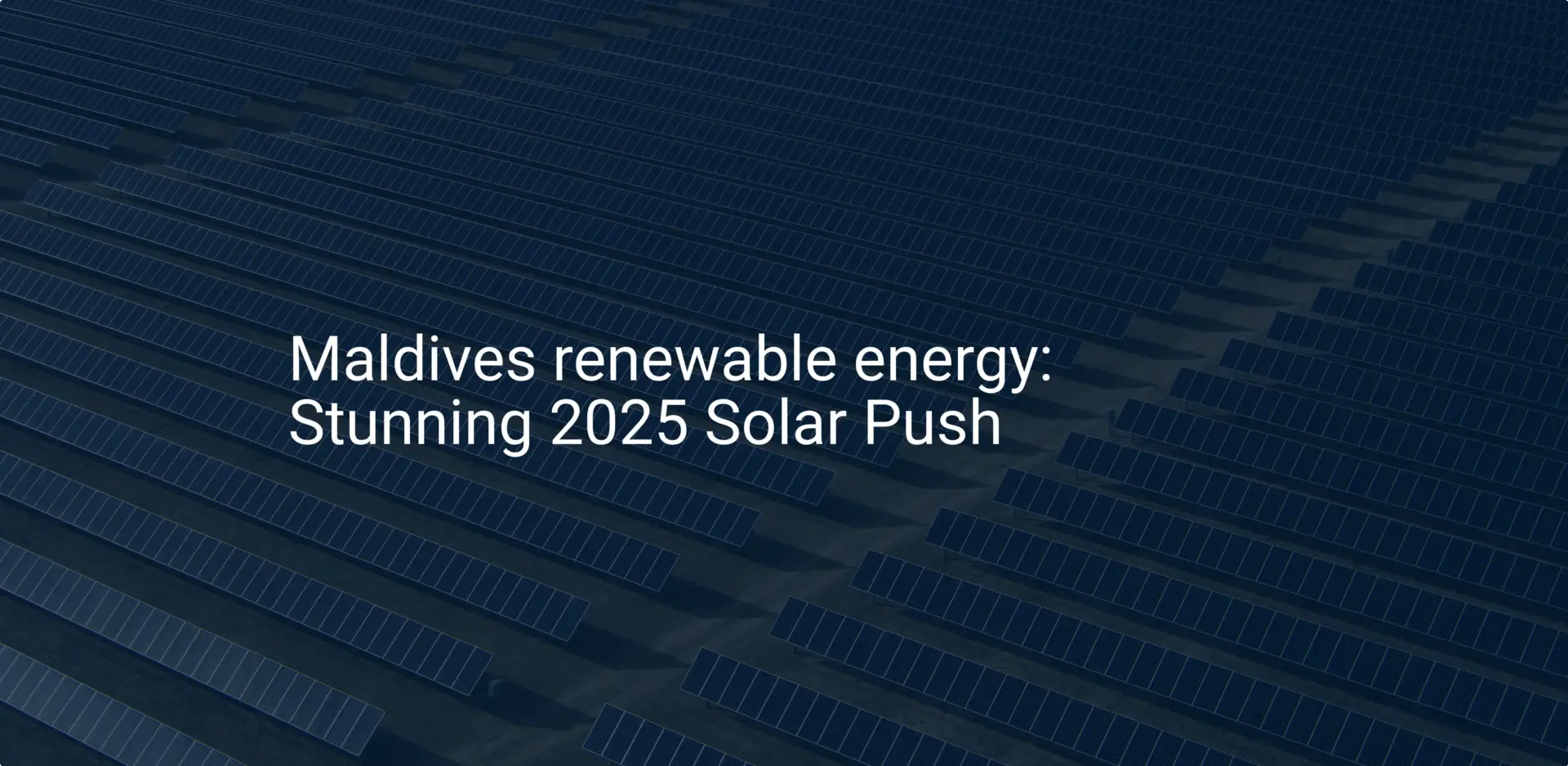

Establishing a manufacturing facility in the Maldives presents a unique set of challenges and opportunities. For entrepreneurs venturing into solar panel production, the nation’s commitment to renewable energy is a powerful driver. Yet this ambition is set against the backdrop of extreme land scarcity and a topography that is among the world’s most vulnerable to climate change. How can anyone build a lasting industrial enterprise in a country where 99% of the territory is ocean and 80% of its landmass sits less than one meter above sea level?

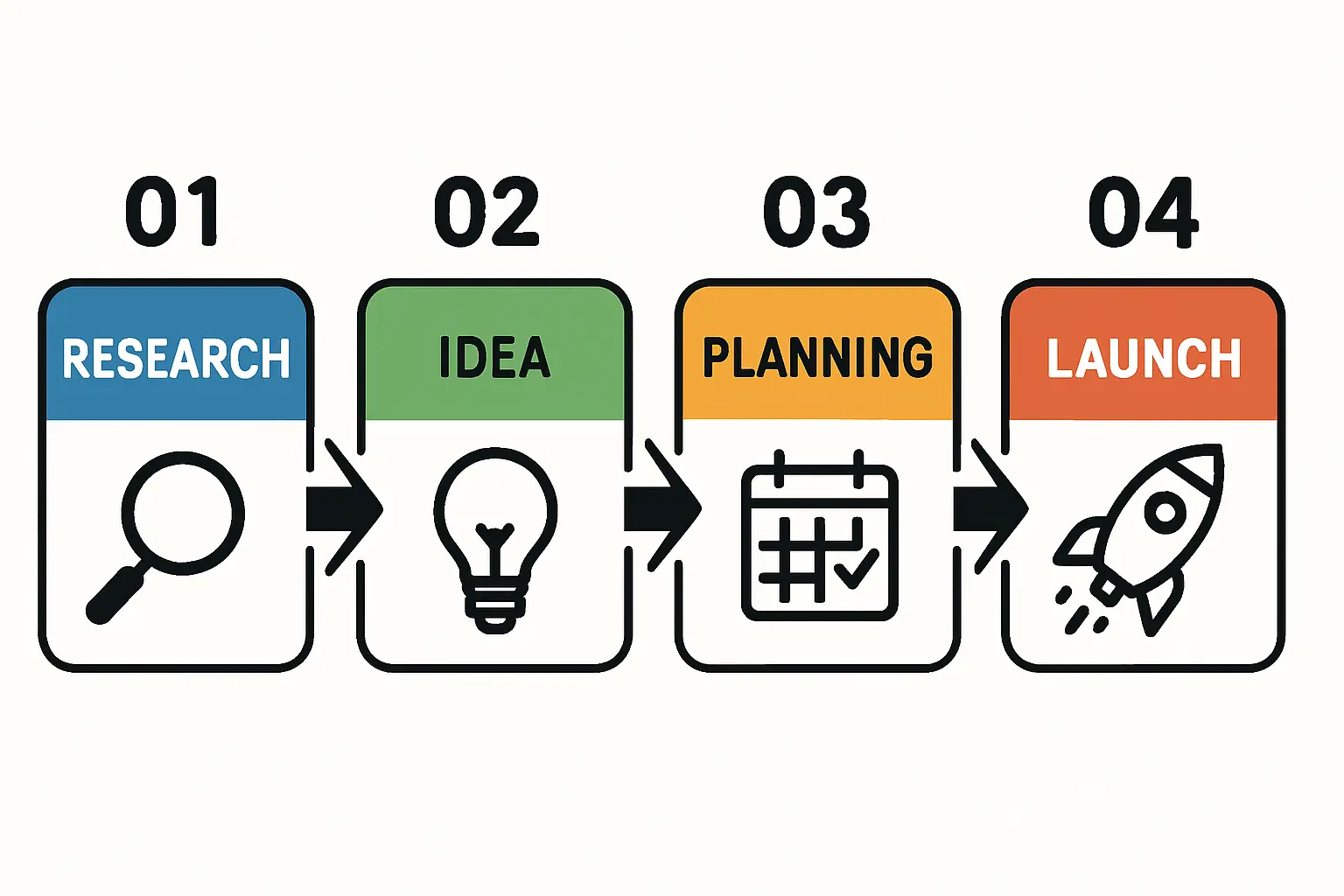

This question is not a deterrent but a crucial strategic consideration. Success in the Maldives requires a departure from conventional site selection models. It demands a forward-thinking approach that integrates climate resilience into the very foundation of the business plan. This guide provides a framework for navigating land acquisition, factory design, and logistical planning within this unique context.

The Maldivian Paradox: Opportunity Meets Environmental Reality

Any serious investment analysis must begin with the Maldivian landscape. The nation comprises roughly 1,192 coral islands, with only 187 inhabited. Its total land area is a mere 298 square kilometers, dispersed across a vast expanse of the Indian Ocean. This geographic reality inherently constrains industrial development.

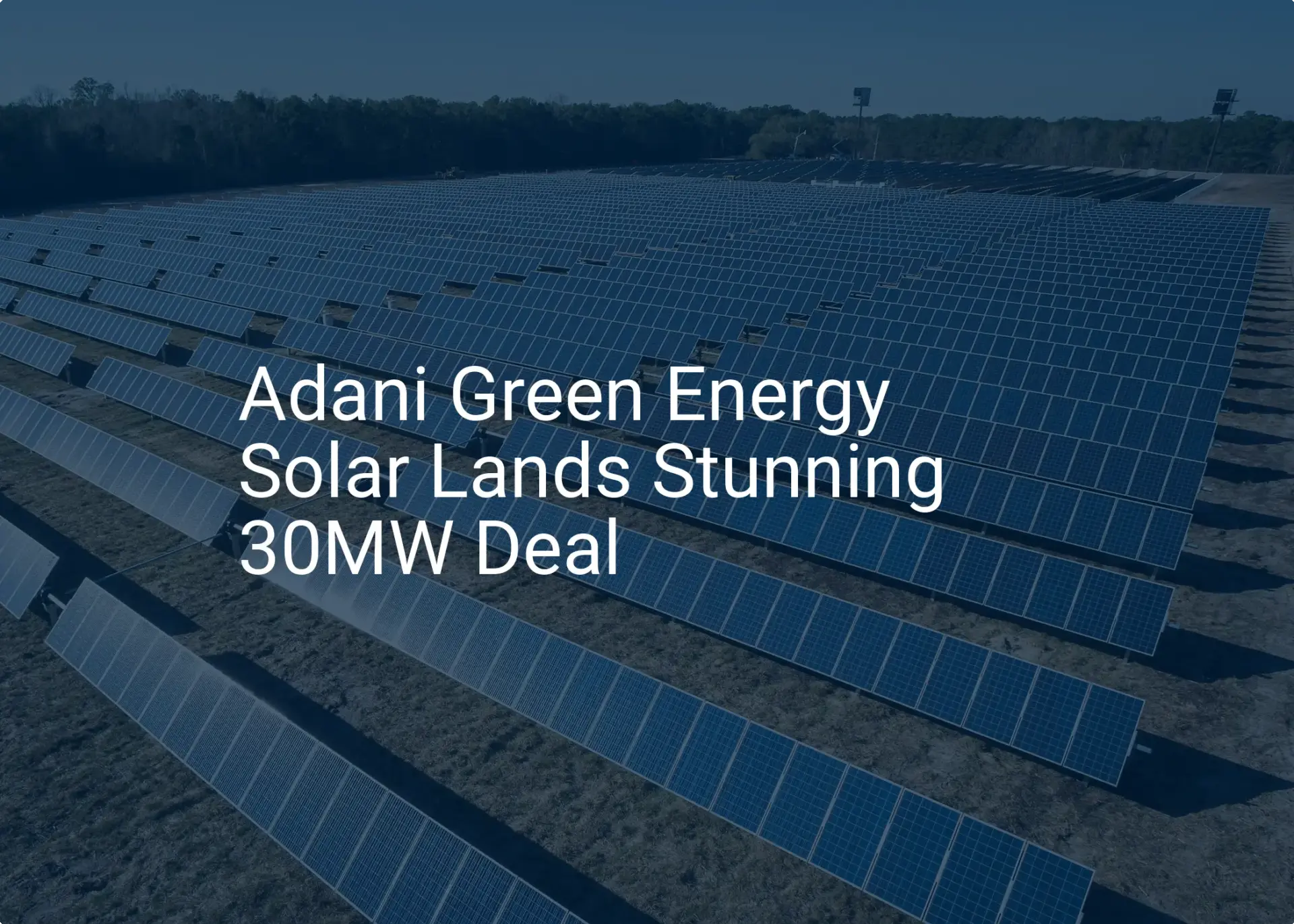

For a solar module manufacturer, the paradox is stark: the country has abundant solar irradiance, making it a prime market for photovoltaic technology, yet the land needed for a factory is exceptionally scarce and environmentally exposed. The existential threat of rising sea levels is no distant forecast; it is a present-day reality that must shape every aspect of infrastructure planning. A successful venture will be one that turns these constraints into a competitive advantage through superior engineering and strategic location.

Navigating Land Acquisition: Key Locations and Strategies

Finding a suitable plot for a factory is perhaps the most significant initial hurdle. Options are limited and require careful evaluation based on logistics, infrastructure, and long-term climate security.

Industrial Hubs and Special Economic Zones

To concentrate infrastructure and streamline development, the Maldivian government has designated specific islands for industrial use. The most prominent of these is Thilafushi, near the capital, Malé. Historically known for waste management, it is being transformed into a comprehensive industrial zone. Locating within such a zone offers access to existing port facilities and utility connections, but investors must still conduct thorough due diligence on a specific site’s elevation and historical land stability.

The Hulhumalé Model: Engineered for the Future

Reclaimed and master-planned islands offer a more forward-looking solution. Hulhumalé, connected to the international airport and the capital, is a prime example. It was engineered with climate resilience as a core principle, with land reclaimed to an elevation of two meters above mean sea level.

Choosing a site in Hulhumalé or a similarly planned development may involve higher initial land lease costs. This premium, however, often translates into lower long-term risk, superior infrastructure, and better access to a skilled workforce. For a high-value manufacturing operation like a solar assembly plant, this stability is a critical asset.

Designing a Climate-Resilient Solar Factory

Once a location is secured, the focus shifts to the physical structure. Standard industrial construction is insufficient for the Maldivian environment. Factory design must mitigate risks from sea-level rise, storm surges, and the corrosive marine atmosphere—all vital considerations detailed in our guide to factory building requirements.

Elevated Foundations and Flood-Proofing

The most critical design adaptation is building on an elevated foundation or stilts. This raises the factory floor well above projected future flood levels, protecting valuable solar manufacturing machines and inventory. The added upfront construction cost is a prudent investment when weighed against the potential for catastrophic losses from a single extreme weather event.

Material Selection and Corrosion Resistance

The high salinity of the air in the Maldives accelerates corrosion in standard metals and building materials. A resilient factory design must therefore specify corrosion-resistant materials—such as high-grade stainless steel, specially treated concrete, and non-corrosive composites—for both the building structure and critical equipment housing. This approach extends the facility’s operational lifespan and reduces long-term maintenance costs.

A Reality Check on Infrastructure and Logistics

A factory does not operate in a vacuum. Its success is inextricably tied to the reliability of its supply chain, energy sources, and transportation networks.

Supply Chain and Maritime Transport

The Maldivian economy depends entirely on sea and air freight. A solar module factory will need to import all its raw materials (from solar cells and glass to aluminum frames) and export its finished products. Proximity to the international seaport in Malé is a major strategic advantage, minimizing the costs and complexities of inter-island transport. Any comprehensive solar panel manufacturing business plan must meticulously account for these logistical realities, including shipping times, import duties, and warehousing.

Energy and Utility Access

Ironically for a solar panel manufacturer, a key operational challenge is securing stable and affordable electricity. Most islands rely on expensive diesel generators for power. This presents both a high operational cost and a strategic opportunity. A factory can partly mitigate this by installing its own large-scale solar power system, showcasing its product and reducing reliance on fossil fuels. This approach is often integrated into the planning for a turnkey solar production line, where energy self-sufficiency is part of the initial design.

Frequently Asked Questions (FAQ)

What is the typical process for acquiring industrial land in the Maldives?

Industrial land is typically acquired through long-term leases from the government or state-owned development corporations rather than outright purchase. The process involves submitting a detailed investment proposal and negotiating lease terms, which often vary depending on the location and strategic importance of the project.

Is it more cost-effective to build on a reclaimed island like Hulhumalé?

While the upfront leasing and construction costs on an engineered island like Hulhumalé may be higher, it often proves more cost-effective in the long run. The reduced risk of climate-related disruption, coupled with access to better infrastructure and utilities, creates a more stable and predictable operating environment, which is crucial for manufacturing.

How does the Maldivian government support foreign investment in manufacturing?

The government actively encourages foreign investment, particularly in sectors like renewable energy that align with its national development goals. Support can include streamlined registration processes and potential incentives within Special Economic Zones. Engaging with local legal and business consultants is essential to navigate the regulatory framework effectively.

What are the main logistical challenges to plan for?

The primary challenges are dependency on international shipping for all materials, the potential for weather-related disruptions to sea transport, and the ‘last-mile’ logistics of moving goods between atolls. A robust supply chain strategy with sufficient buffer inventory is critical for maintaining uninterrupted production. Experience from J.v.G. turnkey projects shows that detailed logistical planning is a cornerstone of a successful factory launch.