Choosing the location for a new manufacturing facility is one of the most consequential decisions an entrepreneur can make. While an empty plot of land might seem like a blank canvas, its value is determined by a complex web of factors.

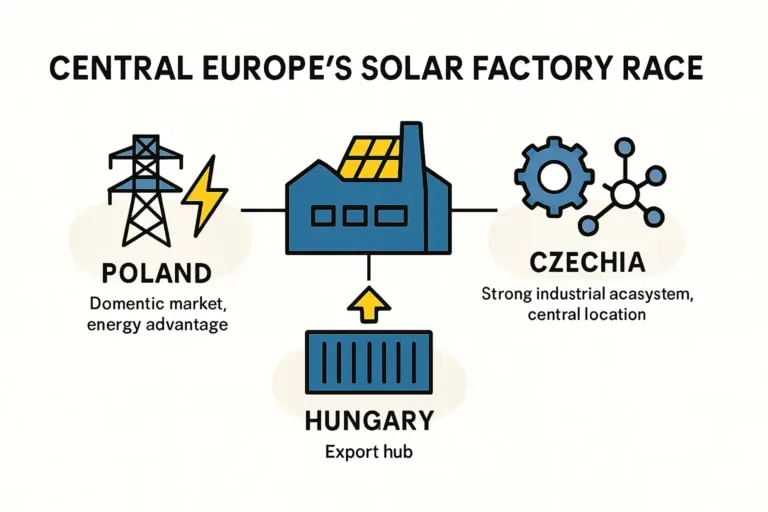

For companies considering a solar module factory, Hungary has emerged as a strategic hub in Central Europe. Its strong industrial base and central location are compelling, but success hinges on a detailed understanding of site selection criteria. The right choice can accelerate a launch by a year, while the wrong one can lead to costly, unforeseen delays.

Why Hungary Presents a Compelling Case for Solar Manufacturing

Hungary’s appeal extends far beyond its geographical position. The country has cultivated a robust manufacturing ecosystem, particularly in the automotive and electronics sectors. This creates a valuable foundation for a new solar enterprise, offering several key advantages:

- Established Supply Chains: Proximity to European suppliers of essential raw materials like high-quality glass and aluminum frames reduces transport costs and lead times.

- Skilled Labor: Regions with a history of industrial production possess a workforce familiar with the technical demands and quality standards of modern manufacturing.

- Government Support: The Hungarian Investment Promotion Agency (HIPA) actively encourages foreign investment with a range of incentives, creating a business-friendly environment.

This combination of factors makes Hungary a prime candidate for investment. Yet these national advantages only come into play if the specific, local requirements of the chosen site are met.

The Critical First Step: Understanding Industrial Parks

For new market entrants, navigating local regulations and infrastructure development can be a formidable task. Hungary’s network of over 200 industrial parks offers a structured solution that significantly reduces setup risks. These designated zones are specifically designed for industrial operations and often include pre-approved zoning and readily available utilities.

Key industrial regions include:

- Central Hungary: The area surrounding Budapest offers unparalleled logistical connectivity but also comes with higher labor costs.

- Western Transdanubia: Located near the Austrian and Slovakian borders (e.g., Győr region), this area provides excellent access to Western European markets and supply chains.

- Northern Great Plain: Centered around cities like Debrecen, this region is a rising industrial hub with strong university ties and good connections to Eastern European markets.

Core Criteria for Site Selection: Beyond the Plot of Land

Selecting the optimal site within an industrial park requires a detailed assessment of factors critical to a solar module factory’s daily operations and long-term viability.

1. Utility Infrastructure: The Power and Water Lifeline

A solar module factory is energy-intensive, making the availability and capacity of utilities non-negotiable.

-

Electricity: A typical 50–100 MW solar module factory requires a stable power supply of 1–2 MW. This requires access to a high-voltage grid connection, typically 20 kV or higher. While a plot of land might be available, establishing a new high-voltage connection can take anywhere from 12 to 24 months. Industrial parks often have pre-installed substations, making grid access a matter of final connection rather than large-scale construction.

-

Water: The production process requires a consistent supply of water for washing solar glass and for cooling systems. While water scarcity is not a primary concern in most of Hungary, the capacity of the local water main and wastewater connection must be verified to handle the factory’s projected demand.

Based on experience from J.v.G. turnkey projects, securing the grid connection agreement is often the most time-consuming task in the pre-construction phase. Selecting a site in an industrial park with an existing substation can shorten the project timeline by more than a year.

2. Logistics and Connectivity: The Arteries of Your Operation

A solar module factory’s efficiency depends directly on its logistical infrastructure. The constant flow of inbound raw materials and outbound finished products requires seamless connectivity.

-

Road Network: Proximity to major motorways (such as the M0, M1, M3, and M5) is essential for efficient truck transport. This affects everything from the delivery of large glass sheets and aluminum frames from European suppliers to the shipment of finished modules to customers.

-

Rail Access: For handling bulk materials, direct or nearby rail access can offer significant cost and efficiency advantages, although it is not a strict necessity for all setups.

-

Airports: Proximity to an international airport like Budapest (BUD) or Debrecen (DEB) is important for technical staff, management, and visiting clients.

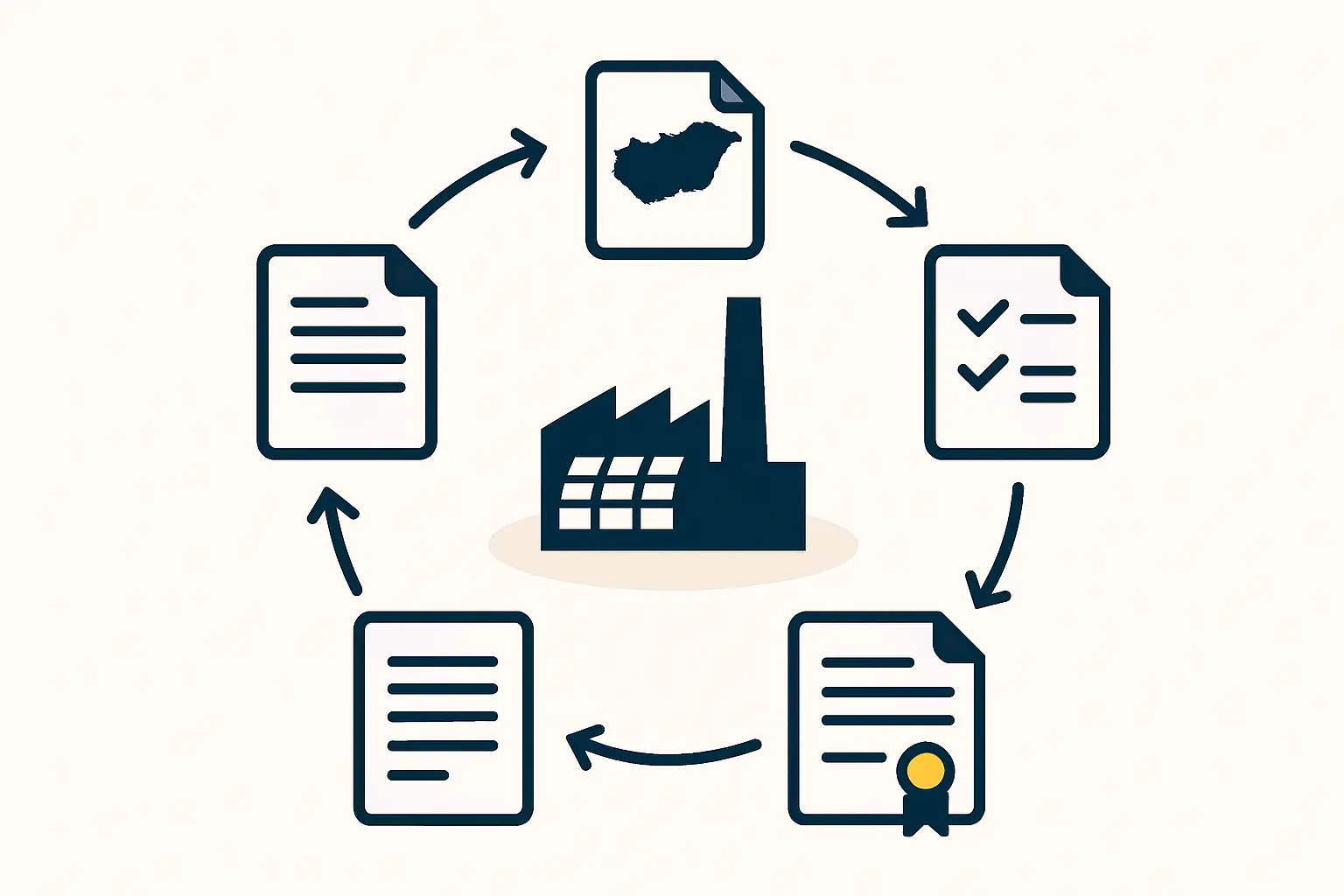

3. Zoning and Permitting: Navigating the Regulatory Landscape

One of the most significant advantages of choosing an industrial park is the streamlined regulatory process. Most of these parks are designated with “GIPZ” (Industrial and Commercial Park Zone) zoning, which pre-approves the land for industrial use.

This doesn’t eliminate all regulatory steps, however. A building permit is still required, and an Environmental Impact Assessment (EIA) may be necessary depending on the scale of the operation. The EIA process typically takes 6–9 months. While these steps are mandatory, proceeding within a GIPZ-zoned area is substantially faster and more predictable than attempting to rezone an agricultural or commercial plot. Understanding this process is a core part of planning the factory’s construction.

4. Labor Pool and Local Ecosystem

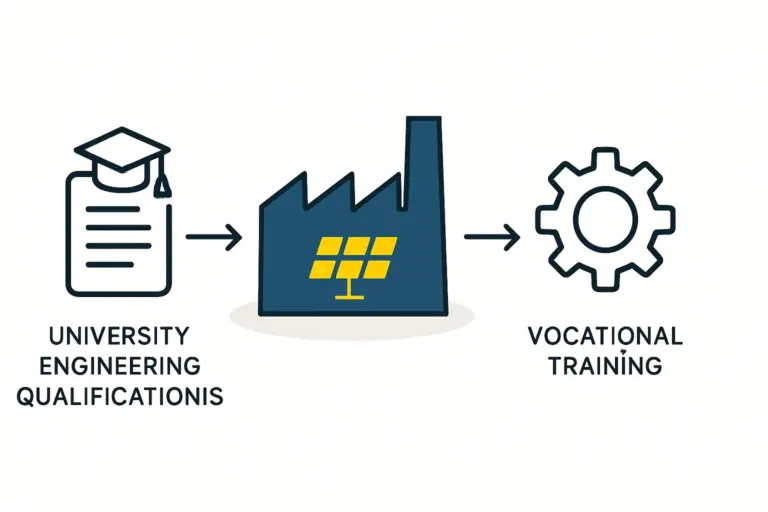

The most advanced machinery is only as effective as the people who operate it. Access to a qualified labor pool is a critical long-term success factor.

-

Skilled Technicians: Regions with a background in electronics or automotive manufacturing, such as those around Győr or Kecskemét, often have a ready supply of technicians and engineers with transferable skills.

-

University Partnerships: For instance, one project in the Debrecen area benefited significantly from proximity to the university’s engineering faculty, which provided a consistent talent pipeline for technical and supervisory roles.

-

Labor Competition: It is also crucial to assess the local labor market. A high concentration of large manufacturers can lead to intense competition for skilled workers, potentially driving up wage expectations.

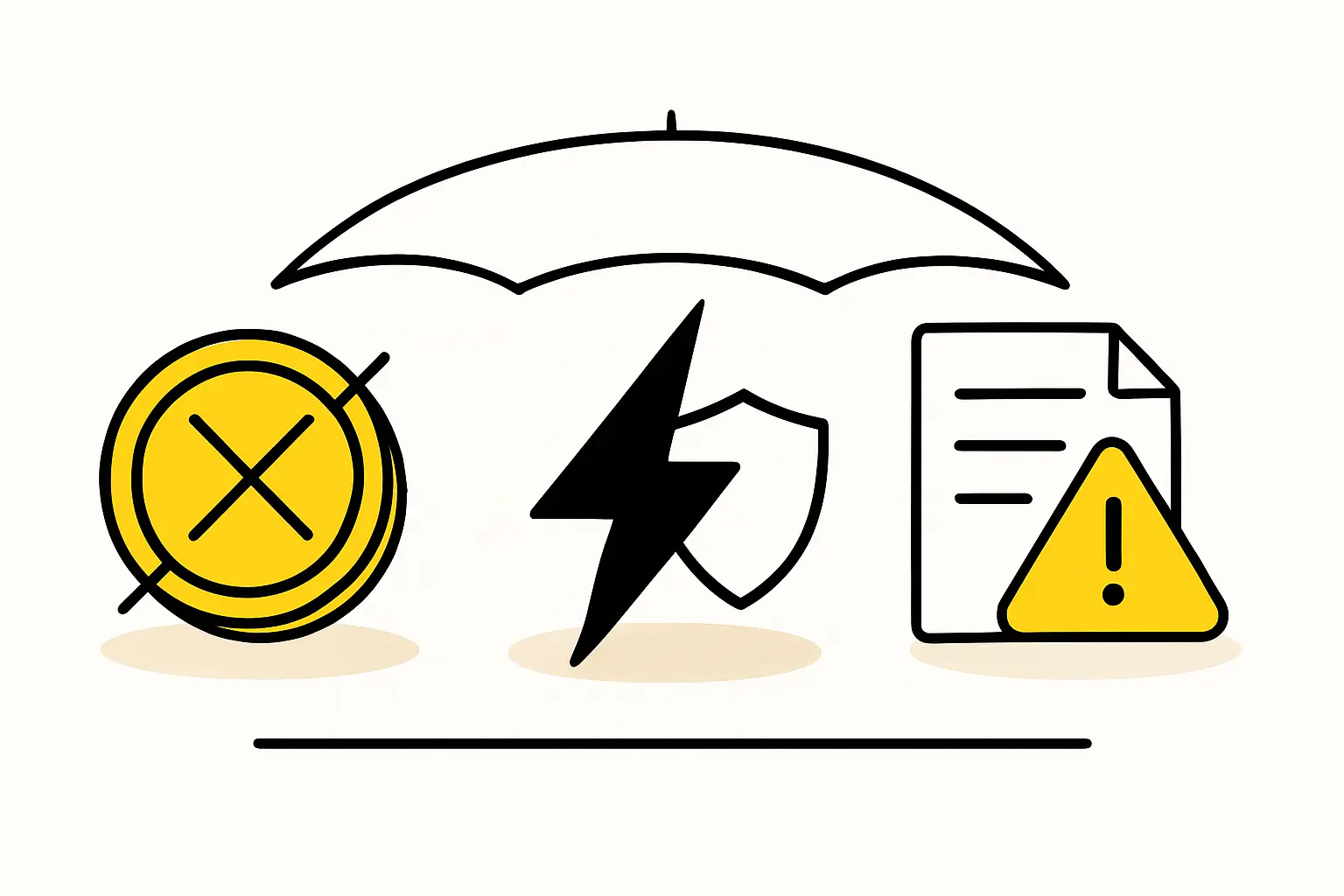

A Common Pitfall: Overlooking Grid Connection Timelines

A common and costly mistake newcomers make is acquiring a seemingly inexpensive plot of land, only to discover that it lacks adequate access to the high-voltage grid. The cost and, more importantly, the time required to establish a new grid connection can nullify any initial savings on the land purchase.

An otherwise perfect site without a viable and timely path to a 1–2 MW power supply is a strategic liability, not an asset.

Frequently Asked Questions (FAQ)

What is the typical size of a plot needed for a 50 MW factory?

A facility with an annual capacity of 50 MW generally requires a plot of 10,000 to 15,000 square meters. This accommodates the factory building itself (around 4,000–5,000 sqm), along with space for logistics, storage, and potential future expansion.

Are government incentives available for setting up in these industrial parks?

Yes, the Hungarian Investment Promotion Agency (HIPA) offers various incentives for foreign investment projects. These can include cash grants, tax allowances, and training subsidies, often linked to the value of the investment and the number of jobs created.

How does the solar panel production process influence site needs?

The linear nature of the solar panel production process makes a long, rectangular plot shape highly efficient for workflow design. The process also dictates specific building characteristics, such as reinforced flooring to support heavy machinery like laminators and high ceilings to accommodate equipment and material handling.

Conclusion: Your Site as a Strategic Foundation

Selecting a site for a solar module factory in Hungary is a decision of strategic importance. While the country offers a fertile ground for manufacturing, the venture’s ultimate success depends on the details of the chosen location.

By focusing on designated industrial parks and rigorously evaluating the critical criteria of utility access, logistics, zoning, and labor availability, an entrepreneur can build a powerful foundation for a resilient and profitable operation. This careful planning transforms a simple plot of land into a strategic asset that will support the business for decades to come.