When planning a new solar module factory, investors tend to focus on machinery, financing, and location. Yet experience shows that the most critical factor for long-term success is a skilled and trainable workforce.

While Kazakhstan is globally recognized for its vast energy resources, its true—and often overlooked—asset for solar manufacturing is its deep-rooted industrial heritage. This analysis assesses the technical labor landscape in Kazakhstan’s key industrial regions. It outlines the opportunities and steps required to build a competent local team, serving as a guide for professionals evaluating the feasibility of a solar module production facility in the country.

The Untapped Potential of Kazakhstan’s Industrial Legacy

Understanding Kazakhstan’s labor market requires looking beyond current economic indicators to its industrial history. The country’s past as an industrial powerhouse within the Soviet Union created a strong foundation in engineering, metallurgy, and heavy manufacturing. This ‘industrial DNA’ means that while few technicians may have direct solar PV experience, there is a large pool of individuals with transferable core competencies.

Engineers and technicians from these traditional sectors possess a fundamental understanding of:

- Mechanical and electrical systems

- Industrial process control

- Quality assurance protocols

- Maintenance of complex machinery

This existing skill set provides a solid foundation for building PV-specific knowledge, significantly reducing the learning curve compared to regions without a similar industrial background. The challenge lies not in a lack of talent, but in creating a structured program to adapt these skills to the precision requirements of modern solar module assembly.

Analysis of Key Industrial Hubs

Several regions in Kazakhstan stand out as prime candidates for a manufacturing facility, each with a unique profile. Our research and project experience show that the Almaty, Karaganda, and Pavlodar regions offer the most promising conditions.

A typical semi-automated production line with a 20–50 MW annual capacity requires a workforce of 30 to 50 people, including engineers, technicians, operators, and administrative staff. The availability of this talent varies by region.

Kazakhstan’s industrial regions provide a solid foundation for developing a skilled solar manufacturing workforce.

Almaty Region: The Commercial and Technical Center

As the nation’s largest city and commercial hub, Almaty has distinct advantages. It is home to leading technical universities that produce a steady stream of engineering graduates, and its workforce is generally more exposed to international business practices and modern technologies.

- Labor Profile: A higher concentration of graduate engineers, particularly in electrical engineering, automation, and IT. Competition for top talent can be higher due to the presence of multinational corporations.

- Wage Structure: Generally the highest in the country. A qualified engineer can expect a monthly salary of USD 1,200–1,500, while a skilled technician typically earns USD 700–900.

- Recruitment Focus: Ideal for sourcing plant managers, process engineers, and quality control specialists who require strong theoretical knowledge and management skills.

Karaganda Region: The Heartland of Heavy Industry

Karaganda has long been the heart of Kazakhstan’s coal mining and metallurgical industries, creating a deep reservoir of experienced technicians and mechanical engineers accustomed to demanding production environments.

- Labor Profile: Strong in mechanical engineering, maintenance, and hands-on problem-solving. These individuals are highly practical and experienced with large-scale industrial equipment.

- Wage Structure: More moderate than in Almaty, with typical salaries around USD 1,000–1,200 for engineers and USD 600–750 for technicians.

- Recruitment Focus: An excellent source for shift leaders, maintenance crews, and machine operators who can be trained on the specifics of PV equipment like laminators and stringers.

Pavlodar Region: Power Generation and Petrochemicals

Located in the northeast, Pavlodar is a hub for power plants, aluminum production, and petrochemical facilities. Its workforce is familiar with 24/7 operations, stringent safety protocols, and process-oriented manufacturing.

- Labor Profile: Expertise in chemical and process engineering, as well as high-voltage electrical systems. There is a strong culture of adhering to standards and procedures.

- Wage Structure: Competitive and similar to Karaganda. Engineers earn approximately USD 1,000–1,200 per month and technicians around USD 600–750.

- Recruitment Focus: Suitable for finding quality assurance managers, process technicians, and personnel comfortable with the precise material handling required in solar module production.

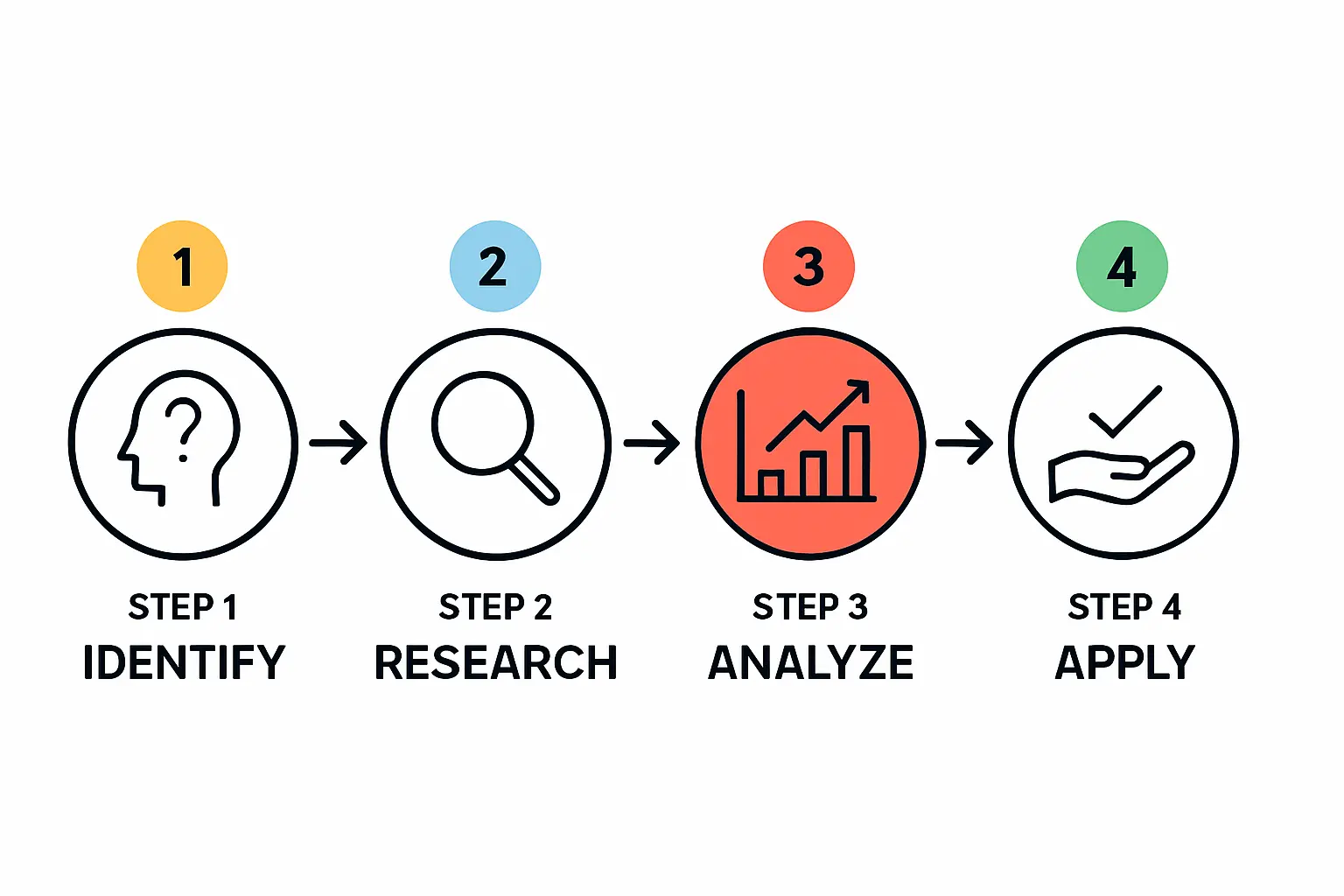

Bridging the Skills Gap: From Traditional Engineering to Solar PV

While these foundational skills exist, a critical step is to bridge the gap to meet the specific demands of photovoltaic manufacturing. For example, a mechanical engineer from a steel plant understands machinery but must be trained on the delicate handling of solar cells and the precision required for bussing and lamination.

Key training areas include:

- Solar Cell Handling: Understanding micro-cracks and the proper handling of fragile silicon wafers.

- Electroluminescence (EL) and IV Testing: Operating and interpreting data from specialized quality control equipment.

- Lamination Parameters: Managing the precise temperature, pressure, and timing cycles crucial for module durability.

- Material Science: Knowledge of EVA, backsheets, and other specialized materials used in module assembly.

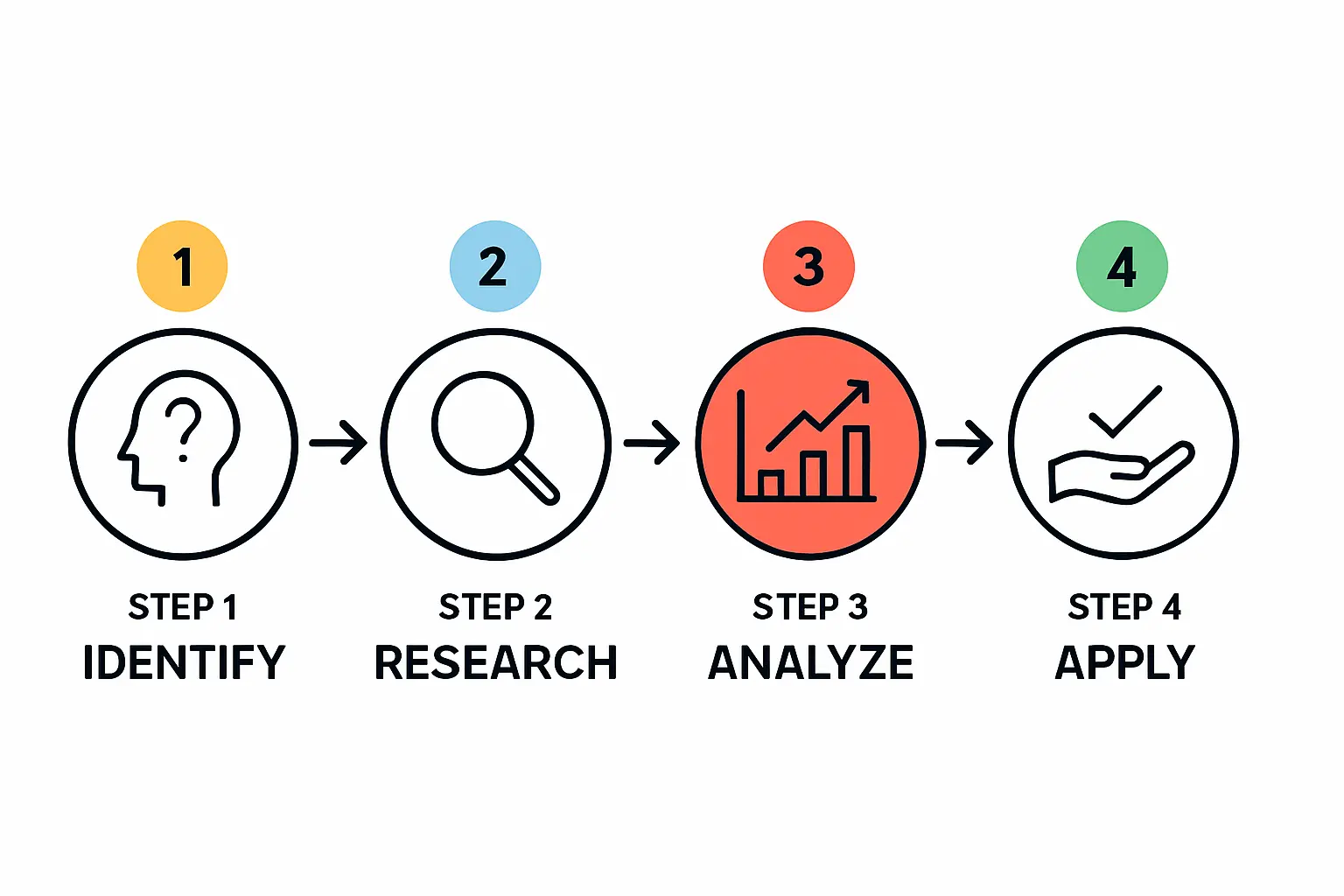

Successfully adapting these skills is a core challenge for any investor. A focus on human capital is therefore a critical component when planning the setup of a turnkey solar production line. A well-structured training program combining classroom theory with hands-on practice is essential. Based on experience from J.v.G. turnkey projects, a three-month intensive program is often sufficient to bring a team with a solid industrial background to the required proficiency.

Frequently Asked Questions (FAQ)

Do we need to hire experienced solar technicians from abroad?

Having one or two expatriate experts to lead the local team during the initial setup and training phase (typically 6–12 months) is advisable. The long-term goal, however, should be to develop a fully self-sufficient local workforce. The talent pool in Kazakhstan is strong enough to make this a realistic objective.

What is a realistic timeframe for training a local team?

A team with prior industrial experience typically requires two to four months of training. This period includes initial classroom instruction followed by hands-on work during the commissioning of the production line. Continuous on-the-job training should follow throughout the first year of operation.

How do wages in Kazakhstan compare to other emerging markets?

Engineering and technical wages in Kazakhstan are competitive—generally higher than in parts of Southeast Asia or Africa but lower than in Eastern Europe or Latin America. The key advantage is the high level of fundamental technical education and industrial experience available for the investment.

What non-technical roles are crucial for a new factory?

Beyond engineers and technicians, it is essential to recruit for roles in supply chain management, logistics, finance, and sales. Given Kazakhstan’s strategic location and developing transport links, experienced logistics personnel are particularly valuable.

Conclusion: Capitalizing on Kazakhstan’s Human Resources

Kazakhstan presents a compelling case for investment in solar module manufacturing, not just because of its market potential but also for the quality of its human capital. The country’s industrial past has forged a workforce with the foundational skills and work ethic needed to master the precision of modern photovoltaic production.

However, this success is not automatic; it requires a deliberate strategy. Investors must conduct thorough regional assessments, design targeted recruitment campaigns, and commit to a comprehensive training program. By transforming this existing industrial talent into a specialized solar workforce, a new enterprise can build a durable competitive advantage and contribute to Kazakhstan’s renewable energy future.