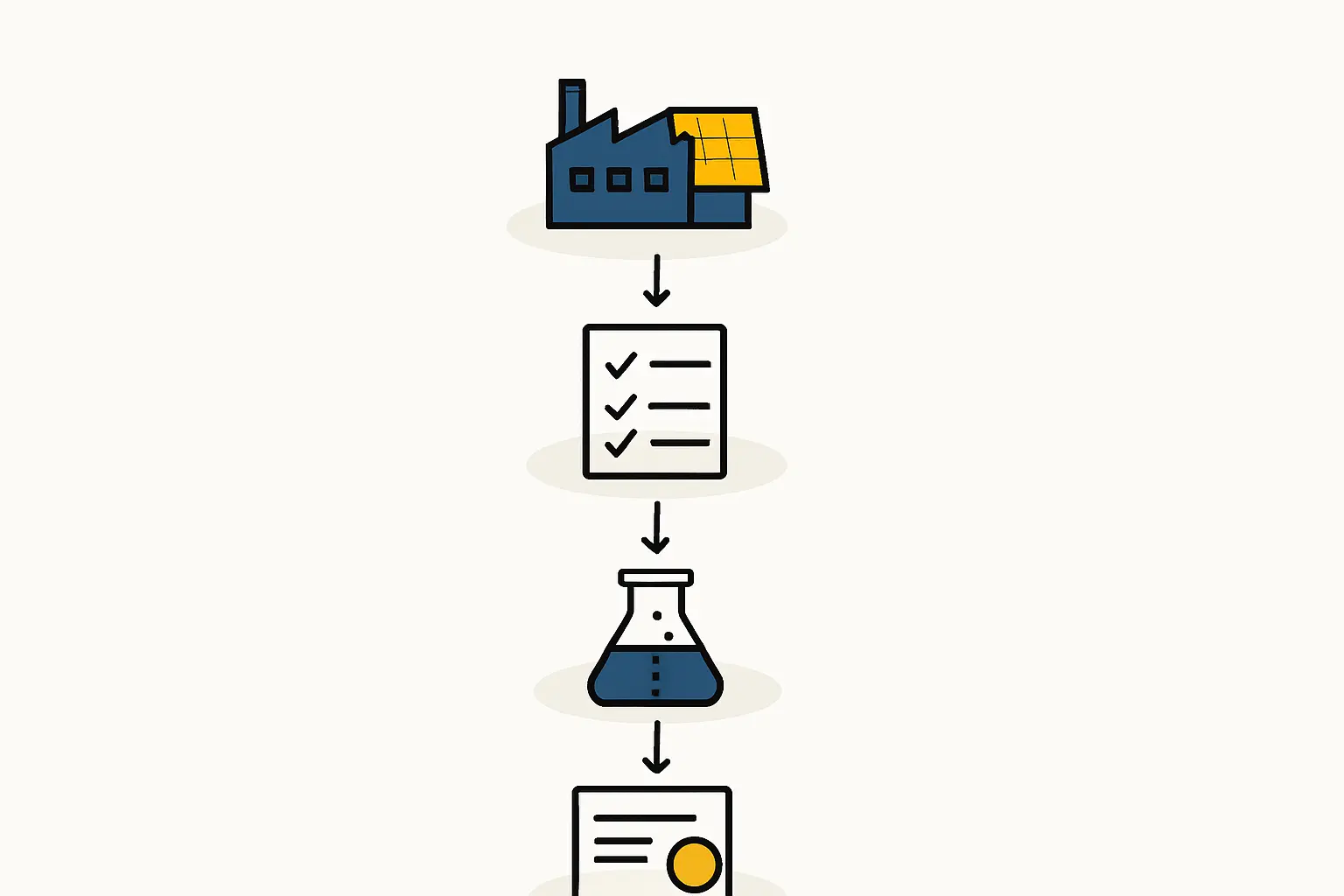

The Certification Process: A Step-by-Step Overview

Achieving BOBS certification is a structured process that begins long before a panel ever reaches a laboratory. It’s closely tied to the design, material selection, and quality control of the entire production line.

Step 1: Design, Material Sourcing, and Production

Certification begins on the factory floor. The quality of your final product depends on the raw materials you use—such as glass, EVA, cells, and backsheet—and the precision of your assembly process. Using high-quality, internationally recognized components and well-calibrated machinery is the first step toward creating a certifiable panel.

Step 2: Sample Selection and Submission

Once the production line is running consistently, a BOBS-accredited laboratory will require a set of sample modules for testing. These samples must be representative of your standard production output, not specially prepared “golden samples.”

Step 3: Laboratory Testing

The selected panels are sent to an accredited third-party laboratory. Here, they undergo the full sequence of performance and safety tests specified in BOS IEC 61215 and BOS IEC 61730. This phase is the most time-consuming and technically demanding part of the process.

Step 4: Factory Audit

In addition to product testing, BOBS may conduct a factory audit. Inspectors will visit your facility to verify that you have a robust Quality Management System (QMS) in place. They will look for documented procedures for everything from receiving raw materials to final product inspection, ensuring that every panel produced meets the same standard as the ones tested.

Step 5: Certification and Market Surveillance

Upon successful completion of all tests and audits, BOBS issues the certification. This allows you to apply the BOBS mark of quality to your products and sell them legally in Botswana. The process doesn’t end there, however. BOBS conducts ongoing market surveillance, periodically re-testing products pulled from the open market to ensure continued compliance.

Common Challenges and How to Prepare

Based on experience from J.v.G. turnkey projects, new manufacturers often encounter a few common challenges on the path to certification.

Challenge 1: Underestimating Costs and Timelines

Laboratory testing is a specialized service with significant costs, and the entire process from sample submission to final certification can take several months. These factors must be built into the initial business plan. When evaluating the investment for a new solar manufacturing line, it’s critical to allocate a specific budget and timeline for product certification.

Challenge 2: Inconsistent Production Quality

A frequent issue for new operations is achieving consistent quality across all shifts and production runs. A minor deviation in lamination temperature or a lapse in cell stringing quality can be enough to cause a test failure, requiring costly and time-consuming rework.

Challenge 3: Navigating Documentation

The certification process requires meticulous record-keeping and formal documentation. For entrepreneurs focused on the operational aspects of the business, managing the required paperwork can be a significant administrative burden.

Frequently Asked Questions (FAQ) about BOBS Certification

How long does the BOBS certification process take?

The timeline can vary, but a manufacturer should typically plan for 3 to 6 months. This depends on factors like the testing laboratory’s schedule, the time required for the panels to complete all test sequences, and how responsive the manufacturing team is to any queries.

Is certification a one-time process?

No. The initial certification is for “type approval,” meaning it qualifies a specific panel design. The certification must be maintained through periodic factory inspections and market surveillance to ensure that production quality remains consistent over time.

Can I use components that are not certified?

While not every single component requires its own BOBS certificate, using key components (like junction boxes, connectors, and laminating materials) that are already certified to international IEC standards drastically improves the likelihood of passing the final module tests. This practice is highly recommended.

What happens if my panels fail the tests?

If a module fails any part of the testing, the laboratory will issue a detailed report identifying the point of failure. The manufacturer must then conduct a root cause analysis to determine if the problem lies with the design, a specific material, or a step in the production process. Once the issue is corrected, new samples must be submitted for re-testing.

Does BOBS certification help with exporting panels outside Botswana?

Yes, it provides a strong foundation. Because the BOBS standards are harmonized with globally accepted IEC standards, the test reports can often be used to support certification applications in other countries, particularly within the Southern African Development Community (SADC) and beyond. This can save significant time and money when expanding into new markets.

Your Next Steps Towards Market Entry

Achieving BOBS certification is a fundamental milestone for any solar panel manufacturer in Botswana. More than an administrative afterthought, it’s a strategic imperative that must be integrated into your business plan from the very beginning. By treating certification as a tool for building quality and trust, you lay the groundwork for a reputable and sustainable enterprise.

Understanding the regulatory landscape is just one piece of the puzzle. For a comprehensive overview of all stages, from initial concept to a fully operational facility, the pvknowhow.com guide on how to start a solar panel factory provides a structured roadmap to success.