The journey of a solar panel production line doesn’t end at the supplier’s factory gate. For an entrepreneur establishing a new solar manufacturing facility in Chile, it’s just the beginning of a complex logistical process.

Imagine two dozen 40-foot containers arriving at the Port of Valparaíso. They hold the future of a new business—laminators, stringers, testers, and conveyors. Yet, between the port and the prepared factory floor lie customs declarations, long-haul transportation, and the unique geographical challenges of one of the world’s most promising solar markets.

Navigating this phase successfully isn’t a matter of luck—it’s the result of meticulous planning. This guide details the critical logistical stages, regulatory requirements, and practical considerations for importing a complete solar module production line into Chile. It provides a foundational understanding for investors, helping ensure their equipment arrives safely, on time, and in full compliance with local laws.

Table of Contents

Why Chile? The Logistical Context

Chile’s strategic appeal for solar manufacturing is undeniable. The Atacama Desert boasts some of the highest and most consistent solar irradiation levels on the planet, making it an ideal location for solar energy generation and, consequently, manufacturing. The country’s stable political and economic framework, coupled with strong government support for renewable energy, further cements its appeal.

However, these advantages come with distinct logistical realities:

- Geographical Span: Chile is over 4,200 kilometers long but averages just 177 kilometers in width, flanked by the Andes Mountains and the Pacific Ocean. This unique geography means inland transportation from major ports to factory sites, especially in the northern regions, can be extensive.

- Port Concentration: While Chile has numerous ports, the primary hubs for containerized cargo are Valparaíso and San Antonio in the central region. Projects in the north may use ports like Antofagasta or Iquique, which require specific logistical coordination.

- Regulatory Precision: Chilean customs authorities (Servicio Nacional de Aduanas) are known for their efficiency and strict adherence to regulations. Importers must ensure flawless documentation and procedural compliance.

Understanding these factors is the first step in developing a robust logistics and supply chain strategy.

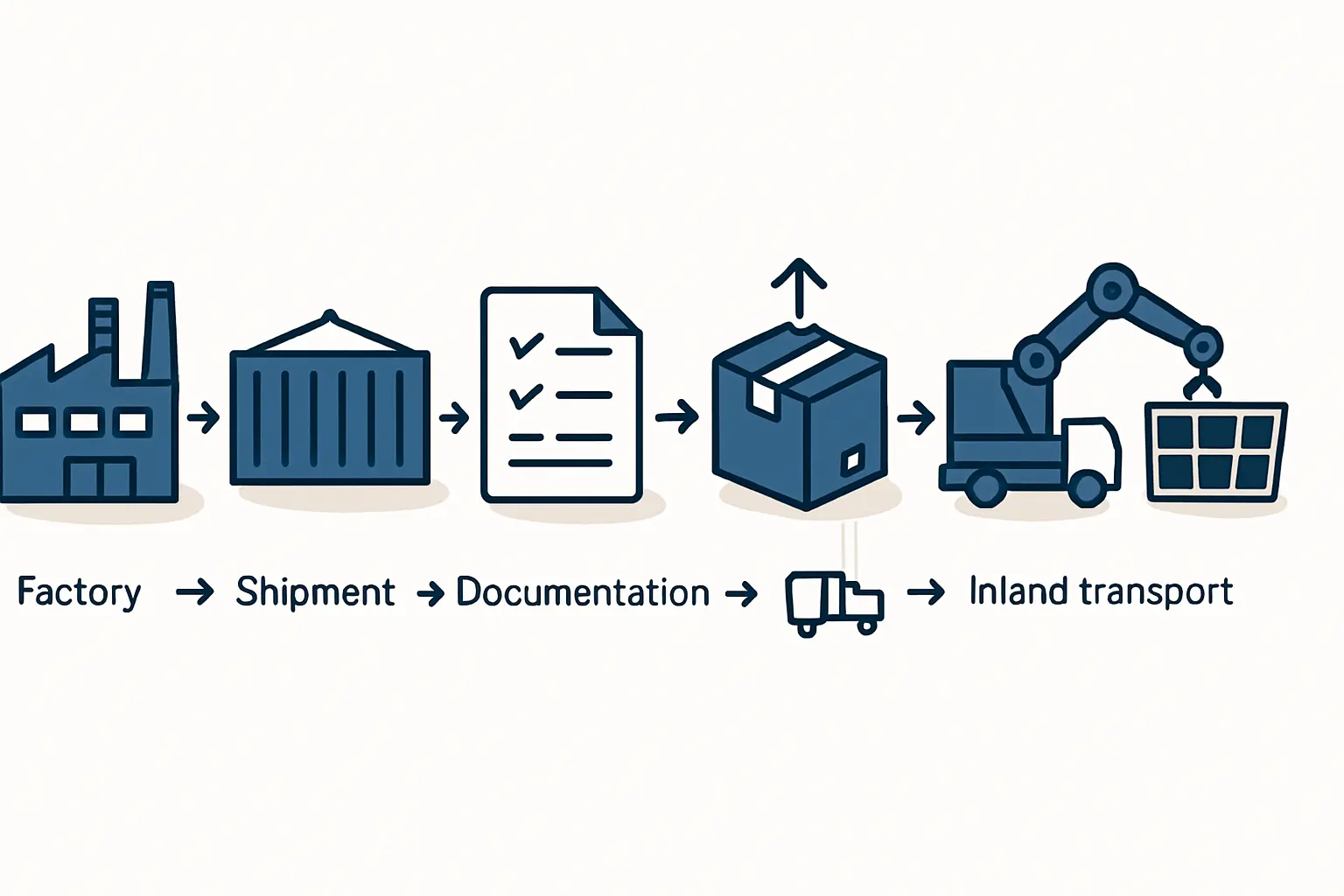

The Three Core Stages of Equipment Importation

Importing manufacturing equipment involves three distinct phases, each with its own partners, documentation, and potential bottlenecks.

Stage 1: Maritime Shipping and Documentation

The process begins long before the vessel leaves its port of origin. Proper preparation at this stage is crucial for preventing significant delays and costs down the line.

Freight and Container Planning: A typical 20-50 MW solar production line may require 15 to 30 shipping containers. While most equipment fits into standard containers, larger or more sensitive machines, such as the laminator, might require open-top or flat-rack containers and specialized handling.

Essential Documentation: Before shipment, the supplier must prepare a comprehensive set of documents. The key items include:

- Commercial Invoice: Details the value of all equipment.

- Packing List: An itemized list of the contents in each container, crucial for customs verification.

- Bill of Lading (B/L): The contract between the equipment owner and the shipping company, which serves as a receipt and title document.

Insurance: Given the high value of the machinery, comprehensive cargo insurance covering transport from the supplier’s factory to the final destination in Chile is non-negotiable.

Properly classifying and documenting the contents of each container is critical for a smooth customs process.

Stage 2: Navigating Chilean Customs Clearance

Upon arrival at a Chilean port, the equipment enters the jurisdiction of the Servicio Nacional de Aduanas. This is arguably the most critical phase, where administrative precision is paramount.

The Role of a Customs Broker: Foreign entities cannot directly handle customs declarations in Chile; they must engage a licensed Chilean Customs Broker (Agente de Aduana). This local expert is responsible for preparing and submitting the Import Declaration (Declaración de Ingreso – DIN), classifying goods according to the Harmonized System (HS) tariff codes, and ensuring compliance with all regulations.

Duties and Taxes: The standard Value Added Tax (VAT, or IVA in Spanish) in Chile is 19%, calculated on the CIF (Cost, Insurance, and Freight) value of the goods. Chile has an extensive network of Free Trade Agreements (FTAs) with major economic blocs, including the EU, the USA, and China. Working with a customs broker well in advance to secure a Certificate of Origin is key to gaining preferential tariff treatment, which can reduce or even eliminate certain import duties.

Inspection and Verification: Chilean customs may select a shipment for physical or documentary inspection. Any discrepancy between the packing list, the commercial invoice, and the actual contents can lead to significant delays and penalties. Experience from J.v.G. turnkey projects shows that meticulous cross-checking of all documentation with the equipment supplier is a critical risk-mitigation step.

Stage 3: Inland Transportation to the Factory Site

Once customs clearance is granted, the final leg of the journey begins: moving the equipment from the port to the factory. This phase brings its own set of challenges, particularly for projects located in remote areas.

Route Planning: The journey from a port like Valparaíso to a site in the Atacama region can cover over 1,000 kilometers of roads that traverse mountainous and arid terrain. A detailed route survey is essential to assess road suitability, bridge weight limits, and overhead clearances, especially for oversized loads.

Specialized Transport: Heavy machinery requires specialized low-bed trucks and experienced operators. Coordinating a convoy of vehicles for a complete production line demands a professional logistics partner with proven experience in industrial project cargo within Chile.

Site Coordination: The arrival of the machinery must be synchronized with factory site preparations. The building must be complete, foundations for heavy machinery prepared, and unloading equipment like cranes and heavy-duty forklifts must be on-site and ready. Any mismatch in timing can lead to costly standby charges for transportation and installation crews.

Frequently Asked Questions (FAQ)

Q: Is it necessary to hire a local logistics partner in Chile?

A: Yes, it’s indispensable. A local partner fulfills two critical roles: they act as a licensed customs broker for legal import processing and as a freight forwarder with deep knowledge of local road networks, permits, and transport capabilities.

Q: How long does the entire import process take, from port arrival to factory delivery?

A: With proper documentation and a pre-vetted customs broker, clearance itself can take 5-10 business days. However, it’s wise to budget for 2-4 weeks to account for potential inspections or port congestion. The inland transport time depends entirely on the distance to the factory site.

Q: Are there language barriers to consider?

A: All official customs documents and communication with government agencies are in Spanish. While international logistics partners often have English-speaking staff, the customs broker operates primarily in Spanish, underscoring their essential role as an intermediary.

Q: What is the most common cause of delays when importing into Chile?

A: Inaccurate or incomplete documentation is the leading cause of delays. Discrepancies between the declared value and the commercial invoice, or a mismatch between the packing list and a container’s contents, will immediately trigger a customs review.

Q: How does a turnkey provider support this process?

A: A turnkey solutions provider, such as J.v.G. Technology GmbH, typically manages the entire logistical chain as part of the project scope. This includes coordinating with shipping lines, preparing export documentation, engaging and managing the customs broker in Chile, and overseeing the inland transport to the final factory location. This integrated approach significantly reduces the logistical burden for the investor.

Conclusion: Planning as the Key to Success

Importing a solar manufacturing line into Chile is a complex yet manageable undertaking. While the country’s favorable conditions for solar energy are a major draw, they are matched by a structured and professional customs regime. Success hinges not on navigating every detail personally, but on foresight, meticulous planning, and the selection of experienced local partners.

By understanding the three core stages—maritime shipping, customs clearance, and inland transport—investors can systematically prepare for every requirement. A well-executed logistics plan ensures that the high-value assets of your new venture arrive safely and efficiently, ready for installation. This allows entrepreneurs to focus on larger strategic goals, confident that the physical foundation of their factory is in expert hands.