With over 3.6 million hectares of arable land, Libya holds immense potential for food production. Yet, less than 10% of this land is currently cultivated, leaving the nation heavily reliant on food imports.

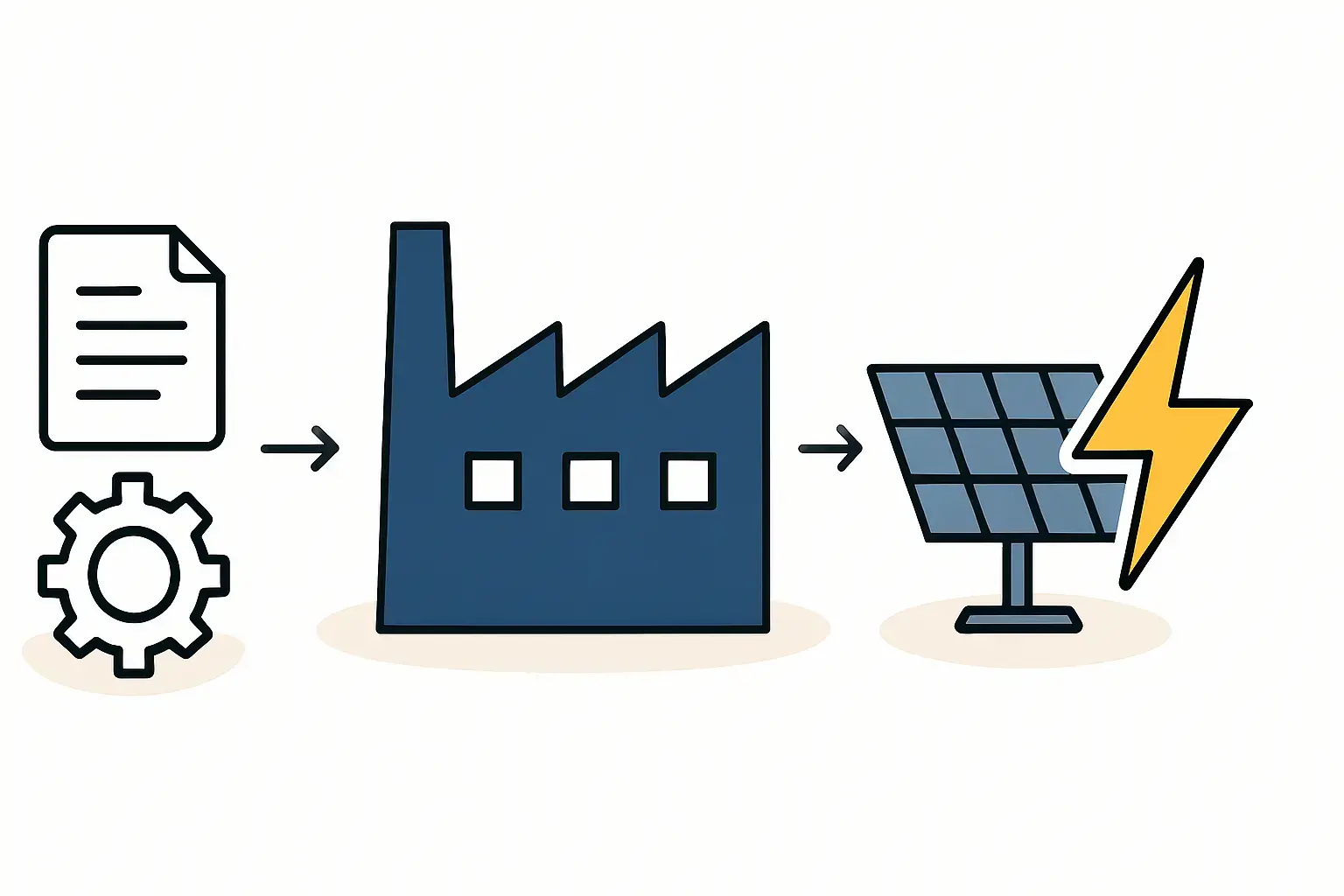

The primary obstacle is not a lack of fertile ground or sunlight, but a critical shortage of the reliable energy needed to access and distribute water. This challenge presents a significant business opportunity: establishing local solar module manufacturing to power a modern, self-sufficient agricultural sector.

This article outlines the strategic case for a turnkey solar factory in Libya, one designed specifically to meet the power demands of large-scale irrigation and agribusiness.

The Energy Challenge Hindering Libya’s Food Security

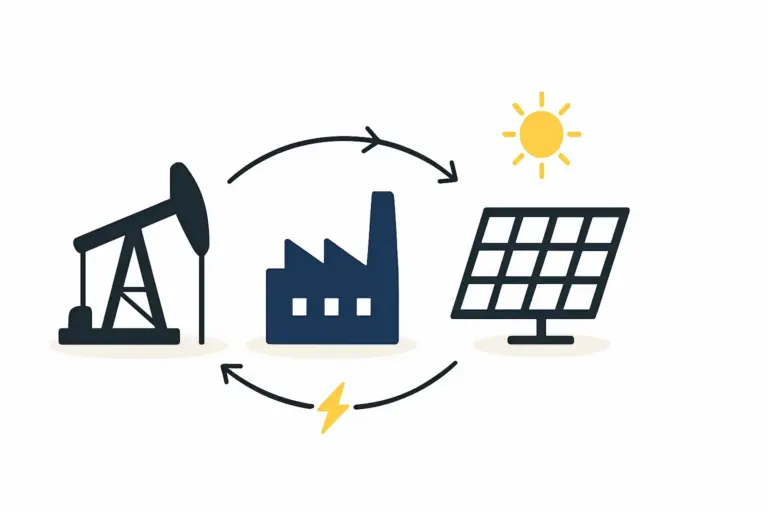

Libya’s agricultural sector, which employs nearly 17% of the workforce, is fundamentally constrained by water and energy. The country’s primary water source is the Great Man-Made River (GMMR), a remarkable engineering feat that pumps fossil water from underground aquifers to coastal regions.

However, the GMMR’s extensive network of pumps requires immense amounts of energy. It relies on an often-unstable national electricity grid, leading to frequent and unpredictable power outages. To compensate, many farms depend on diesel generators—an expensive solution, subject to volatile fuel prices and burdened by significant logistical and maintenance challenges. This energy instability directly impacts crop yields, limits expansion, and stifles the growth of a modern food processing industry.

Solar Energy: The Logical Solution for Libyan Agriculture

With solar irradiation levels exceeding 2,200 kWh/m² per year, Libya is one of the most sun-rich countries in the world. This abundant natural resource offers a direct and sustainable solution to the agricultural sector’s energy problem.

Solar photovoltaic (PV) systems can provide decentralized, reliable power precisely where it is needed, independent of the national grid. For agriculture, the applications are immediate and transformative:

- Irrigation: Powering water pumps for drip, pivot, and sprinkler systems.

- Processing: Supplying stable electricity for milling, packaging, and preservation facilities.

- Cold Storage: Ensuring an unbroken cold chain for perishable goods like fruits and vegetables, which reduces post-harvest losses.

Deploying solar power enables agricultural enterprises to achieve energy independence, reduce operational costs, and significantly improve their productivity and reliability.

The Business Opportunity: Local Manufacturing for Local Needs

While importing solar panels is an option, a far more strategic approach involves establishing local production. The business case for starting a solar module factory in Libya is compelling. This approach shifts the country’s role from a consumer of foreign technology to a producer, capturing more value locally and building technical capacity.

A local factory can:

- Create Skilled Jobs: Directly employing technicians, engineers, and administrative staff.

- Reduce Supply Chain Risks: Mitigating dependency on international shipping and currency fluctuations.

- Customize Products: Designing and producing modules specifically optimized for Libya’s harsh desert climate.

- Support National Goals: Aligning with government initiatives to diversify the economy away from oil and enhance food self-sufficiency.

Blueprint for a 50 MW Solar Factory for Agribusiness

A mid-sized factory with an annual capacity of 25–50 MW provides a strong starting point for entering the market. Such an operation can be established efficiently using a turnkey solar production line, a model where a single partner provides the machinery, process knowledge, and training. This approach is particularly well-suited for entrepreneurs or companies entering the solar industry for the first time.

Key Business Model Components:

- Target Market: Primary clients would be large-scale private farms (over 100 hectares), agricultural cooperatives, and food processing companies looking to secure their energy supply.

- Operational Scale: A 50 MW facility typically requires a building of approximately 3,000 square meters and can be operated by a staff of 40–50 employees.

- Value Proposition: The factory would offer a reliable, locally produced, and technically supported solution for energy independence, directly addressing the core operational challenge of its customers.

Technology Suited for the Libyan Environment: The DESERT+ Module

Not all solar panels are created equal, especially when deployed in demanding desert conditions with high temperatures, sand, and dust. Standard modules can suffer from accelerated degradation, reducing their power output and lifespan.

Manufacturing the right solar module technology is therefore a key success factor. An excellent example is the DESERT+ module technology from J.v.G. Technology GmbH, specifically engineered for hot and arid climates. It incorporates features such as:

- High-Temperature Performance: Specialized cell technology that maintains efficiency even during peak summer heat.

- Durable Construction: Reinforced frames and robust materials to withstand sand abrasion and strong winds.

- Specialized Coatings: Glass treatments that reduce soiling from dust and make cleaning more effective.

Producing such purpose-built modules locally offers a distinct competitive advantage over standard imported panels.

A Phased Business Plan for Market Entry

A strategic, phased rollout would ensure sustainable growth and build a strong market presence.

Phase 1 (Years 1–2): Irrigation Focus

The initial focus will be on supplying solar systems to replace diesel generators for water pumps on large farms. Each successful installation serves as a powerful case study, demonstrating a clear return on investment.

Phase 2 (Years 3–4): Agribusiness Expansion

With a proven track record, the business will expand its offerings to power cold storage facilities, food processing plants, and packaging centers, supporting the development of a complete agricultural value chain.

Phase 3 (Year 5+): Diversification

Once established as a key supplier to the agricultural sector, the factory can expand into adjacent markets, such as rural electrification projects, commercial rooftop systems, and small-scale solar farms.

The investment requirements for such a project are well-defined, allowing for clear planning around equipment costs, facility needs, and operational capital.

Frequently Asked Questions (FAQ)

What level of technical expertise is needed to run a solar factory?

With a turnkey production line, the supplier provides core process engineering and training. The local management team can then focus on production, quality control, and business operations without needing deep solar technology expertise from day one.

How long does it take to set up a production line?

From final planning and contract signing to the first module being produced, a typical timeline for a turnkey project is between 9 and 12 months. This includes machine delivery, installation, commissioning, and staff training.

Is a 50 MW factory large enough to make an impact?

Absolutely. A 50 MW annual output can produce enough modules to power thousands of irrigation systems. More importantly, it establishes a foundational industrial asset and a center of excellence that can scale as the market grows.

What are the main raw materials needed?

The key components are solar cells, tempered glass, aluminum frames, encapsulant (EVA), backsheets, and junction boxes. A reliable international supply chain for these materials is critical to the business plan.

Conclusion: From Oil Economy to Solar-Powered Breadbasket

Libya stands at a crossroads, with a unique opportunity to leverage its immense solar resources to build a resilient and prosperous agricultural sector. Establishing a local solar module factory is more than an industrial project; it is a strategic investment in the nation’s food security, economic diversification, and technological independence.

By transforming sunlight into the energy that pumps water and powers industry, Libya can turn its vast, arid lands into a thriving agricultural heartland for generations to come.