Entering the solar manufacturing sector in a new region presents a unique set of challenges. While machinery and materials can be sourced globally, the most critical asset—a skilled workforce—must be developed locally.

For an investor considering Botswana, the question isn’t whether a labor force exists, but how to transform available talent into a team of proficient solar module technicians. This isn’t merely a human resources task; it’s a core pillar of operational success.

A common oversight is to underestimate the gap between general technical aptitude and the specific, process-driven skills required in modern photovoltaic manufacturing. This article outlines a structured framework for developing a training program in Botswana, transforming the skills gap from a challenge into a strategic advantage for a new solar enterprise.

Table of Contents

Understanding the Botswana Context: Opportunity and Challenge

Botswana presents a compelling case for investment in renewable energy. Guided by its “Vision 2036,” the government aims for significant economic diversification away from diamond dependency, with a target of generating 50% of its electricity from renewable sources by that year. This forward-thinking policy environment creates a supportive climate for solar manufacturing.

From a labor perspective, two key factors stand out:

-

A Motivated Labor Pool: With a youth unemployment rate that has often hovered between 35-40%, there is a substantial and available workforce eager for stable, skilled employment in a growing industry.

-

A Foundational Skills Gap: While Botswana has well-established Technical and Vocational Education and Training (TVET) colleges and institutions like the Botswana International University of Science and Technology (BIUST), a gap often exists between general engineering or electrical qualifications and the precise demands of a solar module assembly line.

The strategic goal, therefore, is to bridge this gap efficiently. A well-designed training program turns potential into productivity, ensuring the factory can meet international quality standards from day one.

A Three-Phase Framework for Technician Training

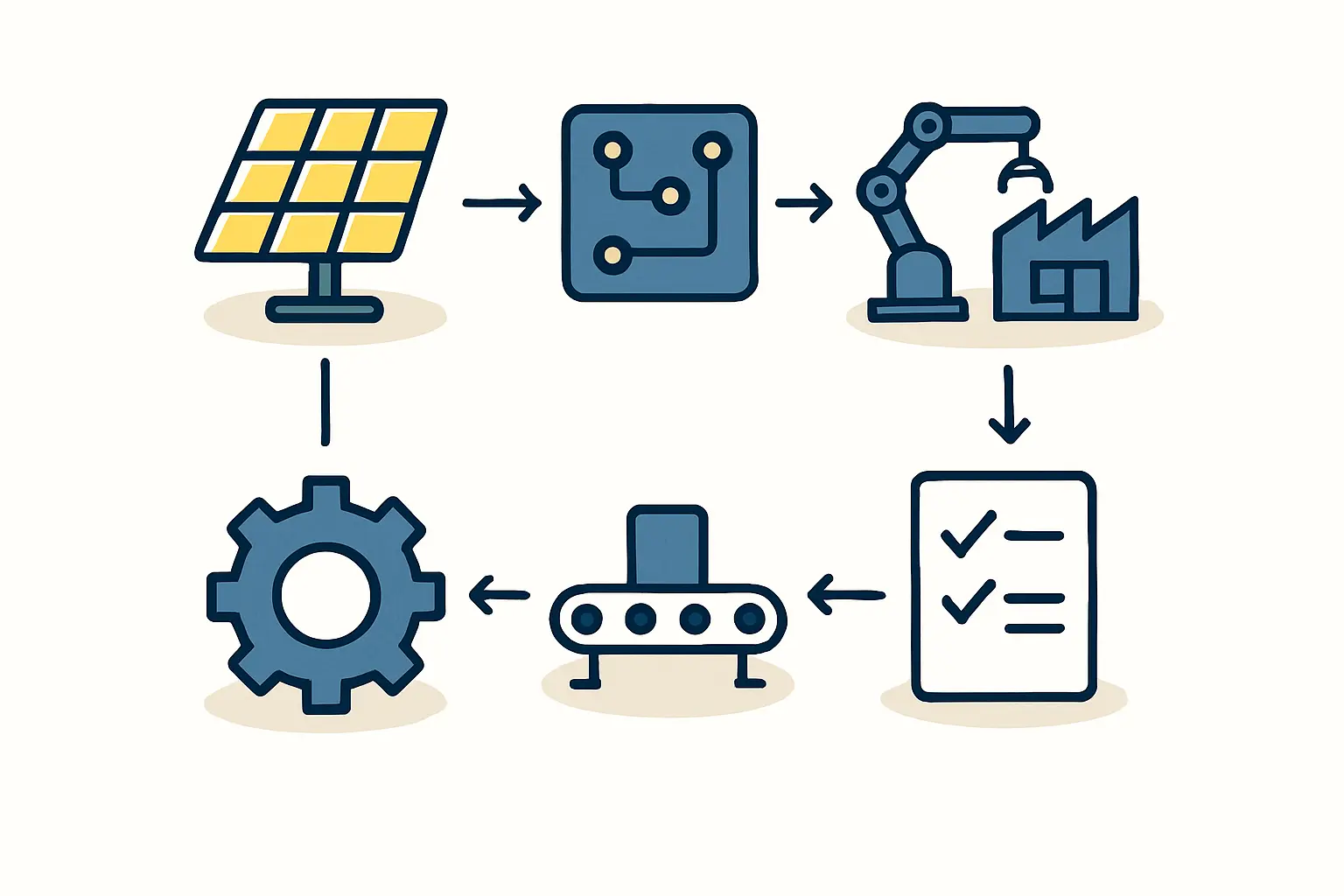

A successful training program is not a single event but a continuous process. A phased approach allows for the systematic development of skills, from fundamental knowledge to specialized operational expertise. Based on experience from J.v.G. turnkey projects, a three-phase structure proves highly effective.

Phase 1: Foundation Building (Pre-Production)

This initial phase takes place before the main production equipment is fully operational. It focuses on instilling the core principles and mindset required for working in a high-precision manufacturing environment.

Objective: To equip new hires with essential theoretical knowledge and a strong culture of safety and quality.

Duration: Typically 4–6 weeks.

Curriculum Focus:

- Introduction to Photovoltaics (PV): How solar cells work, the structure of a solar module, and basic terminology.

- Workshop Fundamentals: Proper use of hand tools, measurement techniques, and basic electrical principles (e.g., series and parallel circuits).

- Quality Mindset: Introduction to concepts like process control, the cost of defects, and the importance of following standard operating procedures (SOPs).

- Health & Safety (EHS): Electrical safety, material handling procedures, and emergency protocols. This is a non-negotiable foundation.

This phase establishes a common baseline of knowledge across the entire technical team, ensuring everyone speaks the same technical language.

Phase 2: Specialized Machine Operation (On-Site)

Once the production line is installed, training shifts to hands-on, machine-specific instruction. This phase is best conducted by experienced engineers, often from the equipment supplier or a technical partner like J.v.G. Technology.

Objective: To develop operator proficiency for each key station on the production line.

Methodology: A “train-the-trainer” approach is often the most sustainable. A core team of local supervisors or lead technicians receives intensive training and is then empowered to train the remaining operators.

Curriculum Focus:

- Hands-on instruction for the key machines in a solar production line, such as the stringer, laminator, and final testers.

- Machine setup, calibration, and routine operation.

- First-level troubleshooting and preventive maintenance tasks.

- Understanding process parameters and their impact on module quality.

Phase 3: Quality Assurance and Certification Readiness (Post-Commissioning)

After the line is running, the focus evolves from simply producing modules to making consistently high-quality ones. This phase integrates quality control into every step of the process.

Objective: To empower the team to self-monitor quality and prepare the factory for international certification audits.

Curriculum Focus:

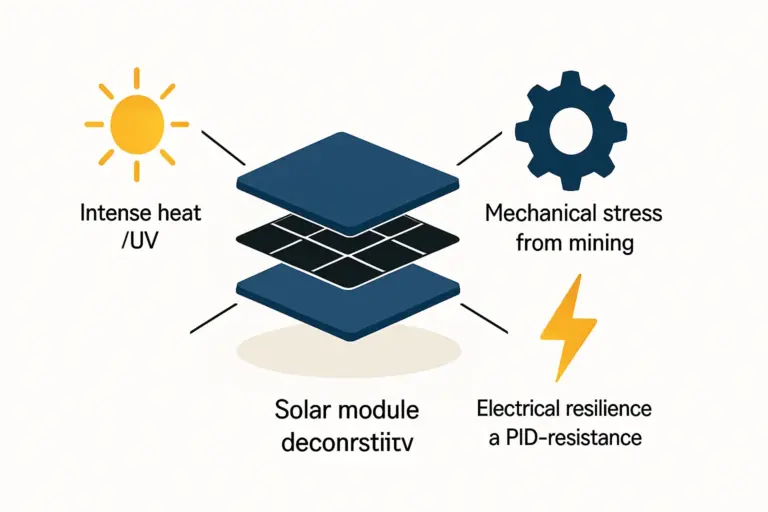

- In-Process Quality Control (IPQC): Performing visual inspections, using measurement tools, and identifying common defects (e.g., microcracks, soldering issues).

- Data Recording and Analysis: Understanding the importance of logging production data and interpreting results from testers (e.g., EL and IV testers).

- Certification Standards: Familiarizing the team with the requirements of standards like IEC 61215 is a crucial part of learning how to get your solar modules certified.

Strategic Partnerships: Leveraging Local Institutions

Investors don’t need to build a training infrastructure from scratch. Partnering with local TVET colleges or BIUST can create a sustainable talent pipeline.

A collaboration could involve:

- Curriculum Co-development: Working with the institution to add a “Solar Manufacturing” module to its existing electrical or mechanical engineering programs.

- Internship Programs: Offering positions to final-year students, providing them with practical experience and allowing the company to identify top talent before hiring.

- Shared Facilities: Using the institution’s classroom facilities for Phase 1 theoretical training.

This approach not only reduces the training burden on the company but also strengthens the local educational ecosystem, demonstrating a long-term commitment to the community.

Assessing the Investment in Training

The costs associated with training should be viewed as an integral part of the initial capital expenditure, not as an optional operating expense. A well-trained workforce directly impacts a factory’s profitability through:

- Higher Yield: Fewer defects and less material wastage.

- Improved Uptime: Better machine handling and basic maintenance reduce downtime.

- Lower Employee Turnover: Investing in employee skills fosters loyalty and reduces recurring hiring and training costs.

The total labor requirements for a solar factory are not just a matter of headcount, but of capability. An investment in training pays dividends over the entire lifetime of the factory.

Frequently Asked Questions (FAQ)

What qualifications are ideal for new technician trainees?

For operator roles, technical aptitude, attention to detail, and a willingness to learn are often more important than formal degrees. Look for graduates from vocational programs in electrical or mechanical trades. For supervisory roles, a diploma or degree in engineering is beneficial.

How long does it take for a new team to become fully proficient?

While foundational training takes 4–6 weeks, reaching peak efficiency and quality consistency can take 6–12 months of hands-on production experience. Continuous learning and refresher courses are essential.

Are there government incentives for workforce training in Botswana?

Investors should engage with the Botswana Investment and Trade Centre (BITC) and the Human Resource Development Council (HRDC). These bodies can provide information on potential grants, tax incentives, or co-funding schemes for skills development initiatives that align with national priorities.

Can J.v.G. Technology assist with creating and implementing these training programs?

Yes. As part of its turnkey factory solutions, J.v.G. Technology provides comprehensive training programs. This support includes developing customized curricula, providing on-site instruction from experienced German engineers, and implementing the “train-the-trainer” model to ensure long-term knowledge transfer.

Conclusion: Building a Sustainable Local Workforce

Establishing a solar module factory in Botswana is a venture with immense potential. Its long-term success, however, will hinge on the quality and skill of its local workforce.

By implementing a structured, three-phase training program and forging strategic partnerships with local educational institutions, investors can effectively bridge the skills gap. This approach not only ensures a smooth production ramp-up but also builds a sustainable, competitive, and truly local manufacturing operation poised for success in Africa’s growing solar market.