The ambition is clear: Burkina Faso, with a national electrification rate of just 21% and rural access as low as 5%, is poised for a significant energy transformation. Government initiatives like the “Yeleen” solar program, which aims to add 50 MW of solar capacity, signal a strong commitment to this future. For an entrepreneur, this creates a substantial opportunity to establish local manufacturing and contribute to national development.

Table of Contents

But even the most sophisticated machinery is only as effective as the people who operate it. In a market where specialized solar manufacturing skills are scarce, a new enterprise must build its production team from the ground up. The success of a new solar module factory hinges on transforming motivated local individuals into skilled technicians. This article outlines a structured, practical framework for doing just that—ensuring quality, safety, and productivity from the very first module.

The Human Capital Challenge in a High-Growth Market

The opportunity extends across the continent. An IRENA report estimates that Africa could capture up to 10% of the global solar value chain, creating immense employment possibilities. Yet this potential can only be realized with a deliberate focus on workforce development.

For any new solar module manufacturing plant, the primary challenge is bridging the skills gap. While a local workforce may possess a strong work ethic and general technical aptitude, the specific processes of solar module assembly—from cell stringing to lamination and testing—demand specialized knowledge. A well-designed training program is not simply an operational expense; it is a critical investment in the long-term viability and quality of the entire venture.

Foundational Principles of a Successful Training Program

Before defining a curriculum, it’s essential to establish the principles that will guide the entire training process. An effective program is built on three pillars:

- Structured and Documented: Informal, “learn-as-you-go” training leads to inconsistent quality and safety issues. Research shows that structured on-the-job training can improve productivity by up to 20% compared to informal learning. Every process must be documented and taught systematically.

- Hands-On and Repetitive: Theoretical knowledge is important, but muscle memory and practical experience are crucial. The majority of training must take place on the actual production equipment under expert supervision.

- Role-Specific Focus: A typical semi-automated 50 MW solar module factory requires 25-35 production staff per shift. Rather than training everyone on every machine, it’s more efficient to develop specialists for critical roles. Understanding the full scope of labor requirements for a solar factory is a key first step in planning this specialization.

A Phased Training Framework for New Technicians

A comprehensive training plan, structured over approximately 12 weeks, moves trainees from general knowledge to specialized operational skills. This timeline allows for a gradual yet thorough transfer of knowledge.

Phase 1: Classroom Foundations (Week 1-2)

The initial phase focuses on essential theory, creating a strong base before any hands-on work begins. This is particularly important for staff who may not have a background in manufacturing or electronics.

- Introduction to Photovoltaics: A basic overview of how solar cells work, how they are assembled into a module, and the module’s role in a solar energy system.

- Factory Safety Protocols: Comprehensive training on electrical safety, machine operation safety, emergency procedures, and the proper use of personal protective equipment (PPE).

- Quality Control Principles: Introducing the concept of “quality at the source.” Technicians must understand why precision is critical, how to identify common defects (e.g., microcracks, soldering issues, cosmetic flaws), and the cost of poor quality.

- Materials Handling: Correct procedures for handling fragile components like solar cells and glass to minimize breakage and waste.

Phase 2: Hands-On Machine Training (Week 3-6)

This phase moves trainees to the production floor to learn the specific operations of the key machines in a solar module line. Training should be led by an experienced engineer or a senior technician—often an expatriate expert in the initial stages of a new factory.

Example Curriculum: Stringer Operator

The stringer machine solders solar cells together to form strings, a process that demands high precision.

- Objective: To operate the stringer machine efficiently, load materials correctly, and perform first-level quality checks on soldered cell strings.

- Key Skills:

– Loading solar cells and ribbon without causing damage.

– Understanding the machine’s HMI (Human-Machine Interface).

– Visually inspecting each string for soldering defects, cell alignment, and microcracks.

– Performing basic machine cleaning and maintenance routines.

Example Curriculum: Laminator Technician

The laminator is the heart of the factory, where the module’s components are bonded together under heat and vacuum.

- Objective: To operate the laminator according to prescribed recipes, understand the lamination cycle, and identify potential issues.

- Key Skills:

– Loading and unloading modules from the laminator safely.

– Selecting the correct production “recipe” for different module types.

– Monitoring cycle parameters (temperature, pressure, time).

– Recognizing common lamination defects like air bubbles or delamination.

Phase 3: Shadowing and Supervised Production (Week 7-12)

In this final phase, trainees begin working on the line under the close supervision of their trainer. The focus shifts from learning the steps to achieving consistency, speed, and quality under real production conditions.

- Week 7-9: Trainees operate their designated machines with the trainer observing, providing immediate feedback, and correcting mistakes. Production targets are introduced but remain secondary to quality and process adherence.

- Week 10-12: The supervisor gradually reduces direct oversight, allowing trainees to build confidence. Performance is measured against key metrics like output, quality pass rate, and material waste.

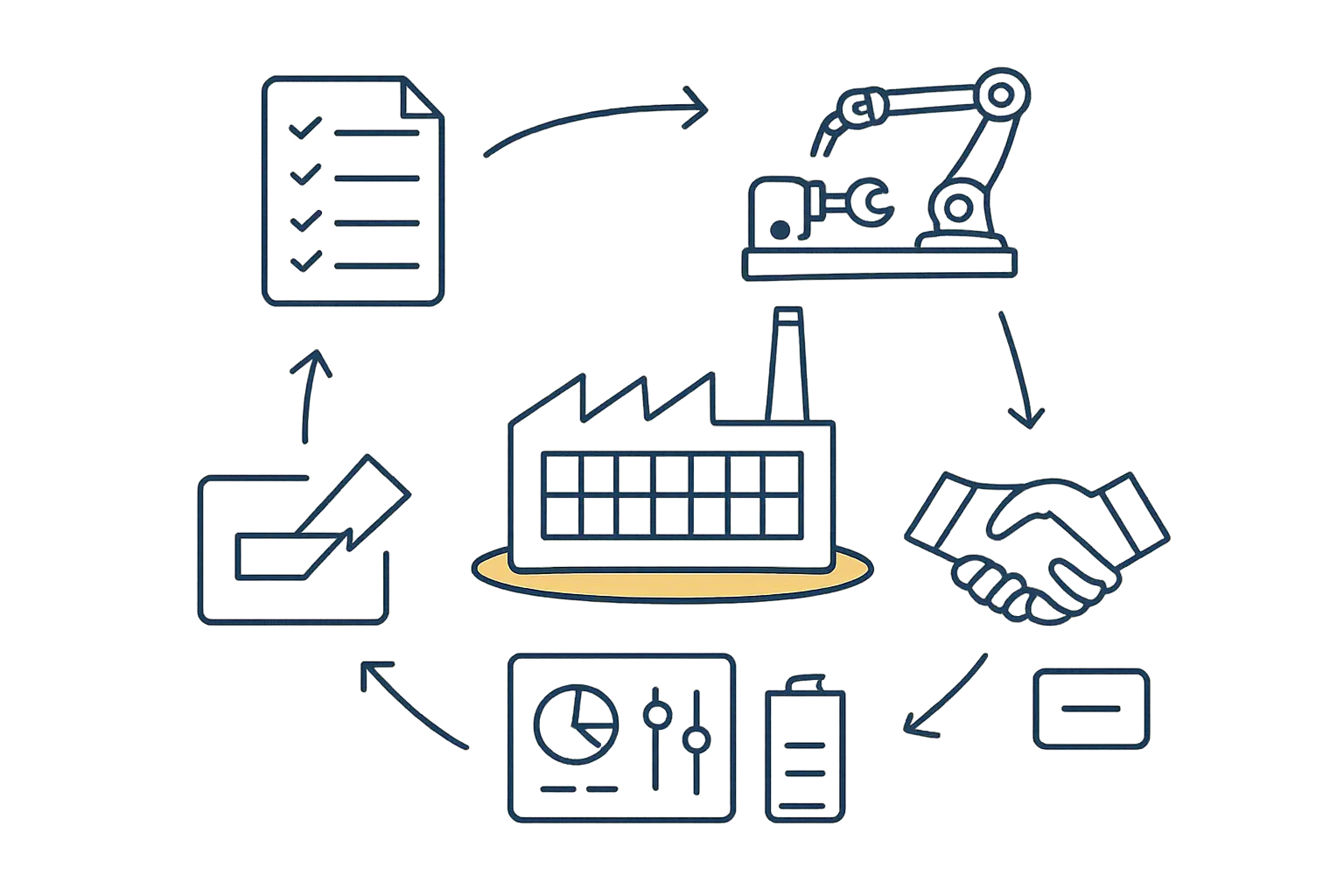

Measuring Success and Ensuring Quality

A training program’s success is ultimately measured by the performance of the production line. Key Performance Indicators (KPIs) should be established to track progress:

- Yield Rate: The percentage of modules produced that pass all quality tests.

- Throughput: The number of modules produced per hour or per shift.

- Material Wastage: The rate of broken cells or other rejected materials.

These metrics do more than gauge workforce competence; they are also essential for the final solar module certification process, which validates that the factory and its products meet international standards.

The Role of Expatriate Expertise and Knowledge Transfer

In a new factory in a developing market, it’s common practice to employ an experienced expatriate production manager or senior engineer for the first one to two years. This individual’s primary role extends beyond managing production; they are also the lead trainer and mentor for the local team.

Experience from J.v.G. turnkey projects shows a successful knowledge transfer plan is critical. The goal is for the expatriate expert to systematically develop local supervisors and team leaders who can eventually take full responsibility for training new staff and managing the production floor independently.

Frequently Asked Questions (FAQ)

Q: How long does it take to fully train a new solar module technician?

A: While this 12-week program brings a technician to operational competence, true mastery and peak efficiency typically take six to nine months of continuous experience on the production line.

Q: What educational background is required for production staff?

A: A formal engineering degree isn’t necessary for most production roles. A secondary school education with a technical or vocational focus is often sufficient. More important are qualities like attention to detail, a willingness to learn, and the ability to follow structured processes.

Q: Can one expert train an entire team of 30 people at once?

A: A “train the trainer” approach is far more effective. The lead expert should first focus on training a small group of three to five promising individuals who will become team leaders. These new leaders can then help train the rest of the workforce.

Q: How does the training period impact the initial production ramp-up?

A: The initial ramp-up will be slower while the team is learning, so it’s important to set realistic production targets for the first six months. Prioritizing quality and process adherence over raw speed during this period prevents costly mistakes and builds a strong foundation for future high-volume production.