While national statistics report an impressive 99.48% electrification rate in Indonesia, the figure belies a more complex reality. Across the vast archipelago of over 17,000 islands, more than 1,300 villages—primarily in eastern provinces like Papua, West Papua, and Maluku—remain without reliable electricity.

This gap between the national average and local reality presents a significant, underserved market opportunity.

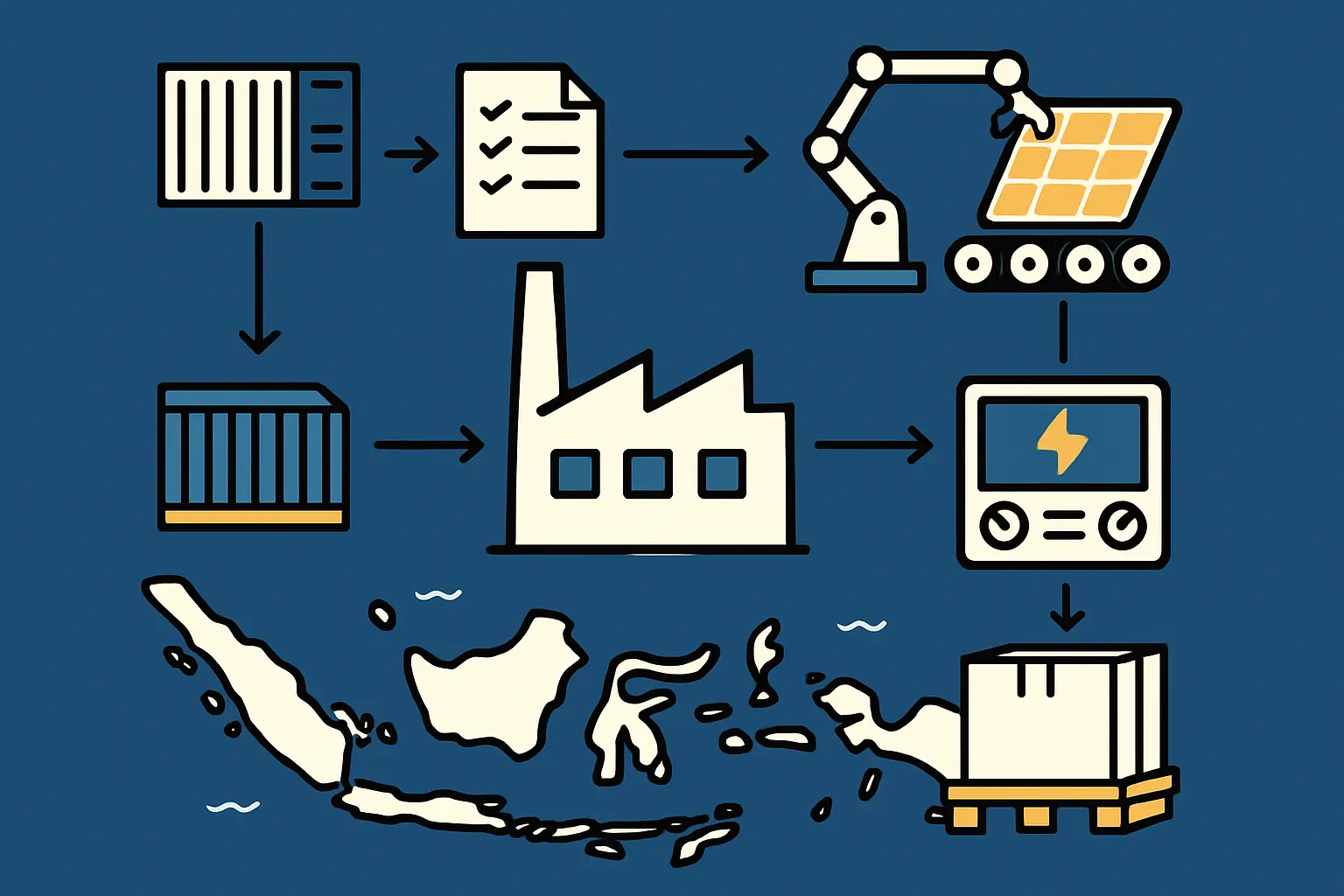

This is not a business case for competing with large-scale solar farms supplying the national grid. Instead, this analysis focuses on a strategic niche: manufacturing specialized solar modules designed for rural electrification and the unique energy needs of Indonesia’s island communities.

Understanding Indonesia’s Unique Energy Landscape

To appreciate this opportunity, one must first understand the geographic and economic factors that define Indonesia’s energy sector. The sheer scale of the archipelago makes conventional grid extension both economically and logistically unfeasible for thousands of communities.

The Challenge of 17,000 Islands

With over 6,000 inhabited islands, Indonesia’s population is geographically dispersed, creating thousands of ‘energy islands’—communities far from the central grid that have historically relied on expensive and often unreliable diesel generators.

The cost of generating power from diesel in these remote areas can range from $0.25 to $0.30 per kWh, creating a strong economic incentive for more affordable, stable alternatives.

This distributed geography is the greatest obstacle to centralized power, but it is also the key driver for decentralized solutions like solar.

Government Mandates and Market Drivers

The Indonesian government is actively promoting a shift toward renewable energy, with a national target of achieving a 23% share in the energy mix by 2025. This commitment is supported by several key initiatives:

- Rural Electrification Programs: The state utility PLN (Perusahaan Listrik Negara) and the Ministry of Energy and Mineral Resources (ESDM) are implementing programs to electrify remote villages, often using solar solutions like centralized solar power plants (PLTS Terpusat) and solar street lighting (PJU-TS).

- Economic Viability: The falling cost of solar technology, combined with the high cost of diesel, makes solar an economically superior choice for off-grid applications, even without direct subsidies.

- Local Content Requirements (TKDN): Government tenders for energy projects often include Tingkat Komponen Dalam Negeri (TKDN), or local content requirements. This policy gives a distinct advantage to manufacturers producing goods within Indonesia.

For entrepreneurs considering starting a solar panel manufacturing business (https://pvknowhow.com/how-to-start-a-solar-factory/), these factors create a protected and growing market for locally produced solar modules.

The Opportunity: Tailored Modules for a Niche Market

Standard solar modules—typically large and designed for grid-tied systems—are ill-suited for the logistical challenges and practical needs of Indonesia’s off-grid markets. The true opportunity lies in manufacturing products engineered specifically for this environment.

Product Specifications for Off-Grid Success

A local manufacturing facility can focus its solar panel manufacturing line (https://pvknowhow.com/solar-module-manufacturing-machines/) on producing modules with specifications that meet the market’s exact needs:

- Size and Power: Smaller modules, in the 50Wp to 150Wp range, are easier to transport by small boat, carry by hand to remote villages, and install on small rooftops.

- Voltage: Production can be standardized for 12V and 24V systems, the common standards for off-grid battery applications that power lights, radios, and small appliances.

- Durability: Modules must be built to withstand the rigors of inter-island transport and resist corrosion in humid, saline marine environments. This requires robust frames and high-quality junction boxes.

- Efficiency: Since installation space is often limited, using high-efficiency cell technology is critical. A deeper understanding of photovoltaic module technology (https://pvknowhow.com/category/solar-module-technology/) is essential to making the right design choices.

Manufacturing these specialized modules locally creates a powerful value proposition that large, international producers focused on commodity products cannot easily match.

The Manufacturing Advantage: Why Produce Locally?

Establishing a domestic production facility offers strategic advantages beyond simply tailoring the product. As seen in J.v.G. turnkey projects in similar emerging markets, a local presence fundamentally changes the business dynamic.

Overcoming Logistical Hurdles

Importing fragile solar modules and distributing them across an archipelago is a costly, high-risk endeavor. A local factory dramatically shortens the supply chain, reducing transportation costs, import duties, and the risk of product damage. This logistical efficiency translates directly into a more competitive price point and greater product availability for end-users.

Aligning with Local Content Requirements (TKDN)

For entrepreneurs aiming to supply government-funded rural electrification projects, local manufacturing is not just an advantage; it is often a necessity. Meeting TKDN requirements can make a local producer the preferred supplier for large-scale tenders, creating a defensible market share.

Building a Brand for Reliability

A local manufacturing presence helps build trust. It signals a long-term commitment to the market and makes it possible to provide reliable after-sales support and warranty fulfillment—critical factors for communities investing in what may be their first-ever source of electricity.

Strategic Considerations for Market Entry

Entering this market requires more than technical production capabilities; it demands a well-considered distribution strategy and a phased approach to investment. A comprehensive business plan for solar panel manufacturing (https://pvknowhow.com/solar-panel-manufacturing-business-plan/) is the foundational document for this process.

Distribution is Key

The greatest challenge is often not production, but distribution. Reaching the end customer on a remote island requires a robust ‘last-mile’ delivery network. Success depends on building strong partnerships with:

- Local hardware and electronics stores

- Inter-island shipping and boat operators

- Community cooperatives and non-governmental organizations

- Regional installation companies

This network is the essential bridge between the factory and the end-user.

Developing a Phased Approach

A manufacturer does not need to start with a massive facility. A logical entry strategy is to begin with a small to medium-sized production line, perhaps with an annual capacity of 20–50 MW. This approach allows the business to establish its brand, refine its distribution channels, and scale production in line with market demand. Structured educational resources, like the e-courses provided by pvknowhow.com, can guide entrepreneurs through this critical planning phase.

Frequently Asked Questions (FAQ)

What initial investment is required for a small-scale module factory?

While every project is different, a 20–50 MW semi-automated line represents a significantly lower capital investment than a large-scale, fully automated facility. The focus is on strategic production for a niche market, not mass production for export.

Is deep technical expertise in solar required to start?

No. Successful entrepreneurs in this sector often come from other industries. The key is to have a strong business background and to partner with experienced technical consultants and equipment suppliers who can manage the project’s engineering, setup, and training.

How can a local factory compete with large international manufacturers?

Competition is not based on price-per-watt alone. A local factory competes by offering a superior solution for its specific market: tailored products, reduced logistical costs, compliance with local content rules, and trusted local support.

What are the biggest non-technical challenges?

Beyond securing financing, the primary challenges are navigating the regulatory landscape, establishing a reliable supply chain for raw materials, and building a resilient distribution network to reach remote customers.

Conclusion: Powering Progress, One Island at a Time

The business case for manufacturing solar modules in Indonesia is built on a specific, compelling opportunity: serving the unmet energy needs of its vast off-grid and archipelago communities. This is a venture where geographic challenges become market differentiators and government policies create a favorable environment for local industry.

For the forward-thinking entrepreneur, this is not merely a manufacturing enterprise. It is a chance to build a profitable business that also delivers tangible social and economic impact, powering progress and illuminating the future for communities across the Indonesian archipelago.