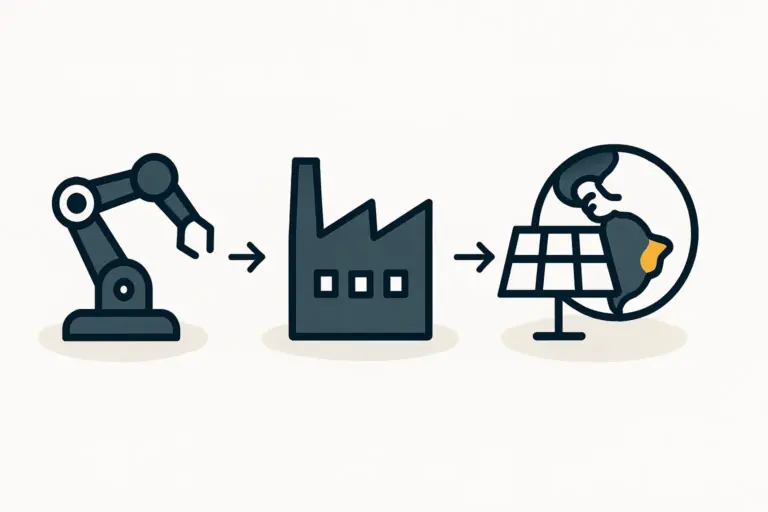

For international investors evaluating new markets, Uruguay presents a compelling case: a stable democracy, a strong commitment to renewable energy, and a strategic location within Mercosur.

But investors often ask a critical question: how do you navigate a labor market known for its strong worker protections and high union density? The answer lies not in avoidance, but in understanding a system built on structure, predictability, and dialogue.

This guide offers a practical overview of Uruguay’s labor regulations, union landscape, and talent development ecosystem for business professionals considering an investment in the country’s growing solar sector. It provides a clear framework for building a skilled and compliant workforce from the start.

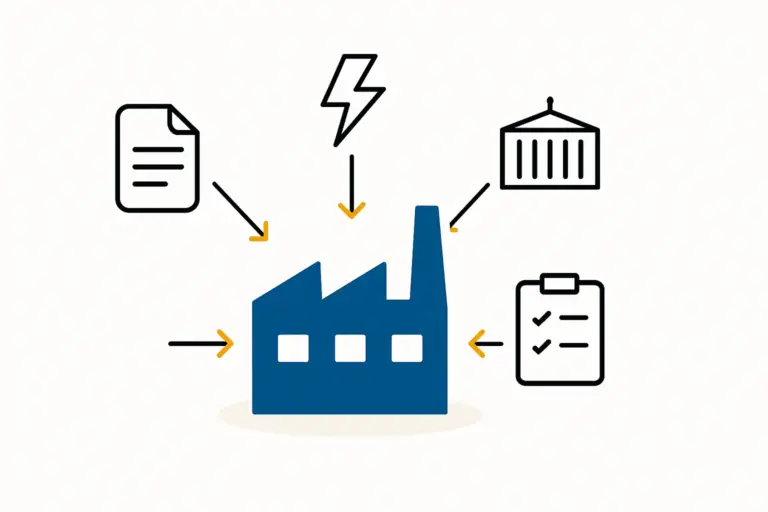

Understanding Uruguay’s Labor Framework: A System of Rules

Uruguay’s labor environment is defined by comprehensive legal protections for employees. While this may seem daunting at first, it creates a clear and predictable operational framework. Instead of navigating ambiguity, investors can plan for well-defined costs and procedures.

Key Regulatory Pillars

Employer-employee relations are built on several key components:

-

Sectoral Wage Councils (Consejos de Salarios): These tripartite bodies, made up of representatives from government, employers, and employees, negotiate minimum wages and working conditions for specific industries. This system ensures that compensation standards are consistent and transparent across a sector.

-

Collective Bargaining: Law 18,566 formally protects the right to collective bargaining, making union negotiation a standard and legally recognized part of business operations. The primary trade union confederation, PIT-CNT, plays a significant role in these discussions.

-

Social Security Contributions: Employers and employees are required to make contributions to the Social Security Bank (Banco de Previsión Social – BPS). Employer contributions, which typically represent a significant percentage of an employee’s salary, must be factored into financial planning as a core labor cost.

-

Termination of Employment: The law allows for the termination of employment contracts at the employer’s discretion, but it mandates severance pay (despido). This payment is calculated based on an employee’s tenure and salary, making workforce reduction a predictable, albeit significant, expense.

Understanding these regulations is a fundamental part of due diligence and central to any viable business plan. They aren’t obstacles, but fixed parameters for calculating your operational expenditures.

Sourcing and Developing Technical Talent

A primary concern for any new manufacturing venture is the availability of a skilled workforce. While Uruguay may not have a large pool of technicians with direct experience in solar module assembly, it has a strong foundation of technical education to build upon.

The Educational Pipeline

Two key institutions form the backbone of technical training in Uruguay:

-

Universidad del Trabajo del Uruguay (UTU): This is the country’s public network of technical and vocational schools, offering programs in electronics, electromechanics, industrial automation, and related fields. Graduates from UTU have the foundational skills necessary for roles in a solar factory.

-

Universidad Tecnológica (UTEC): A newer public university focused on technology and engineering, UTEC provides higher-level education in areas relevant to modern manufacturing, graduating engineers and technologists ready to fill supervisory and process-management roles.

The challenge for a new solar enterprise is to bridge the gap between this general technical knowledge and the specific requirements of PV module production. This requires a dedicated and structured in-house training program.

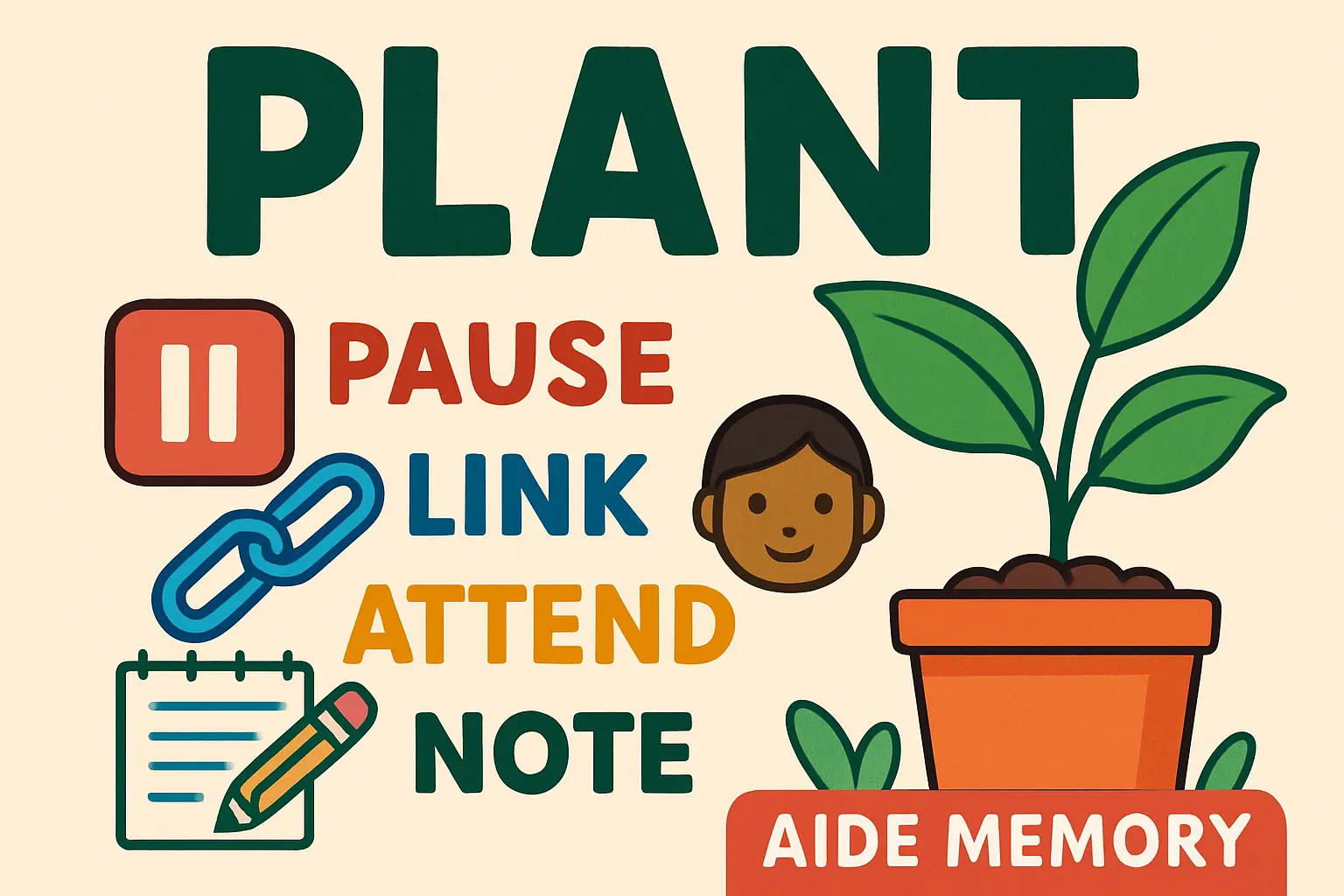

Practical Strategies for Recruitment and Training

A proactive approach to workforce development can turn this potential challenge into a competitive advantage. The goal is to build a proficient, motivated team aligned with the company’s quality standards.

Step 1: Partner with Local Institutions

Rather than simply posting job openings, successful investors engage directly with institutions like UTU and UTEC. This can involve:

- Presenting the company’s project to faculty and students.

- Collaborating on curriculum adjustments to better align with industry needs.

- Establishing internship programs to identify and cultivate promising talent before graduation.

Step 2: Leverage Government Training Incentives

The National Institute for Employment and Professional Training (INEFOP) is a crucial government agency that offers co-financing for workforce training initiatives. By presenting a well-structured training plan, companies can receive significant subsidies to offset the cost of upskilling their new employees. This support is a clear signal of the government’s commitment to attracting and enabling new industries.

Step 3: Implement a Rigorous In-House Training Program

Since prior experience in solar manufacturing will be rare, the responsibility for creating experts falls to the company. A successful program should include:

- Classroom Instruction: Covering the fundamentals of photovoltaic technology, quality control standards, and safety protocols.

- Hands-On Machine Training: Supervised, practical training on each piece of equipment, from the stringer and laminator to the final testing station.

- Certification and Progression: A clear system for certifying operators on specific tasks and a defined career path for advancement within the factory.

Based on experience from J.v.G. turnkey projects, a well-documented training matrix is one of the most critical assets a new factory can develop in its first year.

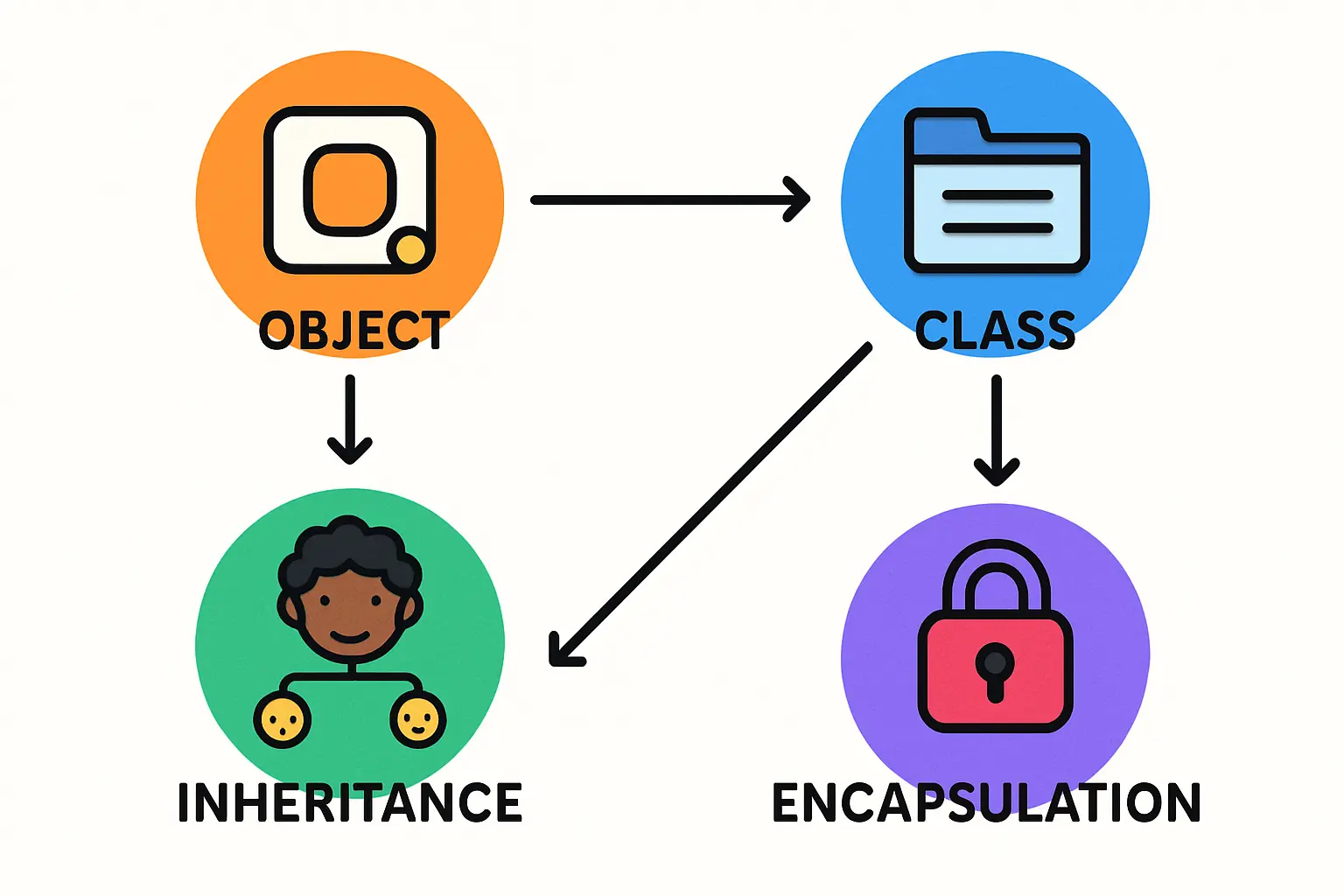

The Role of Unions and Collective Bargaining

For many international investors, the concept of mandatory union negotiation can be unfamiliar, but in Uruguay, it is a standard and structured process. Approaching this with professionalism and a spirit of partnership is essential for long-term operational stability.

Engaging with union representatives through sectoral wage councils is not inherently adversarial. It is a negotiation to establish mutually agreed-upon terms for wages, benefits, and working conditions. A clear, fair, and legally compliant approach builds trust and reduces the risk of labor disputes. This predictable labor landscape is a key factor in strategic site selection for a new facility.

Frequently Asked Questions (FAQ)

-

What are the standard working hours in Uruguay?

The standard working week is typically 44 to 48 hours, with a maximum of 8 hours per day. Overtime work is regulated and must be compensated at a higher rate. -

How are social security contributions calculated?

Both the employer and employee contribute a percentage of the employee’s gross salary to the BPS. The employer’s portion is larger and represents a mandatory, significant component of total labor costs. Exact percentages can vary and should be confirmed with a local legal or accounting advisor. -

Is it difficult to terminate an employee contract?

Termination is legally straightforward but includes a financial obligation. An employer must provide severance pay (despido), calculated based on the employee’s length of service. This makes the process predictable from a financial planning perspective. -

Are foreign managers and technical experts permitted to work in Uruguay?

Yes, Uruguay is open to foreign talent, particularly for specialized roles not available locally. However, all employees working in the country, regardless of nationality, are subject to Uruguayan labor laws and regulations. -

What is the best way to ensure compliance with all labor regulations?

The best approach is to engage a reputable local law firm and accounting firm specializing in labor law and corporate compliance. Their guidance is invaluable for navigating the specifics of contracts, contributions, and regulatory reporting.

Conclusion: Planning for a Stable and Skilled Workforce

Uruguay offers a regulated, stable, and predictable environment for establishing a solar manufacturing operation. Its strong legal framework and established systems for social dialogue, while requiring careful planning, ultimately reduce operational uncertainty.

Success depends on a proactive strategy: engaging with educational institutions, investing in robust training, and approaching labor relations as a structured, professional partnership. By integrating these considerations into an initial business plan, investors can build a skilled and dedicated workforce—the true engine of any successful manufacturing enterprise.