Establishing a solar module factory involves major strategic choices, from technology and scale to location. But one frequently underestimated factor—the choice of an import port—can significantly impact operational efficiency and profitability.

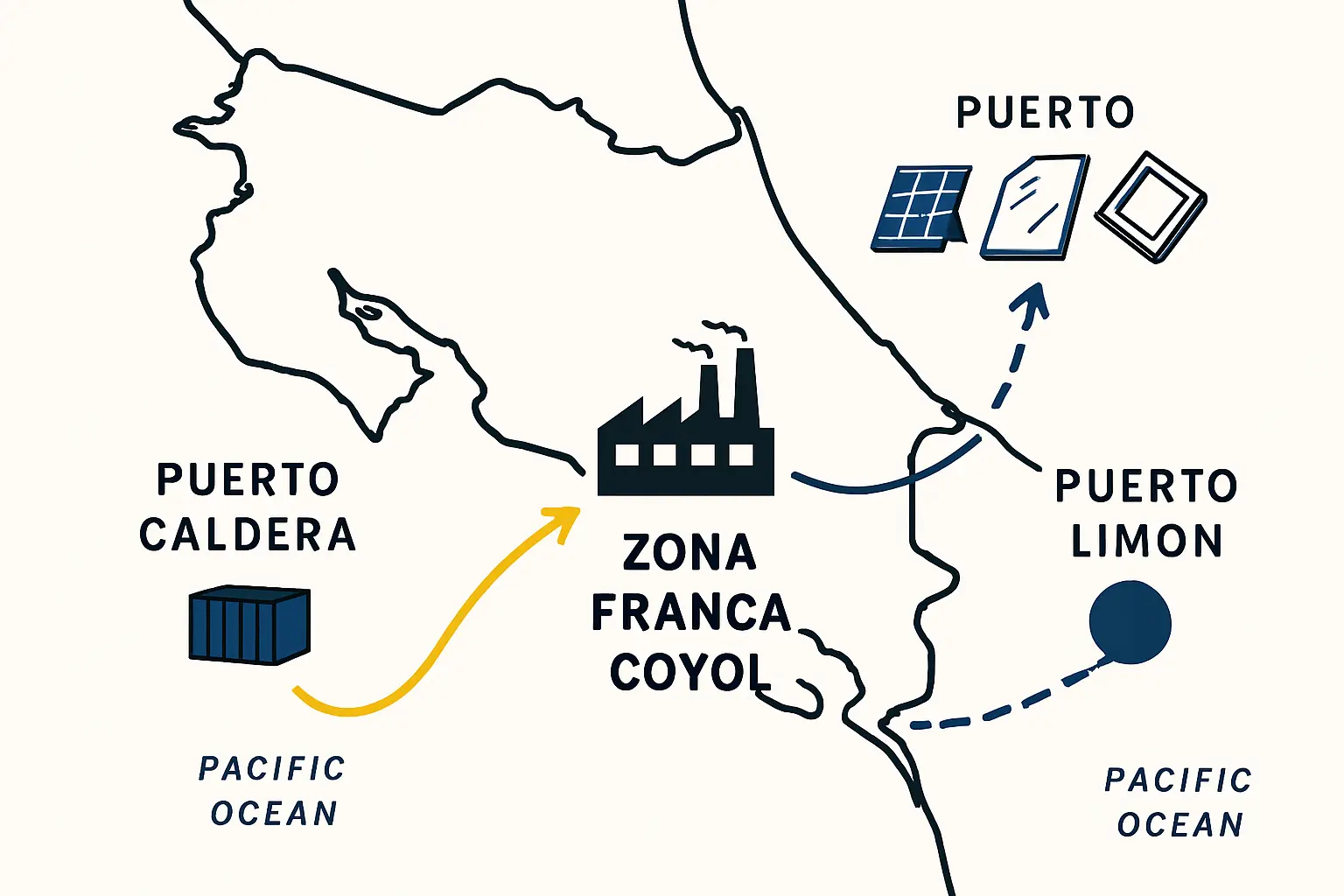

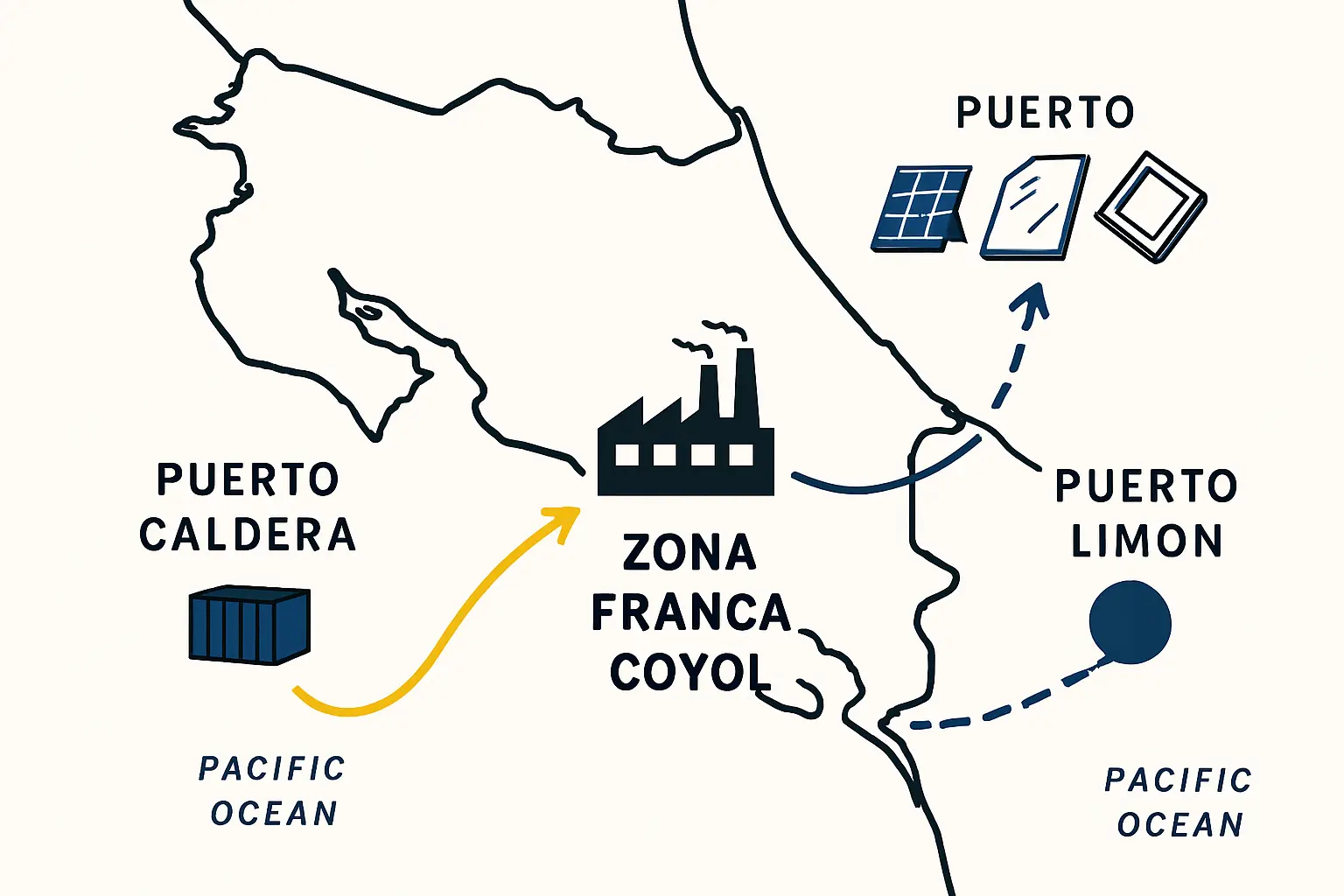

For a manufacturing venture in Costa Rica, selecting between the Caribbean port of Limón and the Pacific port of Caldera isn’t just a geographical preference. It’s a critical business decision with far-reaching consequences for the entire supply chain.

This analysis compares Costa Rica’s two primary maritime gateways, focusing on the import of solar manufacturing components. It examines the key factors an investor must consider—from ocean trade routes and port infrastructure to the reliability of inland transportation—to ensure a smooth, cost-effective flow of materials to the factory floor.

The Strategic Importance of Port Selection in Solar Manufacturing

A solar module assembly operation relies on a consistent influx of specific components: solar cells, encapsulant films (EVA), backsheets, aluminum frames, and specialty glass. The geographic origins of these materials dictate the most logical shipping routes.

Key inputs like solar cells, EVA, and backsheets are predominantly manufactured in Asia.

In contrast, aluminum frames and high-transmissivity glass are often sourced from suppliers in North America or Europe.

This global sourcing map immediately presents a logistical challenge for a Costa Rican enterprise. The country’s two major ports serve different oceanic trade routes, making one more suitable for Asian cargo and the other for transatlantic shipments. The wrong choice can lead to longer transit times, higher costs, and, most critically, unpredictable delays that can halt production.

An Overview of Costa Rica’s Primary Maritime Gateways

Costa Rica’s strategic position grants it access to both the Pacific and Atlantic Oceans, served by Puerto Caldera and Puerto Limón, respectively. Most industrial and manufacturing activity, including potential sites for a solar factory, is concentrated in the country’s central valley, known as the Greater Metropolitan Area (GAM), which includes the capital, San José. The critical logistical challenge, therefore, isn’t just ocean transit but the vital inland journey from the port to the factory.

Deep Dive: Puerto Limón (APM Terminals, Moín)

Located on the Caribbean coast, Puerto Limón is Costa Rica’s largest port complex. The modern Moín Container Terminal (MCT), operated by APM Terminals since 2019, handles approximately 80% of the country’s containerized cargo.

Atlantic Gateway & Modern Infrastructure

As the nation’s gateway to the Atlantic, Limón is the natural entry point for goods shipped from Europe and the East Coast of the United States. Its state-of-the-art infrastructure can accommodate large Post-Panamax vessels, ensuring high efficiency and capacity for significant cargo volumes. For a solar manufacturer sourcing high-quality aluminum frames from Germany or specialized glass from the U.S., Limón offers the most direct and cost-effective sea route.

The Inland Challenge: Route 32

The primary obstacle for cargo arriving in Limón is the 160-kilometer inland journey to the GAM via National Route 32. This highway traverses mountainous, rainforest terrain and is notoriously susceptible to frequent closures from landslides, especially during the rainy season.

These aren’t minor inconveniences—closures can last for days, leaving trucks stranded and disrupting production schedules. The business impact of this unreliability is significant, potentially leading to:

- Production Stoppages: A factory can run out of essential components, forcing a costly shutdown.

- Demurrage and Detention Fees: Containers delayed at the port or with the shipping line incur substantial daily penalties.

- Increased Inventory Costs: To mitigate risk, a factory may need to hold a larger “safety stock” of components, tying up capital.

Deep Dive: Puerto Caldera (SPC)

Situated on the Pacific coast, Puerto Caldera is the main gateway for trade with Asia and the West Coast of the United States. While its infrastructure is older and has less capacity than Limón’s MCT, it offers a compelling alternative due to its geographical advantage for certain components and its more reliable inland connection.

Pacific Gateway & Asian Sourcing

For a solar manufacturer, the most critical and highest-value components—solar cells—are almost exclusively sourced from Asia. Caldera is the logical port of entry for these shipments, offering shorter and more direct ocean voyages from China, Taiwan, South Korea, and other regional producers.

The Inland Advantage: Route 27

The journey from Caldera to the GAM covers approximately 90 kilometers via National Route 27. This modern toll road is significantly more reliable and less prone to weather-related closures than Route 32. While toll fees add to the transport cost, the predictability and speed it offers are invaluable. This reliability is a key factor in the overall factory planning process, allowing for leaner inventory management and more precise production scheduling.

A Comparative Analysis for Solar Component Imports

The choice between Limón and Caldera requires a careful evaluation of a manufacturer’s specific sourcing strategy and risk tolerance. A direct comparison highlights the trade-offs:

Puerto Limón (Caribbean)

- Primary Trade Routes: Europe, US East Coast

- Ideal for Components: Aluminum Frames, Specialty Glass

- Port Infrastructure: Modern, high-capacity (MCT)

- Inland Route: Route 32 (160 km)

- Inland Reliability: Low (prone to landslides/closures)

- Primary Risk: Production delays from transport disruption

Puerto Caldera (Pacific)

- Primary Trade Routes: Asia, US West Coast

- Ideal for Components: Solar Cells, EVA, Backsheets

- Port Infrastructure: Older, smaller capacity

- Inland Route: Route 27 (90 km)

- Inland Reliability: High (modern toll road)

- Primary Risk: Port congestion during peak times

While managing a global supply chain may eventually require a dual-port strategy, choosing the most critical path is essential for an initial setup.

Making a Business-Oriented Decision

For a new solar module manufacturing venture in Costa Rica, the bulk of shipment value and volume typically originates from Asia, particularly solar cells. For this reason, despite the modern facilities at Limón, Puerto Caldera often emerges as the more prudent primary choice. The reduced risk of inland transport delays simply outweighs the potential for port congestion.

The timely arrival of your solar module manufacturing equipment is paramount, making logistical predictability a top priority. For entrepreneurs establishing a turnkey solar production line, minimizing these external risks is essential for meeting project timelines and controlling startup costs. The superior reliability of the Caldera-GAM corridor provides a more stable foundation for a just-in-time or lean manufacturing model.

Frequently Asked Questions (FAQ)

Which port is better if I source most components from China?

Puerto Caldera is the superior choice. It offers direct Pacific shipping routes from Asia and a much more reliable inland transport connection to the central valley via Route 27, minimizing the risk of costly production delays.

Are customs procedures significantly different between the two ports?

Limón’s modern terminal features highly streamlined and automated customs processes. However, its high cargo volume can still lead to bottlenecks. Caldera’s processes may be less automated, but its lower volume can sometimes result in faster clearance for individual shipments. Engaging a proficient local customs broker is crucial for navigating either port effectively.

How do weather conditions impact these logistics chains?

The Caribbean coast (Limón) is more exposed to the Atlantic hurricane season, and Route 32 is highly vulnerable to landslides during Costa Rica’s rainy season (May to November). The Pacific coast and Route 27 are generally less affected by severe weather events, offering greater year-round reliability.

Can a single factory use both ports?

Yes. A sophisticated logistical strategy can involve using both ports—Caldera for Asian components and Limón for European or American goods. While this approach offers maximum flexibility, it increases logistical complexity and is typically adopted by more mature operations. For a new venture, focusing on a primary port is advisable.

The selection of an import port for a Costa Rican solar factory is a strategic decision that balances ocean freight costs against inland logistical risks. While Puerto Limón offers world-class facilities, the unpredictable nature of its connection to the country’s industrial heartland presents a significant business risk. For most new solar manufacturing ventures dependent on Asian components, Puerto Caldera provides a more stable and predictable logistics chain—the cornerstone of an efficient and profitable operation. Understanding these logistical nuances early in the planning stage is key for any entrepreneur looking to build a resilient and cost-effective manufacturing enterprise from day one.