A state-of-the-art solar module production line is a significant capital investment. Imagine a critical lamination cycle, which requires uninterrupted power for 15 minutes, being cut short by a sudden blackout.

The result isn’t just a delay—it’s wasted materials, strained equipment, and a direct loss of revenue. For entrepreneurs entering the solar manufacturing sector in India, this scenario is more than a hypothetical risk; it’s a daily operational challenge.

This article examines the critical issue of grid instability for industrial users in India, detailing the direct impact on solar module manufacturing and exploring technical solutions to ensure production continuity and protect a factory’s profitability.

The Paradox of Power in a Fast-Growing Economy

India’s energy landscape is one of remarkable growth and inherent contradictions. The nation is the world’s third-largest consumer of electricity and has rapidly expanded its renewable energy capacity, with over 72 GW of solar installed by late 2023. This progress, however, coexists with persistent infrastructure challenges.

For industrial enterprises, the reality on the ground often includes:

- Voltage Fluctuations and Frequency Deviations: Unstable power quality that can stress sensitive electronics.

- Scheduled and Unscheduled Outages: Blackouts and brownouts that disrupt production schedules.

- High Transmission and Distribution (T&D) Losses: In many areas, losses can reach 20–25%, reflecting an aging grid straining to meet surging demand.

While nationwide improvements are ongoing, localized grid instability remains a fundamental business risk that must be addressed at the factory planning stage.

How Grid Instability Directly Impacts Solar Module Production

An inconsistent power supply isn’t a minor inconvenience; it has direct and severe consequences for every stage of solar module manufacturing. Understanding these risks is the first step toward mitigating them.

Production Downtime and Its Cascading Effects

A power outage, even for a few minutes, can halt the entire production line. Machines like stringers, laminators, and testers must be safely shut down and then recalibrated upon restart. This process can lead to hours of lost production time, creating bottlenecks that affect output targets and delivery schedules. The financial impact of this idle capacity accumulates rapidly.

Risk to Sensitive and High-Value Equipment

Sudden power surges or drops upon grid restoration can inflict serious damage on sophisticated machinery. The control systems for laminators, the precision robotics in cell stringers, and the sensitive measurement tools in sun simulators are particularly vulnerable. Repairing or replacing these components is not only expensive but can involve long lead times for specialized parts, extending downtime from hours to weeks. The risk to this sensitive manufacturing equipment (https://www.pvknowhow.com/solar-module-manufacturing/equipment) cannot be overstated.

Compromised Product Quality and Certification

Consistency is paramount in manufacturing high-quality, bankable solar modules. Unstable power can compromise critical processes:

- Soldering: Inconsistent temperature in automated stringers can lead to weak or defective cell connections, creating hot spots in the final product.

- Lamination: An interrupted lamination cycle can result in improper curing of the EVA encapsulant, leading to delamination and moisture ingress later in the module’s life.

- Testing: Fluctuations can affect the accuracy of IV-testers, leading to incorrect power class sorting and potentially damaging the factory’s reputation.

These quality issues can increase the defect rate, lower the average module efficiency, and ultimately jeopardize the certifications required for market access.

The Financial Cost of Unreliable Power

According to research by the World Bank, power outages can cost businesses in India an estimated 4–6% of their annual turnover. For a high-value manufacturing operation, these losses can significantly erode profitability.

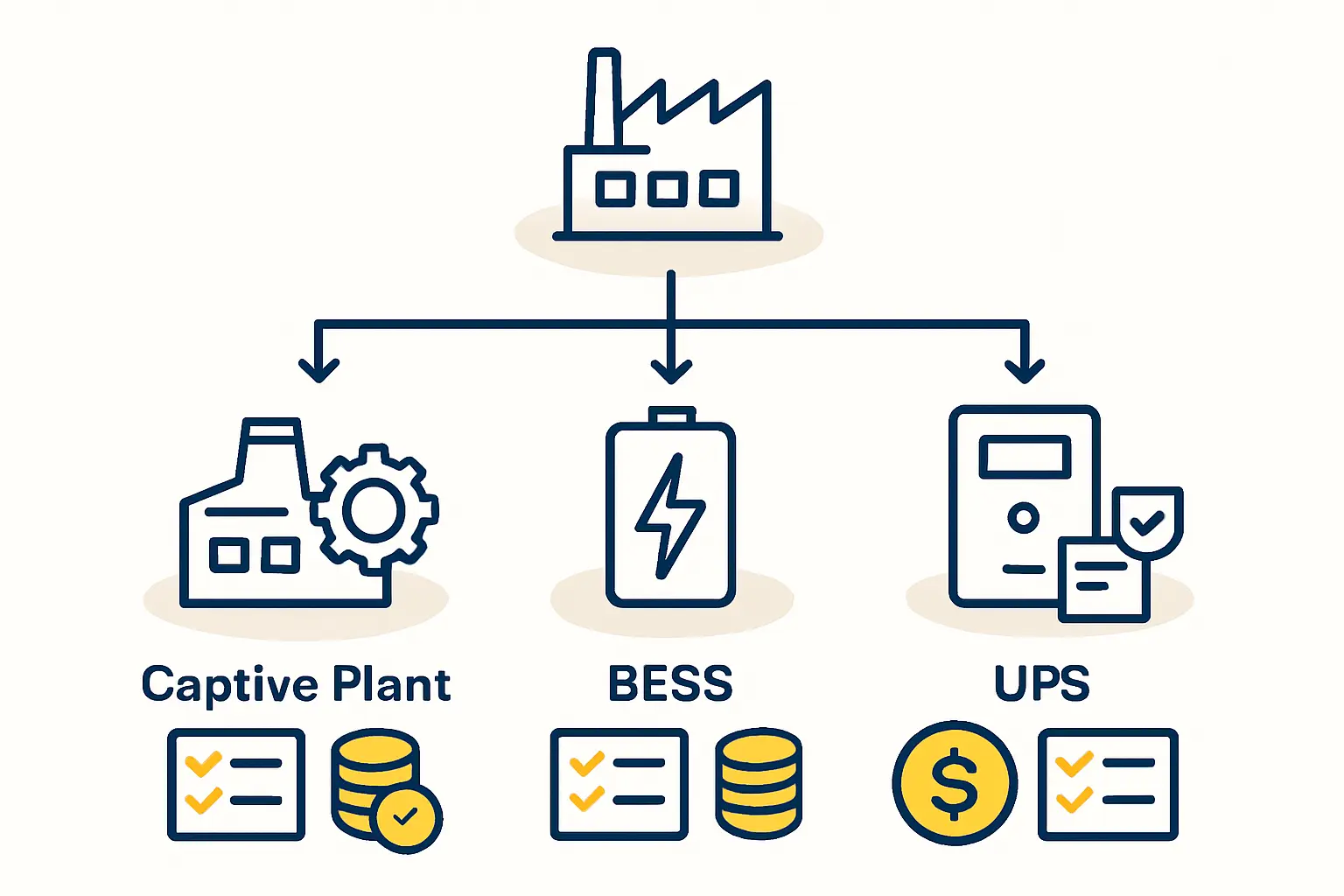

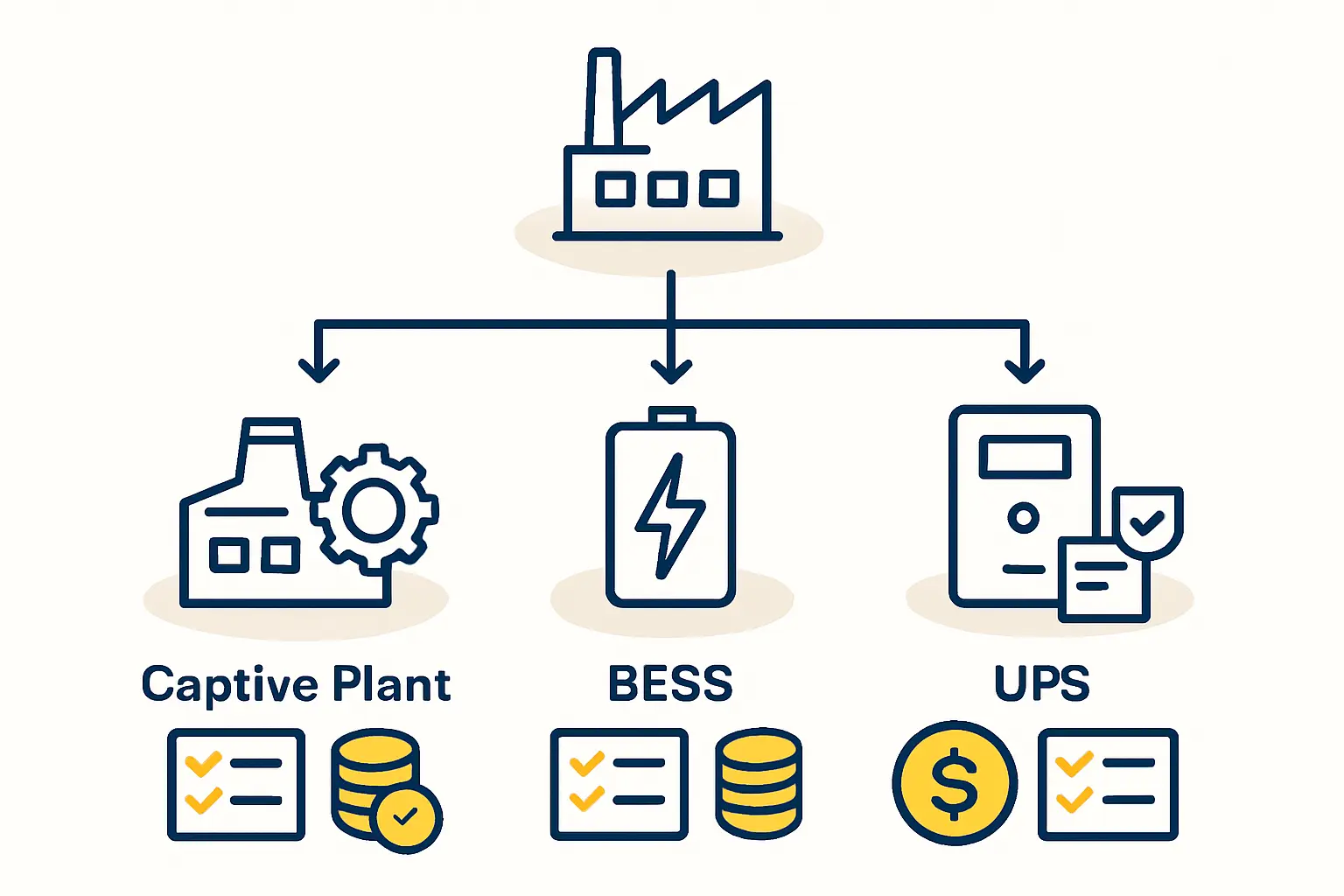

Evaluating Power Redundancy Solutions for Your Factory

A reliable power strategy is a prerequisite for a successful solar manufacturing venture in India. This involves creating layers of redundancy to insulate the operation from grid failures.

Option 1: The Traditional Diesel Generator (DG) Set

Diesel generators are the most common form of backup power, offering a straightforward solution to blackouts. However, they come with significant operational disadvantages:

- High Running Costs: The cost of electricity from a DG set can be as high as ₹15–20 per kWh, driven by fuel prices and regular maintenance.

- Environmental Impact: DG sets produce significant carbon emissions and are subject to increasingly strict environmental regulations.

- Delayed Switchover: There is typically a brief delay between a grid failure and the generator starting, which can still be enough to disrupt sensitive processes.

Option 2: The Captive Solar Power Plant

A compelling solution for a solar module factory is to use its own product to generate power. A captive solar plant, installed on the factory rooftop or adjacent land, offers clear benefits:

- Low Energy Cost: The Levelized Cost of Energy (LCOE) from a captive solar plant is low, often around ₹2.5–3.5 per kWh, offering substantial savings over grid and DG power.

- Energy Synergy: It showcases the factory’s commitment to its own technology.

- Limitation: A solar-only system can power the factory only during daylight hours and provides no solution for grid outages at night.

Option 3: Battery Energy Storage Systems (BESS)

Battery storage is a modern solution that addresses both power continuity and quality. A BESS can be charged by the grid or a captive solar plant and delivers instantaneous backup power with no interruption.

- Uninterruptible Power Supply (UPS): A BESS acts as a large-scale UPS, ensuring that production continues seamlessly during a grid failure.

- Power Quality Improvement: It can absorb voltage spikes and stabilize frequency, protecting sensitive equipment.

- Falling Costs: BESS prices have fallen by over 80% in the last decade, making the payback period of 5–7 years increasingly attractive when factoring in the avoidance of production losses.

The Optimal Strategy: A Hybrid Solar + BESS System

For maximum resilience and economic efficiency, a hybrid system combining a captive solar plant with a BESS is the superior long-term solution. This integrated approach creates a microgrid for the factory:

- Daytime Operation: The solar plant powers the factory directly, with any excess energy used to charge the BESS.

- Night-time & Outages: The BESS powers the factory during the night or instantly takes over when the grid fails.

This model offers energy independence, low and predictable electricity costs, and the highest level of protection against grid instability.

Planning and Implementation Considerations

Based on experience from J.v.G. turnkey projects, the power supply strategy must be an integral part of the initial factory design, not an afterthought. A thorough electrical load analysis is essential for correctly sizing the backup systems (DG, solar, and BESS) to meet the factory’s peak demand.

This planning is a core component of defining the factory’s infrastructure (https://www.pvknowhow.com/start-solar-factory/infrastructure-building). Investigating state-level policies in India is also critical, as incentives like net metering or subsidies for renewable energy systems can significantly improve the financial viability of a hybrid power solution.

Frequently Asked Questions (FAQ)

Is a DG set still necessary if I have a solar + BESS system?

For maximum security, a DG set is often recommended as a final layer of backup for prolonged outages (e.g., multiple days) or during critical BESS maintenance. However, its operational hours and fuel consumption will be reduced by over 95%, drastically lowering costs.

How much space is required for a captive solar plant?

A general rule of thumb is around 1 acre (about 4,000 square meters) of land for every 1 MW of ground-mounted solar capacity. Rooftop installations are an excellent, space-efficient option for many factory buildings.

What is the typical payback period for a Solar + BESS system in India?

This varies based on local grid electricity tariffs, system size, and available subsidies. However, the payback period typically falls between 5 and 8 years. After this point, the factory benefits from very low-cost electricity for decades.

Can these systems power the entire manufacturing process?

Yes. A correctly sized hybrid power system is engineered to handle the full operational load of the production line, including the high inrush currents from energy-intensive machines like laminators and furnaces. A detailed analysis ensures the entire manufacturing process (https://www.pvknowhow.com/solar-module-manufacturing/process) is supported without interruption.

Conclusion: Building a Foundation of Operational Resilience

For any business professional planning to establish a solar module factory in India, addressing power instability is non-negotiable. Relying solely on the grid introduces an unacceptable level of operational and financial risk.

A proactive power strategy, centered around a hybrid Solar + BESS solution, transforms this vulnerability into a strength. It’s not merely an expense but a strategic investment in production continuity, product quality, and long-term profitability. By securing an independent and reliable power supply, a factory builds the essential foundation for success in a competitive market.