Even with a robust business plan, secured financing, and the best production technology, a project’s success in a highly regulated market like Canada hinges on more than machinery. It depends on navigating a complex web of permits, assessments, and environmental regulations.

For investors new to the country, this landscape can be formidable, causing significant delays and unforeseen costs without a clear understanding from the outset. This guide breaks down the typical regulatory pathway for establishing a solar module manufacturing facility in Canada. Its goal is to demystify the process—from initial environmental screenings to ongoing operational compliance—and help business leaders plan with greater confidence.

Table of Contents

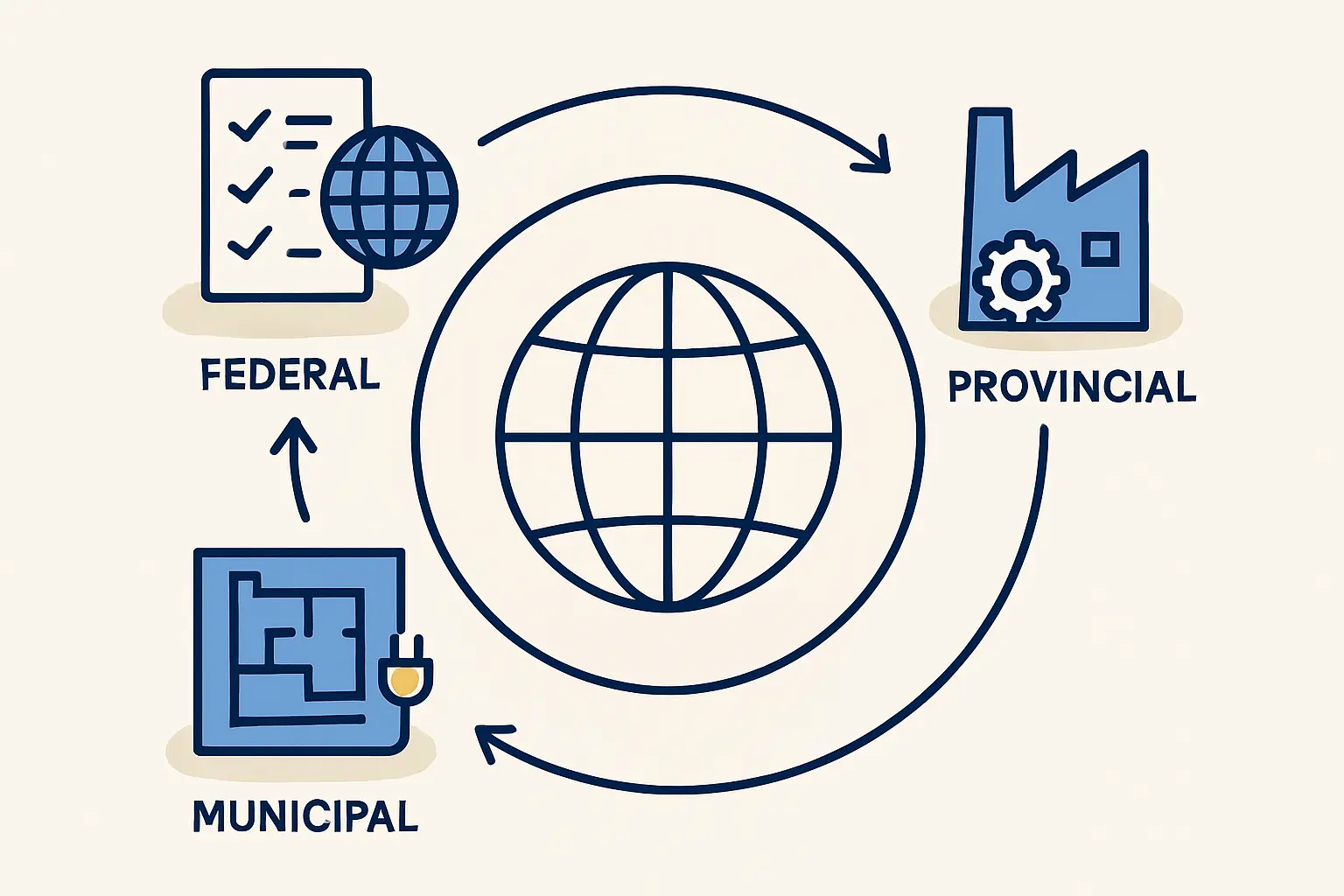

Understanding Canada’s Regulatory Framework: Federal vs. Provincial Jurisdiction

The first crucial concept to grasp is Canada’s division of powers. Both the federal government and the ten provincial governments have distinct, and sometimes overlapping, authority over industrial projects.

Federal Jurisdiction

Federal authority typically comes into play under specific circumstances. For example, the federal Impact Assessment Act (IAA) applies if a project is located on federal lands (e.g., a port or an airport), involves certain types of activities listed in regulations, or could affect areas of federal responsibility like fisheries or Indigenous rights.

Provincial Jurisdiction

Most industrial regulation, including environmental permits, land use, and worker safety, falls under provincial authority. Each province, whether Ontario, Alberta, or Quebec, has its own Environmental Assessment (EA) act and a unique set of regulatory bodies and requirements. For a typical solar factory, the provincial process will be the primary focus.

Understanding which jurisdiction takes the lead is a critical first step in mapping out a compliance strategy.

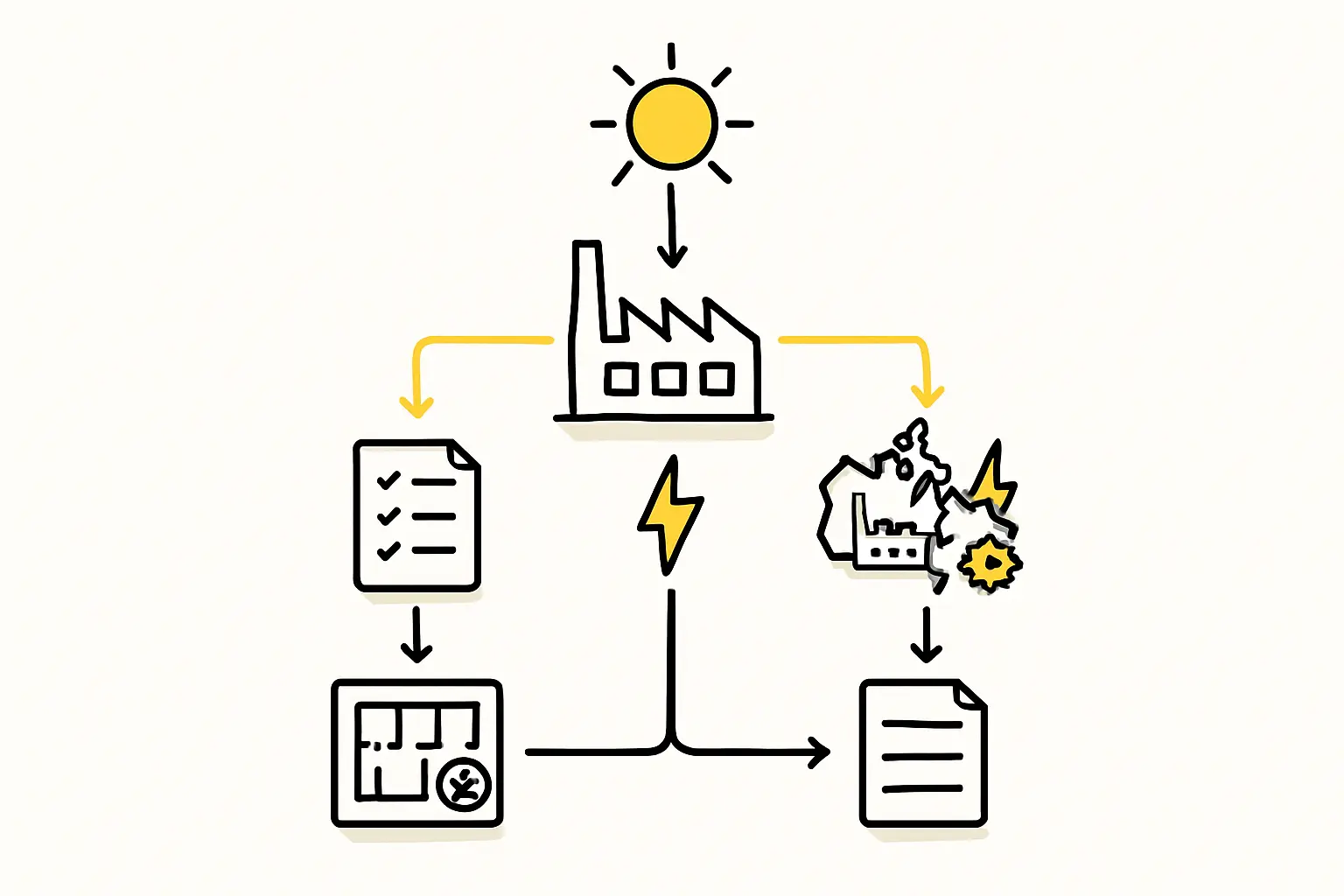

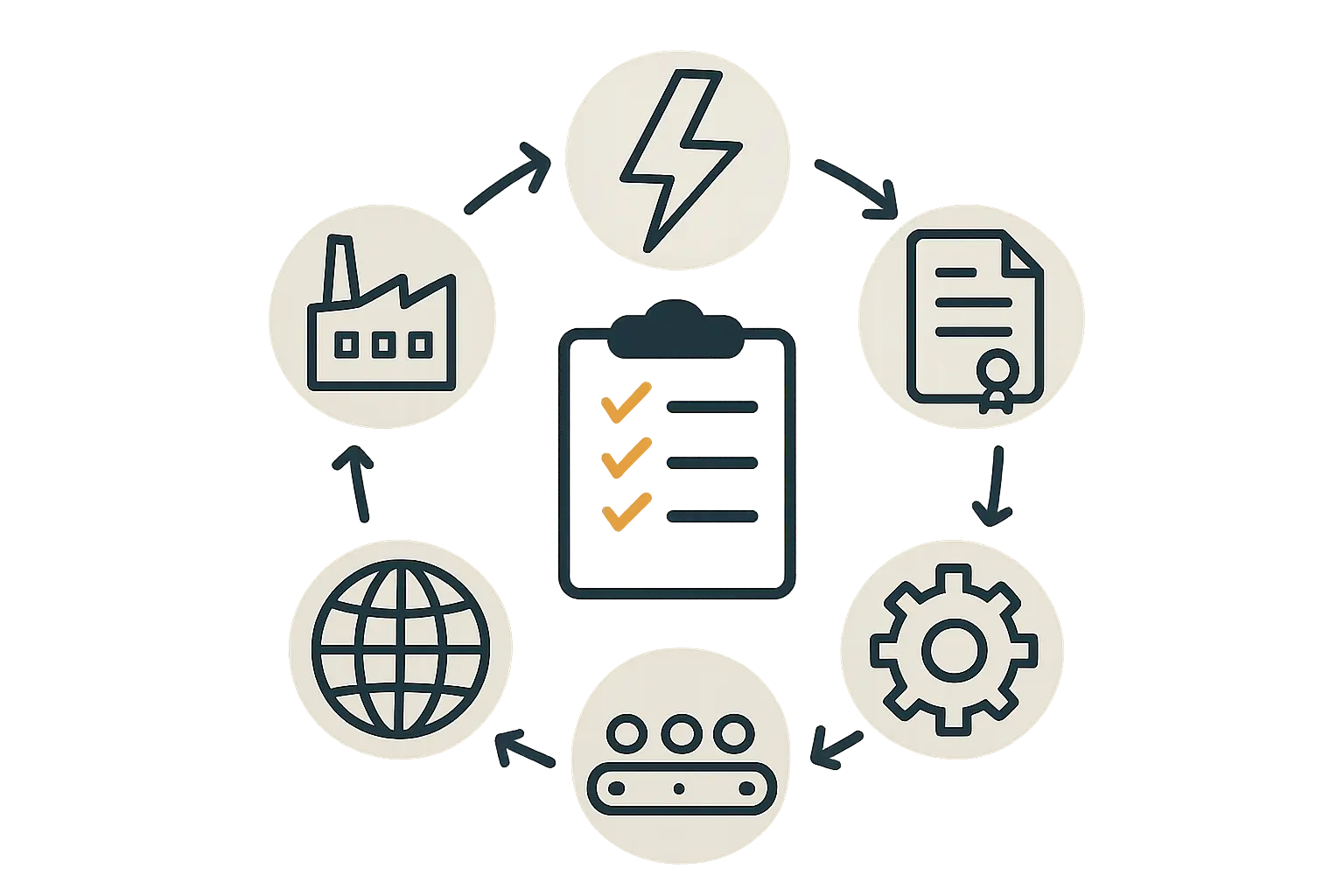

The Core Approval Process: A Step-by-Step Overview

While specifics vary by province, the journey from concept to operation generally follows a predictable sequence. A well-structured approach anticipates these stages and integrates them into the overall project timeline and budget.

Step 1: The Environmental Assessment (EA) or Impact Assessment (IA)

Before any ground is broken, most provinces require an Environmental Assessment. This formal process evaluates a project’s potential environmental, social, and economic effects before it can proceed. The goal is to identify potential negative impacts and determine how they can be mitigated.

A solar module manufacturing facility, depending on its scale and location, will likely undergo a provincial EA screening to determine the level of review required. This process involves detailed studies and engineering assessments on potential impacts on air quality, water resources, local ecosystems, and community health.

A critical and legally mandated component of the EA process is consultation with Indigenous communities whose rights or lands may be affected by the project.

Step 2: Securing Land Use and Building Permits

Once the project clears the environmental assessment stage, the focus shifts to municipal-level approvals. This phase ensures the physical facility complies with local planning and safety standards.

Zoning and Land Use: The proposed site must be zoned for industrial manufacturing, a classification that can be confirmed with the local municipal planning department. This is a fundamental due diligence step before acquiring land.

Building Permits: After zoning is confirmed, detailed architectural and engineering plans are submitted to obtain a building permit. These plans must adhere to the National Building Code of Canada and any specific provincial codes, covering everything from structural integrity and fire safety to electrical systems. A well-considered factory layout that accounts for safety and workflow can significantly streamline this approval phase.

Step 3: Obtaining Operational Permits and Licenses

Once the facility is constructed, a final set of permits is required to begin operations legally. These permits are often tied to the specific industrial processes involved in manufacturing solar modules. Key examples include:

- Air and Water Permits: Manufacturing processes can generate air emissions or liquid effluent. Permits issued under regulations like the Canadian Environmental Protection Act (CEPA) or provincial equivalents will set strict limits on pollutants and require monitoring and reporting. The federal Fisheries Act also imposes stringent rules to protect water bodies.

- Waste Management: A plan for handling, storing, and disposing of both hazardous and non-hazardous waste must be approved.

- Worker Safety: Each province has its own occupational health and safety regulations. The facility must demonstrate compliance through proper training, equipment, and procedures to protect its employees.

Key Challenges and How to Prepare

Navigating this process efficiently requires foresight and specialized expertise. Investors should be prepared for several common challenges.

Navigating Timelines and Costs

The entire permitting process, from initial EA screening to final operational licenses, can take anywhere from 6 to 24 months. This timeline must be realistically integrated into the project’s overall business plan. Engaging experienced environmental and regulatory consultants is not an optional expense but a strategic investment. These professionals can anticipate data requirements, manage stakeholder communication, and prevent common missteps that lead to costly delays.

The Importance of Early Consultation

Inadequate consultation with local communities and Indigenous groups is a frequent source of delay. Modern Canadian regulations mandate meaningful, two-way dialogue, starting early in the planning process. Proactively engaging stakeholders to listen to concerns and co-develop solutions builds trust and creates a smoother path to approval.

Staying Abreast of Policy Changes

Canada’s policy landscape is dynamic, with a clear federal and provincial trend toward supporting renewable energy and clean technology manufacturing. While this creates a favorable business environment, the specific regulations can change. Successful projects depend on staying current with any new environmental standards or policy shifts that could impact the facility’s design and operation.

Frequently Asked Questions (FAQ)

Q: Do I need a consultant to manage this process?

A: For investors unfamiliar with the Canadian system, engaging a local regulatory and environmental consultant is highly recommended. Their expertise in navigating specific provincial rules and their relationships with regulatory bodies are invaluable.

Q: How does the process differ between provinces like Alberta and Ontario?

A: The differences are significant, as each province has its own environmental assessment act, regulatory agencies, and specific requirements for consultation and technical studies. A strategy for Ontario will not be directly applicable in Alberta.

Q: What happens if my project is on federal land or near a major waterway?

A: Projects on federal land will almost certainly trigger a federal Impact Assessment under the IAA. Projects near water may also trigger federal reviews under the Canadian Navigable Waters Act or the Fisheries Act, in addition to any provincial requirements.

Q: Are there special permits for using certain chemicals in the manufacturing process?

A: Yes. The storage, handling, and disposal of chemicals used in solar cell and module production are strictly regulated under both federal and provincial environmental protection laws, requiring specific permits and management plans.

Conclusion: Planning for a Smooth Regulatory Journey

Establishing a solar factory in Canada offers a stable and promising opportunity. However, success is built on a foundation of thorough regulatory planning. By understanding the division of federal and provincial powers, following the structured sequence of approvals, and proactively engaging experts and stakeholders, investors can navigate these complexities with confidence.

While the machinery and technology are vital, the careful management of the permitting and compliance process is what turns a well-laid plan into an operational reality. Building these steps into the earliest planning stages ensures that a project for turnkey solar production lines is not only technically sound but also legally and socially robust.