Afghanistan stands at a fascinating crossroads. The nation is grappling with significant energy challenges, yet, almost poetically, it’s drenched in sunshine—we’re talking over 300 sunny days a year and a staggering solar capacity estimated at over 220 GW. This abundant sunshine isn’t just a nice feature; it offers a genuine pathway toward greater energy independence and a stronger, more resilient economy. But here’s the big question: how do we go from all that brilliant potential to actually making solar panels right there in Afghanistan? To do that, we need to roll up our sleeves and take a good, honest look at the realities of the labor market and the intricacies of supply chains on the ground.

So, let’s dive in and explore the practicalities of setting up solar manufacturing in Afghanistan. Think of it as a ground-level view: who could do the work, where the materials would come from, and how everything would get from point A to point B. If you’re an entrepreneur with a vision, an investor looking for impactful opportunities, or a policymaker shaping the future, understanding these grassroots factors is more than just important—it’s fundamental. For a broader perspective, you might also find our overview of Solar Manufacturing Opportunities in Afghanistan a useful read.

Table of Contents

Finding the Right People: Afghanistan’s Labor Market for Solar Manufacturing

It’s a simple truth: you can’t build solar panels without skilled hands and bright minds. Getting a handle on the workforce situation is step one. Afghanistan’s labor market presents a mix of real opportunities and, let’s be frank, some pretty tricky hurdles to navigate.

A Quick Glance at the General Workforce

First off, Afghanistan has a young and growing population, which means a significant number of people are of working age. That’s a definite plus. However, unemployment and underemployment are persistent challenges the country continues to wrestle with. This large pool of individuals could, in theory, provide the necessary manpower for new industries like solar manufacturing.

The All-Important Skilled Workers

Now, even if we’re initially focusing on assembly, making solar panels isn’t child’s play. It demands a specific set of skills:

- Engineers and Technicians: You absolutely need professionals in electrical, mechanical, and industrial engineering. These are the folks who get a plant designed and running, oversee processes, keep a keen eye on quality control, and troubleshoot when things (inevitably) go a bit sideways. Right now, finding enough seasoned specialists in advanced manufacturing is, admittedly, a tough ask.

- Manufacturing Specialists: We’re talking about workers who are comfortable with precision assembly, have a good understanding of electronics, and know the ins and outs of quality assurance. These are key players on the factory floor.

- Education and Vocational Training: While universities and vocational centers exist, their curricula and hands-on training in solar technology and modern manufacturing need a significant boost to align with what the industry requires. Interestingly, data from PVKnowHow suggests that project managers in the solar sector might earn around $950/month. This hints that some level of expertise is already present, but it’s likely on a smaller, more project-based scale rather than in widespread manufacturing.

- Bridging the Skill Gap: This is a big one. Closing the gap between general educational attainment and the specific technical competencies needed to thrive in solar manufacturing will be a major undertaking.

Unskilled and Semi-Skilled Labor: Untapped Potential?

- Plenty of People: There’s a substantial supply of unskilled and semi-skilled workers, particularly in and around urban centers. This is a resource waiting to be mobilized.

- Ready to Learn: The encouraging part is that these workers can often be trained for roles in assembly lines, material handling, and operating basic machinery. Any successful manufacturing venture would need to build robust on-the-job training programs right into its DNA.

- Wage Considerations: Wages for unskilled labor are comparatively low (for instance, available data points to a minimum wage for temporary workers around $79/month). On paper, this could look like a cost advantage. However, this must be carefully weighed against productivity levels and the investment needed for skills development to get a true picture of cost-effectiveness.

The Labor Scene: What to Watch Out For and What to Hope For

So, when we look at the workforce, what are the main speed bumps we need to be aware of?

- Security Concerns: The ongoing security situation is a serious factor. It can make it difficult for people to commute to work safely and might understandably discourage skilled individuals from staying in or relocating for a job.

- Brain Drain: It’s a tough reality that when skilled professionals leave the country, it shrinks an already limited talent pool even further.

- Building Up Skills Infrastructure: There’s a real need for a coordinated, national effort to strengthen technical and vocational training, ensuring it’s directly relevant to what industries like solar manufacturing require.

But it’s not all doom and gloom. There are some genuinely exciting possibilities on the horizon:

- Creating Jobs: Solar manufacturing could be a powerful engine for creating much-needed employment, especially for the country’s youth.

- Boosting Skills: Investing in training for a solar plant doesn’t just benefit that one factory; it contributes to a more skilled and adaptable workforce for the entire economy.

- Growing Local Know-How: Over time, as people work in this sector, local talent can develop into genuine experts in solar technology, creating a sustainable knowledge base.

Taking Apart the Supply Chain: What Goes Into a Solar Panel in Afghanistan?

Ever stopped to think about what actually goes into a solar panel? It’s a surprisingly complex mix—far more than just glass and metal. You have everything from basic materials like aluminum to highly specialized, high-tech components like solar cells and inverters. Trying to build a local supply chain for all of that in Afghanistan is a pretty big puzzle to solve.

The Big Picture: Most Parts Will Come From Abroad (For Now)

Let’s be upfront: the global solar supply chain is an incredibly efficient, established powerhouse, and China plays a dominant role, particularly in producing polysilicon, wafers, cells, and modules. For a country like Afghanistan, which is essentially starting fresh in this area, it means that, for the foreseeable future, many components—especially high-value, super-technical ones (think solar cells, specialized plastics like EVA, and backsheets)—will almost certainly need to be imported. That’s just the pragmatic reality of starting out.

Sourcing Locally: What Could Realistically Be Made in Afghanistan?

So, what could potentially be sourced or made within Afghanistan?

- Basic Materials:

- Aluminum: Afghanistan has bauxite deposits (the raw ore for aluminum). However, the capacity to process this into the high-quality aluminum frames needed for solar panels is likely underdeveloped and would require a serious injection of capital and technical expertise.

- Glass: The raw materials for glass, such as silica sand, might well be available. But—and it’s a big but—setting up a factory to produce the specialized solar-grade, tempered, low-iron glass that panels require is a major investment and demands very specific technology.

- Simpler Components:

- Junction Boxes, Cables, Connectors: It’s conceivable that some basic electrical components are already manufactured locally, or that developing this capacity would be less complex and capital-intensive than, say, cell production.

- Advanced Components (Likely to be Imported):

- Solar Cells: Producing solar cells from silicon wafers is an incredibly complex and capital-intensive process. It needs ultra-clean factory environments and highly advanced technology. Realistically, this is very unlikely to be feasible in Afghanistan in the short to medium term.

- Silicon Wafers: Making silicon ingots and then slicing them into wafers is an even earlier, more specialized stage of the value chain, currently dominated by just a handful of countries.

- EVA (Ethylene Vinyl Acetate) and Backsheets: These specialized plastic films are absolutely vital for encapsulating and protecting the solar module. You’ll almost certainly need to source these from established international suppliers.

- Inverters: These power electronics are sophisticated devices. Local assembly might be a very long-term aspiration, but initially, they will be imported.

Getting Parts In: The Logistics of Importing

- Routes and Partners: Afghanistan is landlocked, so importing components relies heavily on strong relationships and smooth transit through neighboring countries like Pakistan, Iran, and the Central Asian republics for access to seaports and overland routes.

- Costs and Timelines: Importing components will inevitably add to the bottom line through transport costs, customs duties, and potentially lengthy lead times. These factors impact final production costs and operational efficiency.

- Signs of Life: It’s encouraging to hear about some local activity already. Reports mention at least one local solar panel manufacturer/assembler, Etemad Sun Solar in Herat. This is a positive sign, suggesting that importing components and assembling them locally is indeed happening, even if it’s on a relatively small scale.

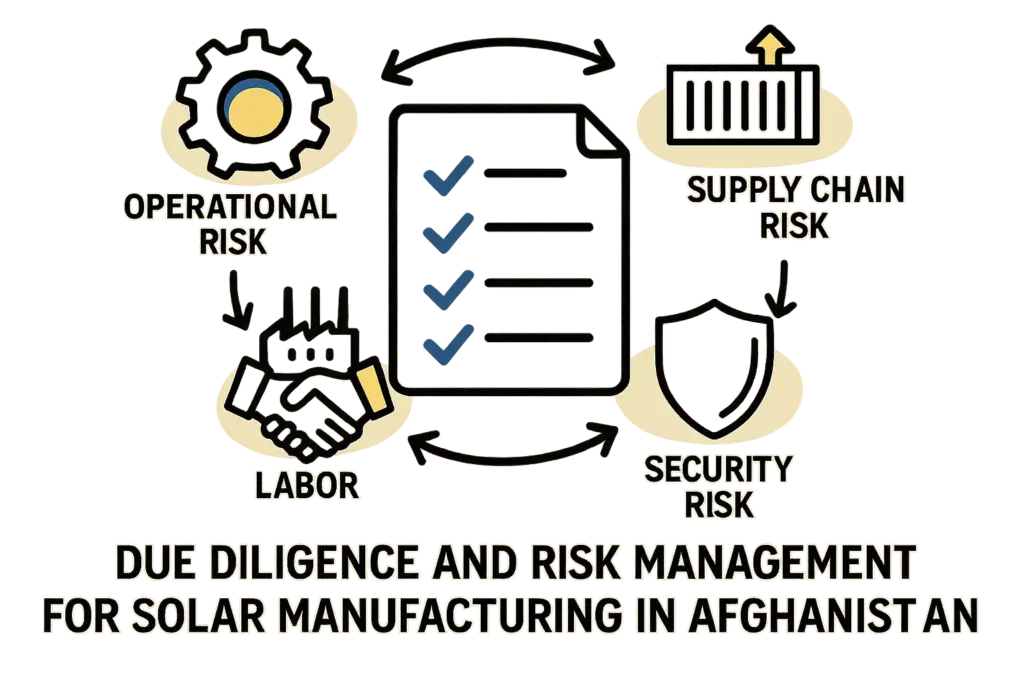

The Supply Chain Puzzle: Sticking Points and Smart Routes

So, what makes building out this supply chain so tricky?

- Few Local Suppliers: For most of the specialized, critical parts, there simply aren’t many (if any) established local companies making them.

- Keeping Quality High: This is non-negotiable. It’s absolutely essential to ensure that any locally sourced basic materials meet stringent standards and that all imported components are top-notch.

- The Maze of Importing: Navigating customs procedures, transit agreements, and international shipping logistics can be a complex and time-consuming dance.

- Cost of Imported Goods: Fluctuations in currency exchange rates and changes to import tariffs can cause significant swings in production costs, making planning difficult.

But where can Afghanistan make some smart moves to get started?

- Start with Assembly: Initially, the most practical and achievable step is to focus on assembling panels from imported components (often referred to as CKD—Completely Knocked Down, or SKD—Semi Knocked Down kits). This gets things moving.

- Grow Supporting Industries: Over time, local businesses could gradually step in and start producing less complex parts—think frames, mounting gear, or basic junction boxes.

- Less Reliance on Imports (Long-Term Goal): With strategic planning and investment, Afghanistan could slowly, piece by piece, reduce its reliance on imports for certain items. This is a marathon, not a sprint.

Roads, Rails, and Reliability: The Logistical Backbone

You can have the best components and the most skilled people, but if you can’t move things around efficiently and reliably, you’re essentially stuck in first gear. Good logistics are the unsung hero here, and let’s be realistic, Afghanistan’s current infrastructure presents some very real challenges.

Getting Around: The Transport Network

- Roads: The vast majority of goods in Afghanistan travel by road. While some major highways exist, many roads, especially in rural areas, are not in great condition. This translates to longer travel times, higher transport costs, and an increased risk of damage to sensitive goods.

- Rail: The rail network is currently very limited, so it’s not a widespread option for freight movement across the country.

- Air Freight: This can be an option for high-value, low-volume components if time is critical, but it’s far too expensive for transporting bulk materials or finished solar panels.

- Crossing Borders: Smooth, predictable customs processes and stable transport routes through neighboring countries are vital, but these can, unfortunately, be subject to disruptions and unpredictability.

Storing Goods: Warehousing

Finding sufficient, good-quality, secure warehousing for sensitive electronic components and finished products can be a challenge, especially outside the main urban centers. Some materials might even require climate-controlled environments, adding another layer of complexity.

Powering the Factories: The Energy Catch-22

Here’s a touch of irony: to manufacture energy-generating solar panels, the factories themselves need an exceptionally reliable and stable power supply. Afghanistan’s national grid, however, often struggles with consistency, facing frequent outages and limited reach (it’s estimated only about 30% of the country has access to grid electricity). This means manufacturers would likely need to invest in their own backup power solutions, perhaps even their own on-site solar installations.

Security’s Shadow Over Logistics

And, of course, the overarching security situation casts a long shadow. It can disrupt transport routes, increase insurance costs significantly, and pose risks to both personnel and cargo. This adds layers of complexity and expense that simply can’t be ignored.

Logistics Lowdown: The Hurdles and the Hopes

So, what are the main logistical headaches to anticipate?

- Infrastructure Needs Work: There’s no way around it—significant investment is needed to improve roads, potentially expand rail, and upgrade other supporting facilities.

- High Transport Costs: Factors like fuel costs, road conditions, and security considerations all contribute to pushing logistics expenses upward.

- Delays and Surprises: Border crossings, checkpoints, and general infrastructure limitations can lead to significant and often frustrating delays in the supply chain.

Are there any silver linings or reasons for optimism on the logistics front?

- Planned Upgrades: Ongoing efforts by the government and international aid organizations aim to improve key transport routes over time.

- Location, Location, Location (Long-Term): Looking much further ahead, if regional stability improves, Afghanistan’s geographic position could one day make it a valuable trade and transit hub. Though, admittedly, that’s a long-term vision.

Rules, Regulations, and Government Backing

It’s encouraging to see the Afghan government signaling its commitment to boosting renewable energy, clearly laid out in its Renewable Energy Roadmap (RER2032) which aims for 2,000 MW of renewable capacity by 2032. That’s a positive first step.

However, the focus must expand from simply deploying solar to actively supporting local manufacturing. To achieve this, specific incentives and a robust regulatory framework need to be fleshed out and implemented consistently. The overall climate for investment, the strength of legal protections for businesses, and how effectively contracts are enforced are all vital pieces of the puzzle for attracting the necessary long-term investment.

Charting a Course: Our Recommendations for a Viable Path

Considering all these challenges and opportunities, how can Afghanistan realistically move forward on this solar manufacturing journey? We believe a pragmatic, step-by-step approach, starting with assembly, makes the most sense:

- Boost Your Workforce: This is foundational. Invest in targeted vocational training programs designed for solar assembly and basic manufacturing skills. Forging partnerships between public institutions and private sector players here could be a real game-changer.

- Source Smartly: Kick things off by focusing on assembling panels using imported, high-quality solar cells and other key components. Then, gradually, begin to explore and cultivate local sources for simpler parts like aluminum frames (only if the quality and cost make solid business sense) or junction boxes.

- Plan Your Logistics Carefully: Develop robust logistical plans that realistically account for current infrastructure limitations and security risks. This might involve identifying more secure transport corridors or investing in localized warehousing solutions.

- Quality is King: This cannot be overstated. Implement stringent quality control measures at every stage of the process—from meticulously checking imported components to rigorously testing the finished modules. There are no shortcuts when it comes to quality.

- Government, Pave the Way: The government has a huge role to play. Clear, supportive policies, attractive investment incentives specifically targeted at local manufacturing (not just deployment), and streamlined customs processes are essential to creating an enabling environment.

- Learn from the Best: Don’t try to reinvent the wheel. Actively seek partnerships with experienced international solar manufacturers. They can bring invaluable assistance with technology transfer, crucial training programs, and best practices—much like how we at PVknowhow.com aim to support new ventures and capacity building around the world.

The Finish Line: A Tough Climb, But a Potentially Amazing View

Let’s be clear: building a thriving solar panel production sector in Afghanistan will not be a walk in the park. It’s a journey that will undoubtedly have its share of bumps in the road, particularly concerning worker skills, gaps in the local supply chain, and logistical hurdles. Our honest take? Initial efforts should zero in on assembly operations. From that foundation, local capabilities can be nurtured and built up gradually, with a keen eye on localizing the production of more parts where it genuinely makes economic and practical sense.

Making this vision a reality will require a concerted effort from everyone involved: developing a skilled workforce, making strategic investments in critical infrastructure, crafting supportive and consistent government policies, and fostering a stable, predictable environment where businesses can not just survive, but thrive. It’s a tough climb, no doubt, but the view from the top—enhanced energy security, new jobs, and sustainable economic development for Afghanistan—could be incredible.

Want to learn more or need expert help? Visit our free e-course or explore our services. Or, if you’re ready to dive deeper, our Premium Business Plan E-Course offers personalized guidance to get your venture off the ground. Let’s make your solar journey smooth and successful.