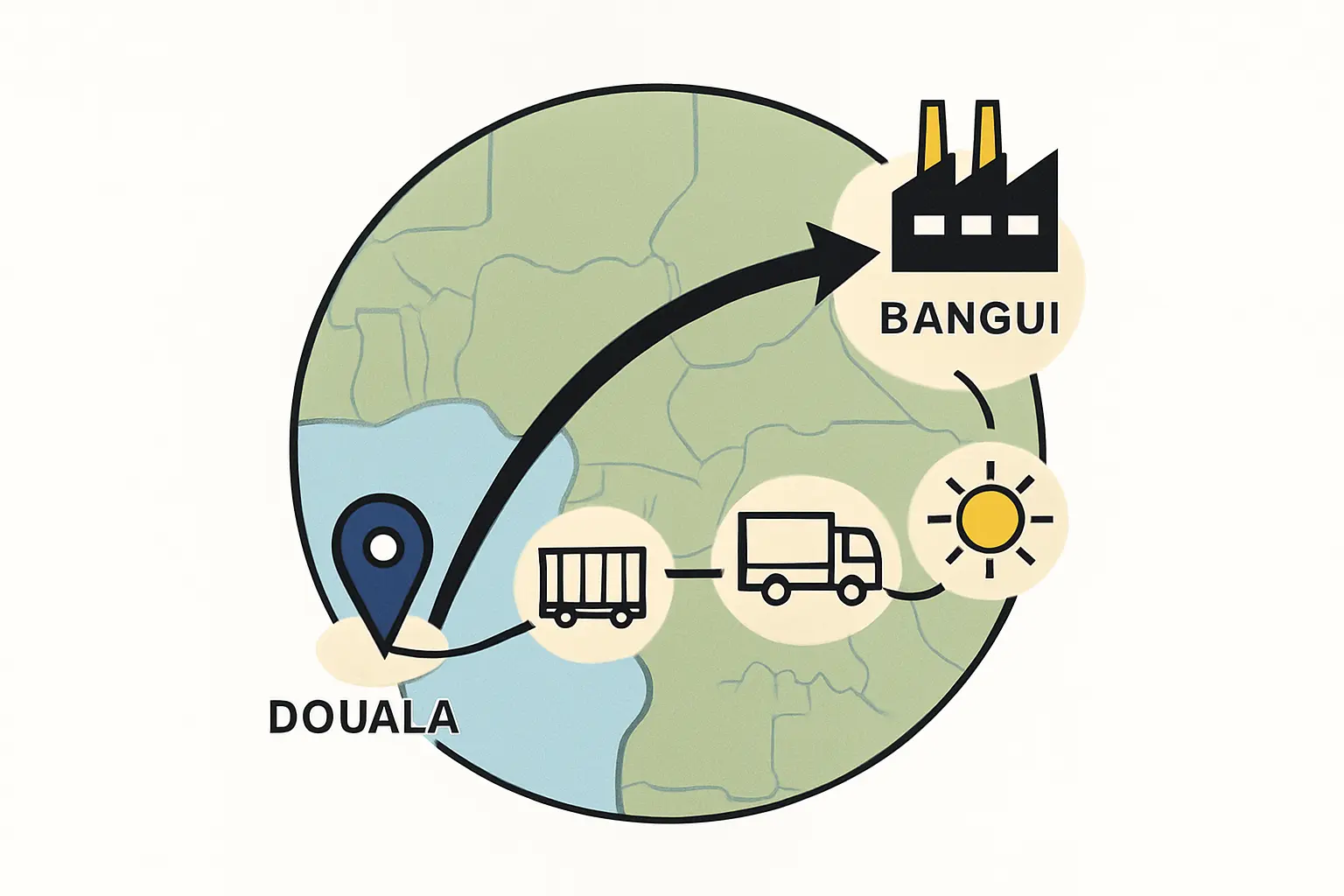

Establishing a solar module factory in a high-growth market like the Central African Republic (CAR) is a significant business opportunity. For a landlocked nation, however, getting essential equipment and materials from a global supplier to the factory floor presents a formidable logistical challenge.

An investor’s success here often depends less on the manufacturing technology itself and more on mastering the supply chain that supports it. This requires a detailed understanding of the primary import corridor, customs procedures, and local infrastructure.

This overview traces these critical logistical considerations, following the journey from the port of entry to the operational facility in Bangui.

Table of Contents

The Primary Gateway: Navigating the Port of Douala

For the Central African Republic, virtually all sea freight arrives via the Autonomous Port of Douala in neighboring Cameroon. This port serves as the primary maritime gateway for the entire region, making it a vital yet challenging chokepoint in the supply chain.

Entrepreneurs must be prepared for the operational realities of this hub. Significant shipment delays are common, with average waiting times for container processing stretching to 20 days due to port congestion. Handling and storage fees at Douala are also comparatively high, adding pressure to the overall project budget.

Successfully navigating this first step means partnering with an experienced logistics provider. Expertise in regional freight forwarding to the Central African Republic is critical for managing documentation, negotiating with port authorities, and coordinating the swift transition of goods from port to inland transport.

The Inland Journey: The Douala-Bangui Corridor

Once cleared from the port, the next stage is the 1,500-kilometer overland journey to Bangui. This corridor is the project’s lifeline, and understanding its characteristics is crucial for realistic planning.

Key Transportation Factors:

- Transit Time: Under optimal conditions, the truck journey from Douala to Bangui takes approximately 7 to 10 days.

- Road Conditions: Road quality is inconsistent. While some sections are paved, others are not, which significantly slows travel and increases the risk of damage to sensitive cargo. Transporting delicate solar manufacturing equipment requires specialized packing and handling.

- Seasonal Impact: The rainy season, typically from May to October, can severely disrupt transportation. Unpaved roads may become impassable, causing delays that can last for weeks. Project timelines must account for this potential disruption.

- Security: Certain segments of the route pose security risks. Arranging for security escorts is standard practice, adding another layer of complexity and cost to the logistics plan.

Careful coordination is essential for the reliable delivery of both heavy machinery and a continuous supply of raw materials for solar panels.

Mastering Customs and Tariffs

Navigating the customs process efficiently is critical to avoiding costly delays. The Central African Republic is a member of the Economic and Monetary Community of Central Africa (CEMAC), which simplifies the tariff structure.

Applicable Duties and Taxes:

- Common External Tariff (CET): For solar manufacturing, the key CET rates are generally favorable.

- Capital Goods (Machinery): 5%.

- Raw Materials: 0%.

- Value Added Tax (VAT): A standard VAT of 19% is applied to the CIF (Cost, Insurance, and Freight) value of the imported goods, plus the customs duty.

While the tariff structure is straightforward, the documentation process is anything but. Paperwork must be precise and error-free, as any discrepancy can lead to goods being held at the border for extended periods. All imports also require an Autorisation Spéciale d’Importation (ASI), which must be secured in advance.

Engaging a reputable local customs broker is therefore not just recommended—it is essential for smooth clearance. These costs must be factored into the overall financial plan for a solar factory.

On-Site Preparedness in Bangui

The final logistical challenge lies within Bangui itself. Local infrastructure, including warehousing and stable power, is often limited. A successful project plan must include provisions for:

- Secure, On-Site Storage: The factory site must be designed with adequate, secure warehousing to store both equipment upon arrival and raw materials for ongoing production. Relying on third-party storage facilities may not be a viable long-term solution.

- Independent Power Generation: With an unreliable power grid, planning for on-site power generation (often a combination of diesel generators and a captive solar array) is an essential part of a robust operational plan.

Experience from J.v.G. turnkey projects demonstrates the critical importance of integrating these infrastructure considerations from the earliest planning stages. A comprehensive approach, like that of a turnkey solar factory solution, anticipates these challenges and incorporates them directly into the factory design.

Frequently Asked Questions (FAQ)

Q: Are there alternative ports to Douala?

A: While other ports like Pointe-Noire in the Republic of Congo or Port Sudan exist, the overland infrastructure connecting them to the CAR is significantly less developed and often less secure than the Douala-Bangui corridor. For these reasons, Douala remains the most practical, albeit imperfect, choice for commercial freight.

Q: How much buffer time should be planned for shipping and inland transport?

A: A conservative approach is prudent. For initial project planning, it’s wise to add a buffer of at least 30 to 45 days to standard shipping and transit estimates to absorb potential delays at the port, on the road, or at customs.

Q: What is the single biggest logistical mistake to avoid?

A: Underestimating the importance of documentation is the most common and costly error. Incomplete, inaccurate, or late submission of paperwork (including the bill of lading, commercial invoice, packing list, and ASI) is the primary cause of customs delays and demurrage charges.

Q: How significant are logistics costs in the overall project budget?

A: Logistics can represent a substantial portion of the initial capital expenditure, especially for a landlocked location. Freight, insurance, customs duties, port fees, inland transport, and security can collectively add a significant percentage to the cost of equipment and materials. These costs must be meticulously budgeted from the outset.

Next Steps in Your Planning Journey

Understanding the logistical pathway is fundamental to developing a viable business plan for a solar factory in the Central African Republic. The challenges are significant, but they are manageable with thorough planning, experienced partners, and a realistic timeline. Addressing these factors early on allows an investor to build a resilient supply chain—the foundation of a successful and impactful manufacturing operation.