Disclaimer: This case study represents a composite example derived from real-world

consulting work by J.v.G. Technology GmbH in solar module production and factory optimization. All data points are realistic but simplified for clarity and educational purposes.

Oman’s Vision 2040 sets a clear course to transform the nation into a diversified, sustainable, and globally competitive economy. Central to this vision is the strategic development of renewable energy, with a target of sourcing 30% of its electricity from renewables by 2030. This ambitious goal is not merely an environmental policy; it represents one of the most significant industrial opportunities in the region.

For the discerning investor or entrepreneur, the question is not if this transition will happen, but how to participate in building the industrial backbone that will support it. The answer lies in a structured collaboration between public ambition and private enterprise.

This article outlines a comprehensive PPP framework for establishing a national solar module factory in Oman, detailing the project’s strategic alignment, key stakeholder roles, and the technical path from concept to full-scale production.

The Strategic Imperative: Why a National Solar Factory Aligns with Oman Vision 2040

Domestic manufacturing capacity for solar modules directly supports several national priorities outlined in Oman Vision 2040. This approach moves beyond simply consuming renewable energy to actively producing the technology that powers it, creating a powerful multiplier effect for the economy.

The case for a national factory is compelling:

- Meeting National Targets: To achieve its 2030 and 2040 goals (39% renewables), Oman requires an estimated 5.5 gigawatts (GW) of new renewable capacity. This translates into massive, long-term demand for solar modules.

- Energy Security and Independence: Relying on imported solar panels exposes national energy projects to global supply chain volatility, shipping costs, and geopolitical risks. Local production ensures a stable, predictable supply for critical infrastructure.

- Economic Diversification: With electricity demand growing at 5-6% annually, a local factory diversifies the industrial base away from traditional sectors and fosters high-tech manufacturing skills.

- In-Country Value (ICV): A local facility directly supports Oman’s ICV policy by creating skilled jobs, developing a local supply ecosystem, and retaining significant capital within the national economy.

Structuring the Public-Private Partnership (PPP) for Success

A PPP provides a robust and legally sound framework for this venture. Oman’s Royal Decree 52/2019, the national PPP Law, was specifically designed to attract private capital and expertise for strategic infrastructure projects. By clearly defining the roles, responsibilities, and protections for all parties, it creates a transparent and de-risked investment environment.

Defining Stakeholder Roles and Responsibilities

A successful PPP for a solar factory relies on a clear division of contributions, where each partner leverages its core strengths.

The Public Sector Partner

Typically represented by entities like the Ministry of Energy and Minerals or OPAZ, the government acts as an enabler. Key responsibilities include:

- Providing Offtake Guarantees: Committing to purchase a significant portion of the factory’s output for national energy projects, securing a foundational revenue stream for the investor.

- Facilitating Land and Infrastructure: Allocating suitable land within a special economic zone (e.g., Duqm, Sohar) with access to utilities and logistics.

- Streamlining Permitting and Approvals: Creating a ‘single window’ for regulatory processes to ensure a timely project launch.

- Offering Financial Incentives: Implementing policies such as tax holidays or exemptions on customs duties for imported machinery.

The Private Sector Partner

The private partner—the investor, entrepreneur, or consortium—is responsible for financing and operating the facility. Their role involves:

- Providing Capital Investment: Securing the funding for the factory building, machinery, and initial working capital.

- Operational Management: Overseeing day-to-day operations, from supply chain management to production and quality control.

- Commercial Development: Driving the business strategy, including sales to private sector clients and potential export markets.

The Technical Partner

For investors without prior experience in photovoltaics, the technical partner is crucial. A firm like an experienced European turnkey engineering team provides the specialized engineering and process knowledge. This partner’s responsibilities include:

- Turnkey Factory Design and Implementation: Planning the facility layout, specifying all necessary machinery, and managing installation and commissioning.

- Process Know-How and Training: Transferring the technical knowledge required to manufacture high-quality, certified solar modules and training the local workforce.

- Long-Term Technical Support: Providing ongoing support for process optimization, quality assurance, and future technology upgrades.

Key Government Incentives and Support Mechanisms

Under the PPP framework, the Omani government can offer several powerful incentives to make the investment commercially attractive. These may include:

- Corporate tax exemptions for the initial 5–10 years of operation.

- 100% foreign ownership rights within designated free zones.

- Waivers on customs duties for all imported equipment and raw materials.

- Guaranteed utility connections at competitive industrial rates.

- Preferential treatment in tenders for government-led solar projects.

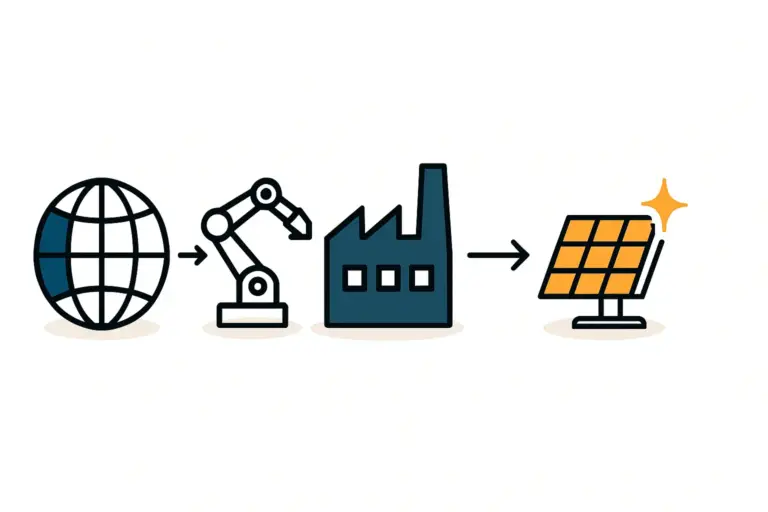

The Turnkey Factory Model: From Blueprint to Production

A turnkey approach is the most efficient method for an investor entering the solar manufacturing sector. It consolidates the complex process of building a factory into a structured, manageable project with a single point of responsibility for technical execution.

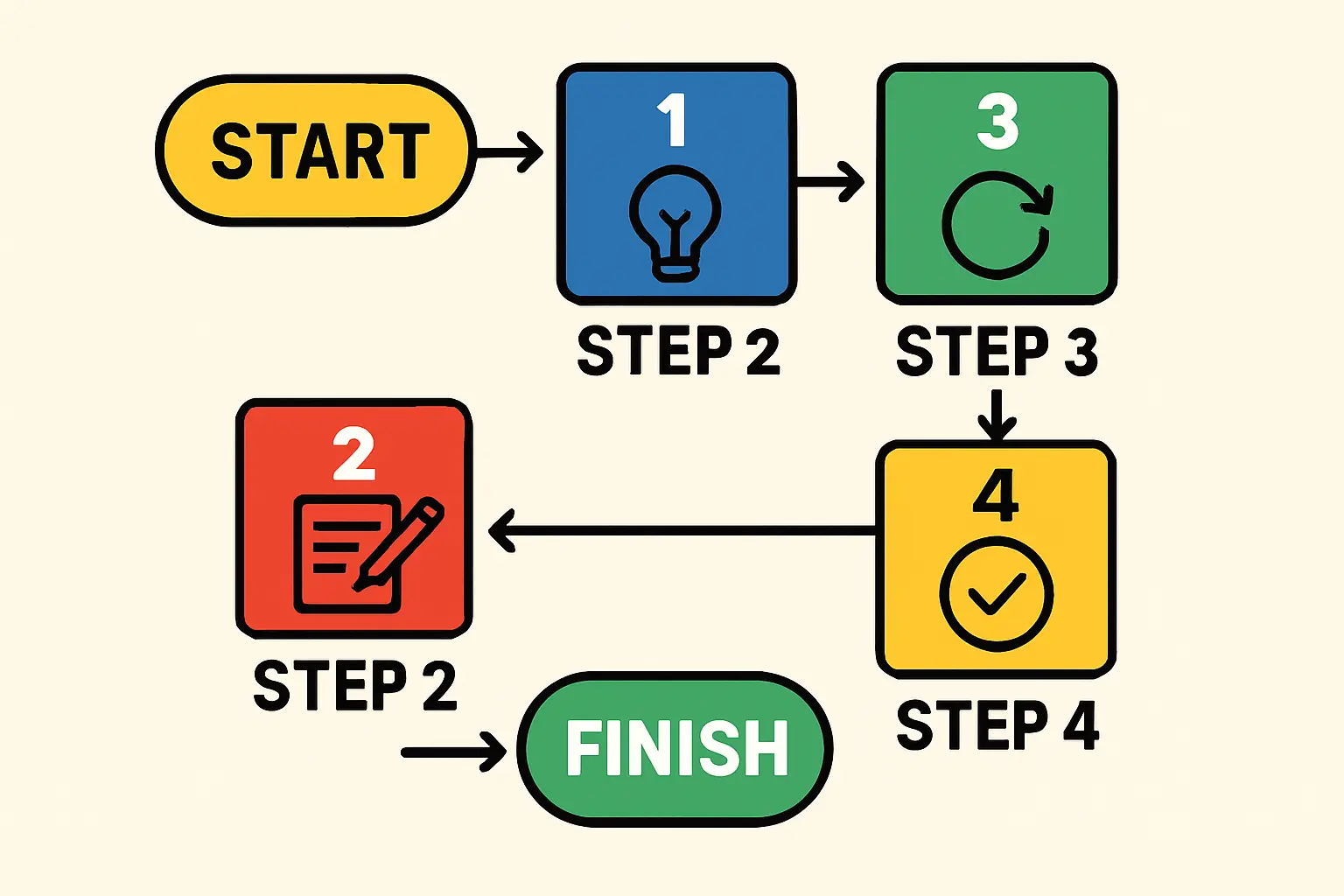

Phase 1: Planning and Feasibility

This initial phase is critical for defining the project’s scope and financial viability. It involves developing a comprehensive solar panel manufacturing business plan that addresses key decisions, including:

- Production Capacity: Starting with a 50–100 MW annual capacity is a common entry point, scalable for future demand.

- Technology Selection: Choosing the appropriate cell technology (e.g., PERC or the emerging TOPCon) to balance cost, efficiency, and market demand.

- Financial Modeling: Projecting capital expenditures, operational costs, and revenue based on secured offtake agreements.

Phase 2: Technical Implementation and Setup

Once the plan is approved, the technical partner oversees the setup of the solar module production line. This phase follows a clear sequence:

- Factory Layout Design: Optimizing the floor plan for material flow, safety, and future expansion.

- Machine Procurement: Sourcing and shipping all required equipment, from cell stringers to laminators and testers.

- Installation and Commissioning: On-site installation of all machinery, followed by rigorous testing to ensure the entire line functions seamlessly.

A well-managed turnkey project can progress from a prepared building to a fully commissioned production line in under a year.

Phase 3: Operations, Training, and Certification

A factory is more than its machines; it is its people and its processes. This final phase focuses on operational readiness.

- Workforce Training: The technical partner conducts intensive training for local engineers and operators on machine operation, maintenance, and quality control. A 50 MW facility typically creates 30–50 direct skilled jobs.

- Process Ramp-Up: Production begins, with a focus on optimizing workflows and achieving target yields.

- IEC Certification: The finished modules undergo testing to achieve international certifications (e.g., IEC 61215, IEC 61730). This certification is a non-negotiable step, ensuring the modules are bankable and can be used in utility-scale projects. The entire manufacturing process is geared towards meeting these standards.

Financial Framework and Projected Returns

The PPP model is designed to create a financially sustainable and profitable venture for the private investor.

Capital Investment Breakdown

The primary capital expenditure is for the machinery, typically ranging from USD 4–7 million for a modern 50–100 MW line. Additional costs include the factory building (if not leased), civil works, and initial working capital for raw materials.

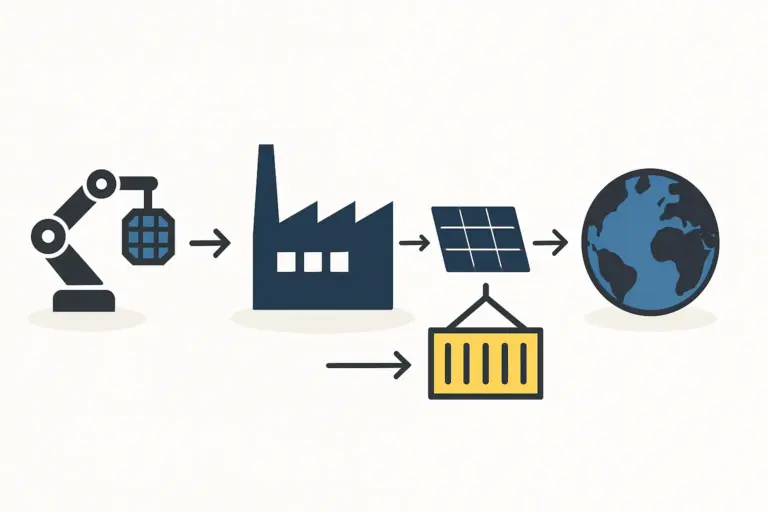

Revenue Streams and Offtake Security

The cornerstone of the business model is the offtake agreement with the government or a state-owned utility. By guaranteeing the purchase of a large percentage of the factory’s output at a pre-agreed price, this agreement removes market demand risk for the initial years of operation. This security makes the project highly attractive for financing.

Further revenue can be generated from:

- Sales to private commercial and industrial (C&I) projects in Oman.

- Exporting modules to neighboring GCC countries.

- Supplying smaller residential solar installers.

Frequently Asked Questions (FAQ)

What is the typical initial investment for a 50 MW solar module factory in Oman?

While varying by technology and scope, the core machinery investment is typically in the range of USD 4–5 million. Total project costs, including the building and working capital, would be higher and require detailed financial modeling.

How long does it take to set up a turnkey solar factory?

With a prepared building and streamlined approvals under a PPP structure, a production line can be fully installed, commissioned, and ready for operation within 12–15 months.

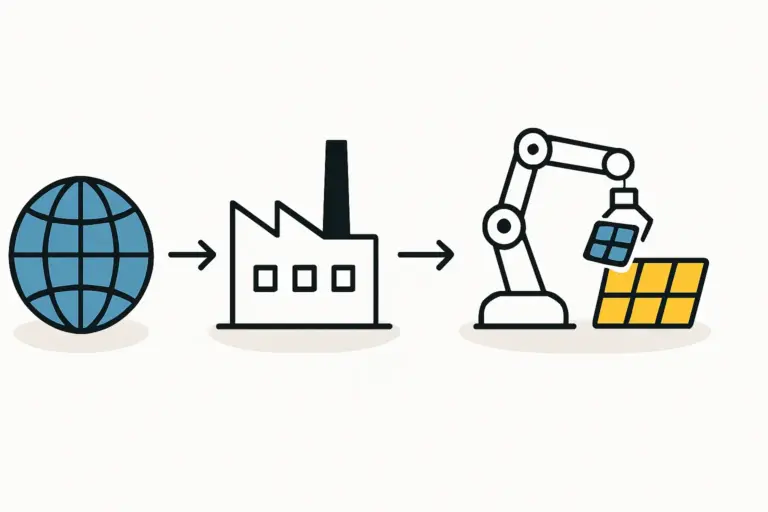

Does the private investor need prior experience in solar manufacturing?

No. The turnkey model is specifically designed for new market entrants. The technical partner provides all the necessary engineering, process knowledge, and training. The investor’s expertise in business management and finance is complementary.

What kind of government support can be expected under a PPP in Oman?

Support typically includes secured offtake agreements, land allocation in free zones, tax holidays, customs duty exemptions on equipment, and streamlined regulatory approvals.

How does a local factory compete with international suppliers?

A local factory competes through several advantages: elimination of international shipping costs and import tariffs, faster delivery times, local customer support, and preferential treatment under Oman’s In-Country Value (ICV) policies for national projects.

The Path Forward: A Structured Approach

The convergence of Oman Vision 2040 and the country’s robust PPP law has created a unique, time-sensitive opportunity. Establishing a national solar module factory is no longer just a possibility; it is a strategic imperative with a clear, de-risked pathway for investors.

For an entrepreneur or investment group ready to explore this opportunity, the next steps are logical and structured:

- Conduct a Detailed Feasibility Study: Develop a bankable business plan with precise financial models tailored to the Omani market.

- Engage with Public Stakeholders: Initiate discussions with the Ministry of Commerce, Industry and Investment Promotion (MoCIIP) and other relevant authorities to formalize the PPP framework.

- Select a Proven Technical Partner: Partner with an experienced engineering firm to ensure the technical success of the project, from design to long-term operation.

This venture offers the chance to build not just a factory, but a cornerstone of Oman’s sustainable energy future, delivering strong financial returns while making a lasting contribution to the nation’s economic resilience.

Download: Oman Public-Private Partnership Case Study (PDF)

Author: This case study was prepared by the

turnkey solar module production specialists at J.V.G. Technology GmbH

It is based on real data and consulting experience from J.v.G. projects

worldwide, including installations ranging from 20 MW to 500 MW capacity.