When an entrepreneur considers building a solar module factory in Somalia, the initial focus is usually on capital, technology, and logistics. The question of the workforce, however, soon follows: Is it possible to find and train the technical staff needed to operate a modern manufacturing facility where the industry is still nascent?

This concern, while understandable, often stems from an incomplete picture of the local labor landscape. While Somalia may lack a pre-existing pool of experienced solar module technicians, it possesses a significant, often overlooked asset: one of the world’s youngest populations.

With approximately 73% of its people under 30, this demographic isn’t a challenge—it’s a vast reservoir of potential, ready to be channeled into new industries with the right approach to training and development.

The Somali Labor Market: A Landscape of Potential and Challenge

Developing a realistic human resources strategy begins with understanding the local context. The Somali labor market has a unique set of conditions that, when properly addressed, can become strategic advantages.

The primary challenge is a high youth unemployment rate, estimated by international bodies at around 67%, compounded by a national literacy rate of approximately 30%. While these figures may seem daunting, they point to a clear need for practical, hands-on vocational training over purely academic instruction.

An entrepreneur bringing structured employment and skills development isn’t just building a factory; they are helping solve a pressing national priority. This position often earns strong governmental and community support.

The key is to view the workforce as a clean slate. Without pre-existing habits from other manufacturing sectors, a new team can be trained from the ground up on global best practices in quality control and operational efficiency.

Leveraging Existing Skills and Training Infrastructure

While direct experience in photovoltaic manufacturing is rare, the foundational skills for technical roles are already being cultivated within Somalia. Organizations like the Norwegian Refugee Council (NRC) have long recognized that Technical and Vocational Education and Training (TVET) is a crucial pathway to employment.

These TVET programs focus on practical skills like electrical wiring, metalworking, and general mechanics. A candidate who has completed an electrical wiring course, for example, already has the fundamental understanding of circuits and safety protocols required to become a junction box operator or an electro-luminescence (EL) tester.

This infrastructure provides a ready pool of pre-vetted candidates who have already demonstrated an aptitude for technical work. Furthermore, governmental and World Bank initiatives like the SCALED-UP project are actively working to improve digital literacy. This aligns perfectly with the needs of a modern factory, where machine operators interact with computer-based interfaces and monitoring systems.

Defining Workforce Requirements for a Solar Module Factory

A common misconception is that a solar factory requires a large team of highly specialized engineers. In reality, a typical 20–50 MW production line operates with a surprisingly lean and structured team.

Based on J.v.G. internal data from numerous turnkey projects, a facility of this size generally needs 25 to 30 employees per shift, segmented into these distinct roles:

-

Machine Operators: This is the largest group. Their primary role is to manage specific stations, such as the stringer, lay-up station, or laminator. The key requirements are not advanced degrees but discipline, attention to detail, and the ability to follow standardized processes.

-

Maintenance Technicians: A smaller, more specialized team is responsible for the upkeep, calibration, and repair of the solar panel manufacturing machines. Candidates with a background in mechanics or industrial electrics from TVET programs are ideal for this track.

-

Quality Control (QC) Inspectors: These individuals are trained to perform specific tests—such as visual inspection, EL testing, and sun simulation—at critical points in the production line to ensure every module meets international standards.

-

Supervisors: These team leaders oversee shift operations, manage production flow, and ensure safety protocols are followed. These roles are often filled by promoting the most capable operators and technicians after a period of strong performance.

The overall solar panel manufacturing plant cost must include a dedicated budget for a robust training program, as this investment is as critical as the machinery itself.

A Structured Approach to Training and Skill Development

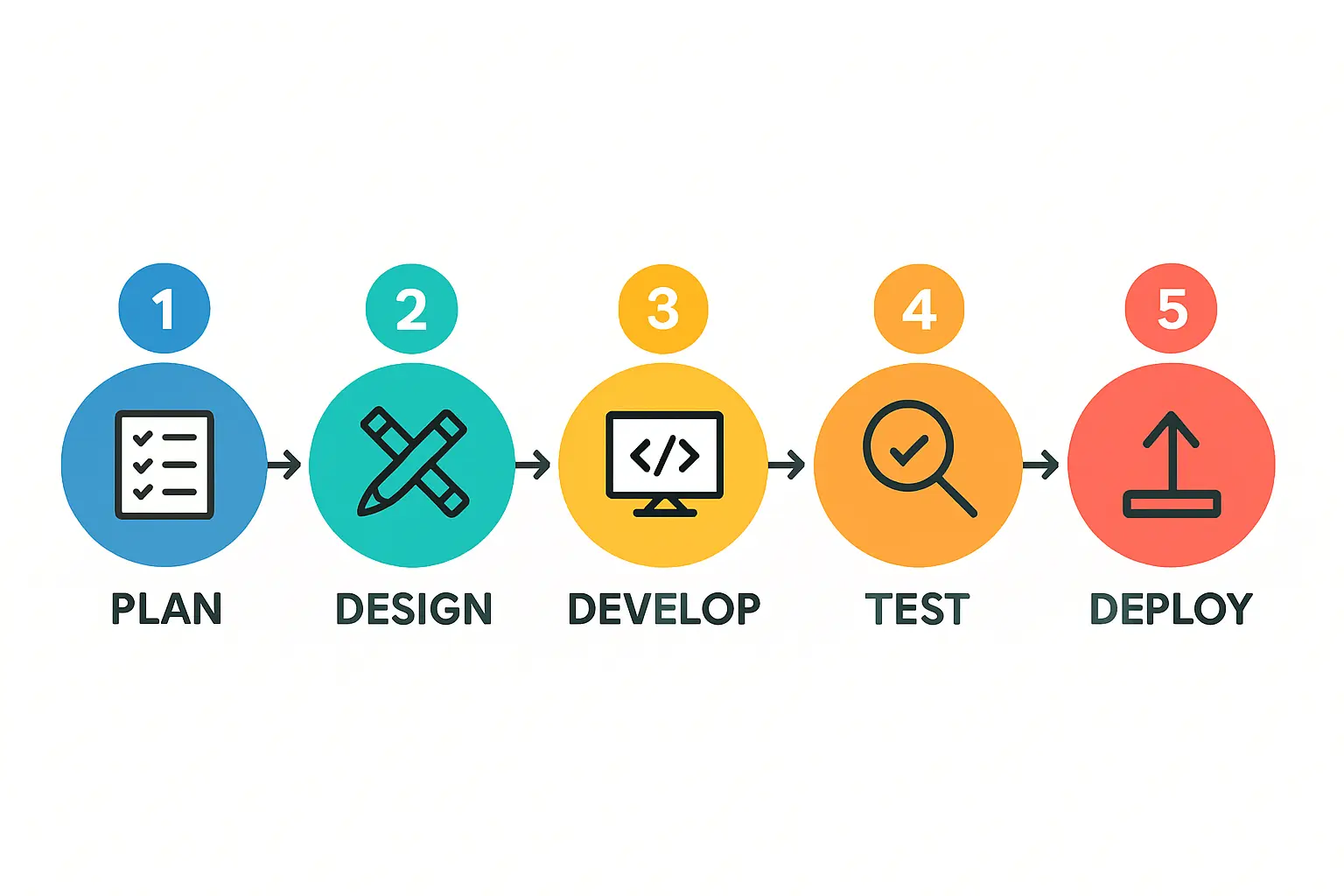

Since a pre-trained workforce isn’t an option, a formal knowledge transfer and training program is essential for success. This systematic process is broken down into phases, ensuring the local team is fully competent by the time the factory begins commercial operation.

Based on J.v.G.’s experience with turnkey projects, a proven methodology includes the following stages:

-

Phase 1: Foundational Classroom Training: Before ever touching the equipment, the entire team undergoes classroom instruction. This covers the fundamentals of photovoltaic technology, material handling, electrostatic discharge (ESD) safety, and the core principles of quality management.

-

Phase 2: On-the-Job Machine Training: Once the production line is installed, training moves to the factory floor. European engineers or master trainers work directly with small groups, demonstrating the operation of each machine. Operators typically need 4-6 weeks to become proficient and consistent.

-

Phase 3: Specialized Technical Training: The maintenance technicians receive intensive, hands-on training focused on the most complex equipment, such as the stringer and laminator. This deep dive into troubleshooting, preventive maintenance, and spare parts management can take up to 3 months.

-

Phase 4: Ramp-Up and Optimization: As the factory begins pilot production, trainers remain on-site to supervise operations, help optimize workflows, and reinforce best practices. This ensures a smooth transition to full-scale, independent production.

Long-Term Benefits of Investing in Local Talent

Building a local workforce from the ground up is more than a necessity; it’s a strategic business decision with significant long-term advantages.

-

Operational Cost-Effectiveness: Local staff wages result in a more sustainable operational cost structure compared to relying on a large contingent of expatriate managers and technicians.

-

Stability and Ownership: A local team that has been invested in shows higher retention rates and a greater sense of ownership over the factory’s success.

-

Community and Government Relations: A factory that provides stable, well-paying technical jobs becomes a valued community asset, fostering goodwill and strong relationships with local and national authorities.

-

Scalability: By developing a core of trained local supervisors and technicians, the business has the in-house ability to train new staff for future production line expansions.

Proper workforce planning is a foundational element in understanding how to start a solar panel factory effectively, especially in an emerging market.

Frequently Asked Questions (FAQ)

What is the minimum educational level for machine operators?

For most operator roles, a primary or secondary school education is sufficient, as long as the candidate is disciplined and can follow instructions. Literacy is important for reading work orders and safety notices.

How long does it take to train a full factory team?

The core team can be trained to operate the line safely and efficiently within 3 months. This timeline includes classroom instruction, hands-on machine training, and a supervised production ramp-up period.

Is it better to hire for attitude or existing skills?

In a market like Somalia, attitude, discipline, and a willingness to learn are far more important than pre-existing skills. Technical skills can be taught through a structured program, but a strong work ethic cannot.

What are the most critical roles to hire and train first?

The maintenance technicians and production supervisors are the most critical. Technicians ensure machine uptime, which is the backbone of production. Supervisors ensure that processes and quality standards are consistently enforced across the entire shift.

Can the entire training program be conducted locally in Somalia?

Yes. A standard part of a turnkey factory solution involves sending experienced engineers to the project site to conduct the full training program locally. This ensures the team learns on the exact equipment they will be using.

Conclusion and Next Steps

The question for entrepreneurs in Somalia is not whether a skilled workforce can be found, but how to build one effectively. The country’s young, motivated population presents a remarkable opportunity. By implementing a structured, phased training program that leverages existing skills from vocational institutions, a new solar module factory can cultivate a world-class technical team from local talent.

This approach transforms a perceived obstacle into a competitive advantage, creating a resilient, cost-effective, and socially impactful operation. This labor force assessment is a critical step in a process that also involves detailed financial modeling, facility planning, and technology selection.