For entrepreneurs and investors exploring new industrial ventures, the renewable energy sector offers a compelling opportunity. Entering the solar module manufacturing space can seem complex, however, filled as it is with technical jargon and logistical hurdles.

This article outlines a structured blueprint for a specific, high-potential business model: establishing a 100 MW high-efficiency solar module factory in the Batam Special Economic Zone (SEZ) in Indonesia. The focus is on producing advanced TOPCon solar modules tailored for the region’s Commercial and Industrial (C&I) sector and for export across the ASEAN market. This model combines cutting-edge technology, a strategic location, and a targeted market approach to create a viable and profitable enterprise.

The Regional Opportunity: Powering Southeast Asia’s Growth

The Association of Southeast Asian Nations (ASEAN) is one of the world’s fastest-growing economic blocs, and its energy demand is surging accordingly. As the region’s largest economy, Indonesia faces the dual challenge of powering its industrial growth while meeting renewable energy targets.

The C&I sector feels this pressure most acutely. Businesses frequently contend with unstable grids and rising electricity costs, making on-site solar generation less of an environmental choice and more of a critical tool for operational stability and cost control. This creates a significant and underserved domestic market for high-quality, locally produced solar modules. Beyond Indonesia, neighboring countries like Malaysia, Thailand, and the Philippines face similar energy dynamics, opening up substantial export opportunities.

The Strategic Foundation: Why the Batam Special Economic Zone?

Location is a critical factor in any manufacturing venture. A Special Economic Zone (SEZ) is a designated geographical area where business and trade laws differ from the rest of the country—a framework specifically designed to attract foreign investment. The Batam SEZ, located just a short distance from Singapore, offers a unique combination of logistical and financial advantages.

Key Benefits of Operating in the Batam SEZ:

- Tax Incentives: Businesses within the SEZ often benefit from exemptions on Value Added Tax (VAT) and import duties for capital goods, machinery, and raw materials. This can significantly reduce the initial investment required to establish a solar panel factory.

- Streamlined Logistics: Batam’s world-class port facilities and proximity to the global shipping hub of Singapore simplify both importing raw materials and exporting finished modules to the wider ASEAN market.

- Simplified Customs: SEZs typically feature streamlined customs procedures, reducing administrative delays and ensuring a smoother supply chain.

- Infrastructure: Established infrastructure for power, water, and telecommunications provides a stable operational environment for a high-tech manufacturing facility.

Choosing an SEZ like Batam effectively de-risks a significant portion of the investment by creating a predictable and cost-efficient operational framework.

The Technological Edge: High-Efficiency TOPCon Modules

Not all solar modules are created equal. To command a premium in a competitive market, the product itself must deliver superior performance. This blueprint centers on Tunnel Oxide Passivated Contact (TOPCon) technology, which represents the next generation in solar cell efficiency.

What is TOPCon Technology?

In simple terms, TOPCon is an advanced cell architecture that significantly reduces the electrical losses common in standard solar cells (like older PERC technology). A micro-thin ‘tunnel oxide’ layer is added to the back of the cell, allowing electrons to pass through more efficiently while preventing energy-sapping recombination.

Business Advantages of TOPCon:

- Higher Efficiency: TOPCon cells convert more sunlight into electricity, meaning a module of the same size generates more power—a key selling point for C&I clients with limited roof space.

- Superior Performance in Heat: The technology performs exceptionally well in high-temperature environments, a crucial advantage in the hot, humid climate of Southeast Asia.

- Lower Degradation: TOPCon modules lose less of their power output over their 25-30 year lifespan, offering customers better long-term value and a more reliable return on investment.

A factory focused on producing specialized DESERT+ modules using TOPCon technology would be well-positioned to serve the premium market segment, setting it apart from lower-cost, lower-performance competitors.

The Factory Blueprint: A 100 MW J.v.G. Turnkey Solution

An investor doesn’t need to be a photovoltaic engineer to set up a solar panel production line. A turnkey solution provides a complete, pre-configured production system—from machinery integration to process training.

Based on J.v.G. Technology GmbH’s project experience, a 100 MW TOPCon facility represents a balanced scale for entering the market. It’s large enough to achieve economies of scale yet nimble enough to adapt to market demands.

A typical 100 MW turnkey line includes:

- Cell Stringing and Bussing: Automated machines (Stringers) that solder solar cells together into strings.

- Layup and Lamination: Stations for assembling the module layers (glass, EVA, cell matrix, backsheet) and a laminator to fuse them together under heat and pressure.

- Framing and Junction Box Assembly: Equipment for adding the aluminum frame and the electrical junction box.

- Testing and Quality Control: Advanced simulators and testers (e.g., Sun Simulators, EL Testers) to ensure every module meets international quality and performance standards.

This entire line can be housed in a building of approximately 5,000 square meters, requiring a workforce of 80 to 100 employees, including technicians, operators, and administrative staff.

Go-to-Market Strategy: A Two-Pronged Approach

A solid solar manufacturing business plan requires a clear strategy for reaching customers. The Batam location is ideal for a two-pronged approach, especially when developed with strategic guidance from market entry specialists like Thoma family consulting.

-

Domestic C&I Market (Indonesia): The primary target is Indonesian businesses seeking energy independence. The sales strategy involves partnering with local solar installers and EPC (Engineering, Procurement, and Construction) companies that serve this market directly. A ‘Made in Indonesia’ label, combined with the superior performance of TOPCon modules, offers a strong competitive advantage.

-

ASEAN Export Market: Leveraging Batam’s logistical strengths and ASEAN free trade agreements, the factory can export modules to Malaysia, Vietnam, Thailand, and the Philippines. This diversifies revenue streams and builds a regional brand presence.

This approach ensures the factory is not dependent on a single market, balancing local demand with the growth potential of the wider Southeast Asian region.

Frequently Asked Questions (FAQ)

What is the primary difference between TOPCon and older PERC technology?

The main difference lies in efficiency and long-term performance. TOPCon cells feature an extra passivation layer that significantly reduces energy loss compared to PERC. This results in higher power output from a module of the same size and better performance in hot climates—a key advantage for business owners calculating their return on investment.

Is a 100 MW factory considered large or small?

In today’s global market of gigawatt-scale facilities, a 100 MW facility is considered a mid-sized or ’boutique’ factory. However, this is an ideal entry size for a new market, allowing for efficient production, a focused product line, and the ability to scale up as the brand and market share grow.

What are the main challenges when setting up a factory in an SEZ like Batam?

While SEZs offer many benefits, challenges can include navigating the specific regulatory framework of the zone, securing a skilled local workforce, and establishing reliable local supply chains for non-specialized materials. Working with experienced consultants who understand both the technology and the local business environment is crucial for overcoming these hurdles.

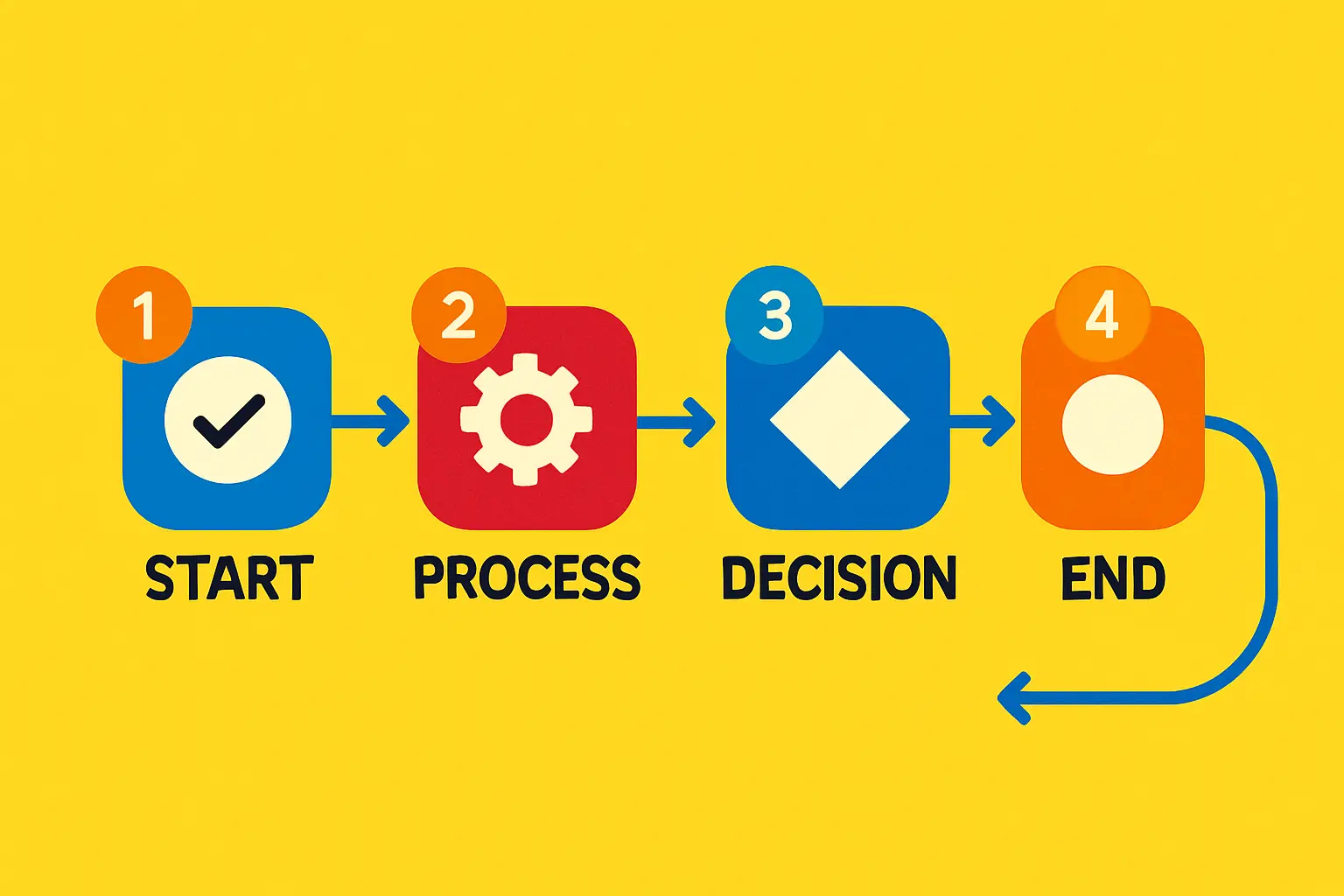

How long does it typically take to get a turnkey factory operational?

From the final investment decision to the first module produced, a turnkey project of this scale can typically be completed in under 12 months. This timeline includes machinery procurement, shipping, installation, commissioning, and staff training.

Do I need a technical background to start this type of business?

No, an investor or entrepreneur doesn’t need to be a solar technology expert. The key is to have a solid business plan and to partner with an experienced turnkey provider like J.v.G. Technology. An experienced provider handles the technical aspects—from factory design to process optimization—allowing the owner to focus on business management, strategy, and market development. Additionally, platforms like pvknowhow.com offer structured educational courses to bridge this knowledge gap.

A Strategic Path Forward

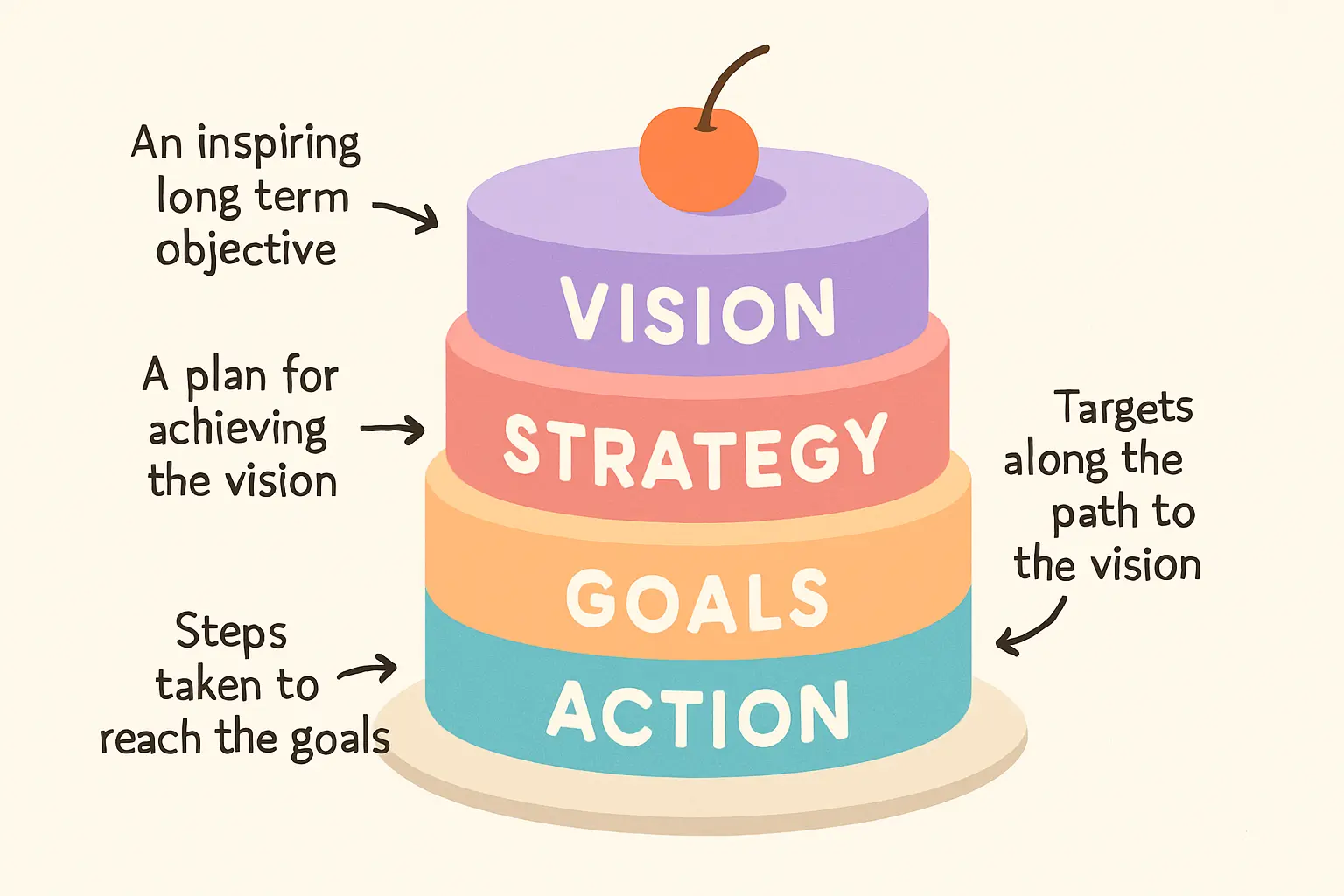

This blueprint illustrates a clear, viable pathway for entering the solar manufacturing industry. It mitigates risk and maximizes potential by combining four key elements: a high-growth regional market, the financial and logistical advantages of a Special Economic Zone, superior next-generation technology, and a focused go-to-market strategy.

For entrepreneurs looking to build a lasting enterprise in the clean energy space, this model offers a structured and strategically sound foundation for success.