A container of high-efficiency solar cells leaves a port in Shanghai, destined for a new solar module factory in Colombia. On paper, the journey seems straightforward. Yet, a single decision made before the ship departs—which Colombian port to use—can alter the project’s timeline, budget, and overall profitability by millions of dollars.

For an entrepreneur entering the solar industry, this logistical choice is one of the most critical, yet frequently underestimated, aspects of setting up a manufacturing operation.

This article explores the logistics of Colombia’s two primary maritime gateways: the Port of Cartagena on the Caribbean coast and the Port of Buenaventura on the Pacific. Understanding their distinct advantages and challenges is key to building a resilient and cost-effective supply chain for your solar factory.

Table of Contents

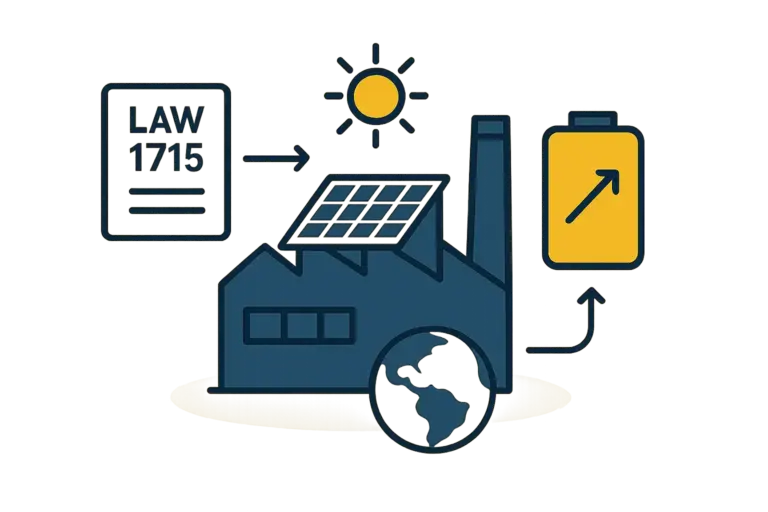

The Strategic Importance of Port Selection

Choosing a port is more than a simple logistical detail; it’s the cornerstone of your entire inbound logistics strategy. This choice directly impacts lead times, inland transportation costs, inventory levels, and exposure to potential disruptions.

A well-planned port strategy ensures a smooth flow of critical raw materials like solar cells, EVA film, glass, and aluminum frames. A miscalculation, however, can lead to costly delays, production stoppages, and unforeseen expenses that erode your margins.

An efficient port is a crucial link in a successful supply chain, acting as the predictable entry point for all essential components. The reliability of this link dictates the operational rhythm of the entire manufacturing plant.

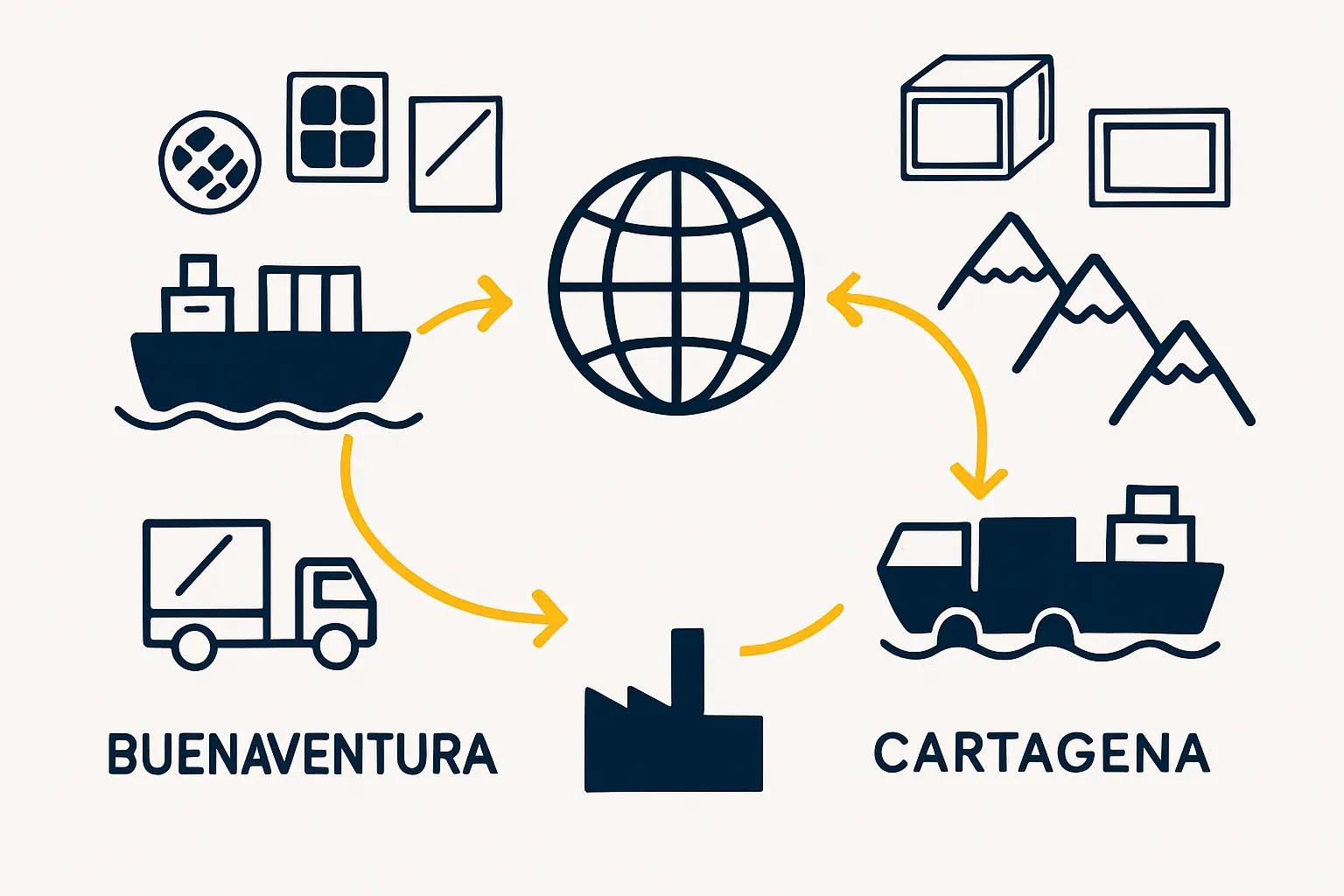

A Tale of Two Coasts: Cartagena (Caribbean) vs. Buenaventura (Pacific)

Colombia’s unique geography, with coastlines on both the Atlantic (via the Caribbean Sea) and Pacific Oceans, offers two distinct logistical pathways. Each serves a different strategic purpose depending on the origin of your goods and your factory’s final location.

Port of Cartagena: The Caribbean Gateway

Located on the northern coast, the Port of Cartagena is one of Latin America’s most efficient and modern maritime hubs. It serves as a major transshipment center, connecting Colombia with key markets in North America and Europe.

Key Advantages:

- Advanced Infrastructure: Cartagena’s container terminals are known for their high efficiency, modern equipment, and streamlined customs processes, leading to faster vessel turnaround times and a reduced risk of port delays and demurrage charges.

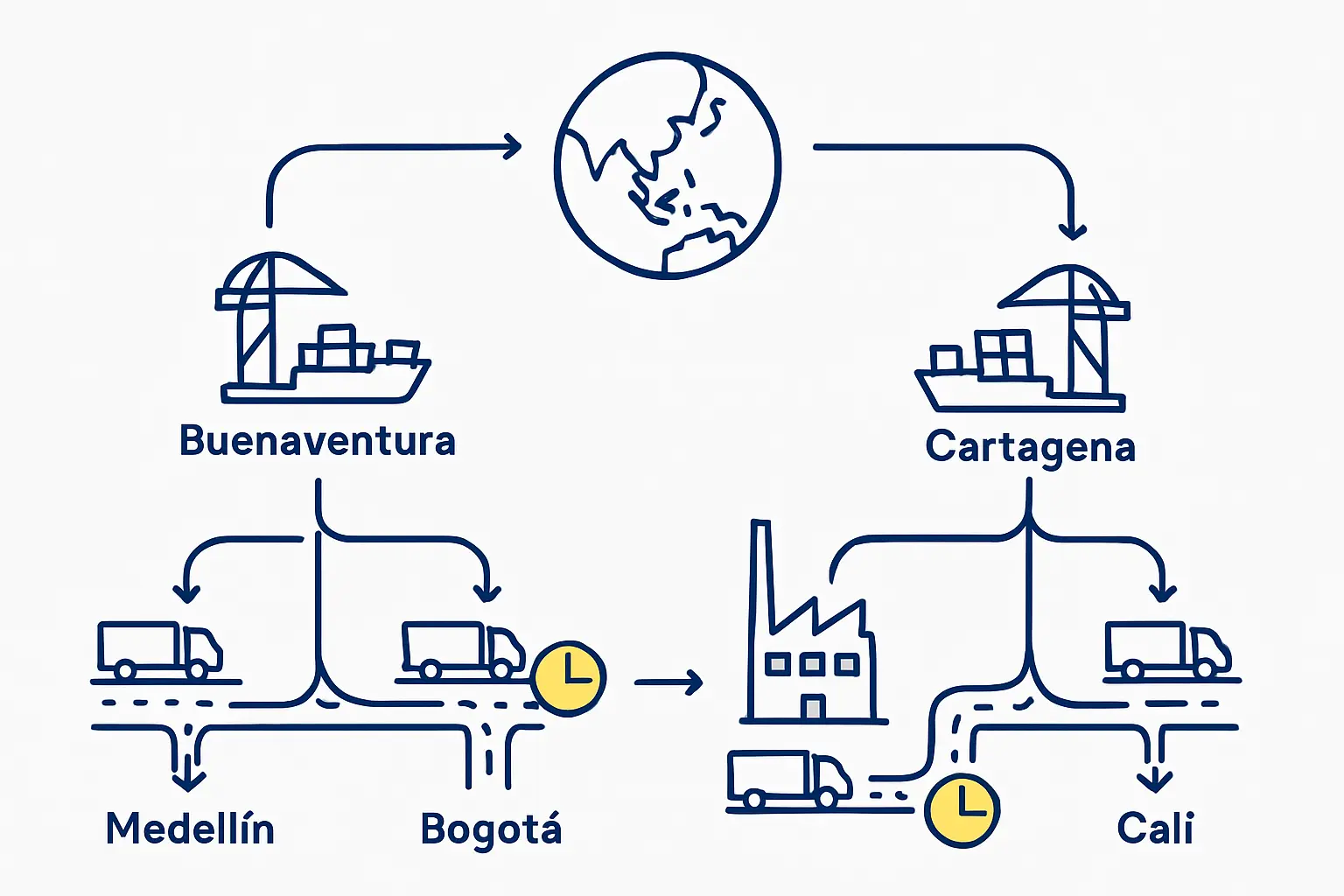

- Superior Inland Connectivity: The port is well-connected to Colombia’s main economic centers—including Bogotá, Medellín, and Barranquilla—via a well-maintained road network. These primary routes are less susceptible to the severe weather-related disruptions that can plague other regions.

- Proximity to Atlantic Trade Routes: For materials sourced from Europe or the East Coast of the United States, Cartagena is the logical and most cost-effective entry point.

Considerations for Solar Manufacturing:

For a factory located near Bogotá or in the northern half of the country, Cartagena is often the most reliable and predictable option. While sea freight from Asia may take longer and cost slightly more than shipping to a Pacific port, its efficiency and reliable inland transport often result in a lower and more stable “total landed cost.”

Based on experience from J.v.G. turnkey projects, this predictability is a vital asset during a factory’s initial ramp-up phase.

Port of Buenaventura: The Pacific Connection

As Colombia’s largest port on the Pacific coast, Buenaventura is the most direct maritime link to Asia—the primary source of solar cells and many other photovoltaic components.

Key Advantages:

- Direct Access to Asian Markets: Shipping routes from China, South Korea, and Southeast Asia to Buenaventura are shorter and typically less expensive than those to Cartagena, which can represent significant initial savings on freight costs.

- Geographic Proximity to Western Colombia: For manufacturing facilities planned in or around the Cauca Valley, such as near Cali, Buenaventura is the undisputed geographical choice, drastically reducing inland travel distances.

Logistical and Infrastructural Challenges:

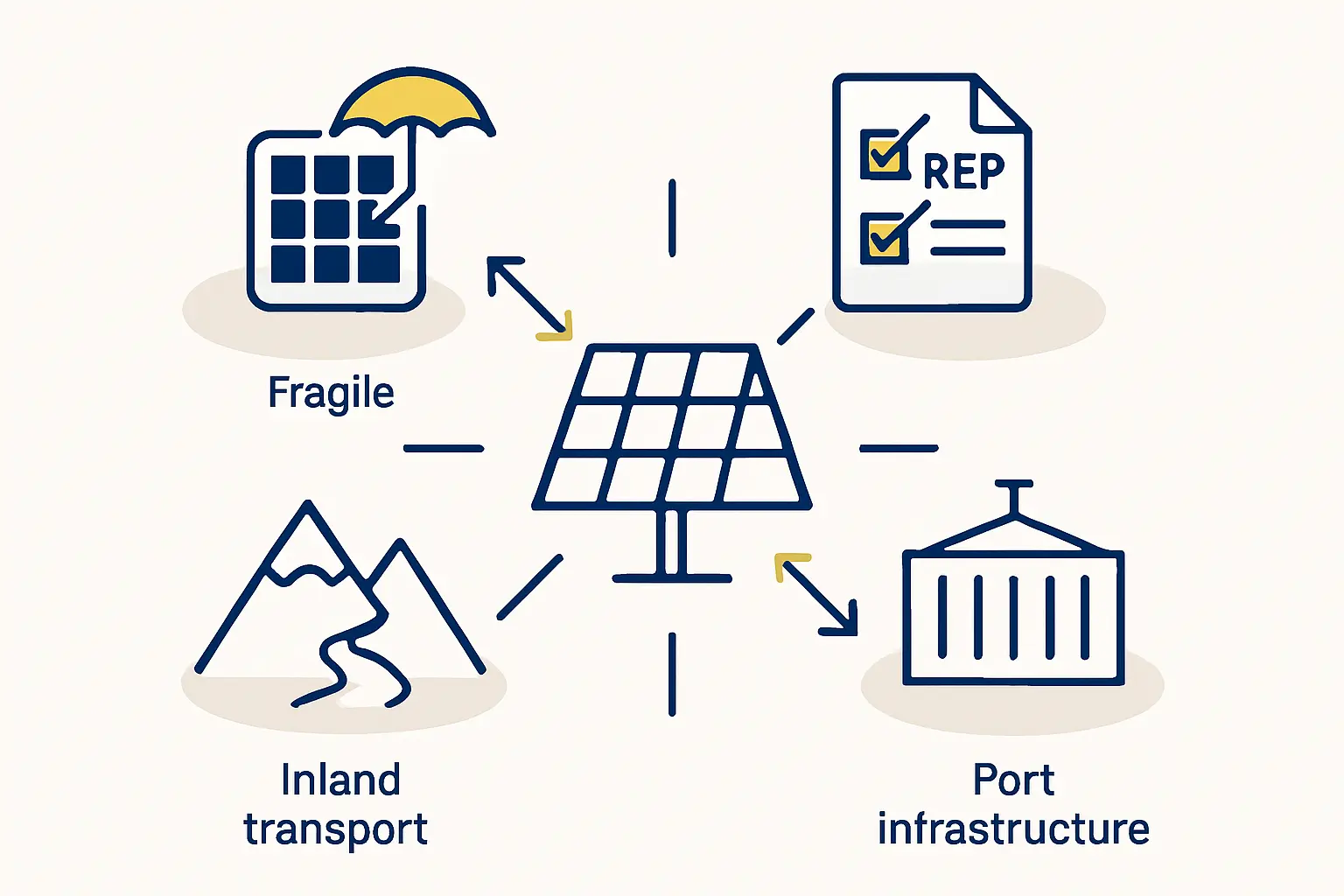

- Inland Transportation Hurdles: The primary challenge lies in moving goods from the port to the country’s interior. The road connecting Buenaventura to Cali and onward to Bogotá traverses the Andes mountains. This route is known for its difficult terrain, susceptibility to landslides during rainy seasons, and historical security concerns—factors that can lead to unpredictable delays and higher insurance and transport costs.

- Port Congestion: While improvements are ongoing, Buenaventura has historically faced greater challenges with port congestion and operational efficiency than Cartagena, potentially adding time and cost to customs clearance and offloading.

Considerations for Solar Manufacturing:

The allure of lower sea freight from Asia can be deceptive. These savings must be carefully weighed against the higher risks and costs of inland logistics. A delay of several weeks due to a road closure can halt production entirely, making the initial freight savings insignificant compared to the operational losses.

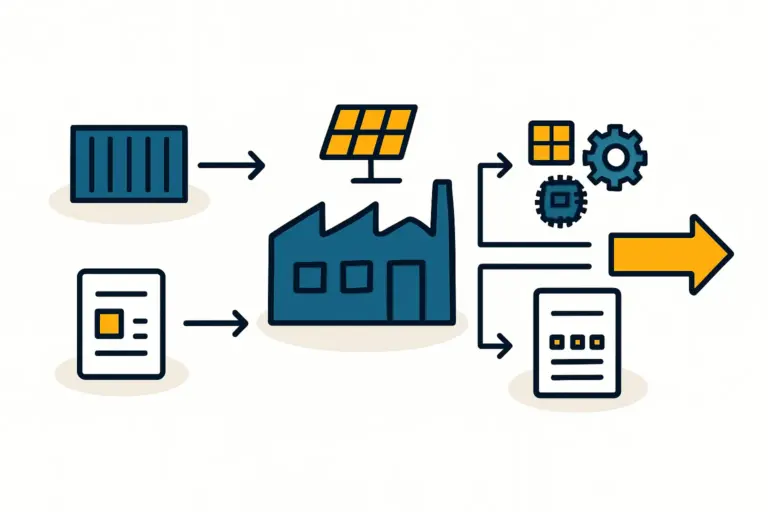

The Financial Equation: Total Landed Cost Analysis

Newcomers often make the mistake of focusing solely on the “Cost, Insurance, and Freight” (CIF) price of imported goods. A more accurate measure is the Total Landed Cost, which includes:

- Sea Freight: The cost of ocean shipping.

- Port Charges: Fees for unloading, handling, and storage at the port.

- Customs & Tariffs: Duties and taxes levied on imported goods.

- Inland Transportation: The cost of trucking from the port to the factory.

- Insurance & Risk Premium: Higher costs associated with less reliable routes.

When comparing a shipment of solar cells to a factory in Bogotá, the analysis might look like this:

- Via Buenaventura: Lower sea freight cost, but potentially higher port charges, significantly higher inland transport costs, and a higher risk premium due to potential delays.

- Via Cartagena: Higher sea freight cost, but lower and more predictable port and inland transport costs, with a lower risk of delay.

For many projects in central Colombia, the total landed cost via Cartagena is often more competitive and, crucially, more stable. This stability is a key factor in managing the overall solar panel manufacturing cost and ensuring financial predictability.

Beyond the Ports: Factors Influencing Your Factory’s Location

The choice of port is directly tied to your factory’s planned location. While logistical access is paramount, other factors must also be considered:

- Proximity to Domestic Markets: Is the factory located near major population centers to reduce final product distribution costs?

- Availability of Skilled Labor: Is there a qualified workforce in the region?

- Energy and Utility Infrastructure: Does the location have reliable and affordable access to electricity and water?

These strategic factors must be evaluated in tandem. The optimal factory location balances inbound logistics from the port with operational costs and outbound logistics to the end customer. This holistic evaluation is a critical part of a solid solar module manufacturing business plan.

Frequently Asked Questions (FAQ)

Q: Which port is generally faster for imports from Asia?

A: In terms of pure sea transit time, Buenaventura is faster. However, the total delivery time to a factory in central Colombia (e.g., Bogotá) is often shorter via Cartagena because of its superior port efficiency and more reliable inland road network.

Q: What are the main risks associated with the Buenaventura-Bogotá route?

A: The primary risks for container transport from Buenaventura to Bogotá are delays caused by landslides and road closures, especially during rainy seasons. The route also has historically higher security risks, which can increase insurance and transportation costs.

Q: How significant is the difference in inland transport costs?

A: The cost to transport a container from Buenaventura to Bogotá can be 30-50% higher, and more volatile, than from Cartagena. This difference stems from the difficult terrain, higher fuel consumption, and security considerations.

Q: Does the choice of port affect customs clearance?

A: Both ports have established customs procedures. However, Cartagena is known for more streamlined and efficient processes, which can lead to faster clearance times and fewer bureaucratic hurdles compared to the occasional congestion and delays reported at Buenaventura.

Conclusion: Making an Informed Logistical Decision

The choice between Cartagena and Buenaventura is not a simple matter of picking the closest or cheapest port on a map. It’s a strategic decision that requires a detailed analysis of total landed costs, risk tolerance, and the specific location of your manufacturing facility.

For entrepreneurs aiming to establish a solar module factory in Colombia’s primary economic zones, Cartagena often provides a more stable, predictable, and ultimately cost-effective logistical foundation, despite potentially higher initial sea freight costs from Asia. The port’s efficiency and the reliability of its inland connections provide the operational certainty necessary to build a successful manufacturing business. Understanding these logistical nuances is a foundational step in transforming a business plan into a productive and profitable reality.