An entrepreneur can invest millions in state-of-the-art solar module manufacturing equipment and build a perfect facility, only to face a critical bottleneck: connecting to the national power grid.

In many emerging markets, particularly in Iran, grid interconnection is not a simple utility request. It is a complex project demanding rigorous technical compliance, strategic planning, and a deep understanding of local regulations.

Failing to plan for this crucial step from the outset can lead to significant delays and unforeseen costs, potentially jeopardizing the entire business case. This guide outlines the landscape, procedures, and technical standards for connecting a new solar module factory to Iran’s national grid, providing the foundational knowledge for effective project planning.

Understanding Iran’s Electrical Grid Landscape

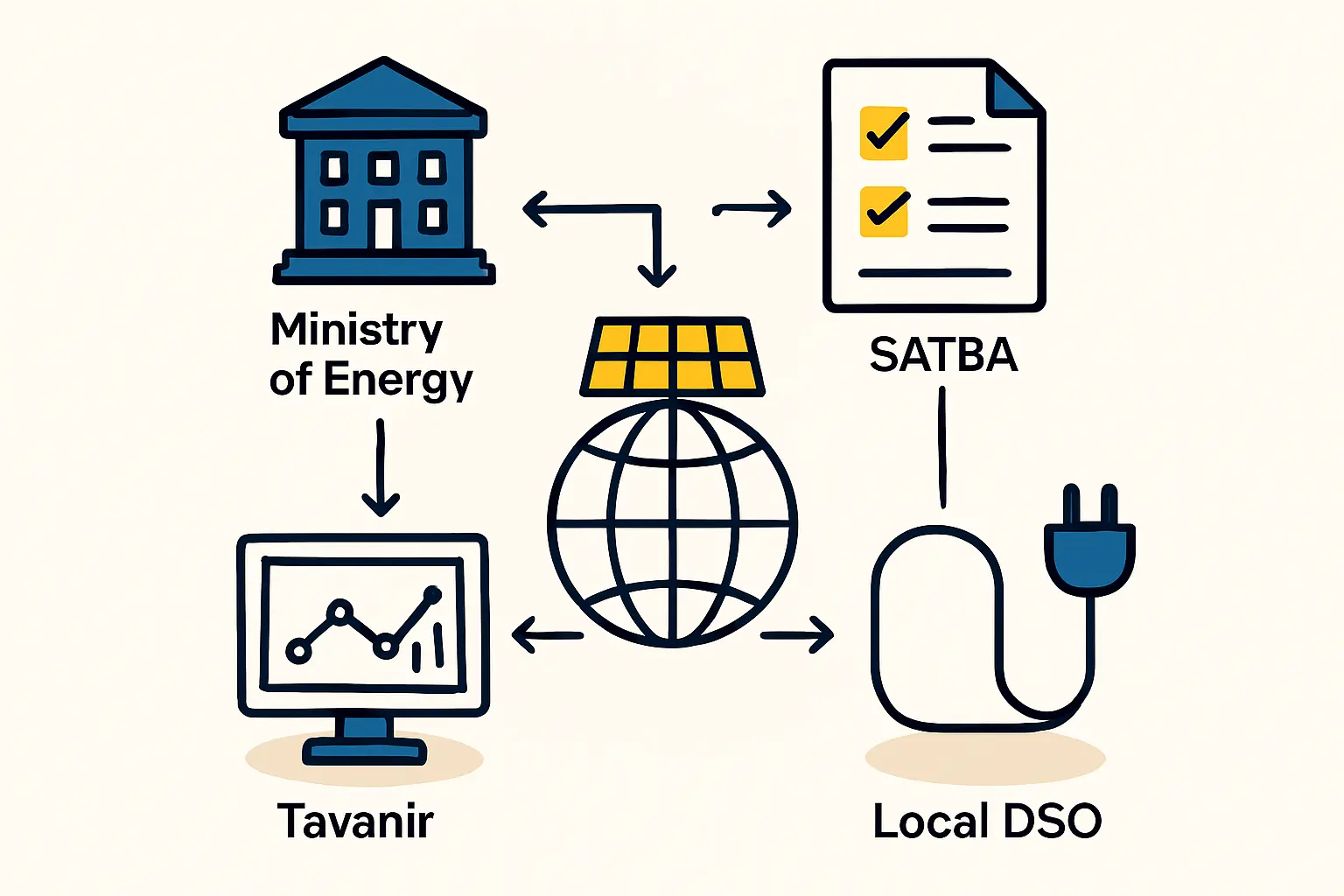

The Iranian electricity grid is a vast and complex network managed primarily by the Iran Power Generation, Transmission and Distribution Management Company (TAVANIR). Connecting any new industrial facility—especially one with the significant and variable power demands of a solar factory—requires adhering to a strict set of rules designed to maintain stability across the entire system.

The country’s renewable energy ambitions are championed by the Renewable Energy and Energy Efficiency Organization (SATBA), which often works with TAVANIR to help integrate green energy projects. For a manufacturing plant, however, the primary relationship will be with the regional distribution company operating under TAVANIR’s authority.

The following image depicts a solar module factory substation setup:

Understanding this dynamic is crucial. The grid operator’s main concern is not the factory’s production schedule but the health and reliability of the electrical network. This means every requirement is aimed at preventing disruptions. A well-prepared project plan accounts for this, incorporating the necessary electrical infrastructure from day one.

The Formal Process of Grid Interconnection

Navigating the grid connection process in Iran involves a series of formal steps, each requiring detailed technical documentation and regulatory approval. While specific procedures may vary slightly by province, the general pathway is consistent.

Step 1: Initial Application and Feasibility Study

The process begins with submitting a formal application to the local electricity distribution company. This application includes preliminary information about the factory’s location, its estimated maximum power demand (in kVA), and the nature of its electrical loads, such as motors, heaters, and electronic equipment. The utility will then conduct an initial feasibility study to determine if the local grid has sufficient capacity to support the new load.

Step 2: The Grid Impact Study (GIS)

If the initial assessment is positive, the utility will require a comprehensive Grid Impact Study. This critical technical analysis, usually performed by a certified third-party engineering consultant, models the effect of the new factory on the local grid. It assesses factors such as:

- Voltage Stability: Will the factory cause voltage drops or fluctuations that affect other users?

- Harmonic Distortion: Do the factory’s machines introduce “noise” into the electrical signal?

- Fault Levels: How will a short circuit at the factory impact the grid’s protective systems?

In J.v.G. Technology GmbH’s experience with turnkey projects in similar markets, the Grid Impact Study is often the most time-consuming phase, requiring close collaboration between the project owner and the utility.

Step 3: Technical Specifications and Equipment Approval

The results of the GIS dictate the technical requirements for the connection. The utility will provide a list of approved equipment and design specifications for the factory’s substation, including transformers, switchgear, circuit breakers, and protection relays. All equipment must comply with Iranian national standards and, in many cases, IEC (International Electrotechnical Commission) standards. Sourcing this equipment requires careful planning, especially given international supply chain complexities.

Step 4: Final Agreement and Commissioning

Once the technical designs are approved, the parties sign a formal connection agreement. This legal document outlines the responsibilities of both the factory owner and the utility, covering tariffs, maintenance schedules, and service levels. After the substation is built and all equipment is installed, the utility will conduct a final inspection and commissioning test before energizing the connection.

Key Technical Requirements and Standards

Compliance with technical standards is non-negotiable. While a factory’s internal electrical systems are important, the equipment that forms the interface with the grid is under the highest scrutiny.

Voltage and Frequency Compliance

Factories in Iran are typically connected to the medium-voltage (MV) network, often at 20 kV (kilovolts). The factory’s substation steps this down to the low voltage (e.g., 400V) used by machinery. The equipment must operate flawlessly within TAVANIR’s specified voltage and frequency tolerances, such as 50 Hz ±1%.

Power Factor Correction

Industrial facilities with numerous electric motors tend to have a poor “power factor,” meaning they draw more current from the grid than they use for productive work. This is inefficient and strains the grid. Iranian utilities impose strict power factor requirements (typically 0.95 or higher) and levy penalties for non-compliance. As a result, installing automatic power factor correction (PFC) capacitor banks is a necessary investment.

Protection and Safety Systems

The factory’s connection must include sophisticated protection relays that can instantly detect faults like short circuits and disconnect the facility from the grid, preventing a problem inside the factory from causing a wider regional blackout. These systems must be precisely calibrated and coordinated with the utility’s own protection schemes—a task requiring specialized engineering expertise as part of a comprehensive factory planning process.

Common Challenges and Strategic Considerations

Entrepreneurs entering the Iranian market should be aware of several potential challenges that extend beyond pure technical compliance.

Navigating Bureaucracy and Timelines

The grid connection approval process can be lengthy, often taking 9 to 18 months and requiring persistent follow-up with multiple departments within the utility. Engaging a reputable local consultant with experience navigating these procedures is strongly recommended.

Infrastructure Limitations in Specific Regions

While major industrial zones generally have robust grid infrastructure, facilities planned for more remote or developing areas may face significant limitations. In some cases, the cost of upgrading the local grid to support the factory may fall to the project owner, adding a substantial and often unplanned expense.

Adapting to Evolving Regulations

As Iran continues to develop its industrial and energy sectors, regulations and technical standards can evolve. All planning must be based on the most current versions of the national electrical code and TAVANIR’s interconnection guidelines. A project plan must account for the regulations in effect at the time of commissioning, not just when planning begins.

Frequently Asked Questions (FAQ)

What is the typical timeline for grid connection approval in Iran?

The entire process, from initial application to final commissioning, can range from 9 to 18 months. The duration depends heavily on the location, the complexity of the Grid Impact Study, and the efficiency of the local utility’s administrative processes.

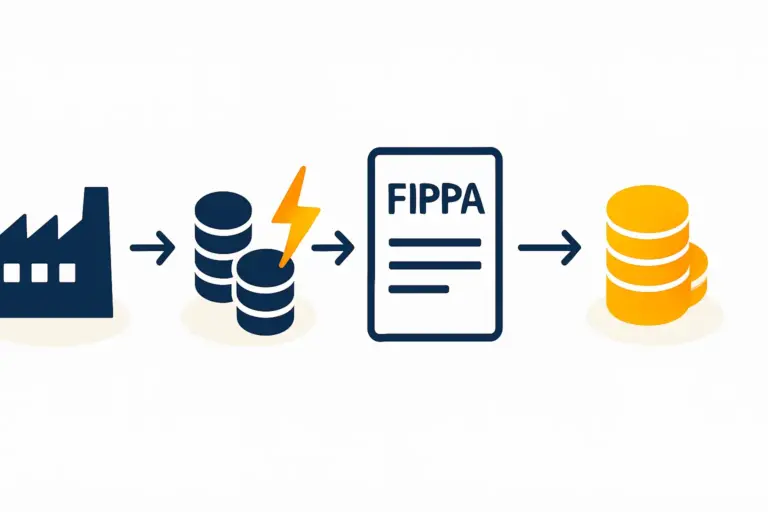

Can a solar factory sell excess power back to the grid?

While the primary purpose of the grid connection is to power the factory, it is sometimes possible to establish a Power Purchase Agreement (PPA) with SATBA or TAVANIR to sell power from a rooftop solar installation, for example. This is a separate, more complex process and should be considered an ancillary project.

What is the role of a local consultant in this process?

An experienced local engineering consultant is invaluable. They understand the nuances of the local utility’s requirements, have established relationships, can manage the application process in Persian, and can oversee the technical design and commissioning to ensure compliance.

How do international sanctions affect sourcing grid connection equipment?

Sanctions can complicate the procurement of high-voltage equipment from European or North American manufacturers. However, many compliant and high-quality alternatives are available from manufacturers in Asia and within Iran itself. A knowledgeable technical partner can help navigate these supply chain challenges.

What is a Grid Impact Study, and who performs it?

A Grid Impact Study (GIS) is a mandatory engineering analysis that models the effects of a new large electrical load on the stability and quality of the public power grid. It must be performed by a TAVANIR-certified engineering firm with specialized software and expertise.

Conclusion: Planning for a Successful Grid Connection

Connecting a solar module factory to the Iranian national grid is a mission-critical undertaking that demands the same diligence and expert planning as the production line itself. Understanding the roles of TAVANIR and SATBA, following the formal interconnection process, and designing for full technical compliance from the start are all key to mitigating risks and avoiding costly delays.

Treating grid interconnection as an integral part of a robust solar business plan, rather than a final item on a checklist, is fundamental to launching a successful and sustainable manufacturing operation in Iran. For those new to the energy sector, partnering with experts who have managed this process is not a luxury, but a strategic necessity.