The Bahamas has set an ambitious goal: to generate 30% of its energy from renewable sources by 2030. This transition paves the way for greater energy independence and supports local industrial development.

For entrepreneurs and investors, a critical question emerges: Is it feasible to establish a solar panel manufacturing facility in The Bahamas? This case study explores the design of a custom turnkey production line tailored specifically to the Bahamian market.

Table of Contents

The Opportunity: The Solar Energy Landscape in The Bahamas

The Bahamas, like many island nations, has historically relied on imported fossil fuels. This dependence creates high electricity costs and vulnerability to global energy price fluctuations, prompting the government to promote solar energy more actively.

This commitment is underscored by plans for a 132 MW solar plant, a significant step toward the nation’s 2030 renewable energy targets. The large-scale project, combined with growing residential and commercial demand, signals a sustainable market for solar panels.

Local manufacturing could capture this demand, reduce the country’s reliance on imports, and position The Bahamas as a potential supplier for the wider Caribbean region.

Solar Production Line for the Bahamian Market” class=”wp-image-34260″ srcset=”https://www.pvknowhow.com/wp-content/uploads/2025/06/Case-Study_-Designing-a-Custom-Turnkey-Solar-Production-Line-for-the-Bahamian-Market-1-1024×683.webp 1024w, https://www.pvknowhow.com/wp-content/uploads/2025/06/Case-Study_-Designing-a-Custom-Turnkey-Solar-Production-Line-for-the-Bahamian-Market-1-500×333.webp 500w, https://www.pvknowhow.com/wp-content/uploads/2025/06/Case-Study_-Designing-a-Custom-Turnkey-Solar-Production-Line-for-the-Bahamian-Market-1-768×512.webp 768w, https://www.pvknowhow.com/wp-content/uploads/2025/06/Case-Study_-Designing-a-Custom-Turnkey-Solar-Production-Line-for-the-Bahamian-Market-1-600×400.webp 600w, https://www.pvknowhow.com/wp-content/uploads/2025/06/Case-Study_-Designing-a-Custom-Turnkey-Solar-Production-Line-for-the-Bahamian-Market-1.webp 1536w” sizes=”auto, (max-width: 1024px) 100vw, 1024px” />

Solar Production Line for the Bahamian Market” class=”wp-image-34260″ srcset=”https://www.pvknowhow.com/wp-content/uploads/2025/06/Case-Study_-Designing-a-Custom-Turnkey-Solar-Production-Line-for-the-Bahamian-Market-1-1024×683.webp 1024w, https://www.pvknowhow.com/wp-content/uploads/2025/06/Case-Study_-Designing-a-Custom-Turnkey-Solar-Production-Line-for-the-Bahamian-Market-1-500×333.webp 500w, https://www.pvknowhow.com/wp-content/uploads/2025/06/Case-Study_-Designing-a-Custom-Turnkey-Solar-Production-Line-for-the-Bahamian-Market-1-768×512.webp 768w, https://www.pvknowhow.com/wp-content/uploads/2025/06/Case-Study_-Designing-a-Custom-Turnkey-Solar-Production-Line-for-the-Bahamian-Market-1-600×400.webp 600w, https://www.pvknowhow.com/wp-content/uploads/2025/06/Case-Study_-Designing-a-Custom-Turnkey-Solar-Production-Line-for-the-Bahamian-Market-1.webp 1536w” sizes=”auto, (max-width: 1024px) 100vw, 1024px” />Market Analysis: Is a Solar Production Line Viable in The Bahamas?

Before designing a factory, a thorough analysis of local conditions is essential. Any viable business plan must account for market size, the available labor force, infrastructure, and unique regional challenges.

Market Size and Demand

The primary driver for a local factory is the domestic demand spurred by government targets and private installations. Projects aimed at meeting the 30% renewable goal will sustain the initial market.

Over time, an opportunity could emerge to export to neighboring Caribbean countries that face similar energy challenges, creating a much larger potential market.

Labor Market and Infrastructure

The average monthly wage for manufacturing roles in The Bahamas is competitive. While specialized training will be necessary for technical positions, a local workforce can be developed for most operational roles.

The Bahamas has capable port facilities, essential for importing raw materials and potentially exporting finished panels. However, factors like logistics, grid stability, and land costs must be carefully integrated into any business plan.

Challenges and Opportunities

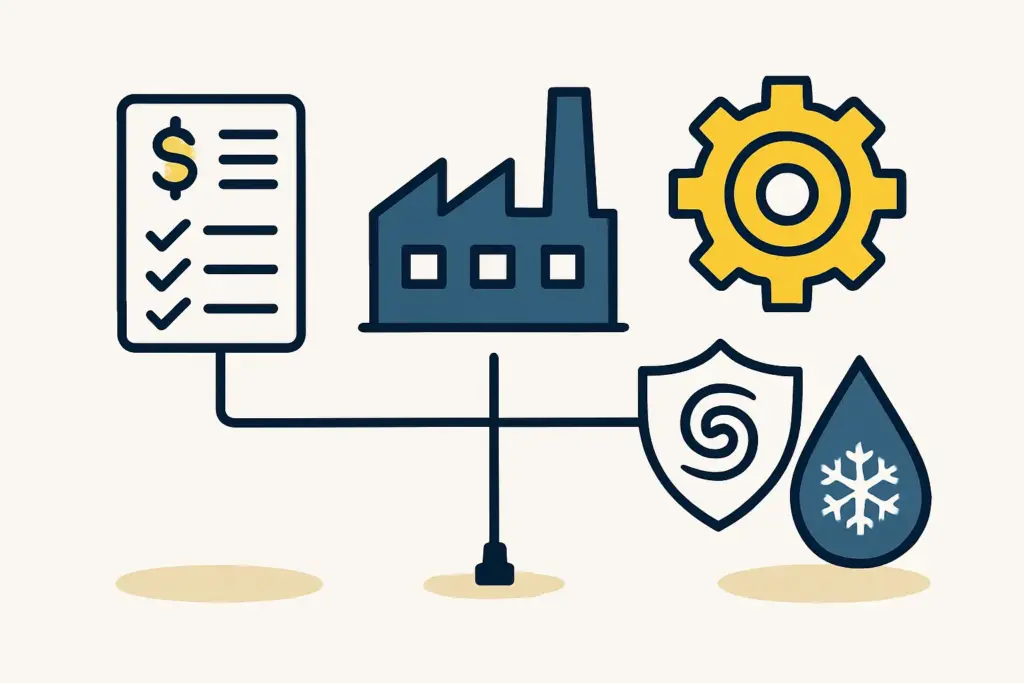

Operating in the Caribbean presents unique challenges. High import costs for raw materials, bureaucratic processes, and the risk of hurricanes are significant considerations. A production facility must be designed with resilience in mind, both in its physical structure and its supply chain.

Despite these hurdles, the opportunities are compelling. Government incentives for renewable energy can lower initial investment barriers. Establishing a local factory would create skilled jobs and contribute to economic diversification, significantly enhancing the nation’s energy security.

The Solution: Designing a Custom 50 MW Turnkey Production Line

Based on the market analysis, a small-to-medium-scale production line is the most logical starting point. A 50 MW semi-automated line offers an ideal balance between investment cost, production capacity, and operational complexity, making it a sound entry point for the Bahamian market.

Key Equipment and Components

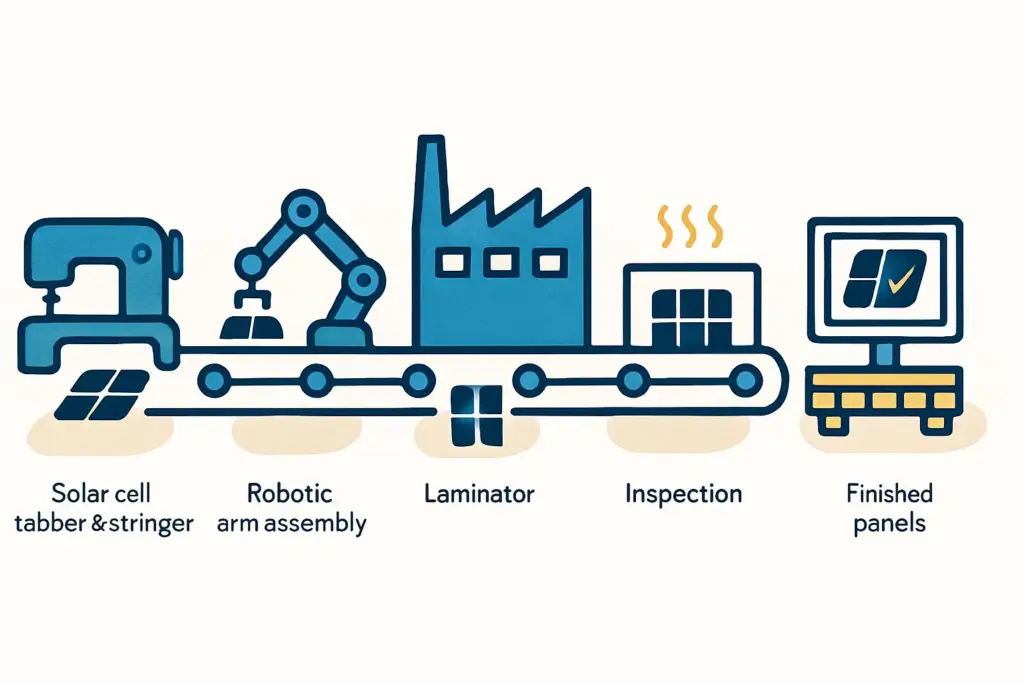

A turnkey solution includes all necessary machinery, process design, and technology transfer. The core components for a 50 MW line would include:

- Solar Cell Tester & Sorter: To test and categorize incoming solar cells.

- Automatic Tabber & Stringer: To solder ribbons onto cells and connect them into strings.

- Layup Station: To assemble the solar cell matrix with glass, EVA, and a backsheet.

- Laminator: To encapsulate the panel components under heat and pressure.

- Trimming & Framing Machine: To finish the panel edges and attach the aluminum frame.

- Junction Box Installation: To attach the junction box and complete electrical connections.

- Final IV Tester (Sun Simulator): For quality control and performance classification of the finished module.

Customizations for The Bahamas

A standard production line isn’t enough—customization is key. For The Bahamas, this requires several specific adaptations:

- Corrosion Resistance: Equipment and facility components must use materials resistant to the salty, humid coastal environment.

- Robust Panel Design: The manufacturing process can be calibrated to produce panels with enhanced structural integrity and wind-load resistance to withstand hurricane conditions.

- Efficient Footprint: The factory layout should be designed to optimize the use of space, helping to manage land and construction costs.

Estimated Cost Breakdown

The investment for a turnkey solar production line involves more than just the equipment. A transparent cost breakdown is crucial for financial planning. Below is an estimated breakdown for a 50 MW semi-automated line.

Category: Turnkey Equipment

- Estimated Cost (EUR): € 1,500,000 – € 2,000,000.

- Description: This covers all core production machinery, installation, and technology transfer.

Category: Raw Materials (Initial Stock)

- Estimated Cost (EUR): € 500,000 – € 750,000.

- Description: Covers the initial supply of glass, solar cells, EVA, backsheets, frames, and junction boxes for the first few months of operation.

Category: Working Capital

- Estimated Cost (EUR): € 300,000 – € 500,000.

- Description: This capital covers salaries, utilities, and other operational expenses during the startup phase.

Category: Facility & Infrastructure

- Estimated Cost (EUR): Variable.

- Description: These costs include land, building construction or rental, and utility connections, all of which are highly dependent on the chosen location.

- Total Estimated Investment: € 2,300,000+.

Excluding facility costs, which vary significantly by site.

The Business Case: ROI and Economic Impact

The business case for solar panels manufactured locally is compelling. By producing modules domestically, the venture can achieve competitive pricing by avoiding import tariffs and reducing shipping costs for finished products.

Return on investment will hinge on production volume and the local market price for solar panels. Just as importantly, the economic impact extends beyond direct profits. The facility would create direct manufacturing jobs while supporting indirect employment in logistics, maintenance, and installations.

It represents a tangible step toward the nation’s goals of achieving energy independence, diversifying its economy, and building a more skilled workforce.

Conclusion

Establishing a solar panel factory in The Bahamas isn’t just an idea—it’s a feasible and strategic venture. A custom-designed 50 MW turnkey production line can meet the specific demands of the market and the region’s environmental conditions. By carefully analyzing the market, designing a tailored solution, and planning for regional challenges, an investor can build a profitable business that contributes directly to a more sustainable and energy-independent future for The Bahamas.

Ready to explore this opportunity further? Start with our free e-course on solar manufacturing, or explore our turnkey services. For a detailed roadmap, our Premium Business Plan E-Course provides the expert guidance you need to launch your venture. Let’s build a successful solar future together.

Frequently Asked Questions

Q: What is the minimum viable scale for a new solar production line?

A: For a new market entry, a line with a capacity of 20-25 MW can be a viable starting point. However, a 50 MW line often provides a better economy of scale, reducing the cost per panel and improving long-term profitability.

Q: How long does it take to set up a turnkey solar factory?

A: From final planning to the start of production, the process typically takes between 9 and 12 months. This timeline includes equipment manufacturing, shipping, facility preparation, installation, and staff training.

Q: Is prior experience in solar manufacturing required?

A: No. A key advantage of a turnkey solution is that it includes technology transfer, process engineering, and comprehensive training. With a strong business background and the right technical partner, entrepreneurs new to the PV sector can successfully launch and operate a solar module factory.