Discussions about establishing a solar module factory often center on market demand, investment capital, and technology. For an island nation like East Timor, however, a project’s viability often comes down to something more fundamental: the movement of goods.

An entrepreneur might have the finest production line and a ready market, but without a robust supply chain, both raw materials and finished products will go nowhere. The entire venture hinges on mastering logistics.

This guide breaks down the critical logistical framework for a solar manufacturing operation in East Timor, covering the port infrastructure, customs processes, and supply chain considerations that any serious investor must understand before committing to a project.

The Strategic Gateway: Dili’s Modern Port Infrastructure

For any manufacturer in East Timor, the primary logistical hub is the port. Until recently, Dili’s old port posed serious limitations for large-scale industrial operations. The development of the new Tibar Bay Port, however, marks a significant leap forward in the country’s logistical capacity.

Operated as a public-private partnership, Tibar Bay Port became fully operational in 2022 and now handles over 90% of the nation’s containerized cargo. For investors planning a solar manufacturing venture, the new port’s specifications are highly encouraging:

-

Enhanced Capacity: With a 630-meter quay and a 15-meter draft, the port can accommodate larger container vessels than ever before. This reduces reliance on smaller, less frequent feeder ships and helps lower freight costs.

-

Modern Equipment: The facility is equipped with two large Ship-to-Shore (STS) cranes and five Rubber-Tyred Gantry (RTG) cranes. This mechanization drastically improves the speed and efficiency of loading and unloading containers, minimizing costly port delays.

-

Future-Proof Design: The port’s initial capacity is around 350,000 TEUs (twenty-foot equivalent units) per year, with the potential to expand to 1 million TEUs. This scalability ensures the port can support the growth of new industries, including solar manufacturing.

This modern infrastructure is a foundational asset, signaling to international investors that East Timor is serious about facilitating trade and providing a reliable gateway for industrial goods.

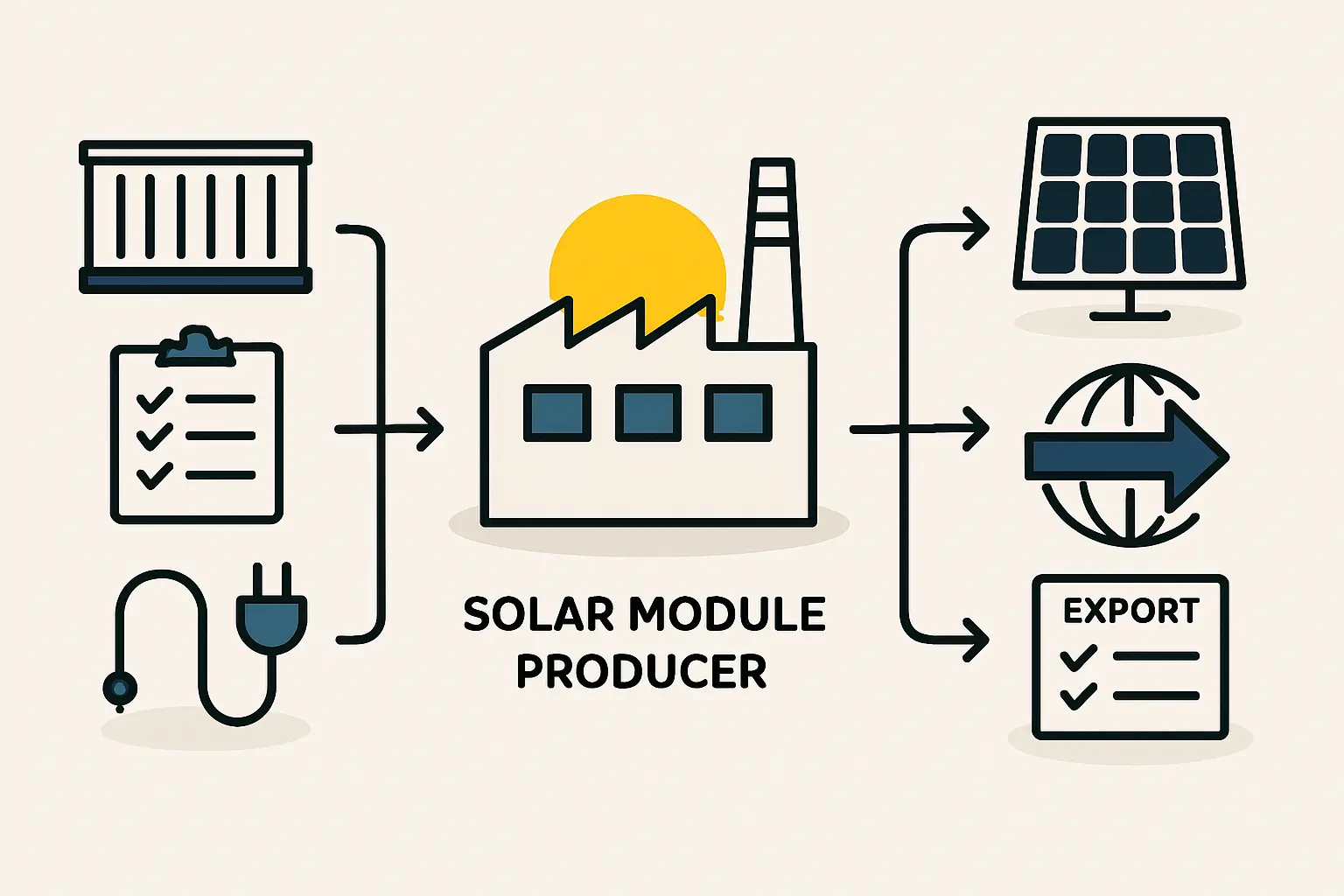

Managing the Flow: From Raw Materials to Finished Modules

A solar module factory depends on a continuous, two-way flow of materials: an inbound stream of components and an outbound stream of finished solar panels.

Inbound Logistics: Securing Raw Materials

A solar module assembly line relies on a steady supply of critical raw materials, all of which must be imported. These include:

- Solar cells

- Tempered solar glass

- EVA (ethylene vinyl acetate) encapsulant

- Backsheets

- Aluminum frames

- Junction boxes

These materials are primarily sourced from major manufacturing hubs in Asia, particularly China and Southeast Asia. The supply chain will therefore depend on shipping lanes connecting these regions to Dili, often transiting through major hubs like Singapore, Darwin (Australia), or Surabaya (Indonesia). Investors must factor in longer lead times and build an inventory strategy resilient enough to buffer against potential shipping delays.

Outbound Logistics: Reaching the Market

Once assembled, finished solar modules can be directed to the domestic market or exported.

-

Domestic Market: Supplying local projects addresses East Timor’s own energy needs and simplifies outbound logistics, requiring only transport by truck.

-

Export Markets: Key regional markets include northern Australia, Indonesia, and other Pacific Island nations. Accessing these markets requires the same diligent planning as importation, from container booking and export documentation to coordinating with international shipping lines.

The efficiency of both inbound and outbound logistics directly impacts production costs and, ultimately, profitability.

Demystifying Customs and Clearance in Timor-Leste

Once a container arrives at Tibar Bay Port, it must clear customs. The Autoridade Aduaneira (Customs Authority) of Timor-Leste manages this process using the ASYCUDA World system, a computerized customs management platform designed to standardize and expedite clearance procedures.

While the system is modern, successful clearance hinges on meticulous preparation. Every shipment needs precise documentation, including a bill of lading, commercial invoice, packing list, and certificate of origin. Any discrepancy can lead to inspections, fines, and significant delays that could halt a production line.

For this reason, engaging a reputable, licensed customs broker in Dili is not an option—it’s a necessity. A competent broker navigates the local regulatory environment, ensures all paperwork is compliant, and acts as the crucial intermediary between the business and the customs authority.

Investors should also investigate the potential benefits offered by Special Economic Zones (SEZs), such as the one in the Oé-Cusse enclave. Operating within an SEZ may provide customs duty exemptions and other fiscal incentives that can substantially improve a project’s financial model.

Key Considerations for a Robust Supply Chain Strategy

A successful logistics plan extends beyond the port and customs office; several other factors demand careful consideration.

Inland Transportation

Once a container leaves the port, its journey isn’t over. The quality of the road network between Tibar Bay and the proposed factory location is a critical factor. A detailed route survey is necessary to ensure the roads can accommodate heavy trucks carrying sensitive materials and specialized machinery.

Freight Costs and Lead Times

As an island nation, East Timor inherently faces higher freight costs and longer transit times than mainland locations with extensive land transport networks. These variables must be carefully calculated and built into the project’s operational budget and financial forecasts. Overlooking these costs is a common pitfall for new investors.

Inventory Management

Due to extended supply chains, a ‘just-in-time’ inventory model is often impractical. A solar factory in East Timor will need a larger buffer stock of raw materials to ensure production continuity during shipping delays. This requires more warehouse space and ties up more working capital—factors that must be accounted for in the initial business plan.

Based on experience from J.v.G. Technology turnkey projects in similar emerging markets, logistical analysis is one of the most critical components of a feasibility study. A common oversight is underestimating the ‘last mile’ costs and complexities of inland freight, which can inflate the final cost per module. The structured guidance available through platforms like pvknowhow.com emphasizes a thorough evaluation of these practical, on-the-ground challenges early in the planning process.

Frequently Asked Questions (FAQ)

What are the main shipping hubs connecting to East Timor?

The primary transshipment hubs for cargo destined for Dili are Singapore, Darwin (Australia), and Surabaya (Indonesia). Most international freight is routed through one of these ports.

How long does customs clearance typically take in Dili?

With all documentation correctly prepared and submitted in advance by a professional customs broker, clearance can be relatively efficient, often within a few days. However, delays can extend to weeks if there are documentation errors or if a physical inspection is required.

Is it better to import all materials or source some locally?

Initially, nearly all specialized components for solar module manufacturing must be imported. Over time, as the local industrial ecosystem develops, it may become feasible to source ancillary items like packaging materials (cardboard boxes, pallets) locally, but this should be viewed as a long-term opportunity.

What is the difference between a freight forwarder and a customs broker?

A freight forwarder is a logistics agent who organizes the shipment of goods from the supplier’s factory to the destination port. A customs broker is a licensed specialist who handles the legal and regulatory requirements to get those goods cleared through customs upon arrival. For a project in East Timor, a business will need both.

Conclusion: Building a Resilient Logistical Foundation

Establishing a solar manufacturing facility in East Timor is a venture with considerable potential. The nation’s new, world-class port infrastructure at Tibar Bay provides a solid foundation for industrial development. Realizing this potential, however, requires a mastery of logistics that goes far beyond sea freight.

Success depends on a comprehensive strategy that accounts for the nuances of customs clearance, the realities of inland transport, and a prudent approach to inventory management. For entrepreneurs and investors, treating logistics not as an afterthought but as a core pillar of the business plan is the key to building a successful and profitable enterprise in this promising new market.