For any entrepreneur entering the solar module manufacturing space, the choice of factory location is one of the most consequential decisions. While labor costs and local incentives are important, an export-oriented business model lives or dies by its logistics. A state-of-the-art production facility means little if its products cannot reach international markets efficiently and cost-effectively.

This analysis explores Thailand as a potential hub for solar module manufacturing, examining the country’s port infrastructure, customs procedures, and connectivity to provide a strategic overview for investors. Understanding these logistics is a critical part of any business plan for a solar module factory with a global customer base.

Why Logistics is a Cornerstone of an Export-Focused Solar Business

The solar module supply chain is inherently global. Raw materials like polysilicon, EVA film, and specialized glass are sourced from various countries, and the finished modules are then shipped to distribution centers or project sites across continents.

In this global context, logistics can account for a significant portion of a module’s final landed price. An inefficient supply chain leads to:

- Increased Costs: Higher freight charges, demurrage fees, and customs duties erode profit margins.

- Longer Lead Times: Shipping delays can impact customer project timelines and damage a brand’s reputation.

- Supply Chain Risk: Relying on a single congested port or transport route creates a vulnerability that can halt operations.

A location with world-class logistics provides a powerful and sustainable competitive advantage.

Thailand’s Strategic Position in Global Trade

Thailand’s geography is its foundational asset. Situated at the heart of mainland Southeast Asia, it serves as a natural gateway to the rapidly growing ASEAN market—a bloc of over 650 million people. Its extensive coastline on the Gulf of Thailand provides direct sea-lane access to major trade routes connecting Asia with the Middle East, Europe, and the Americas.

This central position allows manufacturers to serve both regional and international markets efficiently, balancing growth opportunities with market risk diversification.

A Closer Look at Thailand’s Key Port Infrastructure

The quality of a country’s ports is the most critical factor for an export business. Thailand’s Eastern Seaboard is home to two world-class deep-sea ports that form the backbone of its industrial economy.

Laem Chabang Port: The Gateway to Global Markets

Laem Chabang is Thailand’s primary container port and one of the busiest in the world, consistently ranking among the top 20 globally by container volume. With an annual capacity exceeding 11 million TEUs (twenty-foot equivalent units), it is equipped to handle the largest modern container vessels.

Key features for a solar module exporter include:

- Deep-Sea Access: The port’s deep-water terminals accommodate Ultra Large Container Vessels (ULCVs), ensuring direct shipping routes to major ports in North America and Europe without the need for transshipment.

- Modern Equipment: The port features advanced ship-to-shore cranes and yard management systems that contribute to efficient vessel turnaround times.

- Expansion Plans: The Thai government is actively developing Phase 3 of the port, projected to increase its capacity by an additional 7 million TEUs. This investment signals a long-term commitment to maintaining its status as a top-tier global logistics hub.

For a solar manufacturer, this means reliable shipping schedules, competitive freight rates from major carriers, and the capacity to scale export volumes as the business grows.

Map Ta Phut Port: An Industrial Powerhouse

While Laem Chabang handles containerized goods, Map Ta Phut is Thailand’s largest industrial port. It specializes in liquid and bulk cargo, primarily serving the petrochemical and heavy industry sectors in the Map Ta Phut Industrial Estate.

For a solar business, the port offers the potential for importing bulk raw materials. Its proximity to the Eastern Economic Corridor (EEC) industrial zones also means that supporting infrastructure for large-scale manufacturing is already well-established.

Navigating Customs and Trade Facilitation

Efficient port infrastructure must be complemented by streamlined customs procedures. To that end, Thailand has implemented several programs that facilitate trade and reduce administrative burdens for exporters.

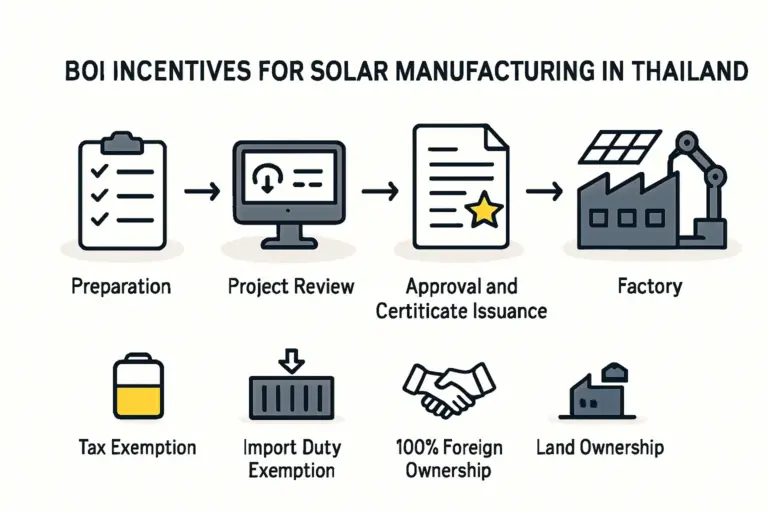

The Advantage of Thai Free Zones

For businesses that import raw materials to manufacture finished goods for export, operating within a designated Free Zone (also known as a Free Trade Zone or Export Processing Zone) offers significant financial and operational benefits.

The principle is simple: goods imported into the Free Zone to be used in products for export are exempt from import duties and value-added tax (VAT). This directly improves cash flow and reduces the production cost per module. The process typically involves:

- Import of raw materials (cells, glass, frames) into the Free Zone, duty-free.

- Manufacturing and assembly of solar modules within the factory.

- Export of the finished solar modules to international markets.

Streamlined Processes: e-Customs and AEO

Thailand has also invested in modernizing its customs clearance through the national e-Customs system. This platform allows for the electronic submission of declarations, reducing paperwork and processing times.

Additionally, businesses can apply for Authorized Economic Operator (AEO) status. This internationally recognized quality mark certifies that a company’s role in the international supply chain is secure and its customs procedures are compliant. AEO-certified companies often benefit from faster customs clearance and fewer physical inspections, further accelerating the export process.

Inland Connectivity: From Factory Floor to Port

The journey from the factory to the port is the critical ‘last-mile’ link in the logistics chain. Thailand’s Eastern Economic Corridor is served by a well-developed road network, including Motorway 7, which directly connects industrial estates to Laem Chabang Port.

This infrastructure ensures containers can be moved from a factory to the port terminal in a predictable and timely manner. However, investors should be aware of potential road congestion during peak hours and factor this into their planning. The network also provides road freight connections to neighboring countries like Cambodia, Laos, Myanmar, and Malaysia, opening up supplementary regional export markets.

Practical Considerations for Investors

When evaluating Thailand, it helps to consider tangible metrics.

- Transit Times: Sea freight from Laem Chabang to major US West Coast ports like Los Angeles typically takes 18–25 days. For key European ports such as Rotterdam, the transit time is around 30–35 days. These are competitive with other major manufacturing hubs in the region.

- Freight Costs: While market-dependent, costs are generally competitive due to the high volume of shipping traffic and carrier competition at Laem Chabang.

- Ecosystem Synergies: The concentration of industrial activity in the EEC has created a mature ecosystem of logistics providers, freight forwarders, and customs brokers. This provides choice and competitive pricing for essential services. The availability of local skilled labor in these industrial zones is another key advantage.

Based on experience from J.v.G. turnkey projects, integrating logistics planning early into the setup of a turnkey solar manufacturing line is crucial for long-term success.

Frequently Asked Questions (FAQ)

What is a TEU?

TEU stands for ‘Twenty-foot Equivalent Unit.’ It is a standard unit of measurement for cargo capacity used for container ships and terminals. One standard 40-foot container, for example, is equivalent to two TEUs and can typically hold between 600 and 900 standard solar modules, depending on their size and wattage.

What is the Eastern Economic Corridor (EEC)?

The EEC is Thailand’s flagship economic zone, a special development area spanning three provinces in the east of the country. It is designed to attract investment in targeted high-tech industries through enhanced infrastructure, tax incentives, and streamlined regulations.

Are there language barriers when dealing with Thai logistics providers?

In major business and logistics hubs like Bangkok and the EEC, English is widely spoken within the professional services sector. Major freight forwarding companies, shipping lines, and customs brokerage firms have English-speaking staff to handle international clients.

How does Thailand’s logistics infrastructure compare to competitors like Vietnam or Malaysia?

All three countries have strong, export-oriented economies with capable port infrastructure. Thailand’s Laem Chabang Port is among the largest and most connected in the region. Ultimately, the choice often depends on specific target export markets, available government incentives, and the overall business ecosystem that best fits an investor’s strategy.

Conclusion

For any investor focused on exporting solar modules to global markets, Thailand presents a compelling case. Its strategic location, coupled with the world-class capacity of Laem Chabang Port, provides a robust foundation for an international supply chain. The government’s commitment to infrastructure development through the EEC—alongside trade facilitation via Free Zones and modernized customs—further enhances this appeal.

A thorough assessment of a country’s logistics capabilities is a non-negotiable step in the due diligence process. The evidence suggests that Thailand’s infrastructure can not only support a large-scale solar manufacturing operation today but is also being actively developed to meet the future demands of global trade.