Australia is at a pivotal moment, with growing ambitions to strengthen its domestic solar module manufacturing capabilities. For entrepreneurs and investors looking to enter this promising sector, strategic site selection is paramount. The right location can significantly impact your operational efficiency, cost-effectiveness, and long-term profitability.

This guide explores the critical infrastructure and logistical factors you’ll need to consider when choosing a site for your solar module production plant in Australia. We’ll expand on the excellent infrastructure analysis from the PVknowhow.com report, “Solar Manufacturing Opportunities in Australia,” to provide a complete picture.

Table of Contents

Understanding Australia’s Solar Manufacturing Landscape

The Australian government is actively fostering a local solar manufacturing ecosystem, most notably through initiatives like the “Solar Sunshot” program and the Australian Renewable Energy Agency’s (ARENA) strategic roadmap. These efforts aim to reduce reliance on imports and leverage Australia’s abundant natural resources and research capabilities.

Establishing a domestic production facility not only aligns with this national priority but also represents a significant business opportunity. Success, however, hinges on meticulous planning—and that begins with where you choose to build.

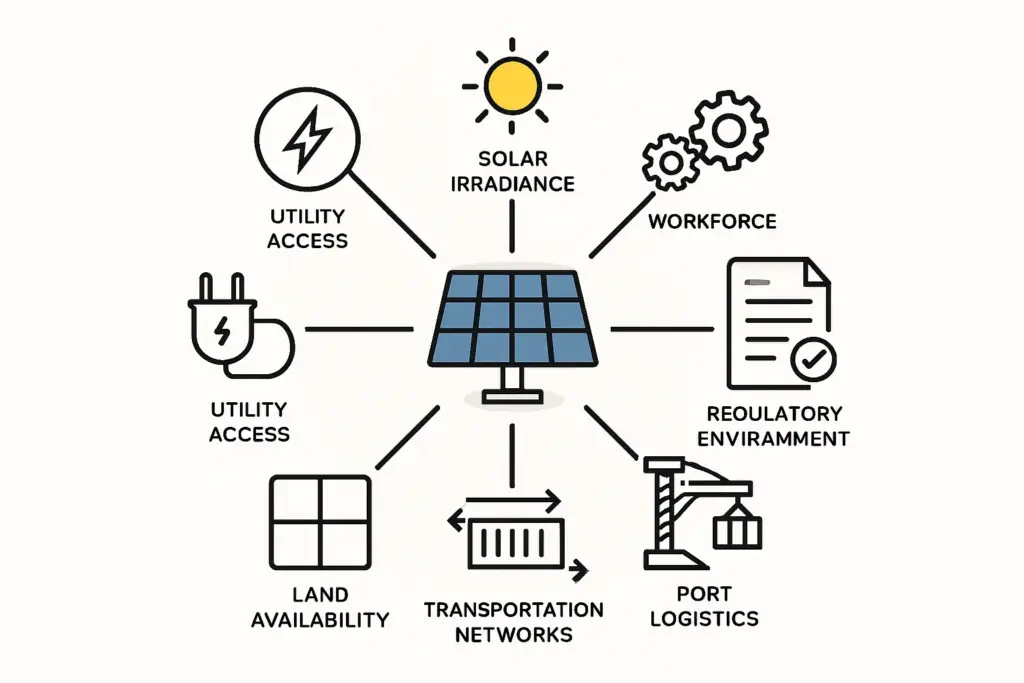

Key Factor 1: Industrial Land Availability and Suitability

Identifying the right piece of industrial land is the foundational first step. Your chosen site must not only accommodate the physical plant but also fit seamlessly within local logistical and regulatory frameworks.

Consider these key aspects:

- Zoning Requirements: First, ensure the land is zoned for heavy or specialized manufacturing. It’s worth investigating specific industrial precincts, such as the Lansdown Eco-Industrial Precinct in Queensland or areas around Mawson Lakes in South Australia, which may already be aligned with renewable energy manufacturing.

- Land Characteristics: The site itself needs to be sufficiently large, relatively flat, and geotechnically stable enough to support the construction of a large-scale manufacturing facility.

- Costs and Acquisition: Land costs vary dramatically between metropolitan and regional areas. The process of acquiring or leasing that land also requires careful navigation.

- Proximity to Renewable Energy Zones (REZs): Locating your facility within or near a designated REZ can be a smart move, offering benefits like easier access to renewable energy sources and potentially streamlined approvals or incentives. States like New South Wales, Queensland, and Victoria are actively developing these zones.

Key Factor 2: Utility Access – Powering Your Plant

Solar module manufacturing is an energy-intensive process, which makes reliable and robust utility access non-negotiable.

Electricity:

- Proximity to Infrastructure: Your site needs ready access to high-voltage transmission lines and substations capable of meeting your plant’s considerable energy demand.

- Grid Capacity and Reliability: How stable is the local electricity grid? Unreliable power can lead to costly production downtime.

- Electricity Costs: Industrial electricity prices will be a significant operational expense. Explore opportunities for Power Purchase Agreements (PPAs) to secure long-term, cost-effective renewable energy.

Water:

- Availability: Manufacturing processes, from cleaning to cooling, require a consistent and substantial water supply. You’ll need to assess whether regional water resources can meet your needs.

- Rights and Costs: Take time to understand local water rights, allocation policies, and all associated costs.

- Wastewater Management: You will also need a solid plan for compliant wastewater treatment and disposal that adheres strictly to environmental regulations.

Key Factor 3: Transportation Networks – Moving Materials and Modules

Efficient transportation networks are the arteries of your operation, vital for both inbound raw materials and outbound finished products. Given Australia’s vast distances, this is a particularly critical consideration.

Be mindful that the long haul between population centers and potential manufacturing sites can inflate transport times and costs, and some regional areas may have less developed infrastructure.

Road Infrastructure:

- Access to Major Routes: Ideally, your site should have direct access to national highways and major arterial roads.

- Heavy Vehicle Suitability: Ensure the roads leading to and from your site can safely accommodate heavy vehicles, such as the B-doubles commonly used for freight across the country.

- “Last Mile” Connectivity: Don’t overlook the final connection. The route from the main road to your plant entrance must be practical and well-maintained.

Rail Infrastructure:

- Proximity and Access: If your operations involve significant bulk material transport (like raw silicon or glass), proximity to rail lines and sidings can offer major cost and efficiency advantages over road freight.

- Intermodal Connectivity: Access to intermodal freight hubs is a huge plus, allowing for the seamless transfer of goods between road and rail.

Key Factor 4: Port Logistics – Importing Components and Exporting Globally

While the goal is domestic production, the reality is that many raw materials and components may initially need to be imported. An export strategy might also be part of your long-term vision.

Proximity to Major Australian Ports:

- Key Ports: Think carefully about your proximity to major international ports such as Melbourne (Australia’s largest container port), Port Botany (Sydney), Brisbane, Adelaide, and Fremantle. Each has varying capacities and specializations.

- Port Facilities: Investigate whether these ports offer specialized facilities or services relevant to manufacturing and heavy cargo.

- Shipping Routes and Connectivity: Ensure your chosen port has reliable access to international shipping lanes. This is crucial for facilitating component imports and, down the track, exporting your finished solar modules.

- Port Efficiency: Look into port turnaround times, customs clearance processes, and potential congestion. These factors can directly impact your supply chain timelines and costs. A key lesson from ARENA’s report on the Nyngan Solar Plant, for example, highlighted the importance of evaluating multiple delivery points and transport modes—a lesson just as applicable to your manufacturing inputs and outputs.

- Logistics Providers: Engaging experienced logistics partners familiar with large-scale industrial projects and Australian customs is crucial for smooth operations.

Key Factor 5: Regulatory Environment and Government Support

Successfully navigating Australia’s regulatory landscape and leveraging available support can make or break your project’s viability.

Navigating Planning Approvals:

- State and Federal Guidelines: You’ll need to familiarize yourself with all relevant state and federal planning guidelines. Each state—be it NSW, Victoria, or Queensland—has its own distinct processes.

- Environmental Impact Assessment (EIA): Be prepared for a comprehensive EIA, as these assessments are standard practice for industrial projects of this scale.

- Community Engagement: Proactive and transparent community engagement is vital for gaining a “social license to operate.” It’s essential to address local concerns head-on and highlight the project’s benefits, especially job creation.

Available Incentives:

- Federal Programs: Explore federal initiatives like the “Solar Sunshot” program, which has earmarked significant funds for domestic module manufacturing.

- State-Based Initiatives: Investigate state-specific grants, tax benefits, or other support programs designed to attract renewable energy manufacturing.

- Agency Support: Bodies like the Australian Energy Infrastructure Commissioner (AEIC) can provide invaluable guidance on site selection and infrastructure development.

Key Factor 6: Economic Viability and Cost Considerations

A thorough economic analysis is essential to ensure your manufacturing plant can be competitive.

- Manufacturing Costs: Understand the comparative costs of manufacturing solar modules in Australia versus key international competitors. While Australian production costs may currently be higher than in regions like China, government support and strategic advantages can help offset this difference.

- Input Costs: The costs of land, labor (including the availability of a skilled workforce), and utilities (especially industrial electricity prices) will significantly impact your project’s overall economics.

- Supply Chain Costs: Carefully evaluate the costs of sourcing raw materials locally versus importing them. The goal is to develop a supply chain that is both resilient and cost-effective.

- The Role of Scale: Achieving economies of scale is critical. For instance, the minimum viable plant sizes for certain upstream processes like polysilicon refining can be substantial, necessitating a strong focus on exports from day one.

Key Factor 7: Environmental and Social Governance (ESG)

Modern manufacturing ventures must prioritize strong ESG principles. This isn’t just a box-ticking exercise; it’s central to long-term success.

- Environmental Footprint: Design your facility and its processes to actively minimize water usage, waste generation, and emissions.

- Land Use: Avoid developing on prime agricultural land or in areas with high biodiversity value. Your site selection should always consider local ecological sensitivities.

- Community Outcomes: Strive for genuinely positive community impacts. This means creating local employment, fostering skills development, and making tangible contributions to the local economy.

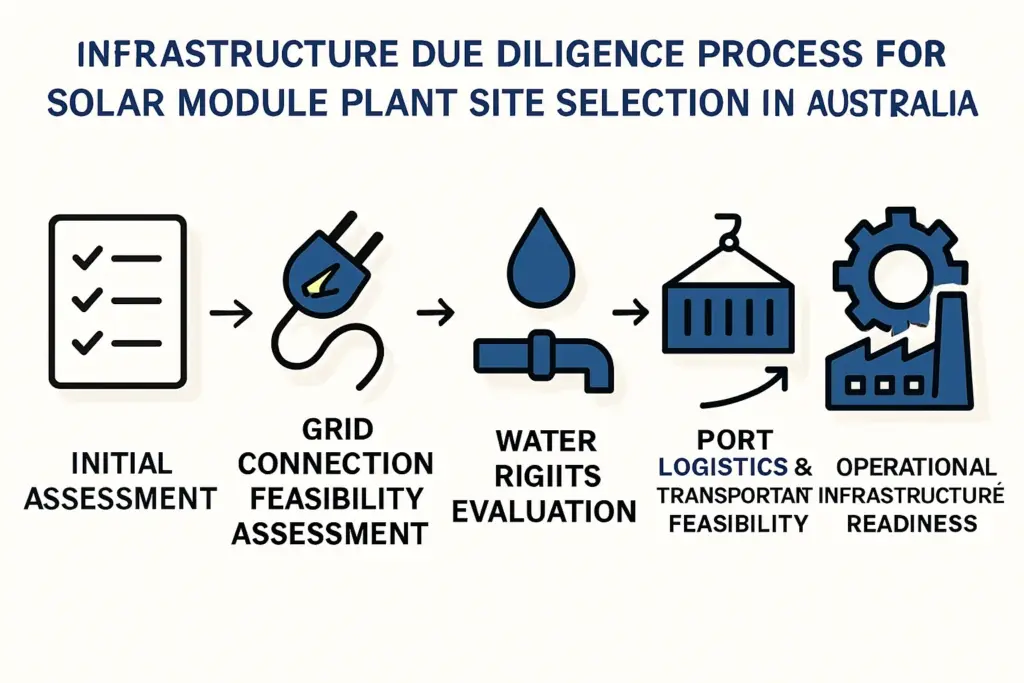

Developing Your Site Selection Strategy: A Framework

How do you pull all this together? Choosing the optimal site requires a systematic, step-by-step approach.

- Define Your Needs: First, clearly outline your plant’s specific requirements for size, utilities, transport access, and workforce.

- Initial Screening: Begin by identifying potential regions and specific sites based on high-level criteria like correct zoning, proximity to REZs, and access to major infrastructure.

- Detailed Evaluation: For your shortlisted sites, conduct in-depth due diligence. This means covering all the key factors we’ve discussed: land suitability, utility capacity and cost, transport logistics, port access, regulatory approvals, economic projections, and ESG impacts.

- Weighting Factors: Decide what matters most for your business model. For example, access to a key raw material via a particular port might be more critical for your operation than immediate proximity to an REZ.

- Site Visits and Stakeholder Engagement: There’s no substitute for getting on the ground. Conduct physical site inspections and engage directly with local authorities, utility providers, and community representatives.

- Risk Assessment and Mitigation: For each promising site, identify potential risks—be they logistical, regulatory, or financial—and develop clear strategies to mitigate them.

Laying the Foundation for a Successful Solar Venture

Selecting the right site for a solar module manufacturing plant in Australia is a complex yet foundational decision. Success demands a thorough evaluation of everything from industrial land and utility access to transportation networks, port logistics, the regulatory environment, economic factors, and ESG considerations.

By carefully analyzing these elements and developing a robust site selection strategy, you can lay a powerful foundation for a successful, efficient, and profitable manufacturing operation. Australia’s deep commitment to renewable energy presents a significant opportunity, and with diligent planning, your venture can play a key role in this burgeoning domestic industry.

Want to learn more or need expert help? Visit our free e-course or explore our services. Or, if you’re ready to dive deeper, our Premium Business Plan E-Course offers personalized guidance to get your venture off the ground. Let’s make your solar journey smooth and successful.