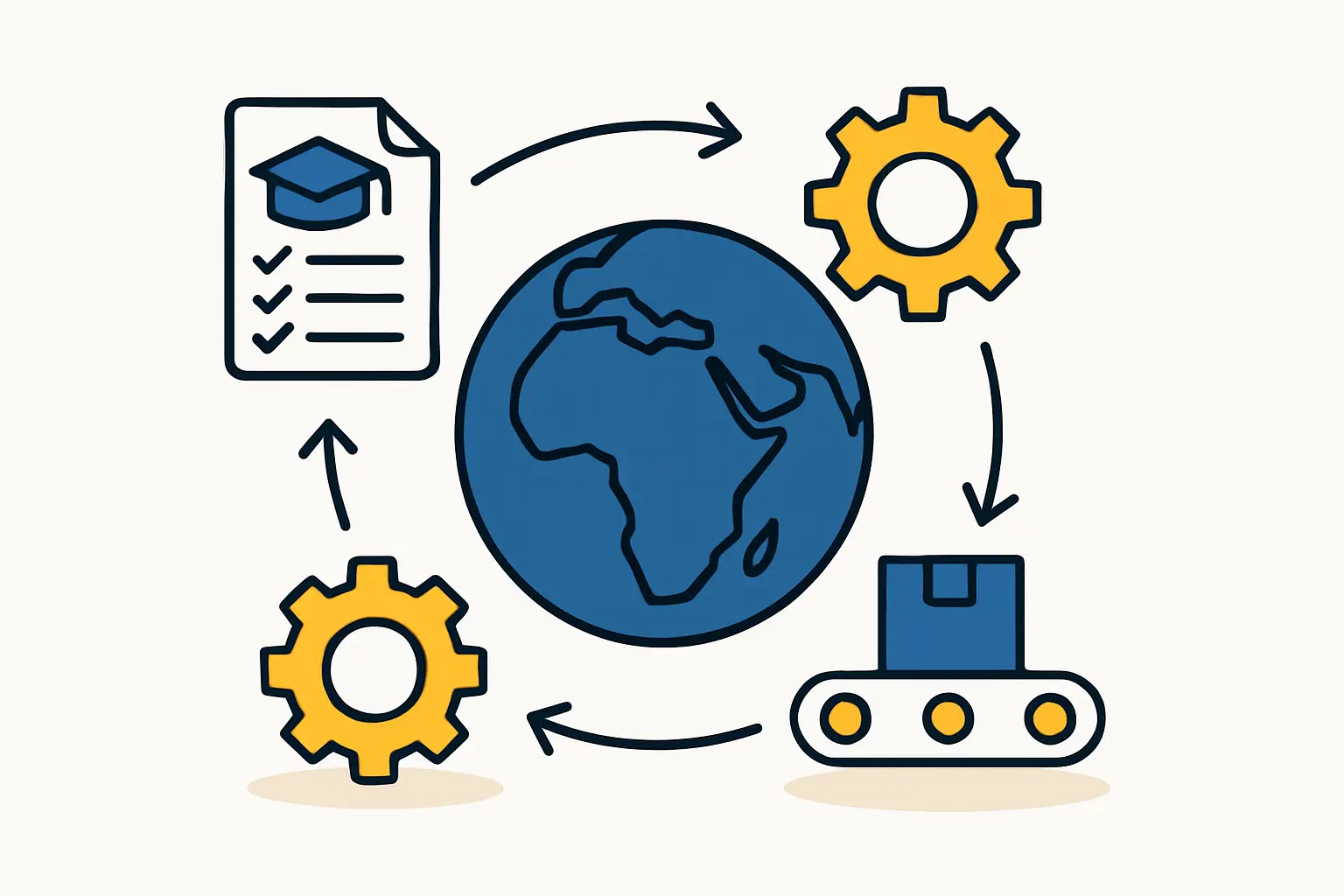

An investor considering a new manufacturing venture in Ghana might look at the country’s labor statistics and see a clear opportunity: a large, young, and readily available workforce.

While this is a significant advantage, establishing a successful solar module assembly line requires a more nuanced perspective. The primary challenge isn’t a shortage of labor, but of specific technical skills.

This assessment offers a realistic look at Ghana’s labor market for entrepreneurs entering the solar manufacturing sector. It outlines the opportunities, addresses the well-documented skills gap, and provides a strategic framework for recruiting and training a proficient technical team from the ground up.

Understanding Ghana’s Labor Landscape: Opportunities and Challenges

A clear understanding of the local environment is the starting point for any successful operation. For new industrial projects in Ghana, the labor market presents both distinct advantages and notable challenges.

The Opportunity:

According to recent studies, Ghana’s labor force is growing at approximately 2.9% annually, creating a substantial pool of potential employees. With a national unemployment rate of 13.4% in 2021 and even higher rates among the youth, there is a large and motivated group of individuals seeking stable employment. The country’s high literacy rate and widespread English proficiency provide a solid foundation for further training.

The Challenge:

The core challenge lies in the ‘skills mismatch’—a gap between the qualifications produced by the formal education system and the practical competencies required by modern industry. Research indicates that while many Ghanaians complete formal education, there is a shortage of hands-on technical and vocational experience.

Key areas lacking include:

- Specialized Technical Skills: Experience with automated and semi-automated industrial machinery is not widespread.

- Problem-Solving: The ability to diagnose and resolve production issues requires practical training.

- ICT and Digital Literacy: While improving, proficiency with industry-specific software and control systems needs development.

Government initiatives such as the ‘One District, One Factory’ policy and reforms in Technical and Vocational Education and Training (TVET) aim to address this gap, signaling a supportive environment for industrial development. However, for the immediate future, the responsibility for developing specialized talent rests heavily on the employer.

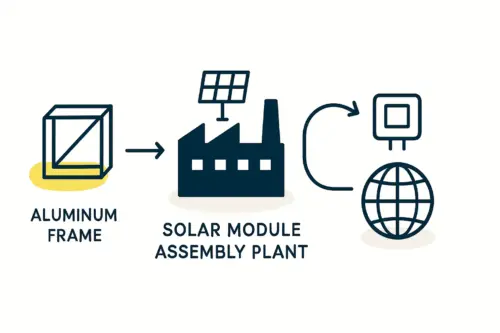

Defining the Core Competencies for a Solar Assembly Line

A solar module factory is a precision environment. Success depends less on heavy labor and more on process discipline, attention to detail, and the consistent operation of specialized equipment. An effective team requires individuals who can be trained for specific roles along the production line.

Key roles and their required aptitudes include:

Ready to make big Profits?

The solar Industry is Booming

WE HELP NEWCOMERS to the solar industry start their own solar module production line. Customers can make BIG PROFITS by selling modules and finding investors, without wasting money and time on things they don't need!

- Machine Operators (Stringer, Layup, Laminator): These roles require focus and dexterity. Operators must follow precise multi-step procedures without deviation. The ideal candidate is methodical and consistent.

- Quality Control (QC) Inspectors: This is one of the most critical functions. QC personnel need a keen eye for detail to perform visual inspections and operate testing equipment like EL testers and sun simulators. They must be empowered to halt production if standards are not met.

- Maintenance Technicians: Individuals with a background in electrical or mechanical systems are ideal. They are responsible for machine calibration, preventative maintenance, and troubleshooting.

- Cell and Material Handlers: These roles require careful handling of delicate and expensive materials like solar cells and EVA foil. Discipline and adherence to cleanroom protocols are essential.

A full understanding of the Solar Panel Manufacturing Process helps clarify these roles and the specific skills each station demands.

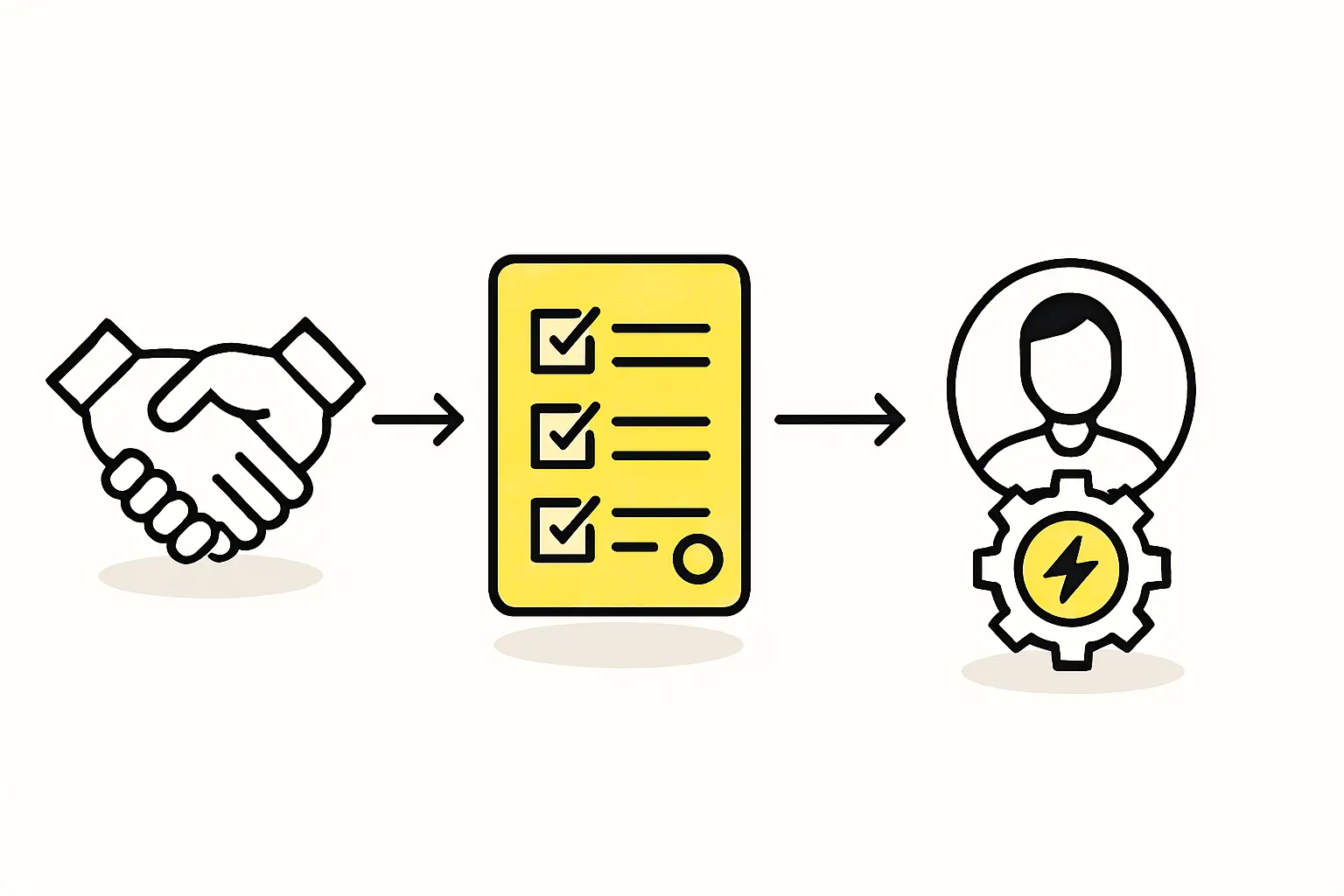

A Strategic Approach to Recruitment in Ghana

Given the scarcity of ready-made solar technicians, recruitment should focus on potential rather than existing experience. The goal is to identify individuals with the right foundational aptitudes and a strong work ethic.

Recruitment Channels:

- TVET Institutions and Technical Universities: Graduates from these institutions have a theoretical understanding of technical principles, making them highly trainable candidates for roles like maintenance and quality control.

- General Labor Pool: For operator and material handling roles, look for individuals with experience in environments that require precision and process adherence, such as electronics assembly or food processing.

- Partnerships: Building relationships with local educational institutions can create a pipeline of talent, allowing for curriculum input that better aligns with industry needs.

During the interview process, prioritize assessments that test for problem-solving ability, attention to detail, and the capacity to follow complex instructions. A candidate’s attitude and willingness to learn are far more valuable than any specific prior experience in the solar industry.

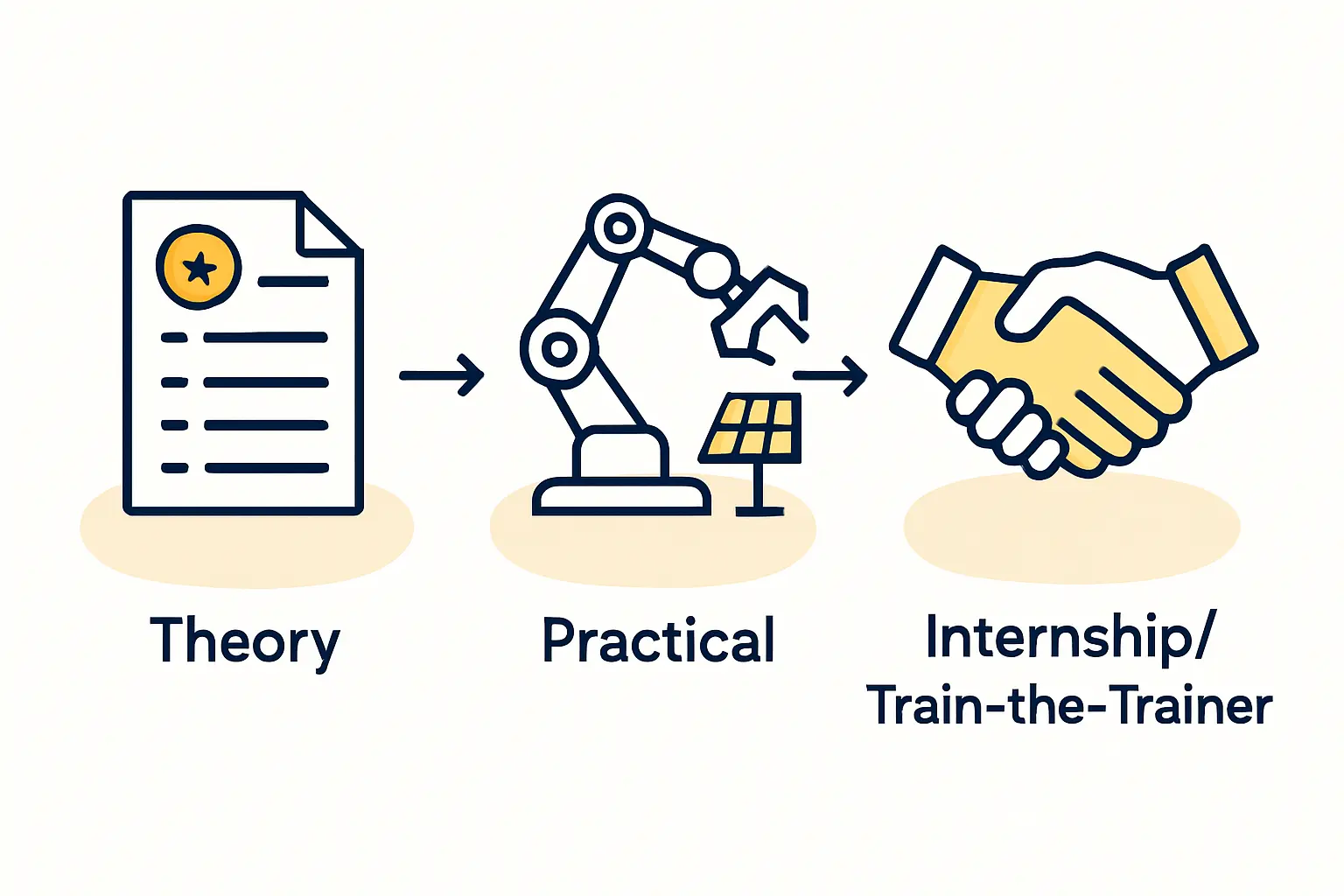

The Critical Role of In-House Training and Skill Development

A comprehensive, structured training program is the most critical investment an entrepreneur will make in their workforce. It is the bridge across the skills gap. A successful program is often integrated into a turnkey solar panel production line setup and typically includes several phases.

Phase 1: Foundational Classroom Training

Before touching any equipment, the entire team must understand the ‘why’ behind their work. This includes basic photovoltaic principles, material properties, contamination control, and safety protocols.

Phase 2: On-the-Job Training (OJT)

An experienced supervisor, often a process engineer provided by the equipment supplier, should lead hands-on training for each station. This involves demonstrating the process, observing the trainee, and providing immediate feedback until proficiency is achieved.

Phase 3: Building a Culture of Quality

Training must extend beyond simple machine operation to instill a deep understanding of quality standards. Every team member should be trained in basic Solar Panel Quality Control, empowering them to identify defects at their station. Experience from J.v.G. turnkey projects shows that creating this shared sense of responsibility is a hallmark of high-performing factories.

Phase 4: Cross-Training and Advancement

To build a resilient and motivated team, cross-train operators on multiple machines. This provides production flexibility and creates clear career progression paths. An operator who masters several stations can be developed into a line supervisor, addressing the common shortage of experienced local managers.

Frequently Asked Questions (FAQ)

How many employees are needed for a small-scale solar factory?

A semi-automated 20-50 MW production line typically requires 25 to 35 employees per shift, including operators, quality control staff, maintenance personnel, and supervisors. The total Investment for Solar Panel Manufacturing should account for salaries and ongoing training costs for this team.

What educational background is best for operators?

A secondary school education is generally sufficient, provided the individual demonstrates strong learning ability and discipline. For technical and quality control roles, a certificate or diploma from a TVET institution is advantageous.

How long does it take to train a new production team?

A well-structured program can bring a new team to a state of basic operational readiness in 4 to 8 weeks. Achieving high levels of efficiency and quality consistency may take 3 to 6 months as the team gains experience and solves real-world production challenges.

Is it possible to find experienced solar technicians in Ghana?

It is highly unlikely. The solar module manufacturing industry is nascent in the region. The most reliable and sustainable strategy is to invest in training and develop local talent in-house. This approach builds loyalty and ensures skills are perfectly matched to your specific equipment and processes.

Conclusion: Transforming Potential into Performance

Ghana offers a significant demographic advantage for new manufacturing ventures. Its large, young, and eager workforce holds immense potential. However, this potential can only be realized through a deliberate and strategic approach to workforce development.

Success is not about finding perfectly qualified candidates; it is about creating them. By focusing recruitment on aptitude and attitude, and implementing a robust, multi-phased training program, an entrepreneur can build a world-class technical team. This investment in people is the cornerstone of a sustainable and profitable solar manufacturing operation. For those planning their entry into the market, understanding How to Start a Solar Panel Factory begins with a clear plan for the most important asset: the workforce.