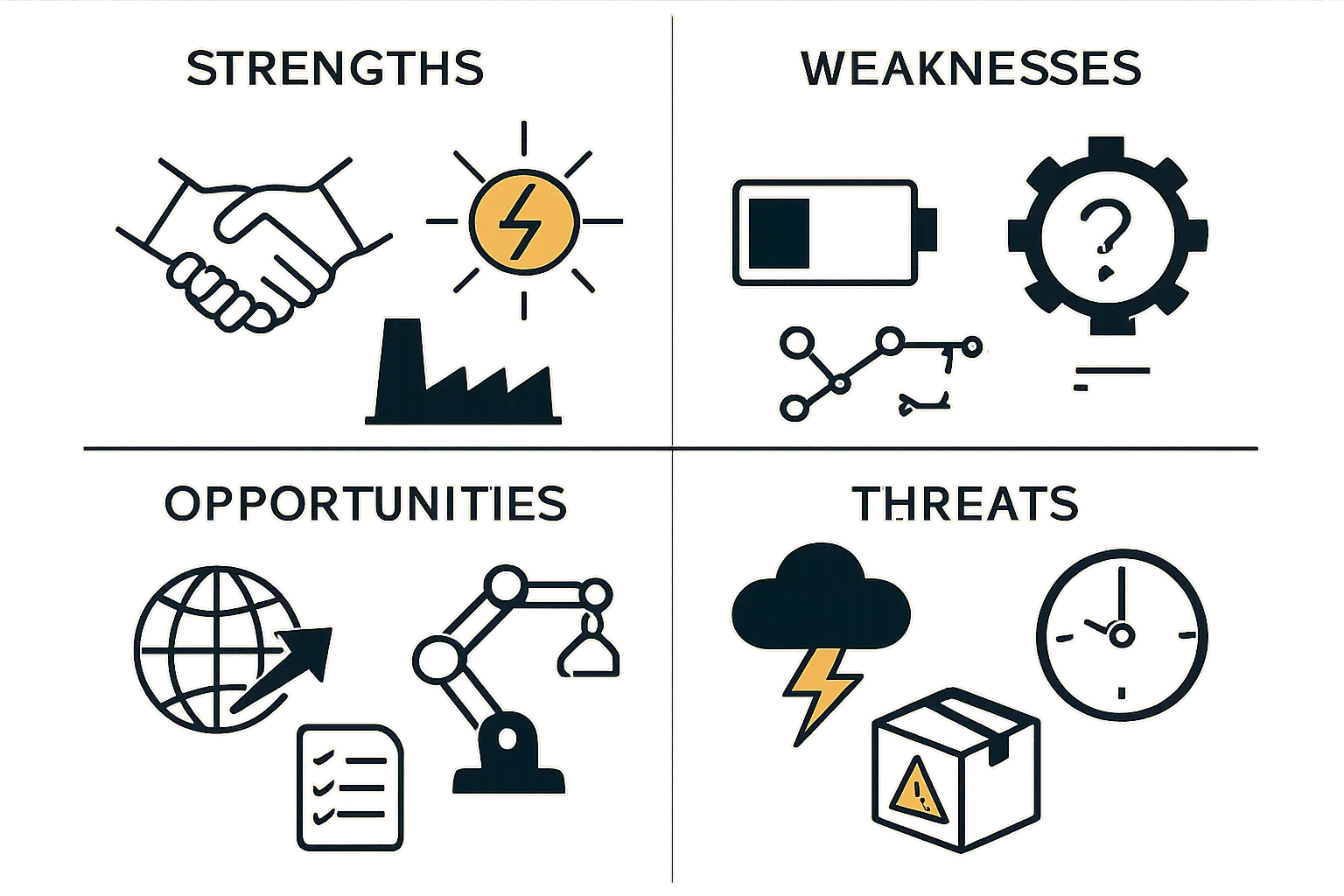

When considering a location for a new solar module manufacturing plant, conversations often focus on labor costs or government incentives. But seasoned entrepreneurs know that the underlying industrial infrastructure—roads, power grids, and data networks—is the true backbone of a successful operation. A factory’s efficiency isn’t just determined by its machines, but by the reliability and connectivity of the environment in which it operates.

Austria, a nation known for precision engineering and a stable economy, presents a compelling case. Its highly developed infrastructure offers a robust foundation for high-tech manufacturing. This analysis examines the key pillars supporting that claim, providing a framework for evaluating the country’s suitability for a solar module production facility.

The Foundation: Selecting the Right Industrial Site

Securing a suitable site is the first step in establishing a production facility. In Austria, this process is well-structured, focusing on designated industrial zones that are pre-vetted for industrial use, which significantly streamlines approvals.

According to the Austrian Business Agency (ABA), the country has over 1,000 developed industrial and commercial parks. These sites typically offer direct access to essential utilities—high-voltage electricity, gas, water, and sewage systems. This plug-and-play approach minimizes initial setup time and reduces the risk of unforeseen development costs.

Key considerations for site selection include:

- Availability: Regions like Upper Austria, Styria, and Lower Austria are traditional industrial heartlands with a significant number of available sites.

- Zoning Regulations: Austrian zoning laws are clear and well-enforced, providing legal certainty for investors.

- Expansion Potential: Many industrial parks are designed with future growth in mind, allowing companies to acquire adjacent plots for later expansion.

For entrepreneurs from regions where securing land and utility connections is a lengthy, unpredictable process, Austria’s organized approach offers a clear operational advantage. Experience from J.v.G. turnkey projects shows that having pre-approved industrial land with ready utility access can shorten a project timeline by several months.

Energy Infrastructure: Powering Production with Stability

A solar module factory is an energy-intensive operation. The lamination process in particular requires a substantial and, critically, uninterrupted supply of electricity. Power fluctuations or outages can lead to costly material waste and production downtime.

Austria’s energy infrastructure is among the most reliable in the world, boasting an average grid uptime exceeding 99.99%—a critical factor for sensitive manufacturing. This reliability is underpinned by a modern grid and a diverse energy mix.

Key Energy Metrics:

- Renewable Energy Share: Over 75% of Austria’s electricity is generated from renewable sources, primarily hydropower. This aligns well with the sustainability mission of a solar company.

- Industrial Electricity Prices: While not the lowest in Europe, industrial electricity prices in Austria are competitive, particularly when factoring in the high degree of grid stability. As of late 2023, average prices for industrial consumers were in the range of €0.15–€0.20 per kWh, subject to market fluctuations.

- Grid Capacity: The national grid operator, Austrian Power Grid (APG), continuously invests in grid expansion to accommodate both industrial demand and the integration of new renewable energy sources.

For any professional accustomed to operating in markets with less stable grids, the reliability of the Austrian system removes a major operational variable and risk factor. The ability to run production lines 24/7 without worrying about power quality is a significant, if often overlooked, competitive advantage.

Logistics and Transportation Networks: A Gateway to Europe

A factory’s location is only as good as its ability to receive raw materials and ship finished products. Situated in the heart of Europe, Austria is a natural logistics hub with a transportation network seamlessly integrated into the wider continent.

Road and Rail Connectivity

Austria is a key node in the Trans-European Transport Network (TEN-T), a system of major roads, railways, and inland waterways designed to create a unified European transport area. Key corridors, such as the Scandinavian-Mediterranean and the Baltic-Adriatic, run directly through the country.

- Motorway Density: Austria has one of the highest motorway densities in Europe, ensuring efficient road transport to neighboring countries like Germany, Italy, and the emerging markets of Eastern Europe.

- Rail Freight: The state-owned railway company, ÖBB, operates an extensive and efficient rail freight network. Intermodal terminals, which allow for the easy transfer of goods between trucks and trains, are strategically located near major industrial zones. For shipping heavy goods like solar modules across the continent, rail is often the more cost-effective and environmentally friendly option.

Proximity to Major Ports

While a landlocked country, Austria has excellent rail and road connections to major European seaports.

- Northern Ports: Hamburg (Germany) and Rotterdam (Netherlands) can be reached by rail in approximately 24–36 hours.

- Southern Ports: The ports of Koper (Slovenia) and Trieste (Italy) on the Adriatic Sea are even closer, providing efficient gateways for sourcing raw materials from Asia and shipping to global markets.

This strategic positioning allows a manufacturer in Austria to manage a global supply chain efficiently. For example, polysilicon and solar cells can be imported via Adriatic ports, processed into modules in Austria, and then distributed throughout the European Union’s single market without customs barriers.

Digital Connectivity: The Nerve Center of Modern Manufacturing

In the era of Industry 4.0, a factory’s digital infrastructure is as vital as its physical one. Automated production lines, real-time quality control, and enterprise resource planning (ERP) systems all depend on high-speed, reliable internet.

Austria has made significant investments in its digital backbone. The government’s Breitbandstrategie 2030 (Broadband Strategy 2030) aims to provide nationwide, gigabit-capable internet access.

- Fiber-Optic Availability: Most industrial parks and business locations already have access to high-speed fiber-optic connections.

- Data Center Infrastructure: The country has a growing number of secure, modern data centers, ensuring low latency and high data security for cloud-based applications and remote monitoring of production processes.

This robust digital infrastructure enables a manufacturer to implement advanced production techniques, improve efficiency through data analysis, and integrate seamlessly with international partners and customers.

A Holistic View: How Infrastructure Influences Investment

Strong infrastructure directly impacts the financial viability of a solar manufacturing project. While initial land or building costs may be higher than in other regions, the long-term operational benefits often yield a strong return on investment. The overall cost of setting up a factory is a complex calculation, and infrastructure plays a pivotal role.

Reliable power prevents waste, efficient logistics cut shipping costs and lead times, and high-speed internet enables process optimization. Together, these factors lower operational expenditures (OPEX) and reduce the project’s overall risk profile. A comprehensive business plan must account for these infrastructural advantages, as they can be decisive for the facility’s long-term success.

Frequently Asked Questions (FAQ)

What are the main industrial regions in Austria?

The most significant industrial activity is concentrated in the provinces of Upper Austria (automotive, machinery), Styria (electronics, manufacturing), and Lower Austria (plastics, technology), as well as the area around Vienna.

How does Austria’s infrastructure compare to Germany’s?

Both countries have world-class infrastructure. Germany is a larger market with more major seaports, but Austria’s central location provides unique logistical advantages for serving both Western and Eastern European markets. Austrian industrial sites can sometimes offer more competitive pricing than those in major German industrial hubs.

Is bureaucracy a challenge when setting up utilities and obtaining permits?

Austria has a well-defined, albeit rigorous, administrative process. While the paperwork can be significant, the rules are clear and consistently applied. Working with local partners or agencies like the ABA can greatly simplify the process, and the system’s structured nature provides a predictability that is valuable for project planning.

Can a foreign company easily access the energy and digital networks?

Yes, Austria’s markets for energy and telecommunications are fully liberalized and open to all businesses, domestic and foreign. Companies can choose from a variety of providers to find the service package that best fits their needs.

Next Steps in Your Evaluation

Understanding a country’s industrial infrastructure is a critical due diligence step. Austria provides a high-quality, reliable, and well-connected environment for advanced manufacturing. These hard factors create the stable platform upon which a successful solar business can be built.

To continue your evaluation, explore our detailed guide on the essential building specifications for a solar factory. This will provide a deeper look at the requirements for a production facility, from floor loading to cleanroom standards.