Alright, let’s get straight to it. Algeria is on an exciting journey, aiming to tap into its massive solar potential with an ambitious goal of 15 GW of renewable energy by 2035. This national ambition is flinging the doors wide open for solar manufacturers ready to establish local production. But, like any venture worth its salt, real success means understanding how things actually work on the ground in Algeria. We’re digging into the essentials: the labor market, training infrastructure, and the nitty-gritty of local supply chain capabilities. Consider this your essential briefing for mapping out your investment. The opportunities are shining bright, but successfully navigating workforce skills, training, and component sourcing requires clever, strategic thinking. So, let’s unpack it all.

Table of Contents

Algeria’s Solar Energy Revolution: Setting the Stage for Manufacturing

Blessed with sunshine that most countries can only dream of, Algeria is making a serious pivot toward renewable energy, with solar power front and center in its national strategy. This isn’t just about switching to cleaner electricity; it’s part of a much bigger picture. The vision is to supercharge industrial development, create a wave of new jobs, and bolster the nation’s energy independence.

A. Government Vision and Targets

The government has laid out some seriously ambitious goals. The headline figure—targeting 15 gigawatts (GW) of renewable energy capacity by 2035—is significant, and a hefty slice of that pie is earmarked for solar photovoltaic (PV) installations. This isn’t just talk; this long-term vision is being backed by various programs and tenders designed to pull in investment and get projects moving.

B. Current Solar Capacity and Key Projects

As of late 2023, Algeria’s installed solar capacity was hovering around 437 megawatts (MW). To close that gap and hit the 2035 target, the country has kicked off several major initiatives. The “Solar 1,000 MW” scheme is a cornerstone, aiming to deliver a quick and significant capacity boost through large-scale solar farms. Furthermore, a 2023 tender for 15 solar farms, each ranging from a hefty 80 MW to 220 MW, underscores the sector’s ongoing momentum. These projects are a clear signal of the growing demand for locally produced solar components.

C. The Strategic Push for Local Solar Manufacturing

Recognizing the economic and strategic advantages, Algeria is actively promoting the growth of a local solar manufacturing industry. This push is about reducing reliance on imports, creating quality jobs, encouraging technology transfer, and building a strong, dependable domestic supply chain. We’re already seeing positive signs, like discussions with international industry leaders such as LONGi to set up local PV module manufacturing lines. It’s a strong indicator of the government’s commitment to nurturing local production capabilities. In fact, current local assembly capacity for solar modules is already around 500 MW, and that figure is expected to climb to 600-700 MW by the end of 2025.

The Algerian Labor Market: Powering Solar Manufacturing

Any successful manufacturing venture leans heavily on its people—a skilled and adaptable workforce is non-negotiable. If you’re seriously considering Algeria for your solar manufacturing base, understanding the ins and outs of the local labor market isn’t just important; it’s essential.

A. Availability of General and Technical Workforce

The good news is that Algeria has a relatively young and growing population, which means there’s a substantial pool of general labor. Reports from sources like trade.gov indicate that “qualified, cost-effective labor” is available. However, when you zoom in on specialized sectors like solar PV manufacturing, the real challenge arises in finding people with specific technical know-how.

B. Assessing Specific Skillsets for Solar Panel & Component Manufacturing

Making solar panels and their components isn’t like assembling flat-pack furniture; it demands a diverse mix of skills. This includes engineers skilled in process optimization and quality control, technicians comfortable with sophisticated machinery, and assembly line workers who can perform precise, consistent tasks day after day.

- Current Strengths: Algeria isn’t starting from a blank slate. It already has a foundation of engineering and technical skills, largely thanks to its established industrial base and its long history in the energy sector.

- Critical Gaps: While general technical aptitude may be there, finding specific experience in PV manufacturing processes—such as delicate cell handling, lamination, tabbing and stringing, and quality assurance protocols unique to solar—is likely to be a challenge. Some market analyses point to a “lack of skilled labor” specifically for these advanced manufacturing roles, which underscores the need for targeted upskilling.

C. Wage Competitiveness and Labor Environment

One factor that can make Algeria attractive for manufacturers is its competitive labor costs, especially compared to many developed nations. Of course, it’s crucial to get a thorough understanding of local labor laws, employment regulations, and typical wage expectations for different skill levels. This isn’t just red tape; it’s vital for accurate financial planning and ensuring compliance.

D. Regional Labor Hotspots and Considerations

It’s also worth keeping in mind that labor availability and skill concentrations can vary quite a bit across Algeria’s different regions. You might find that industrial zones or areas with a history of manufacturing offer a more readily available technical workforce. Naturally, being close to universities and vocational training centers can be a significant advantage.

Bridging the Skills Gap: Training and Workforce Development for the Solar Industry

To get its growing solar manufacturing sector firing on all cylinders, strong training and workforce development programs aren’t just a nice-to-have; they’re essential. The good news is that Algeria has recognized this and is starting to put serious effort into addressing it.

A. Overview of Existing Vocational and Technical Training Infrastructure

Algeria already has a network of vocational training centers and technical institutes. What’s encouraging is that their focus is increasingly shifting to weave renewable energy technologies into their curriculum.

B. Current Solar-Specific Training Programs

Several initiatives are already underway, aiming to build solar-specific skills:

- The Centre de Développement des Energies Renouvelables (CDER) has been active in rolling out training programs covering PV system sizing, installation, and maintenance.

- Interesting partnerships are also emerging, like the one between TotalEnergies and DEMJ (Direction de l’Enseignement et de la Main d’Œuvre Jeunesse), which has launched courses such as “Hydro and Solar PV.”

- International cooperation is also playing a part, with organizations like TİKA (Turkish Cooperation and Coordination Agency) supporting renewable energy training. These efforts are positive signs of a commitment to building a skilled workforce.

However, it’s important to assess how much these programs are specifically geared toward manufacturing roles, as opposed to installation and maintenance, since the skillsets differ significantly.

C. Identifying Critical Training Needs for Solar Component Manufacturing

For solar manufacturing, training needs go deeper than basic PV knowledge. The curriculum should also cover:

- Operating and maintaining automated manufacturing equipment.

- Cleanroom protocols, which are critical when handling sensitive components like solar cells.

- Quality control techniques specific to PV module production (like EL testing and sun simulation).

- Managing the supply chain and logistics for all manufacturing inputs.

- Health and safety standards within a manufacturing environment.

D. Opportunities for Public-Private Partnerships in Skilling the Workforce

This presents a fantastic opportunity for solar manufacturers to partner with local educational institutions and government agencies. By co-developing training programs tailored to the industry’s actual needs, these partnerships can ensure the curriculum is relevant, providing a steady pipeline of skilled workers ready for manufacturing roles. This approach could echo successful models like the European Solar Academy, adapted for the Algerian context.

Untangling the Algerian Solar Supply Chain: Capabilities for Manufacturers

A resilient and cost-effective supply chain is the backbone of competitive solar manufacturing. It’s vital to get a clear picture of what’s locally available in terms of components and raw materials and to understand the country’s logistical capabilities.

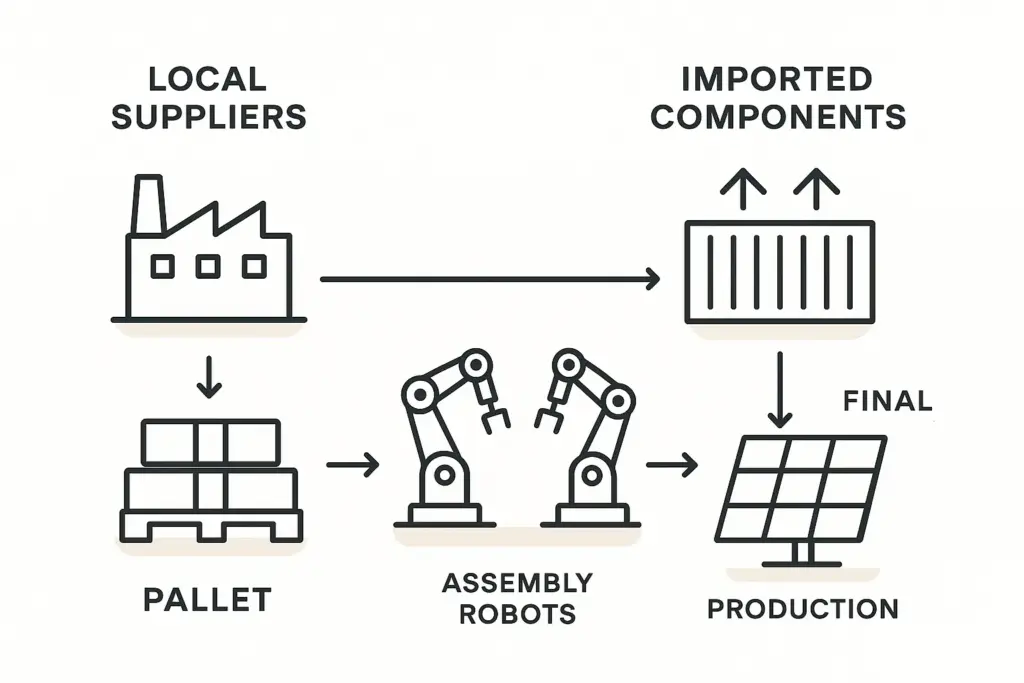

A. Current State of Local Manufacturing for Solar Components

Algeria’s solar supply chain has been on an upward curve over the past decade, with an increasing focus on localizing production.

- PV Module Assembly: As mentioned earlier, Algeria has existing module assembly capacity. Currently, this primarily relies on imported solar cells and other specialized materials. The goal is to ramp up this capacity and, ideally, deepen the value chain over time.

- Inverters and BoS (Balance of System) Components: While some basic BoS components like mounting structures or certain cables may have local sourcing potential, more sophisticated components like inverters are largely imported. There is a strategic interest in developing local production for these items as well.

- Raw Materials for Manufacturing: The local availability of key raw materials for PV manufacturing (such as high-purity glass, EVA encapsulant, backsheets, aluminum frames, silicon wafers, and solar cells) is a critical point to investigate. Currently, Algeria relies heavily on imports for most of these specialized raw materials and upstream components.

B. Logistics and Infrastructure: Ports, Transport, and Industrial Zones

Algeria has established ports and a transportation network that’s steadily improving. The country’s historical strengths in logistics and civil engineering, particularly from the oil and gas sector, can certainly be leveraged for the solar industry. You may also find that designated industrial zones offer better infrastructure and logistical support, which can be a real boon for manufacturing setups.

C. The Role of Imports: Key Components and Materials Sourced Externally

Despite efforts to localize, manufacturers will likely need to import a significant portion of specialized components (like high-efficiency solar cells and advanced inverters) and specific raw materials. A firm grasp of import regulations, customs procedures, and lead times is essential to avoid surprises.

D. Government Initiatives and Incentives to Bolster the Local Supply Chain

The Algerian government is keen to attract investment into the local supply chain. Discussions with international companies like LONGi about setting up local production lines are aimed squarely at facilitating technology transfer and building up domestic capabilities. It’s highly probable that incentives will be available for companies that contribute to local value addition.

E. Identifying Strengths, Weaknesses, and Gaps for a Resilient Manufacturing Supply Chain

Let’s break it down:

- Strengths: A growing domestic market, solid government backing for localization, existing module assembly experience, and good potential for BoS component manufacturing.

- Weaknesses: A heavy reliance on imports for critical raw materials and advanced components (cells, wafers, specialized polymers, high-quality glass) is a key challenge. Plus, there is limited upstream manufacturing (polysilicon, ingots, and wafers).

- Gaps: There is a clear need—and therefore opportunity—for greater investment in upstream manufacturing and the development of a robust ecosystem of local suppliers for specialized materials.

Operational Intelligence: Navigating Investment and Setup

Successfully setting up a solar manufacturing facility in Algeria isn’t just about having a great product; it requires careful planning and a solid understanding of the local operational environment. Here are some key areas to have on your radar.

A. Regulatory Framework for Foreign Investors in Manufacturing

As an investor, you can’t skip this homework: thoroughly research Algeria’s investment laws. You’ll need to understand regulations concerning foreign ownership, profit repatriation, and any sector-specific requirements for renewable energy manufacturing. Engaging local legal and business consultants early is highly advisable, as their guidance can be invaluable.

B. Key Incentives for Solar Manufacturing Ventures

The Algerian government, keen to see this sector flourish, is likely to offer various incentives to attract investment in solar manufacturing. These could include tax breaks, customs duty exemptions for imported machinery and raw materials (a big help to your bottom line), access to land in specialized industrial zones, and perhaps preferential treatment in public tenders for locally produced goods.

C. Potential Challenges and Mitigation Strategies

It’s wise to go in with your eyes open to potential hurdles. Manufacturers might face challenges such as:

- Bureaucracy and Regulatory Delays: Navigating administrative processes can sometimes be slow. Being proactive, ensuring your documentation is in order, and building strong local partnerships can help smooth out potential bumps in the road.

- Access to Finance: Securing local or international financing will require a robust business plan and a good understanding of the financial landscape. It’s best to start these conversations early.

- Grid Integration for Offtake (if selling locally): While this is primarily a concern for power producers, manufacturers supplying large local projects should be aware of grid capacity and stability. This can impact your customers and, by extension, your business.

- Developing a Skilled Workforce: As we’ve emphasized, investing in training and skills development isn’t just an option; it’s crucial for long-term success.

Conclusion: Capitalizing on Algeria’s Solar Manufacturing Potential

Algeria presents a compelling, though admittedly complex, opportunity for solar manufacturers. The nation’s strong commitment to solar energy, coupled with a growing domestic market and a strategic push for local industrialization, creates a favorable wind for investment.

The key to unlocking this potential lies in thorough due diligence and smart, strategic planning. Understanding the nuances of the labor market, participating in workforce development, and skillfully navigating the evolving supply chain are critical pieces of the puzzle. While challenges related to specialized skills and reliance on imports exist, they also represent significant opportunities for pioneering companies to step in, innovate, and help build a robust local solar ecosystem.

For entrepreneurs and companies ready to invest the time to understand these dynamics and partner to build local capabilities from the ground up, Algeria offers the chance to be part of a significant energy transition and industrial development story. With experienced guidance and a clear-eyed strategy, manufacturers can tap into this promising North African market. We’re here to help you explore that journey.

Want to learn more or need expert help? Visit our free e-course or explore our services. Or, if you’re ready to dive deeper, our Premium Business Plan E-Course offers personalized guidance to get your venture off the ground. Let’s make your solar journey smooth and successful.

Frequently Asked Questions (FAQs)

Let’s tackle some common questions:

Q1: What are the most critical skills gaps for solar manufacturing in Algeria?

A1: While general technical labor is often available, the more specialized skills tied directly to advanced PV manufacturing processes often need dedicated development. These include the delicate handling of solar cells, operating sophisticated automated production lines, and specific quality control methods for PV modules like electroluminescence testing. Targeted training programs, ideally designed with industry input, are essential to bridge these gaps effectively.

Q2: How reliable is the local supply of raw materials for solar panel manufacturing in Algeria?

A2: This is an important consideration for any manufacturer. Currently, Algeria relies heavily on imports for most of the specialized raw materials crucial for making solar panels. This list includes high-purity silicon, solar cells (unless produced in-house), specialized glass, EVA encapsulant, and backsheets. While more basic materials like aluminum for frames might be easier to source locally, a comprehensive sourcing strategy will need to include managing international supply chains for these key inputs.

Q3: Are there specific government incentives for setting up solar manufacturing plants in Algeria?

A3: Yes, the Algerian government is actively encouraging local manufacturing and is likely to offer various incentives. These could take the form of tax concessions, exemptions on customs duties for imported machinery and raw materials, access to land in designated industrial zones, and potentially support through public procurement policies that favor locally made goods. For the most current information, it’s best to contact the relevant Algerian investment promotion agencies.

Q4: What is the biggest challenge for foreign solar manufacturers entering Algeria?

A4: Navigating the regulatory and administrative environment can be a significant hurdle. This involves understanding investment laws, obtaining all the necessary permits, and dealing with bureaucratic processes that can be time-consuming. Alongside this, developing a skilled workforce tailored to your specific manufacturing needs and establishing a reliable supply chain for specialized components are key operational challenges. These require careful planning and strong local partnerships to navigate successfully.

Q5: What support can PVknowhow.com offer for establishing a solar factory in Algeria?

A5: At PVknowhow.com, we bring over two decades of hands-on experience to the table, offering end-to-end solutions for anyone looking to establish solar module production lines. This isn’t just about providing turnkey production equipment; we also dive into crucial business planning (including financial modeling and market analysis, which you can explore through our Premium E-Course with personal mentoring). We offer technical consulting and provide practical guidance on factory layout, process engineering, and technology transfer. Our goal is to empower entrepreneurs and companies to confidently navigate the complexities of setting up and successfully operating a solar factory in high-potential markets like Algeria. We would be happy to discuss how we can support your venture.