An investor considering Malaysia for a new solar module factory often sees the obvious advantages: a stable economy, strong infrastructure, and a strategic position in Southeast Asia for exports.

A common oversight, however, is to focus solely on the global market and miss a more immediate and significant opportunity: the protected domestic market created by the Malaysian government’s own policies.

Understanding the nuances of regulations like Local Content Requirements isn’t just about compliance—it’s the key to unlocking a foundational customer base and building a resilient business from day one. This article breaks down the essential regulatory framework that new manufacturers must grasp to succeed in Malaysia.

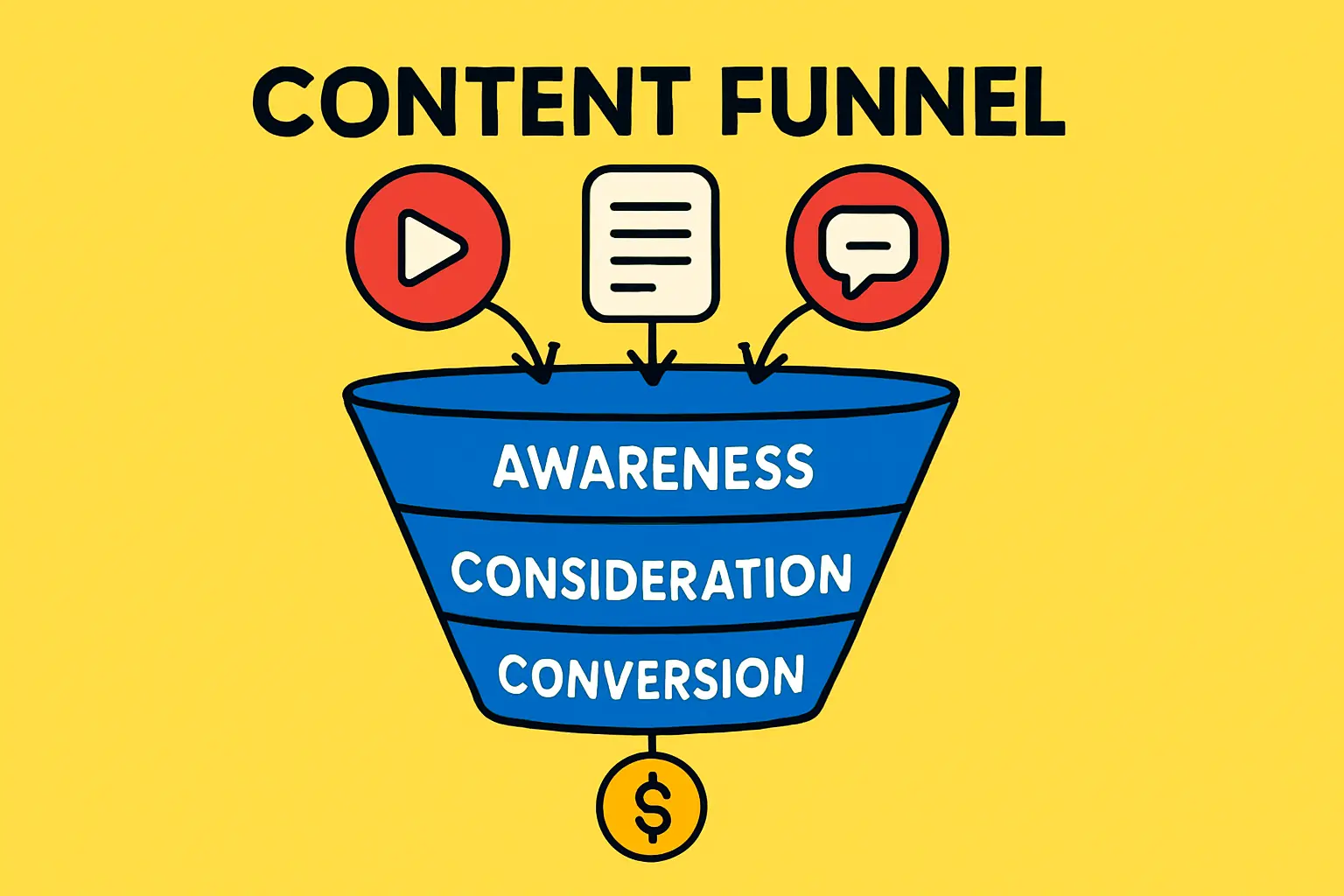

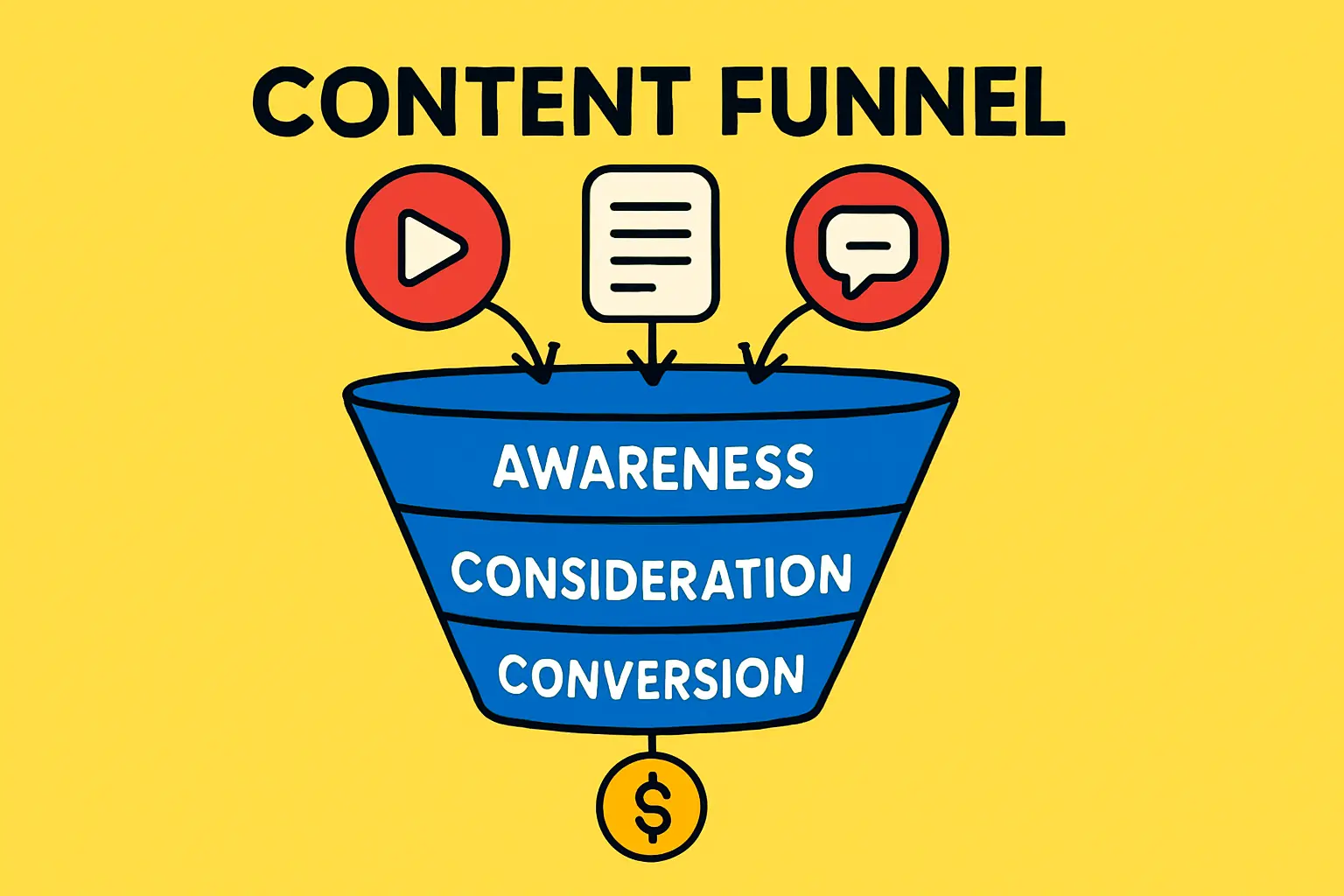

What are Local Content Requirements (LCR)?

A Local Content Requirement (LCR) is a policy that obligates companies to use a certain percentage of locally sourced goods, services, or labor in their projects. These policies are designed to foster domestic industry, create skilled employment, and enhance the nation’s technological capabilities, reducing reliance on imported products.

For a new solar module manufacturer in Malaysia, this means that to supply certain large-scale projects, your products must be certified as ‘Made in Malaysia.’ This goes beyond simple final assembly and often involves meeting specific criteria for local value addition defined by the authorities.

These requirements are typically embedded within government-led initiatives, making them a critical factor for any company aiming to participate in the national energy transition.

The Role of SEDA and the Large-Scale Solar (LSS) Program

The key institution at the center of Malaysia’s renewable energy landscape is the Sustainable Energy Development Authority (SEDA). SEDA is responsible for implementing government policies aimed at promoting sustainable energy, including the country’s flagship initiative for solar power, the Large-Scale Solar (LSS) program.

The LSS program is a competitive bidding process where developers submit proposals to build and operate large solar power plants. Since its third round (LSS3), the Malaysian government has established local content requirements as a key evaluation criterion. This gives a significant advantage to project bids that commit to using locally manufactured solar modules.

This policy creates direct and predictable demand for Malaysian-made panels. It is the government’s primary tool for ensuring the country’s growth in solar energy also spurs a domestic manufacturing ecosystem. For an investor, this policy effectively creates a captive market.

Understanding Domestic Market Obligations (DMO)

While Malaysia may not have a formal Domestic Market Obligation (DMO) that mandates selling a fixed percentage of production locally—as seen in some natural resource industries—the LSS program functions as a powerful de facto DMO.

The mechanism is market-driven rather than mandated:

-

Government Tender Advantage: Developers bidding for LSS projects are incentivized to source modules locally to strengthen their proposals.

-

Created Demand: This incentive generates consistent and substantial demand from LSS project winners who need to fulfill their commitments.

-

Market Focus: New local manufacturers find that their most immediate and accessible market is not overseas, but right at home, supplying these large-scale projects.

Ignoring this dynamic in favor of an export-only strategy means forfeiting access to the most stable and government-supported segment of the market. This insight must be a cornerstone of the business plan, directly influencing the financial projections for your factory.

Practical Implications for New Solar Manufacturers

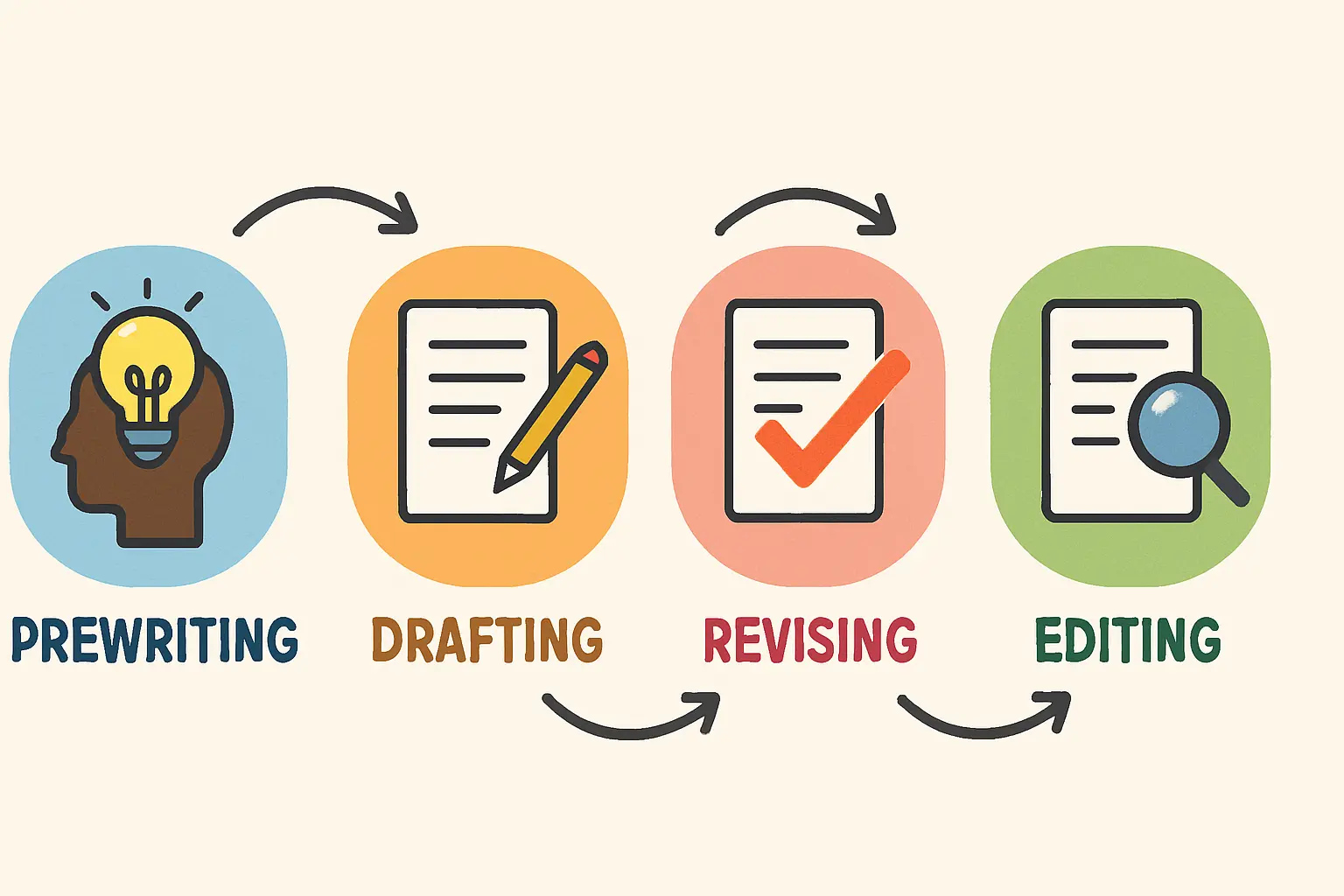

Aligning a new manufacturing venture with these regulations requires a strategic approach from the very beginning.

Sales and Marketing Strategy

The primary sales focus, particularly in the initial years, should be on positioning the company as a preferred supplier for LSS project developers. This involves building relationships with local engineering, procurement, and construction (EPC) companies and understanding the LSS auction pipeline.

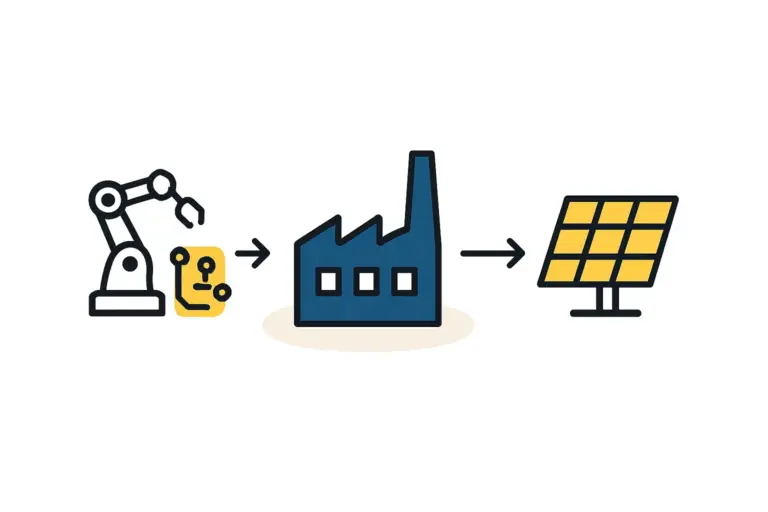

Production and Technical Setup

The design of the solar module production line must ensure the output meets the technical specifications and quality standards required by LSS projects. This includes module efficiency, durability, and compliance with national standards.

Compliance and Certification

To be recognized as a local product, modules must undergo testing and receive the necessary certifications, such as those issued by SIRIM, the national standards and quality organization. This is a non-negotiable step to qualify for local content schemes. Experience from J.v.G. turnkey projects in emerging markets shows that aligning a factory’s technical setup with local regulatory requirements from day one is a critical success factor.

Frequently Asked Questions (FAQ)

Do these rules apply if my factory only plans to export from Malaysia?

The rules are specifically tied to supplying domestic programs like the LSS. An export-only factory is not obligated to meet them. However, it would be unable to compete for the large, government-backed domestic projects, which often represent the most reliable initial revenue stream.

How can I determine the exact local content percentage required?

The specific requirements, including percentages and definitions of ‘local content,’ are detailed in the Request for Proposal (RfP) documents published for each LSS auction round. These criteria can be adjusted by the government between rounds, so consulting the latest official documents is essential.

Does assembling modules in Malaysia automatically qualify them as ‘local’?

Not always. Qualification often depends on meeting a more detailed definition of local value-add. This may include criteria beyond final assembly, such as the use of local labor and potentially sourcing other components domestically. The precise definition is set by the authorities managing the LSS program.

Are there other domestic markets besides the LSS program?

Yes. The Net Energy Metering (NEM) program, which encourages rooftop solar for commercial, industrial, and residential customers, is another significant source of domestic demand. Corporate Power Purchase Agreements (PPAs) for green energy also contribute to the market, providing a secondary sales channel for local manufacturers.

Conclusion: Strategic Planning is Key

Malaysia’s solar policies are intelligently designed to build a self-sustaining domestic industry, not just to generate clean energy. For a prospective investor, understanding the interplay between Local Content Requirements and the LSS program is strategically vital.

These regulations are not obstacles; they are invitations to become a foundational part of a protected and growing market. By incorporating these realities into the business plan from the outset, a new manufacturer can build a stronger, more resilient enterprise.

For those in the early stages of planning, the structured resources at pvknowhow.com can provide a foundational understanding of how to align a factory’s technical and business strategy with such market-specific regulations.