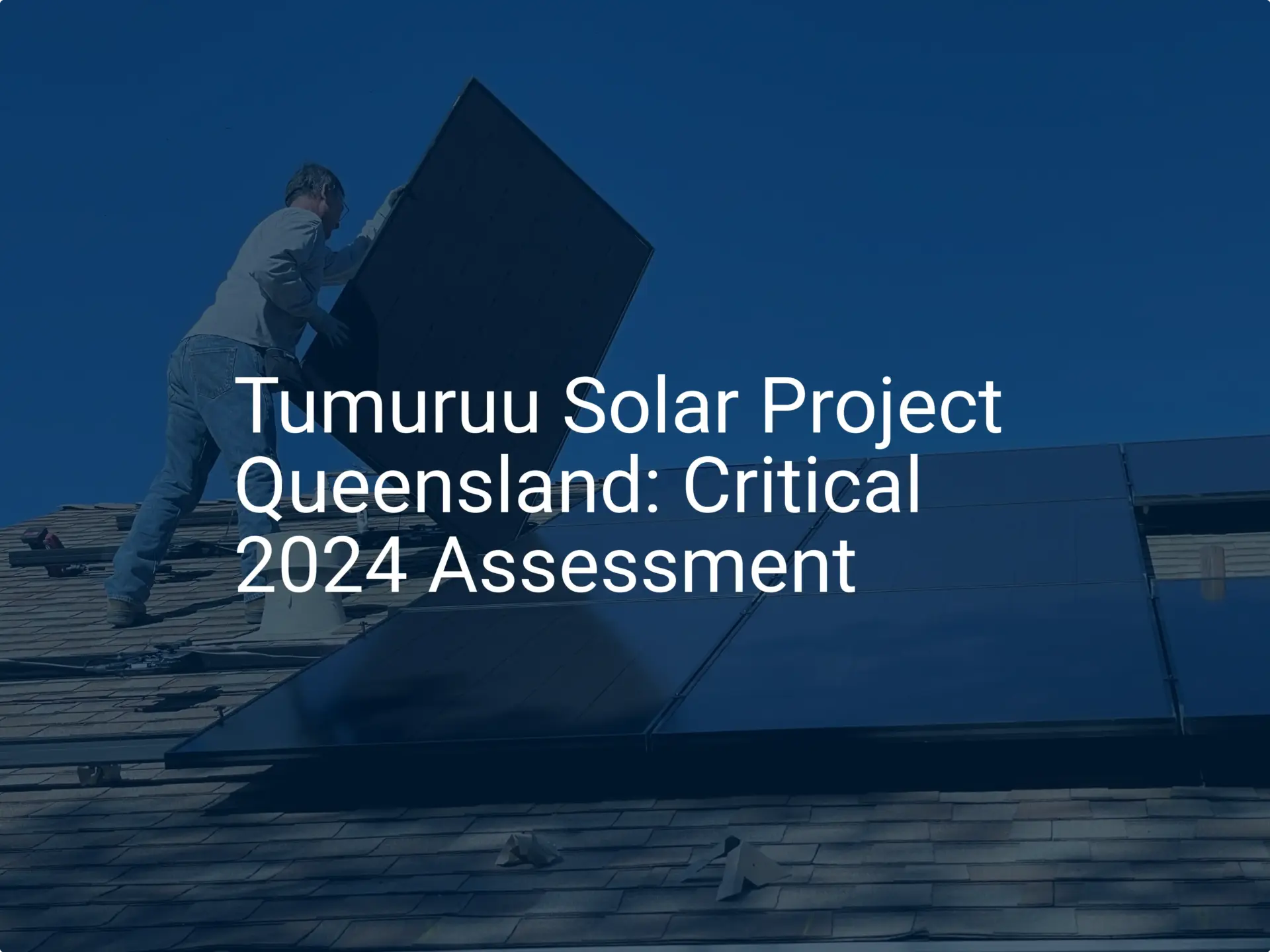

With Australia’s growing commitment to solar energy, a significant opportunity is emerging to establish local solar manufacturing facilities. It’s an exciting prospect, but turning this ambition into a reality requires a critical resource: a skilled and available workforce.

For any entrepreneur or investor looking at this sector, understanding the nuances of building that workforce isn’t just important—it’s fundamental.

Table of Contents

The Australian Solar Manufacturing Landscape & Workforce Imperative

Right now, Australia’s solar manufacturing capacity is focused primarily on module assembly, with limited upstream capabilities in areas like polysilicon, wafer, or cell production. The existing capacity stands at around 160 MW. However, government ambitions, such as the Solar Sunshot program, signal a clear drive to expand domestic production.

This expansion isn’t just about producing panels. It’s about strengthening our energy security, fostering genuine innovation, and creating substantial employment. A complete domestic solar manufacturing value chain could create up to 60,000 jobs in Australia. Realizing that potential hinges on one thing: developing a robust domestic workforce with the specialized skills needed for modern solar manufacturing.

Decoding the Skills Matrix: What Expertise Does a Solar Factory Need?

Building a solar factory workforce demands more than filling general manufacturing roles; it requires a specific blend of technical, engineering, and operational expertise.

Engineering & Design

Qualified engineers are the brains of the operation, crucial for process optimization, quality assurance, and innovation. Key roles include:

- Process Engineers who design, implement, and continually refine manufacturing processes.

- Electrical Engineers to handle system design, integration, and troubleshooting of complex electrical systems.

- Chemical Engineers, essential for upstream processes like polysilicon refining or wafer manufacturing.

- Material Scientists to focus on material selection, quality control, and the development of next-generation solar cell technologies.

- Research & Development (R&D) Roles to drive continuous improvement and adapt to the fast-paced world of new PV technologies.

Skilled Technicians

Your technicians are the backbone of day-to-day operations, ensuring machinery runs smoothly and product quality remains consistently high.

- Automation & Robotics Technicians: Modern solar manufacturing is highly automated, making technicians skilled in programming and maintaining robotic systems absolutely vital.

- Maintenance Technicians: Specialists in the upkeep and repair of sophisticated—and often expensive—solar manufacturing equipment.

- Quality Control (QC/QA) Technicians: Tasked with implementing quality checks at every stage of production to ensure each module meets stringent standards.

- Solar Cell and Module Fabrication Technicians: Possessing the delicate, specific skills needed to handle and process components like solar cells and assemble them into modules.

Production & Operations

Of course, efficient management and execution are what turn a factory into a successful business.

- Plant Managers & Production Supervisors: Responsible for overseeing operations, managing teams, and ensuring production targets are met.

- Machine Operators & Assembly Line Workers: Skilled operators who can handle specific manufacturing equipment and perform assembly tasks with precision.

- Supply Chain and Logistics Personnel: Needed to manage the seamless flow of raw materials in and finished products out.

Essential Soft Skills & Emerging Competencies

Beyond technical qualifications, certain soft skills are indispensable: strong problem-solving abilities, meticulous attention to detail, and effective teamwork. As factories become “smarter,” competencies like data literacy and an understanding of the Internet of Things (IoT) in a manufacturing setting will only grow in importance.

Bridging the Gap: Training & Developing Your Solar Workforce

While Australia has a strong foundational education system, targeted upskilling and specialized training will be essential to meet the demands of a burgeoning solar manufacturing sector. Tapping into a skilled expatriate workforce may be a practical first step, but the long-term goal must be a sustainable, local talent pipeline.

Leveraging Australia’s Education System

- Vocational Education and Training (VET) Sector: Technical and Further Education (TAFE) institutes are invaluable resources, offering adaptable courses in manufacturing, engineering trades, and electronics. Apprenticeships will be a key pathway for developing hands-on skills.

- Universities: Graduates from engineering (electrical, mechanical, chemical, materials science) and renewable energy programs provide a pool of high-level talent. Collaborations between industry and universities can help tailor curricula to meet specific manufacturing needs.

Industry-Specific Training & Certifications

Organizations like the Clean Energy Council offer various programs, but there is a growing need for specialized training modules focused directly on solar manufacturing processes. These could cover everything from silicon purification to advanced module assembly techniques.

In-House Training & Upskilling Strategies

Companies will need to invest in robust internal training programs. This includes structured on-the-job training, mentorship programs, and, critically, knowledge transfer from experienced international staff to local hires. Continuous professional development will also be essential to keep pace with rapid technological advancements.

Government Support for Workforce Development

The Australian Government recognizes the need to build skills for the clean energy workforce. We’re seeing initiatives like a $91 million investment over five years (from the 2024–25 budget) aimed at developing this sector. State-level programs also offer models of support that could be expanded. Investigating all available federal and state funding for training and apprenticeships is a crucial step.

Understanding Labor Costs in Australian Solar Manufacturing

Labor costs are a significant factor in a solar factory’s operational expenditure. A clear understanding of these costs is crucial for financial planning and assessing competitiveness.

Typical Salary Ranges

Salaries will vary based on role, experience, qualifications, and location. While precise data for solar manufacturing roles is still emerging, we can look to related sectors for guidance:

- Engineers (e.g., Solar, Process, Electrical): Entry-level positions might range from AUD $70,000 to $90,000 per annum. Mid-career engineers could expect AUD $90,000 to $140,000+, while senior roles can exceed AUD $150,000.

- Specialized Technicians (Automation, Maintenance, QC): Salaries could range from AUD $65,000 to $95,000+, depending on specialization and experience.

- Production Supervisors: Likely to be in the AUD $75,000 to $110,000 range.

- Skilled Operators & Assemblers: Wages might range from AUD $55,000 to $75,000.

Remember, these are indicative figures and should always be validated through specific market research during your planning phase.

On-Costs and Total Cost of Employment

Beyond base salaries, employers must account for significant on-costs—a critical point that is often underestimated. These include:

- Superannuation: Currently 11% (and legislated to rise).

- Payroll Tax: Varies by state and territory.

- Workers’ Compensation Insurance: Premiums vary by industry risk and claims history.

- Leave Entitlements: Annual leave, personal/carer’s leave, and long service leave.

All told, these on-costs can add approximately 25–35% or more to the base salary, which significantly impacts the total cost of employment.

Factors Influencing Labor Costs

Several factors will influence your specific labor costs:

- Location: Wages and on-costs differ between states and between metropolitan and regional areas.

- Experience and Skill Specialization: Highly specialized individuals will command higher salaries.

- Unionization: Enterprise bargaining agreements (EBAs) can influence wage rates and conditions.

Competitiveness

Australian manufacturing labor costs are generally higher than in major solar manufacturing regions like China. Reports suggest Australian solar module production costs could be around AUD $0.17/W compared to China’s AUD $0.12/W, with labor being a key contributor. Strategies to enhance productivity and automation will be critical for maintaining competitiveness.

Recruitment & Retention: Attracting Australia’s Best Solar Talent

Securing the right talent requires a proactive approach.

- Targeted Recruitment: Use industry-specific job boards, professional networks like LinkedIn, and forge partnerships with educational institutions.

- Addressing the Expatriate Need: A clear strategy for attracting skilled expatriates, coupled with robust knowledge transfer programs, will be crucial in the initial phases.

- Attractive Work Environment: Competitive remuneration is just the start. Opportunities for career advancement, investment in training, and a positive company culture are key to attracting and retaining staff.

- Diversity and Inclusion: Building a diverse workforce brings a wider range of skills and perspectives. Past initiatives focusing on including women, youth, and Indigenous Australians provide a great model to follow.

The Path Forward: Building a Sustainable Solar Manufacturing Workforce

Developing a skilled and sustainable solar manufacturing workforce in Australia is a long-term commitment. It requires genuine collaboration between industry, government, and educational institutions. This involves:

- Investing in modern training facilities and programs.

- Creating clear and rewarding career pathways within the solar manufacturing sector.

- Promoting the industry as an attractive, innovative, and stable source of employment.

Ultimately, investing in your workforce is not merely an operational cost; it is a strategic investment in the long-term success of your solar manufacturing venture and in Australia’s clean energy future.

Want to learn more or need expert help? Visit our free e-course or explore our services. Or, if you’re ready to dive deeper, our Premium Business Plan E-Course offers personalized guidance to get your venture off the ground. Let’s make your solar journey smooth and successful.

Frequently Asked Questions (FAQs)

Q1: What are the most critical skill gaps in Australia for solar manufacturing?

A: While Australia has a skilled general manufacturing and engineering base, the specific gaps are in advanced solar PV manufacturing. This includes cell fabrication, operation of specialized automated lines, and process engineering for solar materials. Initially, experienced expatriates will likely be needed to fill these roles.

Q2: How significant are labor costs in Australian solar manufacturing compared to international benchmarks?

A: Labor costs in Australia are higher than in major hubs like China, impacting production costs (e.g., AUD $0.17/W vs. China’s AUD $0.12/W). To manage this, a focus on efficiency, automation, and producing high-value products will be key to remaining competitive.

Q3: What government support is available for training a solar factory workforce?

A: The federal government has committed significant funds (e.g., $91 million over five years) to support clean energy workforce development. State governments also offer grants and subsidies for vocational training and apprenticeships. Researching current programs through Jobs and Skills Australia and relevant state departments is recommended.

Q4: How can a new solar manufacturing company attract experienced engineers and technicians?

A: Beyond competitive salaries, companies can attract top talent by offering work with cutting-edge technology, clear career paths, and visible investment in training. Fostering an innovative culture and highlighting the company’s role in Australia’s renewable energy future are also powerful motivators.

Q5: What role do VET (Vocational Education and Training) providers like TAFE play?

A: VET providers are crucial for developing the skilled technician and operator workforce. They offer specialized courses, certifications, and apprenticeships in manufacturing, electronics, and renewable energy. Close collaboration between manufacturers and TAFE institutes is essential to ensure training programs meet real-world industry needs.