Disclaimer: This case study represents a composite example derived from real-world

consulting work by J.v.G. Technology GmbH in solar module production and factory optimization. All data points are realistic but simplified for clarity and educational purposes.

For many successful entrepreneurs considering diversification, the energy sector presents a significant opportunity. Yet, entering a technically complex field like solar module manufacturing can seem daunting. The perceived barriers—high investment, complex technology, and market uncertainty—often halt promising ventures before they begin.

But a strategic approach, particularly in a high-potential location like Ghana, can transform this perception. This article lays out a detailed financial model for establishing a 50 MW solar module factory within Ghana’s Tema Free Zone. This isn’t a theoretical exercise; it’s a practical blueprint based on real-world project data. We will examine capital and operational expenditures, the location’s strategic advantages, and the projected returns to demonstrate how a well-planned facility can become a profitable hub for supplying West Africa’s growing demand for clean energy.

Why Ghana’s Tema Free Zone is a Strategic Choice

Selecting the right location is crucial to the success of any manufacturing enterprise. Ghana, and specifically the Tema Free Zone, offers a unique combination of economic stability, market access, and government support that mitigates risk while enhancing profitability for solar manufacturers.

The country’s stable political climate provides a secure foundation for long-term investment. More importantly, Ghana is a key member of the Economic Community of West African States (ECOWAS), a trading bloc of 15 countries with a combined population exceeding 340 million. A factory based in Ghana gains preferential access to this vast and energy-hungry market, which is actively seeking to expand its renewable energy capacity.

The Ghana Investment Promotion Centre (GIPC) also offers powerful incentives for businesses operating within designated free zones like Tema. These benefits, designed to attract foreign investment, can include:

- A 10-year corporate tax holiday.

- 100% exemption from customs duties and levies on imported machinery and raw materials.

- No restrictions on the repatriation of profits.

These incentives directly improve the financial viability of a solar factory by significantly reducing initial setup costs and boosting the long-term return on investment.

Deconstructing the Investment: A 50 MW Turnkey Factory Model

A 50 MW annual production capacity is a substantial, industrial-scale operation capable of producing approximately 150,000 to 170,000 solar modules per year, depending on the specific wattage. This scale is ideal for supplying both large utility projects and smaller distributed energy initiatives across the ECOWAS region.

Capital Expenditure (CAPEX): The Initial Investment

The primary capital outlay is for the production equipment. A turnkey solar panel production line from an experienced provider like an EU PV factory turnkey supplier ensures that all machinery—from the stringer and laminator to the final tester—is fully integrated and optimized.

A comprehensive CAPEX budget for a 50 MW facility typically includes:

- Production Machinery: The complete turnkey line.

- Building & Infrastructure: Modification of an existing warehouse or construction of a new facility (approx. 3,000–4,000 sq. meters).

- Initial Raw Materials: A starter stock of solar cells, glass, encapsulants, and other components.

- Logistics & Installation: Shipping, installation, and commissioning of the equipment.

- Contingency: A reserve fund for unforeseen expenses.

The total initial investment for a 50 MW setup, based on premier EU provider’s turnkey projects, typically ranges from €6 million to €8 million. Critically, the GIPC’s duty-free import incentives directly and significantly reduce this initial cost.

Operational Expenditure (OPEX): The Day-to-Day Costs

Once operational, the factory’s ongoing costs determine its profitability. The main components of OPEX are:

-

Raw Materials: This is the largest variable cost, accounting for over 70% of a finished module’s price. Strategic procurement of solar cells, tempered glass, EVA/POE encapsulant, backsheets, and aluminum frames is critical.

-

Labor: A 50 MW facility operating on two shifts typically requires 80–100 employees, including operators, technicians, engineers, and administrative staff. Ghana’s competitive labor market offers a cost advantage compared to many other regions.

-

Utilities: Electricity and water are essential for production. While grid stability can be a concern in some areas, facilities in the Tema Free Zone often have access to more reliable infrastructure.

-

Logistics & Shipping: Costs associated with exporting finished modules to other ECOWAS countries.

-

Maintenance & Certifications: Ongoing upkeep of machinery and renewal of product certifications (e.g., IEC).

The Role of Technology: Why DESERT+ Modules Matter

In a market defined by high temperatures and intense solar irradiation, not all solar module technologies are equal. Standard modules can suffer from accelerated degradation in such climates, reducing their energy output and lifespan.

This financial model is built around the production of DESERT+ modules. This technology is specifically engineered for hot and arid environments. Key features include:

- Enhanced Heat Tolerance: Specialized cell and material combinations that maintain higher efficiency at elevated operating temperatures.

- Increased Durability: Robust construction that resists potential-induced degradation (PID) and other climate-related stresses.

Manufacturing a premium, climate-specific product like DESERT+ offers a crucial competitive advantage. It allows a new factory to offer a superior value proposition—higher long-term energy yield and greater reliability—to customers across West Africa, justifying a premium price point and building a reputation for quality.

Projecting Profitability: ROI from the ECOWAS Market

The ultimate goal, of course, is a strong and sustainable return. By combining the benefits of the Tema Free Zone with the large, underserved ECOWAS market, a favorable financial outcome is well within reach.

A simplified projection illustrates the potential:

- Annual Production: 50 MW (approx. 160,000 modules at 310Wp).

- Estimated Revenue: Based on a conservative wholesale price per watt, annual revenue can be calculated.

- Net Profit: Revenue minus total OPEX.

- Payback Period: The time required for cumulative net profits to equal the initial CAPEX.

With the GIPC’s 10-year tax holiday, the initial payback period is significantly shortened, as all profits can be reinvested or repatriated without corporate tax deductions. This accelerates capital recovery and allows the business to scale more rapidly. Detailed financial modeling, which can be developed with a sample business plan, shows that a payback period of 4 to 6 years is a realistic target for a well-managed operation.

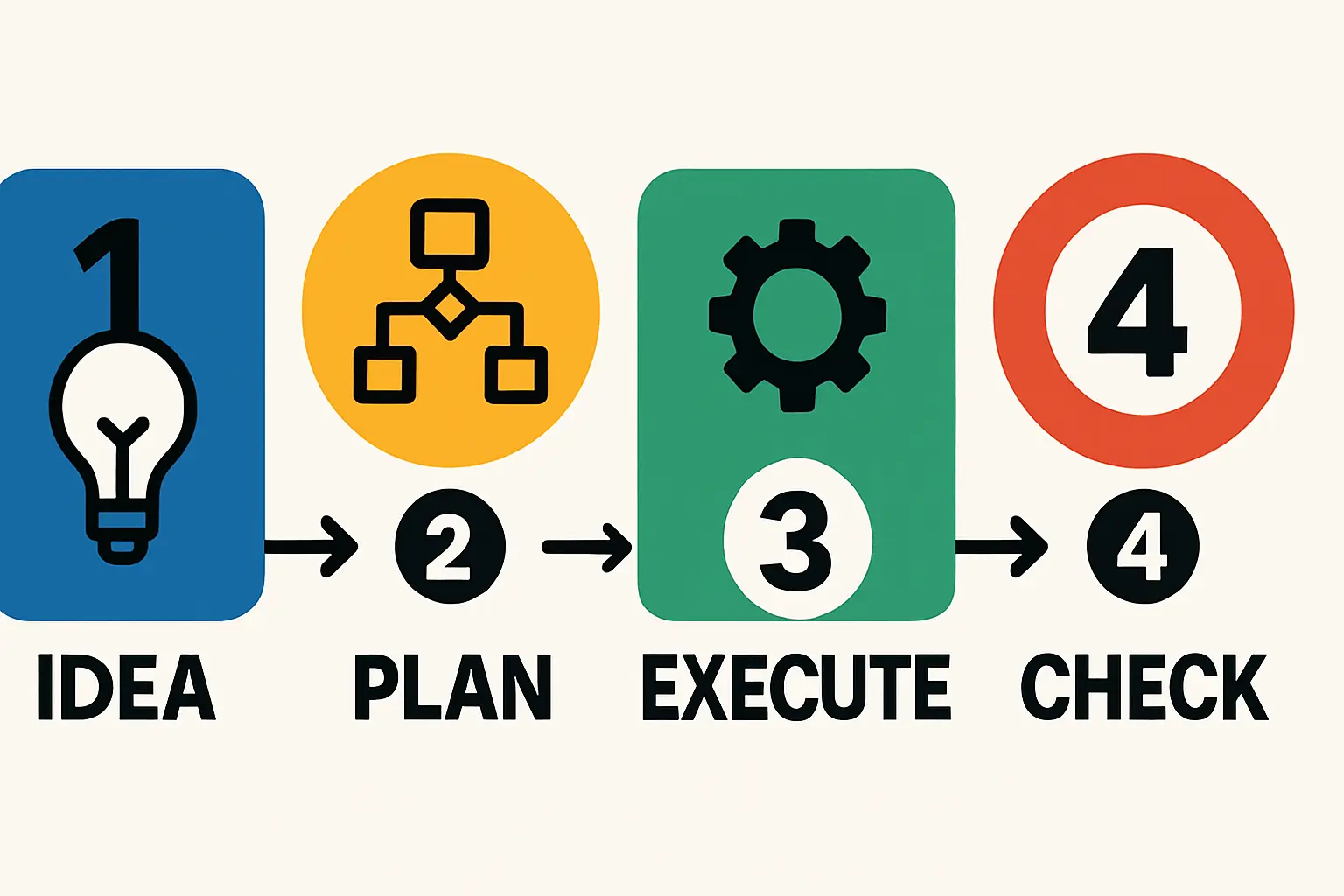

Navigating the Process: From Concept to Production

Understanding the financial model is the first step, but executing the vision requires a structured process. The typical journey for starting a solar manufacturing business involves several key phases:

- Feasibility Study & Business Plan: A deep analysis of the market, costs, and projected revenues.

- Securing Financing: Presenting the business plan to investors or financial institutions.

- GIPC Application: Formally applying for free zone status and associated incentives.

- Factory Setup & Commissioning: Partnering with a turnkey provider for equipment installation and staff training.

- Launch & Market Entry: Commencing production and establishing distribution channels within ECOWAS.

pvknowhow.com provides structured resources, including an online e-course, to guide entrepreneurs through each of these critical stages.

Frequently Asked Questions (FAQ)

What is the typical timeline for setting up a 50 MW factory?

From a final investment decision to the start of production, a timeline of 9 to 12 months is standard. This includes equipment manufacturing, shipping, installation, and commissioning.

How many employees are needed for a 50 MW line?

A 50 MW line typically requires approximately 40-50 personnel per shift. For a two-shift operation, a total workforce of around 80-100 employees is common.

What are the main challenges for a new manufacturer in this region?

The primary challenges often relate to supply chain logistics for raw materials and developing a skilled local workforce. Partnering with an experienced turnkey provider who includes comprehensive on-site training can effectively mitigate the labor challenge.

Do I need a technical background to start this business?

No. Many successful solar manufacturing entrepreneurs come from non-technical business backgrounds. The key is to partner with a reputable technology provider who handles the engineering, installation, and training, allowing the owner to focus on business strategy, finance, and market development.

How do GIPC incentives work in practice?

Once a company is registered and approved by the GIPC to operate in a free zone, it receives official documentation to present to customs authorities. This ensures that all imported capital equipment and raw materials specified in the business plan are cleared without duties or VAT.

Conclusion: Your Next Steps in Exploring Solar Manufacturing

Establishing a 50 MW solar module factory in Ghana’s Tema Free Zone is a commercially sound and strategically powerful venture. The convergence of a large, protected regional market, significant government incentives, and access to specialized technology creates a compelling business case. It’s an opportunity not just for financial return, but for building a cornerstone of West Africa’s renewable energy future.

For entrepreneurs seriously considering this path, the next logical step is to dive deeper into the specific requirements. Exploring the components of a turnkey production line and developing a detailed business plan are essential steps for transforming this blueprint into a successful enterprise.

Download the 50 MW Ghana Solar Factory Case Study (PDF)

Author: This case study was prepared by the

turnkey solar module production specialists at J.V.G. Technology GmbH

It is based on real data and consulting experience from J.v.G. projects

worldwide, including installations ranging from 20 MW to 500 MW capacity.