An entrepreneur has a comprehensive business plan for a new solar module factory in N’Djamena. The market analysis is positive, the production technology has been selected, and the financial models are sound. Yet, the project’s success or failure hinges on a single question: how will critical raw materials—solar cells from Asia, glass from Europe, and aluminum frames from the Middle East—reach a factory in the heart of Africa, reliably and cost-effectively?

Logistics is a critical function for any manufacturer. For a factory in a landlocked nation like Chad, however, it becomes a core strategic challenge. Here, we break down the logistical pathways, customs procedures, and practical hurdles of supplying a solar factory in Chad, focusing on the primary shipping corridor through the port of Douala, Cameroon.

Table of Contents

The Landlocked Challenge: Why Logistics is a Core Business Strategy

Unlike facilities with direct seaport access, factories in landlocked countries depend on a multi-stage, multi-jurisdiction supply chain. Each leg of the journey introduces potential costs, delays, and risks that must be managed proactively. The voyage for raw materials doesn’t end when a container ship docks; often, it’s not even halfway complete.

Chad’s economy relies heavily on transit corridors through its neighbors, with the route from the port of Douala in Cameroon being the most critical. This dependence means the factory’s supply chain is vulnerable to the infrastructure, regulations, and stability of another nation.

A successful logistics strategy is as crucial to the business’s viability as the efficiency of its production line. Failing to plan for this reality can lead to production stoppages, budget overruns, and an inability to meet market demand.

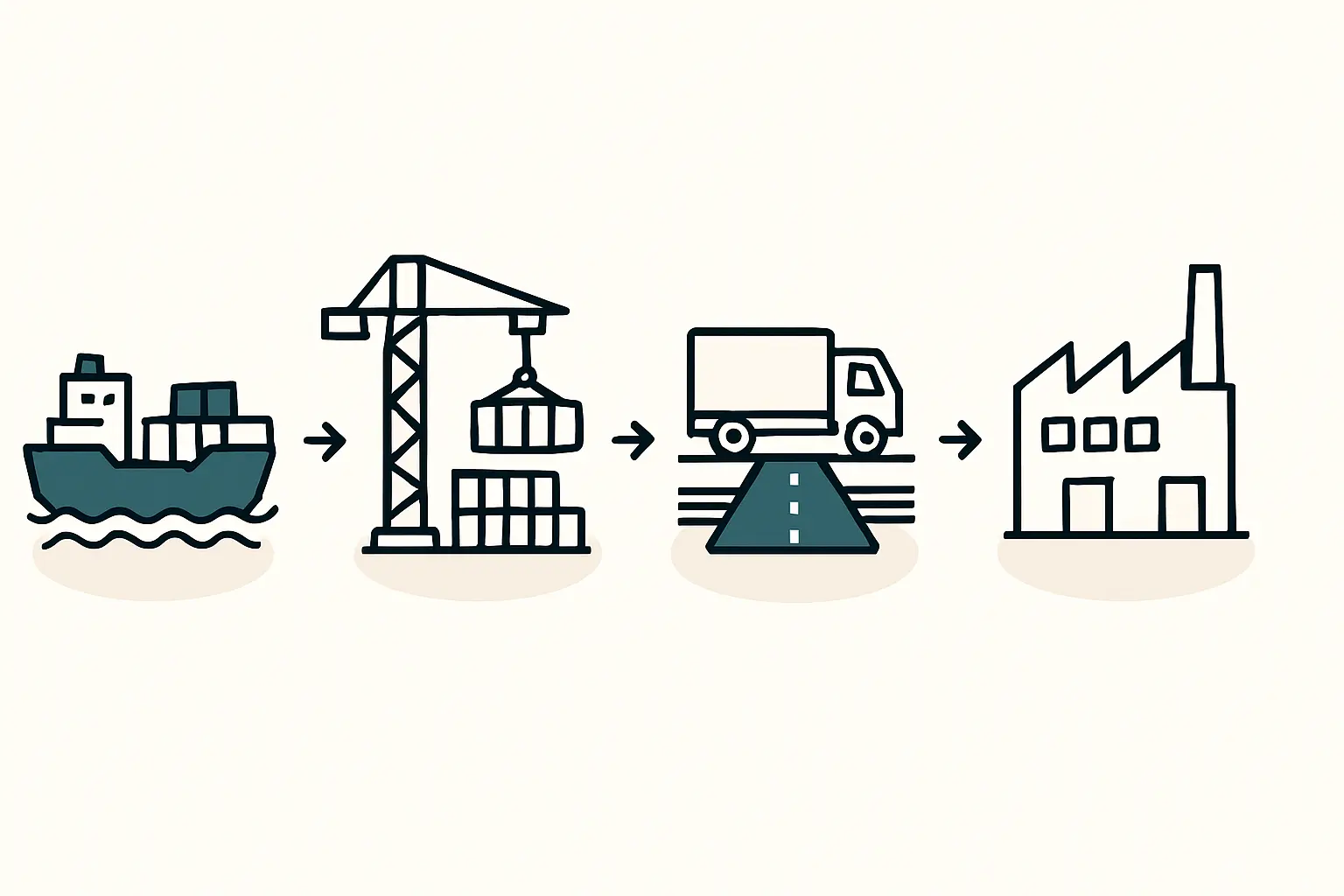

Mapping the Primary Supply Route: From Global Supplier to N’Djamena

Getting a container of solar cells or glass from its origin to a factory in N’Djamena is a complex process. Understanding each step of this journey is essential for accurate planning and risk mitigation.

Step 1: Ocean Freight to the Port of Douala, Cameroon

The journey begins with ocean freight from major suppliers of solar raw materials, typically located in Asia and Europe. A 40-foot container, loaded with carefully packaged components, is shipped to the Port of Douala. As the main gateway for goods destined for Chad and the Central African Republic, the port handles a significant volume of cargo, which can lead to congestion.

Step 2: Port Operations and Customs in Douala

Once the vessel arrives, the container is offloaded, and the most complex phase of the transit journey begins. This involves:

- Customs Clearance: The goods are not being imported into Cameroon but are in transit to Chad. This requires a specific customs procedure, often known as a T1 transit document, which allows cargo to move through Cameroon under bond without paying local duties.

- Engaging a Freight Forwarder: A reliable, experienced freight forwarder with a strong presence in both Douala and N’Djamena is indispensable. This partner handles all aspects of freight forwarding to Chad, managing port-side operations, documentation, and coordination for the overland transport.

- Potential Delays: New investors commonly underestimate the time required at this stage. Port congestion, bureaucratic processes, and random inspections often mean a container spends anywhere from one to three weeks in Douala before it begins its journey inland.

Step 3: The Overland Corridor – Douala to N’Djamena

The next leg is the roughly 1,500-kilometer journey by truck from Douala to N’Djamena. This vital economic corridor presents its own set of challenges:

- Road Conditions: The quality of the road network can vary, impacting travel times and increasing the risk of damage to sensitive cargo if not properly secured.

- Seasonal Factors: During the rainy season (typically May to October), parts of the route can become difficult to traverse, leading to significant delays.

- Border Crossing: The process of crossing the border from Cameroon into Chad at Kousséri/N’Djamena involves further inspections and document checks.

Calculating transit time based on distance alone is a common oversight. A realistic plan must account for all these variables. While the drive could theoretically take a few days, a prudent estimate for the entire overland journey—including wait times and border formalities—is between 10 and 20 days. Factoring these variable transit times into the business plan is essential for maintaining production schedules.

Step 4: Final Customs and Delivery in Chad

Upon arrival in N’Djamena, the shipment undergoes final customs clearance for import into Chad, where all duties and taxes are paid. Once all paperwork is in order, the container can finally be delivered to the factory, completing its long journey.

Key Raw Materials and Their Logistical Considerations

The various components of a solar module have unique handling requirements, each adding another layer of logistical complexity.

Solar Glass

Solar glass is heavy, bulky, and fragile. It requires specialized wooden crating to prevent breakage during the rough overland transit. The weight of the glass also limits how much can be loaded into a single container, impacting per-unit shipping costs. A standard 40-foot container might hold enough tempered glass for approximately 800 to 1,000 solar modules.

Solar Cells

As the most delicate and high-value component, solar cells are paper-thin and extremely susceptible to micro-cracks from shock or vibration. They must be shipped in specialized, shock-absorbent packaging to prevent significant financial losses. The quality of these cells directly impacts the final product’s efficiency and bankability—a critical factor when commissioning a turnkey solar manufacturing line.

Aluminum Frames and Backsheets

While less fragile, these components are still prone to cosmetic damage like scratches and bending if not packed and secured correctly. Their bulkiness also means that maximizing container space is key to managing costs.

Mitigating Risks: Strategies for a Resilient Supply Chain

A proactive approach to logistics management is crucial for success. Key strategies include:

- Partner with Experienced Freight Forwarders: Avoid selecting a logistics partner on price alone. An established forwarder with proven experience on the Douala-N’Djamena corridor is a critical asset, possessing the local knowledge and relationships to navigate bureaucratic hurdles efficiently.

- Maintain a Buffer Stock: Given the high variability of shipping times, a factory cannot operate on a just-in-time inventory model. A buffer stock of two to three months’ worth of key raw materials is a prudent strategy to ensure continuous production.

- Secure Comprehensive Insurance: Your cargo insurance policy must provide “warehouse-to-warehouse” coverage, as standard ocean freight insurance may not cover losses or damage occurring during the overland portion of the journey.

- Ensure Documentation Accuracy: A single error on a bill of lading, commercial invoice, or certificate of origin can hold a shipment at port or the border for weeks. Meticulous attention to paperwork is non-negotiable. Experience from J.v.G. Technology GmbH turnkey projects shows that documentation issues are one of the most common and avoidable causes of costly delays.

Frequently Asked Questions (FAQ)

Q: What is the typical lead time for materials from Asia to a factory in N’Djamena?

A: Including production time, ocean freight, port clearance in Douala, and overland transport, a realistic estimate is between 60 and 90 days. To be safe, it’s advisable to plan for 90 days.

Q: Are there alternative ports to Douala for Chad?

A: While other routes exist, such as through Port Sudan or ports in Nigeria, the Douala corridor is the most established and utilized commercial route for N’Djamena. These alternatives present their own distinct logistical and geopolitical challenges.

Q: How much do logistics add to the final cost of raw materials?

A: As a general guideline, the total cost of logistics—from ocean freight and insurance to port fees and inland transport—can add 15% to 25% to the raw materials’ initial Free on Board (FOB) price. This landlocked premium must be accurately factored into financial projections.

Q: Can raw materials be sourced regionally in Africa?

A: Enhancing local content and shortening the supply chain is a common objective. While components like aluminum extrusions or packaging might be sourced from regional hubs, high-technology items like solar cells and specialized solar glass will, for the foreseeable future, come from a concentrated group of global manufacturers in Asia and Europe.

From Logistical Planning to Operational Reality

The logistical journey to a factory in N’Djamena clearly illustrates that for a landlocked manufacturer, supply chain management isn’t a support function—it’s a central pillar of the operation. The challenges are significant but manageable with diligent planning, strategic partnerships, and a realistic grasp of the local context.

You don’t need to be an expert in Chadian customs or Cameroonian port procedures to succeed. Success hinges on basing the business plan on expert guidance and working with reliable local partners who navigate these complexities daily. Understanding these supply chain dynamics is fundamental to building a successful solar panel production business.